The issue of flushing the engine before the next scheduled engine oil change becomes relevant for several reasons:

- switching to products from another oil manufacturer;

- noticeable deterioration in the condition of the used lubricant before replacement (thickening, severe blackening, presence of contaminants, etc.);

- operating the car much longer than expected without changing the oil;

Engine flushing is recommended in any of the above cases. The main task is to effectively remove residual old lubricant from the engine before adding fresh lubricant.

We also recommend reading the article on diesel fuel additives. From this article you will learn about the types of additives that are designed to improve the performance properties of diesel fuel and prevent diesel equipment.

Flushing is inevitable

It is necessary to flush the drive in the following situations:

- You purchased the vehicle from the previous owner, he did not indicate what brand of motor mixture was used, or how much he drove on it. Before selling the car, the seller could fill in a low-quality product in order to save money, or deliberately hide the actual mileage on the filled oil.

- The car has more mileage than expected without a scheduled engine fluid change.

- The mixture in the engine is highly contaminated; it contains particles of spent fuel and sludge.

- If gas stations changed frequently, fuel from different manufacturers was filled, for example, during a long trip.

- When using products from another brand.

There is no need for flushing if:

- the car is new (ex-showroom);

- you are completely confident in the quality of the diesel fuel you are filling;

- Are you confident in the quality of the oil you fill?

Watch a video about flushing a diesel engine:

In what cases is engine flushing necessary?

Flushing, even if done correctly, can cause significant damage to the engine during its subsequent operation. That is why you should definitely make sure that this procedure is necessary. Typically, flushing is required under the following conditions:

- purchasing a car with a diesel engine that previously belonged to another person;

- changing the type of lubricant being poured;

- purchasing a new car;

- intensive use of the vehicle;

- outdated motor samples.

The first two cases are correlated with each other: often the new owner of the car does not know what kind of lubricant the previous owner filled in. If the type of lubricant changes, it is advisable to soft flush the engine with a new sample of the product. However, it is possible to operate the car without this procedure.

Flushing is important when the engine is under heavy load, as this can cause oil deposits that have a detrimental effect on the efficiency of the car engine. A similar problem may also appear in models with an outdated engine modification - soot may accumulate under the valve.

Standard oil flush with reduced drain interval

To flush the engine, use regular oil, which is poured into the power unit instead of waste fluid. Then operate the power unit in normal operating mode and perform the next engine fluid change at a reduced interval - this is 3 thousand mileage. After that, the car oil is drained and the same is poured into the engine. It is driven for the full interval regulated by the oil manufacturer.

This flushing method has a clear advantage: a motor mixture with good performance consists of a base base and additives. Additives work effectively for the first few thousand mileage, so they can clean the engine when used in normal operation, without causing any harm to the engine, rubber gaskets, or clogging the internal combustion engine channels.

Among the disadvantages, high cost should be highlighted. This flushing option is quite expensive and requires up to three replacements of the engine mixture and oil filter every 3 thousand kilometers.

Let's sum it up

- To prevent the accumulation of deposits and sludge in the engine, you should use only high-quality oils recommended by the manufacturer that meet all tolerances and standards.

- Using one brand of lubricant and changing lubricants strictly according to regulations allows you to avoid the further need to use flushing.

- Saving on oil quality is unacceptable. At the initial stage, external signs of engine contamination are often not visible.

- Adding aggressive flushing compounds to the oil can even “kill” a worn out and contaminated engine.

It is worth understanding that flushing methods using flushing oils or driving with regular oil with more frequent changes can only remove minor deposits. Heavy contamination must be removed from the surfaces of parts only by mechanical cleaning, which will require dismantling the valve cover, cylinder head, oil pan, etc.

Flushing mixtures

Flushing oil is poured into the drive after draining the used engine mixture. It has an increased amount of detergent additives and a high alkaline number, a reduced amount of anti-wear substances. Thanks to this structure, it ensures maximum dissolution of various deposits.

The basic basis of such a washing mixture is obtained by hydrocracking from mineral water. You can wash the power unit with it if, after filling it, the engine runs at idle for up to 10 - 15 minutes. Then this engine fluid is drained and the drive is filled with oil recommended by the dealer for viscosity class and performance properties. Its base can be mineral or synthetic.

Manufacturers of car flushing oils claim that their products after flushing (residues remaining in the engine) have a structure that will not change the characteristics of the filled oil for subsequent operation of the engine.

The advantage of this method is the minimal risk of clogging the oil channels and the absence of aggressive interaction of additives with engine elements.

The disadvantage of this method is the price, flushing mixtures are quite expensive, plus after them it is necessary to use motor fluid of the same brand, using a different brand of motor oil can lead to negative consequences, their compositions will react and the resulting oil will not protect the engine from wear and tear sludge formation.

