Although on many cars the alternator belt is not as important an element as the timing belt, this element still needs to be checked and replaced regularly. The reason is that the generator drive belt allows both the car generator itself and other attachments (power steering, air conditioning compressor, etc.) to operate on cars.

Of course, if the belt breaks or there are any problems with the drive, the power steering, air conditioning, generator and other equipment will not work normally. Extraneous noises, squeaks, whistling of the generator belt, etc. also often appear.

Next, we will look at when to change the alternator belt, how to replace the drive belt, and what features you need to pay attention to as part of this procedure.

When and how to change the V-belt.

The main problem in a car when the drive belts wear out at the initial stage are various creaks and whistles that occur during the rotation of the pulleys transmitting torque to the engine attachments. If these creaks and whistles occur, one of the drive belts may simply break soon. Dear friends and our readers, we offer you detailed information about the types of belts installed in modern cars. Our information directory will help you find out when it is necessary to change drive belts and also how to determine the degree of their wear, how a drive belt differs from a timing belt and what is the average cost of drive belts on the Russian market, and at the same time get for yourself and answers to other questions that interest you directly related to these belts.

First, let's immediately dot the i's and find out what they are - drive belts.

A car drive belt is an element of a belt drive, a specific working part of vehicles and mechanisms that serves to transmit engine torque.

The transmission of torque occurs due to frictional forces or engagement forces (timing belts, V-belts).

There is a misconception that the timing belt (timing belt drive) is not a drive belt. Actually this is not true. The timing belt also falls into the category of drive belts.

Drive belts are divided into several types, namely:

— Timing belt (timing belt drive).

— Drive belts for auxiliary components (engine attachments).

There are 3 (three) types of car belts:

1. Timing belt - as a rule, it is toothed.

2. Poly V-belt transmitting engine torque to engine attachments.

3. V-shaped (V-belt) transmission of engine torque to engine attachments.

Belts No. 2 and No. 3 in our country also have additional names, that is: flat belt (V-ribbed belt) or ripple belt (V-belt).

Unlike timing belts, which are subject to fairly strict requirements, such as mandatory timely scheduled replacement in accordance with the service life established by the manufacturer, drive belts that ensure the operation of engine auxiliary (attachment) equipment do not require such close attention.

But, nevertheless, this does not mean at all that they do not need our attention. They also periodically require scheduled replacement. Moreover, it is not advisable to wait until the belts fail, since these belts ensure the operation of important equipment in the car (cooling, battery charging, air conditioning, etc.).

Thus, if you suddenly hear a squeak or whistle under the hood of your car, we advise you to pay attention to it. Remember that extraneous noise under the hood is not only a nuisance for your hearing, but also something more. If a creaking or whistling noise appears under the hood of the car, this indicates that the drive belt is slipping on the pulleys. For example, if the belt is old, then its tension may be significantly weakened, which causes the belt to slip on the pulleys and produce a squealing noise while the engine is running.

Typically, when a belt is worn out or has loose tension, the slipping or squealing will only worsen in rainy and cold weather as the belt loses its grip on the pulley due to moisture.

If you, friends, heard a single squeak or whistle of a belt under the hood of your car, especially after driving through a deep puddle, then there is no particular reason to worry. In this case, the drive belt is most likely too wet, which has reduced its adhesion specifically to the pulley. If you hear this whistle (squeal) under the hood after starting the car in the morning or after several kilometers, or after starting to drive, or when the engine warms up, then most likely your drive belts (or belt) are worn out or weakened the tension of these drive belts itself.

When is it time to change

There is usually no strict regulation on the timing of replacement of drive belts for mounted units. The working life of the alternator belt is usually approximately 50...60 thousand kilometers. Automakers recommend checking its condition every 10 thousand kilometers or every six months, and changing it as necessary.

The need to replace the drive may be indicated by a decrease in generator performance (if there is a corresponding sensor) and specific sounds under the hood, especially when starting the engine or when the speed increases. However, sounds can not only occur due to a worn belt.

If the drive makes a high-frequency whistle, it may be due to improper installation or deformation of one of the pulleys.

