During the operation of a car, a common situation is that after turning the ignition key, the car starts, the engine starts to work and stalls after a few seconds. As a rule, 3-5 seconds pass from the moment of starting to stopping the internal combustion engine. Before the engine stops completely, engine vibrations are also noticeable, the power unit shakes and operates very unstable.

This happens as a result of a decrease in speed, the resonance effect of a rotating crankshaft, etc. When you try to start the engine again, the engine may no longer start, or the situation described above may repeat again.

The reasons for this problem vary. The main thing is that if the car starts and stalls, this indicates that in-depth diagnostics are needed. Next we will talk about what to do in such a situation, as well as how to find the reason why the engine stalls after starting.

Read in this article

The engine starts and stalls: troubleshooting

So, if a similar problem appears, then it is necessary to take into account a number of features. First of all, the operation of the internal combustion engine after startup will be influenced by the following factors:

- fuel supply;

- air supply;

- spark on spark plugs (for gasoline internal combustion engines);

- correct operation of glow plugs (for diesel engines);

- proper operation of the ECM and electronic sensors;

With that said, you should first start by checking the main possible causes:

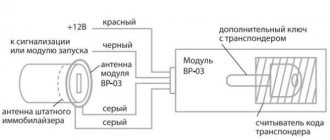

- Quite often, malfunctions in the operation of the alarm system and the anti-theft system can cause the engine to fail to operate after starting. In other words, the immobilizer does not turn off and continues to block the start of the internal combustion engine, which is its main function to prevent vehicle theft. If the alarm blocks the engine, then you need to check the operation of all elements, try to reset the error, turn off the anti-theft system, etc.

- Problems with the IAC and idle air valve often arise due to contamination of these elements. You should also pay attention to the cleanliness of the throttle valve. As for the crankshaft sensor, incorrect data that it transmits to the ECU can cause the engine to stall immediately after starting.

- Poor quality fuels and lubricants can also cause problems. As a rule, problems begin in cases where low-grade fuel was filled or the engine uses motor oil that does not meet the recommendations/has lost its properties.

- A faulty fuel pump, air leaks in the fuel line, the formation of air pockets and dirty fuel filters do not allow creating the required pressure in the power system or supplying fuel in the required volume.

- The air filter and its contamination leads to the fact that the working mixture is significantly over-rich. In other words, the engine does not have enough air to burn fuel, and the spark plugs flood.

- Problems with ECM sensors (EGR sensor, oxygen sensor, DPKV, etc.) can lead to both unstable engine operation at idle and a complete engine stop after starting.

Now let's look at the most common problems and how to fix them, looking at them in detail.

- First of all, the culprit may be the low level of fuel in the gas tank and its quality. If gasoline or diesel fuel runs out, then the engine will start using the remainder in the power system, but further operation will be impossible.

Common Cummins maintenance tasks:

- Regular oil changes

- Fluid replacement

- Replacing the air filter

- Replacing the fuel filter

As for filters, it is probably a good idea to replace them according to the manufacturer's recommendations. You can find such information on the packaging or on the manufacturer's website.

What to do and what not to do...

It's a well-known fact that an ounce of prevention is worth more than a cure, so perform preventive maintenance to avoid wear and tear. Also pay special attention to the fuel injector, replacing the injector will save you money, don't wait until it eventually cracks. Another helpful tip is to add a bottle of diesel every time you fill the tank. This will prevent the diesel fuel from becoming saturated with impurities floating around your tank, which will prove beneficial to your parts.

Do not drain engine fluids until they are at a cool temperature. Diesels tend to run much hotter than gas engines, and if they are hot, it can cause serious injury and, more importantly, engine damage.

Key diesel engine components to watch out for...here's a short list of symptoms to look out for:

Gasket leak:

The extreme pressure your gaskets endure can cause them to wear out. If the engine produces a high-pitched sound, then there is a chance that it could be the diesel fuel pump. Different pumps will make different sounds, but this gives you a reason to start checking.

Thick smoke:

If you see a trail of thick smoke following you from your rearview mirror, the color of the smoke may reveal the source of the problem.

- Black: Diesel injector, pump or air filter is faulty.

- Blue: Engine oil burning.

- White: Possible water ingress into the engine or low compression.

What's the result?

As you can see, there are quite a few reasons why the engine starts running and stalls after starting. However, most of them are usually associated with the fuel system, ignition system and electronic control system.

In this case, it is appropriate to talk about low compression in the cylinders due to the fact that the engine has exhausted its service life (the cylinder walls, rings, etc. are worn out), that is, the unit needs major repairs. Compression can be measured at a service station or yourself using a compression meter.

The engine stalls at idle: what to check. Possible causes of malfunction on engines with a carburetor, injector, and diesel power plants.