The best analogues of injector cleaners

The best product for flushing the injector system is the original one. But such additives have their drawbacks, the main one being the high price. If you want to save money, you can replace original products with analogues.

If you make the right choice, taking into account the properties of the liquid, you can achieve good results. The level of performance of proven analogues is comparable to the level of performance of the originals.

D4 Injector Cleaner under Toyota brand

A budget wash that is suitable not only for Japanese cars. Pour it into the fuel tank. The effectiveness is average, the best option for prevention (but not suitable for serious cleaning).

Mixtures - “five-minute” and long-acting

“Five-minute” and long-acting mixtures are concentrates with a large amount of detergent additives, which are poured into the old motor fluid before replacement. The motor runs on such a “cocktail” for 10 minutes, in the case of a “five-minute” up to 200 km (when using a long-acting concentrate). Then the mixture is drained and new oil is poured into the engine.

Using “five minutes” you can remove various deposits in a short period. In addition, flushing and changing the oil are performed as one process.

Of the minuses: such reagents can be used to remove small deposits, plus they can aggressively interact with the material from which engine parts, gaskets, and so on are made.

Winter diesel fuel additives – the best according to test results

What to use it for

Diesel fuel has one insidious property - in severe frosts it loses its fluidity. This happens because paraffin molecules are released from diesel fuel when cooled. Connecting with each other, they form a crystal lattice. Depending on the degree of thickening, power limitation and loss of traction may be observed. Or the fuel filter becomes clogged, diesel fuel does not enter the engine, and the car does not start. If you do not foresee such a situation and do not take measures, you can be left alone on the road in severe frost with a stalled car. To prevent diesel fuel from thickening in the cold, depressant additives for diesel fuel are used. Their second name is antigels.

Attention! Some drivers, to prevent diesel fuel from thickening, dilute it with kerosene or add brake fluid. Not only is this ineffective, but it also worsens the characteristics of diesel fuel - cetane number and lubricity. This leads to poor performance and accelerated engine wear.

When to apply

How not to damage the engine?

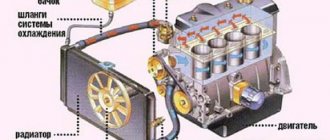

We need to clarify right away: when changing the engine mixture, you can flush a diesel engine only with the use of special flushing oils. Do not use products intended for gasoline engines. This recommendation is explained not only by the different structure of deposits formed on engine elements, but also by the fact that for normal operation of a diesel unit, a larger amount of engine mixture is needed in the friction units; the rubbing elements of the engine must “float” in the lubricant. Oil for flushing power units running on gasoline will not be able to provide such an effect. A similar result is obtained when using “five minutes”; they dilute motor fluids too much. Therefore, special detergents are needed to clean a diesel engine.

When choosing a flush, keep in mind: if there is a lack of the necessary additives, you can get the engine jammed. Because the main task of washing is to first loosen contaminants and then dissolve them. Loose deposits will not adhere to the surface of the drive elements, they will come off and fall into the crankcase of the power unit, where the engine mixture is taken, then clog the filter, made in the form of a mesh - this will lead to a decrease in the throughput of the oil pump and provoke dry friction in the components motor. A high-quality additive, with the right amount of reagents, can dissolve loose deposits.

Please note:

- when regularly replacing the engine mixture, flushing the engine is eliminated, because motor oils have detergent additives that can clean the engine of contaminants;

- When changing motor oil, it is not advisable to mix mineral water with fully synthetic products.

Should you use cleaning additives?

As mentioned above, cleaning additives for diesel injectors are more of a preventive measure. Although in most cases, when there is not a lot of carbon deposits on the injectors, they can be used as cleaning agents. However, the subtlety of use is to apply them on a regular basis. The specific mileage or time value is additionally indicated in the instructions for a particular product. If the nozzle is significantly dirty, then a cleaning additive is unlikely to help. In particularly advanced cases (for example, when there is practically no fuel flow), it is necessary to dismantle the specified unit, and, using additional equipment and tools, diagnose the diesel injector and, if possible, clean it with special means.

Please note that most diesel injector cleaners are highly toxic. Therefore, all work with them must be carried out in the fresh air or in a room with good forced ventilation. It is also advisable to work with rubber gloves, avoiding contact of the product with the skin. However, in the case of skin, it can be quickly washed off with water, and it will not cause harm. But you definitely shouldn’t allow the additive to get into the oral cavity! This is very harmful to the human body and threatens severe poisoning!

As practice and numerous reviews from car owners show, the use of cleaning additives for diesel injectors in most cases has a positive result. In any case, there will definitely be no negative consequences from their use. The main thing to remember is to strictly follow the recommendations given in the instructions for use of a particular product. Therefore, the cleaning additive will be a useful addition to any diesel driver’s collection of auto chemicals.