Drive grinding noise can also be caused by an incorrectly installed or damaged pulley. In addition, in this case, you need to check the bearings and tensioner.

If there is low frequency noise, try cleaning the pulleys first.

If you hear a hum, the culprit is most likely a bearing.

Drive vibrations may occur due to a damaged pulley or faulty tensioner.

Before changing the alternator belt, check all other drive elements and correct any faults, if any. If this is not done, the new strap may fail much earlier than expected.

The condition of the belt itself is determined by visual inspection. While turning the crankshaft by hand, carefully inspect the strap along its entire length. It should not have deep cracks or delaminations. Serious damage, even in a small area, is grounds for replacement.

If the belt is in satisfactory condition, check its tension. When exposed to a load of 10 kgf, it should bend by about 6 mm. If the length between the pulley axes is more than 300 mm, a deflection of about 10 mm is allowed.

Adjust tension if necessary. Just be careful not to tighten it too much, as this may place excessive load on the alternator bearing, and the belt itself will wear out faster. If tightening does not produce results, it means that the belt is too stretched and needs to be replaced.

You can purchase belts, tensioners and drive rollers for generators and other attachments for Chinese cars in the Chinese online store.

Function of the drive belt (V-V and poly V-belt)

A V-shaped or poly-V belt is part of the engine drive belts, which serves as an auxiliary component that ensures the functionality of the attachments of the car’s power unit (water pump, air conditioning, generator, hydraulic booster).

The belt rotates due to the torque of the engine during operation. Torque is initially transmitted by the crankshaft of the engine itself. Next, the torque is transmitted through belts and pulleys to auxiliary equipment located under the hood.

For example, a V-belt has a V-shaped cross section, which allows the belt to transmit torque to the vehicle accessory pulleys. This type of belt drive is called V-belt torque transmission.

For example, this type of belt is often used to transmit engine torque to an electric generator that charges the battery.

The rotation of the generator produces electricity, which supports the operation of all electrical equipment in the vehicle.

Also, in many modern cars, this type of belt is also used to transmit torque to the electric power steering, to the cooling fan, to the water pump (coolant pump), to the air conditioning compressor and to the classic power steering wheel. Since this belt is subjected to enormous loads and constant temperature changes, it is made, as a rule, of hard rubber and a metal core, which provides strength and durability to the belt. Also, many belts have a durable textile thread, which allows the belt to withstand the transmission of high torque.

So, friends, remember, each car, in addition to the timing belt (some cars also use a timing chain), has one or more belt drives (depending on the technical features of the car), which ensure the functionality of engine attachments.

Modern production technologies and advantages of Bosch components

The use of high-quality synthetic materials in the production of Bosch belts allows for reliable operation of the drive system and long service life. In research centers, scientists and developers are using the latest polymer bases, and are also developing methods for connecting different structures into a single external form. Bosch produces both poly-V-ribbed and bevel-toothed belts, which provide a high coefficient of friction and transmission of the required torque. The engines of modern cars are becoming more and more compact. Reflecting this trend, manufacturers are increasingly eliminating tensioners in accessory drive systems, preferring to use high-tech multi-V belts with an elastic backing. They have become a suitable technical solution and are used in many modern car models.

As a company with direct contacts with engine developers and car manufacturers, Bosch has the most up-to-date information on the technical requirements of drive systems. That is why the characteristics of Bosch belts clearly correspond to factory parameters.

Taking into account the specifics of vehicle operation, the temperature and chemical stability of the materials used in the manufacture of belts is taken into account. Bosch components perform just as reliably in the hottest climatic conditions of the equator as in polar latitudes. In the latter, maintaining the vehicle’s energy balance is a primary task for service station repairmen. Over many years of operation around the world, Bosch drive belts confirm their best qualities. In addition, Bosch belts meet the highest demands on wear resistance. This ensures uninterrupted operation of the auxiliary drive system for a long time.

