Many cars have shiny VVT badges. They can be found even more often on engine covers. “What are these letters?” – the question sometimes confuses sales consultants and even service technicians. At best, you will hear something obscure about the gas distribution mechanism. Your request to clarify: what advantages and advantages these “three cheerful letters” provide – often remains “without comment”.

But the variable valve timing system (VVT [English Variable Valve Timing] is one of its trade names) or “phase shifter” will soon celebrate the 100th anniversary of its appearance on internal combustion engines. However, for too long such systems were used exclusively in motorsports and racing, and when they appeared on “ordinary” cars, they did not become an object of desire, such as, for example, turbocharging or “16 valves,” while playing a primary role in the perfection of engines.

In this article we will restore justice and tell you what VVT, CVVT, VANOS, MIVEC, and similar names are, which essentially refer to the same system, which is very important and useful.

Why do you need a valve timing control system?

The simplest experience that explains everything you need

Let's do a simple experiment. Take a long rigid tube more than 1 meter long and an internal diameter of approximately 1 cm plus or minus half a centimeter. Wipe the edge from germs, because you will have to take it into your mouth (I’m serious, no stupid laughter))). Draw in as many lungs of air as possible. AND ….

First part of the experience . Covering the edge of the tube tightly with your lips, slowly blow air into it and when the breathing ends, sharply close the hole with your tongue. How do you feel? Almost nothing. So... maybe the tongue will lightly press inside the hole, and no more

1st part of the experiment... Slowly blow air into the tube, then press the hole with the tongue... Almost nothing happens

Second part of the experience. Also hermetically sealed... But now, suddenly, with the effort of all your lungs, “until there is enough breathing room”, blow the entire volume of air into the tube and immediately (!) plug the hole with your tongue... O-pa! The air flying through the pipe, by inertia, tries to suck almost the entire tongue into this hole behind it!!!

2nd part of the experiment... Powerfully blow air into the tube with maximum pressure, then clamp the hole with your tongue... The inertia of the air strives to pull the tongue in!!!

The essence of the experiment is that, thanks to it, you really feel that the air has mass (m) and momentum (p = mv) - the higher the speed (v) this mass moves through the tube, the greater the momentum, and therefore the inertia.

People became interested in this effect back in the 1910s, and implemented it through a short phase of mutual opening of the intake and exhaust valves at the border of the 4th and 1st strokes of a 4-stroke internal combustion engine. That is, at the moment when the 4th exhaust stroke comes to an end and the exhaust gases rush through the exhaust manifold, their inertia can be used to forcefully suck in fresh mixture from the intake manifold. A kind of inertial supercharging. This is true.

While the operating speeds of the internal combustion engine (up to 60-70) were in the zone of up to 3-4,000 rpm, it was enough to simply record the duration of this phase of mutual opening. However, as engines improve, the zone of their most effective revolutions increases and expands (up to 5-6,000 rpm), as well as a general increase in crankshaft speed (up to 8,000 rpm and above) in combination with options for increasing/decreasing the diameter piston and its stroke - it became possible to control the “character” of the engine - make it more high-torque or faster, high- or low-speed, aggressive or comfortable, etc.

Back in the 70s, a problem arose - at low speeds the intake valves would have been opened later, and at high speeds - earlier. Then the engine can be made more universal by instilling in it a “character” that is equally friendly to both “athletes” and “dacha residents”. How to do it? And in the 80s, the first mass systems for changing valve timing appeared.

Comparison of operating cycles of 4-stroke internal combustion engines with and without VVT

A little history: where it began

The first officially patented and workable technology for changing valve timing using a mechanism strongly reminiscent of a desmodromic one (currently a “trademark” of Ducati motorcycle engines) was patented by Porsche in 1959, but it never reached serial implementation, flashing in the Formula 1 and Le Mans. By the way, there are also earlier patents from Cadillac, Vauxhall, etc., issued back in the 30s and 40s, but the matter did not progress further than experiments.

The first was FIAT, or rather its brilliant sports Alfa Romeo 75, which in 1986 received a 2-liter “Twin Spark” petrol engine, which is stunning even today with its “advancement”. In addition to two spark plugs per cylinder and two camshafts (Twin Cam), with an 8-valve (!) scheme (16-valve will appear in 1997), for the first time in the world it was serially equipped with an electromechanical valve timing system using an electromagnetic clutch, with which One of the ignition distributors was also connected to the “odd branch” of the spark plugs.