At idle the speed “floats”: why does this happen? The main malfunctions associated with idle speed on gasoline and diesel engines.

The main reasons why the engine starts to stall after warming up. Frequent problems of carburetor and injection engines, fault diagnosis.

The reasons why, after pressing the gas pedal, dips occur and the engine begins to choke. Gas engine failures when switching from gasoline to gas.

Why the engine may not pick up speed: gasoline engine, diesel unit, car with LPG. Fault diagnosis, useful tips.

Reasons why the engine may stall when you press the brake. The power unit stalls during sudden braking, when the clutch and brake are depressed, etc.

Why doesn't the injection Gazelle 405 start? Main reasons

There are various difficulties with cars, unfortunately the Gazelle 405 injector won’t start

for some reason in most cases. Drivers begin to rack their brains, but from time to time it is impossible to find a solution to the problem in any case.

At the moment, several more possible breakdowns will be considered, during which the car will not start.

When this happens, the first thing our client needs to do is look at the wires, spark plugs, rail pressure and injectors. In most cases, the Gazelle 405 injector will not start specifically because of the spark plugs, so just change them. Alas, when problems arise that are more serious than candles.

Compression reduction

In a diesel engine, the air-fuel mixture ignites under pressure. When compression drops, the air and fuel are not compressed to the required level in the cylinder. Because of this, the working mixture does not heat up to the nominal temperature. Self-ignition of atomized diesel does not occur and the engine does not start.

A similar situation occurs when the crankshaft speed is insufficient. During compression, part of the air manages to escape through the cracks and gaps into the sub-piston space. Because of this, the working mixture is not compressed to the nominal pressure and does not spontaneously ignite.

Car service to help

Read:

If you decide to contact a car service, first of all carry out engine diagnostics. Few inexperienced drivers understand the cause of the breakdown. At the same time, the Gazelle 405 may not start for various reasons, and some of them can be resolved on the spot.

When you finally take your car to a car service center, at least consult with its employees; most likely they will tell you what the problem is.

It is very important to know absolutely everything about your car.

to protect yourself on the road and do extra work. Sooner or later, any part can break, but it will be better if you are prepared for this.

Valve clearances on the Gazelle Next car engine

The gaps are set by cleaning the dipstick. It must be placed between the rocker arm and the bar connecting a pair of valves

Intake valve clearance is 0.25mm

Exhaust valve clearance is 0.5mm

The lock nut on the rocker arms is loosened. The adjusting screw is guided using an asterisk which is inserted into the end of the adjusting screw. By rotating the screw, the probe is clamped so that it can move with little effort. If you press down hard on the dipstick. The valve will be squeezed out. The adjustment gap will disappear. The probe should not move freely. But a little effort must be present.

Special cases

In addition to all of the above, other adventures happen with the Gazelle 405. Many drivers do not notice how the chain on the engine jumps. Accordingly, the engine refuses to come to life until the chain is in its place.

Your task is simply to open the hood and check if the chain is in order

, if not, then put it in its place. This procedure will take you 10 minutes at best, but you will be able to start your car. Otherwise, the Gazelle 405 injector does not start due to other problems.

It is quite difficult to answer this question, so we have simply listed for you several of the most common breakdown options. You can get an accurate answer only after a thorough diagnosis. It is at this stage that you can find out the reason why the car refuses to start. Therefore, do not rack your brains and better contact a car service center.

Yes, you will spend money, and most likely a lot, but at least you will be able to continue to quietly drive around in your gazelle.

Advantages of a gazelle car with a Cummins diesel engine

The main advantages of Cummins engines include the following characteristics:

- high power;

- unpretentiousness;

- excellent power to speed ratio;

- insensitivity to overheating.

All these indicators make the Kamens engine indispensable on the roads for modern GAZ cars.

Let's see what the owners of these cars write in reviews.

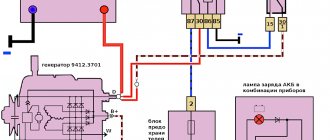

The fuel pump does not work, the relay turns on.

Checking relay power.

Gazelle next fuses and relays

In the case when the fuel pump relay turns on when the ignition is turned on, but the pump itself does not work, you need to check the power at pin 87 of the fuel pump relay. To do this, touch terminal 87 of the relay socket with the output of the control lamp connected to the vehicle ground, and the lamp should light up. If the lamp does not light, it means the fuse has blown or there is a break in the wire.

If there is power at terminal 87, you should remove the relay from the socket, and instead place a jumper between pins 87 and 30. In this case, if the pump and connecting wires are working properly, the pump should start working and if this happens, the relay should be changed. If the pump does not start working, then, without removing the jumper, you need to touch the power wire on the fuel pump with a test lamp connected to the vehicle ground.