If the drive belt is cracked.. (consequences)

If the drive belt (or belts) in your car are worn out, they will have cracks and abrasions on their surface. Eventually, while the car is moving, a whistle will begin to appear. In this case, it should be clear that the time has come for their planned replacement. Remember, friends, that if you do not change the drive belt on time, you risk being left without working car equipment. For example, if a belt has reached the end of its service life due to severe wear and tear, it will naturally break sooner or later.

Typically, when the drive belt breaks, you will hear a loud bang from under the hood. As a result, the equipment receiving torque from it will cease to function. For example, if the drive belt that powers the generator breaks, it will simply stop charging the battery and powering all the electrical equipment of the car. As a result, you will see the battery icon light up on the car dashboard.

Also, if the belt breaks, the power steering will stop working. As a result, your steering wheel will become very difficult to turn. But the most important problem when the drive belt breaks is the lack of rotation transmission to the water pump, which promotes the circulation of coolant through the engine cooling system. As a result, the engine can quickly overheat. In this case, you must immediately stop driving, stop and turn off the engine.

Therefore, friends, while driving, constantly monitor the engine temperature sensor, which should show the same temperature of 90 degrees after the engine warms up. If you notice that the temperature needle on the device has gone up and is approaching the dangerous red zone, then in this case you need to stop, turn off the engine and diagnose the cooling system.

Attention! Overheating of the engine can lead to its premature failure (damage to valve stem seals, head gaskets, and also damage to the piston system). Therefore, friends, do not under any circumstances allow the power unit to overheat; monitor the engine temperature on the dashboard.

How to understand that the belt needs to be changed

To understand what is wrong with the car, you need to analyze the functions of each device. The battery in the car is needed in order to maintain a small supply of much-needed electricity. And when the car is already running, then the battery can only take a small charge from the generator, but will no longer release energy.

The main task then lies with another energy creator, which uses the mechanical energy of the crankshaft during rotation. In the process of creating an electric charge, several shafts take part, which are connected by a belt. To understand when it is best to change the belt, you need to constantly listen to the car’s operation.

If the car is equipped with a generator sensor, it can automatically show that the part is reducing its performance and this will be an important signal for the car owner. A belt rupture can lead to many consequences, so it is better to immediately look inside the car when these problems appear.

Why might a belt wear out?

- due to the displacement of the generator pulley from the crankshaft line;

- a bad or low-quality part was installed;

- the service life of the part has been exhausted (with a mileage of more than 100,000 km);

- weak tension or breakdown of the tension unit.

What determines the service life of drive belts?

Modern drive belts have a fairly long service life, all thanks to their design and modern reliable materials. On average, a high-quality belt can last up to 25 thousand hours of operation. Please note that the service life is indicated in hours, and not in kilometers, since the mileage itself does not directly affect the service life of the drive belts. After all, these belts are in motion even when the car is standing still and the engine is idling.

But this is in theory and according to information provided by the belt manufacturers themselves to consumers.

In practice, the service life of drive belts may differ significantly from that declared by the manufacturer. The point is that the wear of drive belts is influenced by many different factors. For example, the way it was installed on the car plays an important role in the long service life of belts. For example, it is not uncommon for car mechanics in technical centers, due to their low qualifications or lack of experience in car repairs, to try to fit a belt onto a pulley using a screwdriver. Ultimately, the new belt will become damaged and will no longer last as long as the manufacturer claims. This method of installing a drive belt is also used when it is necessary to speed up the process of replacing it, so as not to remove the pulley.

In addition, the service life of belts is also affected by the storage conditions of these components in the warehouse and during their transportation. For example, it is not uncommon for car dealerships to sell drive belts that have expired. Yes, drive belts certainly have an expiration date. The point here is this: the chemical composition of the materials of drive belts changes over time, and if the drive belt was produced 5 years ago and was incorrectly stored in a warehouse, then when installed on a car it will naturally not last very long.

Weather can also affect the durability of belts in a car. For example, if you live in a region with a hot climate, then you often use air conditioning. This means that the air conditioning compressor must then receive more of the required energy. As a result, this belt, which transmits torque to the air conditioning compressor, begins to experience increased load.

In particular, drive belts can quickly wear out if the machine is operated for a long time in cold and damp weather. For example, in winter, the electrical equipment of a car requires more power than in warm and dry weather.