Alfa Romeo 2.0 Twin Spark engine is the first production engine with variable valve timing system

For the late 80s, the power output from 2 “atmospheric” liters was 148 hp. was considered “monstrously” high, and taking into account the maximum power developed from 5600 rpm up to the “red zone” at 8000 rpm and the “cut-off” at 8700 rpm: no one even thought to doubt that the “Alphas” - This is truly a “Ferrari for everyone.” Alfa Romeo's success was accompanied by brilliant triumphs in the coolest international and national racing championships, as well as victories of its “sister” Lancia Delta on rally tracks with the same engines.

Japanese Honda, which had already become an authority in Formula 1 in the late 80s with its racing engines and the championship titles of Ayrton Senna and Alain Prost, converted its technological advantage into production technology. Since 1989, sports cars Honda Integra, Civic CRX and others have gone on sale, equipped with a 1.6-liter naturally aspirated engine with PGM-F1 injection technology and a VTEC variable phase system, which made it possible to extract a record 150-160 hp from a modest displacement. With. The success was amazing, cars and engines became legendary, and the potentially large resource inherent in the “Japanese” only “warmed up” attention to new products. While these cars were new, everything went well, but as the mileage accumulated, shortcomings appeared.

Their “Achilles heel” was... not so much mechanical or operational reliability, but social and regional! Having arrived in Russia in the 90s, these “purebred horses” were not driven by the foreign “Super 95 or 98”, but by “whatever was necessary”, including the “singed” 92nd. The motor oils used were also by no means prescribed, and in which we had to drive for much longer than indicated in the factory technical regulations. Therefore, this stunning technology in Europe, America and Japan lived with us for a very short time. Thanks to the Kulibins and Lomonosovs, it was possible to extend the service life to several hundred thousand kilometers, but this was only an “extension of the agony.” It was clear to automaker engineers that some simpler and more reliable system was needed. Therefore, until the early 2000s, most high-volume engines did not have phase regulators.

In 1992, Porsche patented the Valvematic system with a phase shift using oil pressure in the main system and the resulting movement of the clutch with a helical guide element. Over the next few years, Denso and Borg&Warner developed similar designs in which phase changes under the influence of oil pressure were carried out by moving a rotor coaxial to the camshaft. Compared to others, the design turned out to be simpler, more compact and reliable, and most importantly, it could be controlled by an external valve of any convenient design, placed in the most suitable place, which would be controlled by the computer’s brain.

In 2000, PSA Peugeot Citroen was one of the first to use the VVT system on a naturally aspirated 2.2 16v 158 hp. (EW12J4). A few years later it was received by “siblings” 1.8/125 hp. (EW7A) and 2.0/140-147 hp. (EW10A/10D). At the same time, Variable Valve Timing was adopted by all the main players in the car market - Toyota, VAG, Ford, GM, Mitsubishi, MB, BMW, etc. There is no point in highlighting the primacy of any one brand - it is a clear prerogative of suppliers of components and technologies , and the VVT principle itself is an example of a “common cause”, which (a rare example in the auto industry) was carried out by all the “grandees” together, understanding the mutual benefit.

Advantages of the VVT system

Primary goals and objectives of the valve timing control system:

- Expand the zones of maximum torque and power in revolutions;

- Optimize filling the cylinder with a fresh charge of the air-fuel mixture while removing exhaust gases more completely and quickly;

- Make engines more flexible;

- Improve engine performance while reducing fuel consumption.

- Reduce the number and frequency of gear shifts (especially with manual transmission), thereby increasing driver comfort.

Sometimes the environmental benefits and “green” benefits of VVT declared by some automakers are already indirect effects that are a consequence of the engine running at a more optimal mixture and increased efficiency. After all, you can’t fool physics! When efficiency increases, everything else increases, including “ecology”. If you try to argue with physics and make something worse “for the sake of the environment,” it is impossible. …. Unless you manipulate facts and engage in fraud with numbers and characteristics.