Cleaning a heavily polluted diesel engine

If there are significant deposits on the engine, it is better to contact a service center, where they will carry out a comprehensive cleaning of all elements of the lubrication system and the engine.

Having decided to flush the drive yourself, approach the flushing process correctly so as not to end up with a major overhaul of the power unit. To do this, follow this scheme:

- fill in flushing oil;

- drain the mixture from the engine, estimate the amount of undissolved sediment in the waste fluid; if there are a lot of deposits, you will need to remove the pan after washing the power unit;

- fill in flushing oil and let the engine run for a while;

- repeat this procedure several times until the flushing oil is clean;

- remove the pan and perform mechanical cleaning with a scraper or brush;

- replace the oil filter.

You can perform these steps only when using high-quality flushing oil; before purchasing it, ask the seller for a quality certificate.

The best manufacturing brands

Should I clean the injector with a detergent, additive or solvent? This question is asked by almost every car owner. And sooner or later he realizes the need for cleaning. But in order not to worry about your car, you should choose products only from trusted manufacturers.

Chevron

The company arose in the late 70s of the 19th century. From the first days it was engaged in the production of petroleum products and chemical compositions for various purposes. Today it occupies a leading position in the industry. Among its range of products, injector flushing into the tank is in great demand. It is presented in a wide range.

Red Line

The company was founded at the end of the last century in California. Its goal is to produce lubricants for the racing segment. Until now, it produces the best products for motorsports, while simultaneously producing formulations for ordinary car enthusiasts.

Royal Purple

One of the oldest companies in the segment. Its specialists have been working on lubricant formulas for more than two centuries. Each new sample is more effective. That's why new items from Royal Purple are instantly sold out.

STP Oil

The company began producing lubricants in the middle of the last century. They gained their fame thanks to Nascar. And they are still considered one of the best.

The most popular additives for cleaning the injector are those added to the fuel tank.

For fuel system

The fuel system is the most capricious and easily clogged. Its repair is quite expensive, so be sure to use specialized flushes.

Fuel Injector Pro – Fuel System & Injector Cleaner

Fuel Injector Pro – Fuel System & Injector Cleaner

Not the most well-known brand produces a high-quality product positioned as a prophylactic product. It has a complex effect:

- improving the quality of gasoline;

- cleaning injectors;

- maintenance of the pump and injector.

It is recommended to use the liquid after refueling at questionable gas stations. Moreover, cleaning needs to be done twice. Conveniently, one package is enough for a full tank.

Pros and cons optimal packaging shape for pouring numerous positive comments noticeable effect even after the first use cost above average frequent counterfeit

On average, the product costs 700-1000 rubles.

Sea Foam SF-16 Motor Fuel Treatment

Sea Foam SF-16 Motor Fuel Treatment

The optimal solution for removing any type of contamination. It is in equally high demand among Russian and foreign car enthusiasts.

The product has a lot of features:

- versatility;

- compatibility with other additives;

- relevance for gasoline and diesel power units;

- removal of the heaviest compounds;

- system lubrication.

Pros and cons the ability to use the lubrication effect for different types of deposits (this is especially important for cars over 10 years old) ease of use (filling is done in the intake tract) high cost of the product - in some retail outlets it reaches 2,000 rubles.

Wynns W89195 DIESEL SYSTEM PURGE

Composition Wynns W89195 DIESEL SYSTEM PURGE

The composition is suitable for those who for the first time decided to clean the system themselves. It copes with all types of deposits. Moreover, the level of pollution does not matter.

After cleaning Wynns W89195 DIESEL SYSTEM PURGE:

- the efficiency of the power unit increases;

- the service life of all components and elements increases;

- the soot concentration in the exhaust is reduced.

Pros and cons allows you to carry out the procedure without disassembling the system convenient packaging high-quality cleaning suitable only for diesel engines rarely found on shelves

Purchasing a flush will cost 700 rubles.

Lucas Oil Deep Clean

A good option Lucas Oil Deep Clean

A good option with a complex effect:

- cleaning;

- system lubrication.

Among the distinctive properties of the product is high efficiency. Already the first flushing it is noticeable:

- improves engine performance;

- reduces the concentration of harmful substances in exhaust gases.

Pros and cons versatility accessibility efficiency not suitable for diesel power units

The cost of the product does not fall below 750 rubles.

Flaws

Result after manual washing. Using diesel fuel as a flushing liquid will not give this result.

For example, diesel fuel, being a fuel, does not dissolve slags and carbon deposits, but peels them off from the walls. These contaminants, which are not completely removed, circulate with fresh motor oil, impairing its beneficial properties. That is, exfoliated contaminants are poorly washed out completely when drained.

They pose a danger in that they clog lubrication channels and mesh, leading to decreased circulation and oil starvation of operating components. The use of flushing fluid with alkaline additives inevitably leads to damage to the rubber gaskets, oil seals, and seals. And this is a direct road to failure of the power unit.