As a result, the alternator requires more energy to maintain the electrical system in the vehicle. Ultimately, the alternator belt begins to experience increased stress due to increased torque.

As a rule, these drive belts last longer in a new car because they were installed at the factory and all the necessary storage conditions were observed before they were installed. Once the factory drive belts are replaced, the service life of the newly installed belts will be reduced.

Each car manufacturer in the technical documentation and in the car service book usually indicates in routine maintenance the date when it is necessary to regularly replace the drive belts. Therefore, we advise you, friends, to carefully read the list of scheduled technical inspections and the regulations for replacing consumables. As a rule, the manufacturer indicates the maximum mileage at which the drive belts must be replaced at a car mechanic's technical center. Thus, you will approximately know for yourself the maximum service life of drive belts. But this does not mean that you should not regularly inspect the condition of the belts. More on this below.

Main problems with the alternator belt

Most often, car owners have to deal with a stretched drive belt. In most cases, this happens over time as a result of normal wear and tear. Exposure of rubber to fuels and lubricants can also contribute to stretching. In addition, premature stretching can occur due to the original poor quality of the product. A sagging strap can be tightened, and perhaps it will last for quite a long time.

General wear usually appears after the drive has been in operation for a long time. Rubber wear due to friction on the pulleys gradually leads to a decrease in the profile and slipping of the belt. This is usually accompanied by a characteristic whistle coming from under the hood. Because the drive belt slips, the generator cannot produce enough power to provide adequate electrical power, especially at full load. Battery charging is also slower.

Rubber delamination is possible in case of violation of the parallelism of the axes of the crankshaft and generator or due to deformation of the pulleys when intense uneven abrasion of the edge occurs. Sometimes the cause of this phenomenon is a banal defect of the product.

A break is an extreme manifestation of problems with the generator drive. Either the owner of the car did not monitor its condition, or they received a low-quality product. In addition, a break can occur if one of the devices to which this drive transmits rotation is jammed. To prevent such a situation from taking you by surprise far from civilization, you should always have a spare drive belt with you, even a used one.

Factors contributing to wear

1. Workmanship. A factory-installed drive usually performs as expected without problems. Universal products that are sold in stores can last quite a long time if they are made from quality materials in compliance with proper technological standards. But you shouldn’t chase cheapness. It’s not without reason that a cheap belt has a low price; such products break at the most unexpected moment.

2. Operating conditions. If dirt and aggressive substances get on the generator drive, the strap will become unusable ahead of schedule. Severe frost and sudden temperature changes are also not good for rubber.

3. Driving style. An aggressive driving style creates maximum stress on almost all components and systems of the car. Naturally, the alternator belt also experiences increased load, which means it will have to be changed more often.

4. Faulty tensioner or incorrectly adjusted tension. If the drive is over-tensioned, the risk of it breaking increases. A sagging belt experiences increased friction on the pulleys when slipping.

5. Violation of parallelism of the axes of the crankshaft, generator or other devices that are driven by this drive, as well as damage to the pulleys of these devices.

Regularly checking drive belts

Periodically, every car owner should check the condition of all drive belts and their tension. To do this, check the belts with your finger while the engine is off. For example, by pressing your finger on the belt, you can understand for yourself whether the belt drive tension has loosened or not. Remember that the belt should not move during this inspection (move 1 - 2 cm). If you see something like this, then the cause is weak belt tension. You should also inspect the belt by touch for damage, and a visual inspection is also necessary for chips, cracks and torn elements on the belt.

To do this, use a flashlight, which will not only make your vision better, but can also help you identify worn areas on the belt (as a rule, worn areas of the belt will shine).

In any case, if you see damaged areas on the belt, then it must be replaced with a new one. Please note that when purchasing new drive belts you do not need to purchase original consumables. Today there are many non-original belts on the market, which are often even superior in quality to factory originals. For example, it has proven itself to be the largest supplier of drive belts.

The average cost of replacing a belt in a car repair shop is approximately 2,500 thousand rubles. The cost of car belts itself depends on the popularity of the brand and the cost of the product. There are both cheap drive belts on the market and expensive ones that have a special design and are able to withstand extreme loads.