And if it’s very “common”, then... Speaking of “petrol engines”, let’s ask ourselves the question: what are good about diesel engines? The fact that they “pull” throughout their entire speed range and the driver always knows that “there is always a reserve under the pedal.” In the late 80s - early 90s, during the heyday of “classic” gasoline 16-valve engines, it was noticed that they had to be “twisted”, and the higher their capabilities, the more actively you had to operate the gas pedal and move the lever more often Manual transmission. This gave rise to a certain discomfort, especially in megacities and traffic jams. So, just to bring the traction characteristics of gasoline engines closer to diesel engines, VVT systems appeared. Gasoline engines with phase regulators have become better at pulling at the bottom. Their efficiency has improved when driving in urban conditions, which means the owner began to spend less money on gasoline. Driving the car has become more comfortable thanks to the greatly reduced need to “oil” the gear shift lever. “Automatic machines” began to live longer, since they need to switch less often. The resource of the internal combustion engines themselves has also increased - remaining in the category of “millionaires”, while significantly increasing their characteristics. The conclusion suggests itself - VVT systems are almost the most driver-friendly, because even in their absence, the engine will be “just a 16-valve”, as in the old joke about the moose, which, when falling from a tree, tore off “something” - “A I'm a moose. Just a moose." Joke!)))

How does this system work at idle?

At idle, the valve overlaps minimally, and the cylinder is filled with fresh air, which allows it to be cleaned of exhaust gases. To achieve maximum savings, the system being considered today can set the intake valve to open and close as late as possible. Thanks to this, the compression stroke becomes minimal, and the working mixture is supplied to the intake manifold. In essence, this reduces the compression stroke, and the actual compression ratio is reduced relative to the geometric one. Sounds complicated? In simple terms, these manipulations reduce the working volume of the cylinder. But the exhaust valve, on the contrary, opens earlier than usual, before the piston reaches BDC on the power stroke. This will give the exhaust gases more time to exit the cylinder.

It is also worth knowing that by changing the opening/closing moment, the phase change system allows you to set a much shorter compression stroke, simultaneously lengthening the working stroke. This all has a positive effect on engine efficiency and savings.

Alternative VVT phase regulators

Currently, there are two systems for changing valve timing:

- On the intake camshaft (“single”);

- On the intake and exhaust camshafts (“double”).

As an example, it is convenient to consider BMW engines: for those with the word VANOS in the trade name, the phases change only at the intake, and for those with Double VANOS - at the intake and exhaust. Toyota has similar designations – VVT-i and DVVT-i.

By the way, the marketing names VVT, СVVT, VVT-i, e-VVT, VTC, VCT, MIVEC and VANOS refer to almost the same design of the phase shifter(s), which differ from each other only in minor and unprincipled nuances.

There is a misconception that changing valve timing is somehow connected with the system for changing valve lift. The essence of these misconceptions is that both were originally created for different purposes and can exist separately, independently of each other, or can be combined together into a single structure. A striking example of this is the PSA engines of the EP family:

- 6 VTi 120 hp (EP6C) “aspirated” with phase shifters on the intake and exhaust, as well as a VTi valve lift system, similar to BMW’s Valvetronic, without a throttle valve;

- 6 THP 150 hp (EP6CDTM) with one VVT clutch on the intake, throttle control with a conventional throttle valve and a Twin Scroll Borg&Warner turbocharger;

- 6 THP 200 hp (EP6CDTX) combines all the innovations of the family: intake and exhaust variator phases, throttleless VTi valve lift and twin-scroll turbocharging.

After all, the camshaft rotates by turning the clutch rotor, which is essentially a toothed belt pulley or a chain “sprocket” in the timing drive, and the lift of the valve plates changes through pushers (“rockers”) - these two mechanisms can only be connected by a control computer. Honda's i-VTEC partially combines these functions, but at the same time the system is noticeably more complex.

Systems for changing the valve lift height (Valvetronic, VTi, Valvelift, etc.) are created as an alternative to the throttle valve, that is, to control the “gas”. Changing the speed using a conventional throttle has a significant drawback - the damper creates impressive resistance to the air flow entering the engine, thereby complicating the formation of mixtures with fuel and worsening the degree of filling of the cylinders with a fresh air-fuel mixture.

By changing the lift height of the intake valves, it becomes possible to vary the amount of incoming mixture without a throttle, which means eliminating pumping losses and harmful damper resistance to air flow. As you can see, this system is not directly related to valve timing. At the same time, it can be in symbiosis with VVT.

Another prejudice: engines with variable phases on the intake and exhaust (example: Double VANOS BMW) are supposedly better, more modern and more advanced than those with a phase shifter only on the intake (simply VANOS). There is no direct relationship between the technical conditions of the motor and the number of its phase shifters. What dominates here is the adaptation of the engine of a particular brand and model to achieve the characteristics and temperament of the power unit specified by the “consumer niche”. And one, two or more VVT clutches does not matter.