Checking the fuel pump power circuit.

If a submersible pump is installed on the car as part of the fuel module, you need to remove the connecting connector and touch one of the thick wires. When you touch one of them, the indicator lamp should light up. If the lamp does not light up on any of the wires, then it is necessary to eliminate the break in the wire from the fuel pump relay to the module connector or the pump itself, if the pump is of a remote type. One of the reasons for the break may be the anti-theft blocking of an installed non-standard alarm system.

In the case when the test lamp lights up on one of the thick wires of the connector or one of the terminals of the remote pump, you need to connect these terminals with a test lamp to each other. In this case, the control lamp should light up. If the lamp does not light, it is necessary to eliminate a break or poor contact in the wire connecting the pump to the vehicle ground.

If, when checking the wires and relay for turning on the fuel pump, no malfunction is detected, the electric motor of the fuel pump or its connection to the module connector is faulty. It is not difficult to find the cause by removing the fuel pump module from the tank. If there is poor contact with the connector, melting of the plugs will be visible. If melting is not noticed, then to check the pump itself, you can connect it to the battery. It should be taken into account that operating a submersible pump without liquid will damage the pump. A faulty pump should be replaced.

One of the most important elements of the fuel injection system of a gasoline engine is the electric fuel pump, which is located in the fuel tank of the car. The fuel pump pumps fuel into the system from the gas tank, creating a certain pressure.

Auto repair experts identify the following common fuel system problems that are related to the fuel pump:

- The fuel pump pumps poorly and does not create the required pressure;

- the fuel pump does not pump when the ignition is turned on;

Considering that the fuel pump is an electromechanical device, the most common fuel pump malfunctions are related to both the mechanical and electrical parts. Next, we will look at what signs indicate a breakdown of the fuel pump and why the fuel pump stops pumping partially or completely.

Read in this article

Fuel cells

Troubleshooting the stove fan

It is worth understanding that almost all elements affect the starting of the motor. For example, since the Gazelle was produced both with carburetor and injection, the injection elements will be different. This means that the reasons for possible breakdowns will not be the same.

The Gazelle-406 engine is an injection version of the vehicle. It has injectors installed, which can be the source of the problem. If cleaning has not been carried out, then most likely the injectors are dirty. To fix this, you need to remove the parts from the machine and send them for cleaning. If, during the process of restoring the functionality of the injectors, it turns out that the product cannot be repaired, then it must be replaced.

A fuel pump malfunction may be due to a breakdown inside the module. To check whether the pump is pumping, you need to get behind the wheel of the car and turn the ignition key to the second position. In this case, a characteristic noise should begin from behind, which will mean that the pump is in working condition.

Particular attention should be paid to the condition of the fuel filter. According to the service manuals and recommendations of the manufacturer, the fuel filter element must be changed every 40,000 km.

If this is not done, the filter becomes clogged and does not allow fuel to pass through properly, which results in a lean mixture in the cylinders, or gasoline does not get in for ignition at all.

Read more: Exiting the acceleration lane, who is inferior?

The starter clicks but does not start the engine

Well, now we come to the most interesting part. Why can there be clicks when turning the key in the ignition, but the engine does not start ? In 60% of cases the problem is in the solenoid relay. However, there may be problems with the wires, which should be checked immediately:

- Low battery . Many people confuse the clicking sounds of the starter with a discharged or failed battery (there will be a kind of crackling sound, but it will not be a one-time sound). There simply isn’t enough power to crank the engine, you just need to recharge or replace the battery.

- Poor contact at the positive terminal . The very first thing we do is look at the terminals on the battery; if there are oxides, then they need to be removed. The thing is that the positive wire goes to exactly one contact of this retractor relay. If the contact is bad, then the system will not work well (and it’s not just the clicks).

- Poor contact at the relay itself. The wire from the battery can also oxidize at the starter itself. This often happens from high mileage. You need to unscrew both power wires (usually they go to the relay) and clean them well. Perhaps the reason will disappear

- Poor ground contact. The negative terminal is attached to ground (often to the car body or engine), if there are oxides here again, either from the terminal side or from the contact point, then they also need to be removed.

- Solenoid relay. This is a common breakdown (especially on old VAZs) - when you turn the key, you hear clicks, but nothing happens. However, if you turn the key several times, for example two or three times, the engine may start on the fourth time. THIS IS DEFINITELY A RELAY; it needs to be changed or cleaned.

- The teeth of either the BENDIX or the flywheel crown have broken . Of course, then not only clicks will be heard, but also a strong crunching sound from under the hood. This happened to me only once in practice.

In my practice, when I had front-wheel drive VAZs, first of all we clean the terminals and contacts of the starter, and then remove the solenoid relay and look at it. It may be better to replace it right away and not have to suffer.