Replacing the alternator belt yourself

As a rule, the replacement process is not complicated and is quite accessible to most motorists.

Before starting work, you must turn off the engine, turn off the ignition and remove the wire from the negative terminal of the battery.

If more than two units operate from one drive, draw a diagram of its location before disassembling. This will prevent you from getting confused when installing a new belt.

The replacement algorithm may differ slightly for different engines and different attachments.

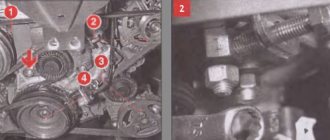

If the drive uses a mechanical tensioner with an adjusting bolt (3), then it must be used to release the belt tension. There is no need to completely unscrew the bolt. In many cases, you will additionally have to loosen the generator housing (5) and move it so that the belt can be removed from the pulleys without much effort.

In some models, tension is carried out directly by the generator without an additional tensioning device.

If the drive is equipped with an automatic tensioner (3), you must first loosen the pressure roller and move (rotate) it so that the belt (2) can be removed. Then the roller must be fixed in the depressed position. After installing the belt on the crankshaft pulleys (1), generator (4) and other devices (5), the roller carefully returns to its working position. Tension adjustment is automatic and does not require human intervention.

After completing the work, check if everything is in order. Connect the previously removed wire to the battery, start the engine and give the generator maximum load, turning on the heater or air conditioning, headlights, and audio system. Then put a load on the engine. If the drive whistles, tighten it.

How to tension, tighten or loosen a drive belt

If the cause of the whistle, squeal or squeak is actually a belt that has become loose and as a result slips on the pulleys, and if the belt does not have any signs of wear or damage, then to remove the extraneous sound you just need to tighten the belt.

Using the same example of a generator belt, this is done using a special adjusting bolt (on modern cars) or using an adjusting bar (on older cars).

For example, to tighten the alternator belt on a modern car, you need to do the following:

— Slightly loosen the generator mounting bolts (upper and lower fastenings).

— Turn the adjusting bolt clockwise, thereby moving the generator away from the engine block and immediately check the belt tension level.

— Then, tighten the nuts of the generator fastening elements.

Please note that in some vehicle systems, the process of tensioning the drive belts is too labor-intensive and requires the use of special tools.

Attention . New generation poly-V-ribbed elastic belts are currently widespread on the market, as well as in many cars. For example, one of the world's well-known manufacturers of such belts is currently. Their products have proven themselves to be the best today. This company is an official supplier for many car factories. Elastic poly V-belts do not require tensioning, tightening, etc. manipulation. Due to their design and material, such belts do not stretch. As a rule, such drive belts last a long time, approximately 120 thousand kilometers.

But for its (their) initial tension a special tool is needed.

In many cars, special belt tension rollers are also used for this, which saves drivers from constantly tightening these belts. The only drawback of this design, as a rule, is that when replacing drive belts, it is also necessary to change the tension roller itself, since its reuse together with a new belt is impossible.

Checking status

On average, the belt resource is 50-60 thousand km. But the duration of its operation largely depends on the operating conditions and the quality of the product.

Determining the condition and level of belt wear depends on the design features of the car. But this definition comes down to a visual inspection of the belt.

First, the belt tension is checked. In normal condition, it should not sag when pressed at a certain distance specified in the technical documentation for the car.

Alternator belt layout

Next, the belt is visually inspected for damage and wear. Protruding reinforcing threads, torn pieces of rubber, traces of fuel and lubricants will indicate the need for replacement.

The squealing can be eliminated by additionally tightening the tension. However, if there is nowhere to tighten the belt, it means it is very worn and requires replacement.

If it is determined that the belt is severely worn, it is replaced. Before performing this operation, you need to purchase a new one. Moreover, you need to select according to the car model, as well as the type of belt. It will be impossible to install a V-belt in place of a multi-ribbed one and vice versa.