Possible problems and solutions

- Engine oil for engines with variable valve timing must strictly comply with the approval or standards of the automaker. Example: in the lubrication system of an “atmospheric” gasoline EW10A, it is prescribed to use Total Quartz 9000 5W-40 or approved PSA B71 2296. The fact is that the correct operation of the phase shifter, namely, displacement by a certain angle at a given speed and load, is directly “tied up” » on viscosity and oil pressure. If it turns out to be more fluid or too viscous, the system’s functioning algorithm will be disrupted, which will worsen engine performance and can subsequently lead to a large number of problems. Therefore, do not “buy” into advertising statements about the “phenomenal benefits” of the products of some fuel and lubricants manufacturers - expectations of a miracle can turn into a shameful fiasco and a big loss of money.

- Saving on the quality of engine oil will also end in failure. Low-quality, counterfeit and surrogate “slurries” will inevitably lead to abundant deposits of wear and oxidation products in the stator chambers of the VVT coupling (there are more than enough places for dirt and debris to accumulate in them). Scores will appear on the friction surfaces. The wear process will become an avalanche. After some time, the phase regulator will begin to “mope.” If this is not “cured” in time, the coupling will jam, after which a long and expensive repair may be required. To prevent this from happening, use engine oil only as prescribed by the manufacturer, change it at the required intervals, and use only those fuels and lubricants of which you are 100% sure of their high quality!

- couplings are just as reliable as “regular” timing belt pulleys and timing chain sprockets. However, even with high mileage they require replacement due to natural wear and tear. Here, too, lurks a potential “time bomb”: on the market there are a large number of fakes and counterfeits from the “Heavenly Empire” made by handicraft methods, because VVT couplings are, although “long-lasting” products, but by no means cheap. Therefore, if replacement is still required, use only “original” or “branded” products from reputable manufacturers. Example: some redneck-minded owners of Peugeot and Citroen, when it is necessary to replace phase shifters on PSA EW7A/10A/12A engines, completely cross out their undeniable durability by using Chinese VVT couplings from Baificar instead of standard Japanese Denso or INA. Result: 30-40,000 km after replacement, they begin to “rattle”, leak oil, the engines run unevenly and refuse to start in winter, while the “original” from Denso and INA work reliably and do not cause problems for 200-300 000 km.

- VVT couplings, be sure to replace all associated rubber gaskets, seals, and seals. After all, phase regulators: units that change “once and for all,” because If there is a mistake or miserly economy “on matches”, to fix the problem you will inevitably have to disassemble everything again and adjust it again and at great expense. Therefore, it is much more profitable to carry out the entire, comprehensive set of component replacements during one act, even if they seem intact and functional, but this is prescribed by technical regulations or repair and maintenance manuals.

- Rubber rubber and gaskets , when replacing phase shifters, of course, must also be from reputable manufacturers or original. When purchasing them, preference should be given only to brands known for their quality and not chase low prices (there are plenty of fakes here too). If you are not an “expert” in this matter, we recommend products – Elring, Febi, Glaser, Goetze, SWAG, Victor Reinz, provided that the purchased product is genuine and purchased from an official dealer of these brands (you can find out on the manufacturer’s website).

- Work on servicing and replacing VVT should only be carried out at specialized service stations by the hands of experienced craftsmen. It will be necessary to use a certain amount of special tools (for some German and Japanese brands, this operation may require up to a dozen special devices!), which are not sold even in reputable auto parts stores, and once in your hands, they require experience and professional use skills. “Improved means” and “it’s not the gods who burn the pots” are inappropriate in this matter - in the event of even an innocent mistake, everything can end in a major overhaul of the engine. The reason for all this is the need to maintain pinpoint accuracy of the work performed and strict adherence to technical regulations, regardless of the brand and degree of complexity of the engine.

- Computer diagnostics of VVT on modern cars does not cause problems. The parameters of its operation are recorded by several sensors, and the operation of the control valve(s) is managed by a separate computer or ECU program. Moreover, testing only in rare cases requires a special dealer diagnostic complex - in the vast majority of cases it is possible to “read” information about the performance of the phase shifter using “unofficial” test computers. The main thing is that the specialist is experienced and understands the essence of VVT.