Replacing drive belts at a technical center

Modern cars today are equipped with sophisticated technologies and new complex engines with additional equipment. Most modern vehicles have very, very little space under their hood. In some cars there is simply no free space under the hood. Therefore, replacing drive belts in new cars yourself is not so easy. After all, in order to replace drive belts, it is necessary to dismantle many attachments. And all this just to get to the belts themselves.

Typically, replacing drive belts along with rollers may take about 1.5 - 2 hours. The average cost of an hour in Russia is currently about 35 - 50 US dollars. Accordingly, the cost of replacing belts can range from approximately 2,500 to 9,000 thousand rubles (depending on the technical center, make and model of the car).

In older cars, the process of replacing drive belts usually lasts no more than half an hour, since due to the simpler design of the engine compartment, access to the rollers and belts is more convenient.

V-belt or poly-V-belt and generator are the most important components of a single system

Speaking about the accessory drive belt, one cannot fail to mention another component of the drive system - the generator. Modern generators are devices that work in close interaction with all electronic systems. Today, when you open the hood of many cars, you will see a Bosch generator there. Depending on the application model, these devices are adapted to operate in 12 or 24 volt networks. This makes it possible to expand the market and coverage of products not only for cars, but also for trucks and special equipment. Designers also pay great attention to the unification of generators in relation to various lines of engines. As a system supplier, Bosch also provides the widest range of spare parts for generator repair shops.

The production of alternators allows Bosch to offer consumers belts that best suit the requirements of the drive system - be it a passenger car or a commercial vehicle.

How can I remove the whistling, squeaking or crackling sound coming from the belt under the hood?

Unfortunately for us, eliminating belt squeal by tightening does not always help. In this case, you need to replace the old belt with a new one. But many car owners prefer to delay this process itself for as long as possible. To do this, they purchase various sprays from auto stores that they spray on belts. As a result, to the surprise of many specialists and others, this helps.

But again, unfortunately, not for long. Some craftsmen even suggest using a screwdriver and a piece of soap to process the side surface of the belt while the engine is running. For our part, we categorically do not recommend doing this, since, on the one hand, it is very dangerous to carry out any work with rotating components while the engine is running, and on the other hand, the effect of such similar old-fashioned methods is short-lived.

Signs and symptoms

There are six main signs that the timing belt has jumped.

- The car engine is unstable.

- The engine constantly stalls.

- Noticeable loss of engine power and thrust.

- The engine starts with problems or does not start at all.

- The power plant is stuck.

- The sound of the engine becomes louder - a metallic knock appears.

Most often, it happens that the product jumps one tooth, and because of this, the engine continues to operate, but increases fuel consumption, and there are also interruptions in operation and starting.

If you suspect that several teeth have jumped, you should not restart the engine. In the worst case, this can cause the valves to bend.

V-shaped - V-belt, poly-V-belt and toothed belt - what is the difference?

The drive belts of engine attachments should not be confused with timing belts, which synchronize the operation of the valves in the cylinder head with the piston system of the engine block using the camshaft.

As a rule, the timing belt is made of a completely different material from the drive belts of the same generator and other auxiliary equipment. Also, in some cars, the water pump drive is driven not by the V-belt or poly-V belt itself, but specifically by the timing belt, which, due to the special design of the engine, in addition to powering the water pump, also synchronizes the operation of the valves with the pistons.

The timing belt is made from a plastic composite material and has many special teeth that protect the belt from slipping. This is necessary so that the valves work synchronously with the piston system itself and do not collide with each other. After all, many of us motorists already understand that if the timing belt slips and the timing of the gas distribution mechanism goes wrong, the engine will not be able to work or will simply fail.

The timing belt also tends to stretch and has a maximum service life. This belt requires closer attention from the motorist, since if it wears out or breaks, the car’s engine can be seriously damaged and damaged, which will ultimately lead to huge financial costs.

Read more about this here.

Timing belts: what they are and why they break

The mechanical gas distribution mechanism is responsible for supplying a mixture filled with fuel and air to the cylinders of the main power unit. If the engine has a valve mechanism, then its operation is monitored by the camshaft, which, in turn, depends on the timing belt. Here is such a complex scheme in which everything is interconnected and dependent.

The consequences of a broken timing belt depend on its type, which is determined by the type of material used:

- metal;

- metallized rubber;

- leather.

The second option is the most common, which is explained by its affordable cost, simple design, which is characterized by high reliability. Metal belts are quite expensive, and their design is very complex. Leather belts are not widely used, although they are the most affordable option. On new cars, a leather chain is not installed at all.

Why does he break?

There are several reasons that cause this problem. You need to know about them in order to nip in the bud any possibility of a belt break;

- chain wear;

- low quality parts;

- jamming of a number of elements in the engine (pump, rollers, camshafts, crankshaft).

If your car's engine has at least one of these problems, then you need to fix it immediately.

What causes a broken timing belt?

The separation of the timing belt, which is responsible for the operation of the gas distribution mechanism, entails serious negative consequences. The design of this mechanism is simple, but the functional component is impressive:

- control of the operation of shafts (crankshaft, camshaft);

- synchronized functioning of pistons and valves.

The situation regarding what will happen if the timing belt breaks has become less vague. The camshaft and crankshaft will begin to work incorrectly, and the synchronicity of the interaction of the pistons and valves will be disrupted, as a result of which their collision will become inevitable. The strength of pistons is higher than that of valves, so in the event of a collision, the design of the latter elements will be damaged.

Not only will the valves require replacement, but the pistons may also develop problems that will incur repair costs.

All these points will cause a malfunction of the power unit and will negate the ability to travel by car.

What to do if the belt breaks

If you are such a conscientious and responsible car owner that you have a spare set of belts, and even have the car’s instructions at hand with a description of this entire procedure, then many may envy you. Unfortunately, such an ideal situation is extremely rare and many drivers are completely unprepared for an emergency car stop and urgent repairs.

Often a driver encounters this problem while on the road. Unprepared and ignorant car owners who previously thought little about what would happen if the timing belt breaks are in for trouble. This part is considered a consumable item, so no one will undertake to repair it. Only a few craftsmen have enough experience to undertake belt restoration. This method of solving the problem is only suitable for getting to a car service center and making a replacement.

What to do if the belt breaks?

If the alternator belt breaks, you need to do the following:

- The car is placed on a flat surface in a garage with a pit or on an overpass; you need to put chocks under the wheels. The parking brake is lifted and first gear is engaged. The engine compartment of the car is opened and the battery is disconnected.

- Use a wrench to loosen the nut of the adjusting bar installed on it (this will free the generator unit). The nut is not completely unscrewed.

- Then the nut used to secure the generator unit at the top is loosened (until the unit can rotate freely).

- Then the generator unit is moved to the side and the torn belt is removed.

- A new product is being installed. First, the belt must be placed on the crankshaft, and then on the generator set pulley. If the car has a carburetor and is equipped with rear-wheel drive, the last thing the drive unit is put on is the pump.

- After installation, you need to substitute a small piece of pipe or a wrench (gas) wrench to bend the assembly away from the motor. This must be done in order to tension the product. At this time, an assistant must tighten the nut located on the adjusting bar at the bottom of the generator.

- Then the battery is reconnected, after which the engine compartment is closed.

Video: replacing the alternator belt

Channel “We Make It Yourself TV!” in his video he showed the process of replacing the alternator drive belt using the example of a Mazda 626 car

How far can you travel?

It is not recommended to use the vehicle for a long time; at most, you can drive to the nearest service station or garage.

The number of kilometers a car can travel depends on two factors:

- battery charge level (the mileage of a car with a charged battery increases to several tens of kilometers);

- the number of electrical devices and equipment connected while driving that can discharge the battery.

What to do if the car won't start?

If the vehicle engine does not start, you need to do the following:

- Charge the battery. Since starting the engine is often impossible due to a low battery, recharging the device will temporarily solve the problem.

- You should try to start the engine using a pushrod.

- Replace the drive belt and move on.

- If there are no auto stores nearby, then you can install a handy product instead of the strap, which will allow you to briefly replace its function. These include durable women's stockings, men's belts, ties, ropes, and inner tubes from bicycle wheels.