- Phase control valve can cause interruptions in engine operation and jumps in its speed. Often this is not the cause, but a consequence of the above problems. The consequences are:

- The spool rod is covered with an excessive amount of deposits and jams;

- Too much debris has settled on the protective nets and their permeability has decreased;

- Due to the large amount of metal “powder”, wear increased the gaps, the tightness was broken, and axial “beating” occurred.

The influence of external influences cannot be ignored:

- Oxidation of VVT valve electrical contacts;

- Natural aging of the insulation of the solenoid coils due to external (if, as a result of tuning, some hot element is installed next to it) or internal (when the housing is covered with a layer of dust or dry dirt, playing the role of a heat-insulating “fur coat”) overheating;

- Mechanical damage caused accidentally and/or unnoticeably during ICE maintenance.

Washing the valve in powerful solvents in order to restore its functionality sometimes helps for a short time, but this does not solve the main problem: if it does not work correctly, especially if it is jammed - in order not to waste a lot of unnecessary time and extra money, it is better to replace it with a new one.

9. Flushing the VVT should only be done after it has been dismantled. Attempts to do this by adding “miracle” detergent additives to the oil are doomed to failure. You need to understand that if the phase regulator is dirty inside, then the amount of slag and deposits in the oil system is no less large. During the dissolution process, heaps of debris can rush through the channels and settle right in the phase shifter chambers, thereby further worsening the situation.

If the coupling is dismantled and immersed in a bath of powerful solvent (even white spirit will do), then its functionality can often be restored. Of course, after such a “bath” it should be additionally and thoroughly washed from the inside with streams of solvent injected through the appropriate channels using special syringes or douches. It will take a fair amount of time - all movements must occur without jamming. This method allows you to free jammed locking pins, clamps and other moving elements of the clutch mechanism. Many of them will have to be pressed using a handy tool - use suitable plastic or wooden sticks for this, which will not scratch the very thin and delicate surfaces of the phase shifters.

However, the effect of such measures may be zero. The reason is that in an environment of accumulating contaminants, the coupling has to work for too long, and by the time it jams, all its internal working surfaces may have supercritical wear. Having dissolved all the “adversaries” and brought the phase regulator into seemingly working condition, the size of its gaps and axial beatings can make its subsequent normal operation impossible. If this is not noticed in time, you can cause fatal damage to the engine.

We dare not deny the effectiveness of VVT clutch flushing, just as we cannot argue with the “miracle of the last straw”. At the same time, based on experience, arguments and facts, it is too often and excessively regularly necessary to state that the purchase and installation of a new VVT clutch to replace a worn one turns out to be tens of times more profitable in all respects than attempts to revive a failed device.

Conclusions about motor phase control systems

VVT phase regulators as systems:

- Simple

- Effective

- Providing many benefits and advantages with a minimum of disadvantages.

For them to work reliably and without problems: they do not require additional conditions and measures - they are exactly the same as those necessary for high-resource, confident and problem-free operation of engines in difficult Russian conditions. If you take care of your car, it will respond with the infallibility of its work, giving you the thrill of owning it for many years and hundreds of thousands of kilometers. Remember the very positive proverb of our driver ancestors: “A car loves: affection, cleanliness and lubrication.” Relevant – even today!

Principle of operation

The principle of operation of the system is to change the position of the camshafts relative to the crankshaft pulley.

The system has two directions of operation:

- Advance valve opening.

- Delay in valve opening.

Advance

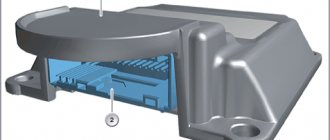

When the internal combustion engine is running, the oil pump creates pressure, which is supplied to the CVVT solenoid valve. The ECU uses pulse width modulation (PWM) to control the position of the VVT valve. When it is necessary to adjust the actuator to the maximum advance angle, the valve moves and opens the oil passage to the CVVT fluid coupling advance chamber. At the same time, liquid begins to drain from the delay chamber. This allows you to move the rotor with the camshaft relative to the housing in the direction opposite to the rotation of the crankshaft.

For example, the CVVT clutch idle angle is 8 degrees. And since the mechanical opening angle of the internal combustion engine valve is 5 degrees, it actually opens by 13.

Lag

The principle is similar to the previous one, however, the solenoid valve at maximum lag opens the oil channel to the lag chamber. At this time, the CVVT rotor moves towards the direction of rotation of the crankshaft.