Unfortunately, it is impossible to accurately answer the question of why the VAZ-2107 (carburetor) does not start, since there are many reasons for such a malfunction. This can be either a breakdown of a particular part or a failure of a certain system. If we ignore the possibility of a lack of fuel in the tank, then we can say that the car is faulty.

Problems starting an injection engine

The last cars to roll off the assembly line were equipped with fuel injection systems. The design of these is somewhat more complicated than carburetor ones. But there can be only 2 reasons for the malfunction:

- weak or absent spark;

- lack of fuel supply.

It is also important to measure the compression - this is often where the problem lies. You will need to purchase a special pressure gauge. The presence of an automatic diagnostic system greatly simplifies troubleshooting. Check Engine solves many problems. It lights up when a malfunction occurs. In 90% of cases, if it is impossible to start the engine, the error code begins in ROZXX.

The presence of such an error indicates missed “flashes” in the cylinders. If one is detected, you should check whether there is a spark or not. There are many diagnostic methods. For an ordinary driver who does not have his own workshop with all the necessary equipment, the following are suitable:

- using a diagnostic scanner;

- checking the ignition module.

Unit repair

According to experts, the service life of the starter is up to 6 years. If this unit has been in regular use for several years and has stopped working, then it should be carefully checked. Regardless of the cause of the breakdown, the first thing that needs to be done is to conduct a visual inspection to identify visible problems.

You should carefully inspect the contacts, since often the starter stops working precisely because of them. An unstable charge can also cause the starter to fail to turn, so you need to try starting the car several times.

But even if the car starts, you should not assume that the breakdown resolved itself. Sooner or later the car will stop starting and the breakdown will need to be solved in a radical way. Simply replacing the starter may not always solve the problem.

To remove a part for subsequent disassembly you need:

- Disconnect the terminals and remove the battery.

- Remove the protective shield under the engine.

- Unscrew all nuts that secure the starter wires.

- Remove the bolts that connect the starter to the crankcase.

- Pull out the starter.

- Unscrew the nuts and remove the relay from the cover.

- Unscrew the bolts, remove the covers, and then remove the rotor.

Replacing bushings

To replace the bushings, you should increase the gap formed between the shaft and the support. The cause is often a misalignment that causes the rotor to touch the plate on the stator. The defect is solved by replacing the part.

- You need to knock out the front support and remove the rear bushing. This can be done with a special puller or by drilling.

- New parts must be installed using soft mandrels. Under no circumstances should you warp the products or use excessive force.

- Before installing the bushing, it is recommended to immerse it in engine oil for several minutes to saturate the porous material.

Replacing brushes

These elements supply voltage to the rotor, or rather its winding.

Instructions for replacing brushes:

- Remove the cover.

- Unscrew the 4 screws that secure the brushes.

- Replace the elements with new ones.

- Clear the cavity from recycling.

Relay repair

This unit is necessary for the gear to move along the rotor. The element is located on the body of the unit.

First, the control relay is checked. The screw securing the part should be tightened thoroughly to check for oxide on the wire and plates.

To test the relay you need to close the drive directly. The unit must be replaced with a new one if the rotor rotates.

If the unit is working properly, the resistance on the coils is 75 - 55 Ohms. If it does not meet these indicators, then they need to be changed, since they cannot be repaired.

Assembly and installation

To assemble the unit, you must perform the same steps, only in reverse order. Correctly install the cotter pins and corkscrew rings that are provided in the design of some elements. Check the node for functionality.

How to determine a malfunction with a scanner?

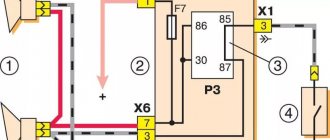

The device for reading error numbers looks like this:

A good solution is to use a Bluetooth adapter to connect. It is designated by a special marking ELM 327. The connection connector is located at the bottom of the car panel above the front passenger’s feet.

Using it will allow you to determine the cause of the malfunction and figure out why the car stalls. Using a scanner allows you to determine the cause of failure of a specific part with 90% accuracy. In the future, it can be repaired or completely replaced.

HBO for cars

A hot engine can also cause a breakdown in the case of an installed gas system. Since driving on gas has recently become profitable, many drivers switched to this type of fuel, however, they did not take into account some of the nuances of the new system. In hot weather, gas expands more, which leads to increased pressure inside the system and often causes damage. This is why it is bad to drive on gas in the heat.

At high temperatures, seals and hoses can fly off, which leads to gas leakage.

The result is an extremely dangerous situation. To avoid this, try not to fill the tank to full gas in the summer, this will reduce the pressure in the system and the risk of breakdown. If a similar problem occurs, it is recommended to let the car cool down and then visit a service station. You should not repair the gas system yourself; the equipment should be adjusted by a specialist.

Checking the ignition module

Often the problem of the inability to start the engine lies in a failed ignition module. This part is a special device that, using special coils, generates energy to generate a spark and further start. The simplest and most reliable way to check serviceability is to install a new module purchased from a store. If the engine started, the problem lay in this part. It should be noted that this process has its own characteristics and subtleties.

If it is not possible to purchase a new module for some reason, you can carry out diagnostics yourself, on site using a tester set to the “ringing” mode. Main stages:

- the module itself is carefully detached from the tips;

- one probe must be connected to the central contact;

- the second probe is connected to ground.

If after performing these manipulations there is no signal on the device, then there is no problem. If the connection is present, the ignition module must be replaced. Since there is a breakdown.

The starter hums, but the engine is silent

In this case, the cause of the breakdown is the bendix (it does not click).

And the buzzing is heard due to the fact that the anchor gets caught on the flywheel, and the launch does not occur. The starter works, turning the armature at high speed, but the engine flywheel does not spin up. Note: when the eccentrics stop functioning normally, the bendix begins to spin in different directions (should only go in one direction), and the gear rotates in the flywheel splines. And the result is a buzzing sound.

If you try really hard, in theory you can repair the gear, but it will be expensive, it will be difficult to find the eccentrics, and it may simply not be possible to put everything back together. In such a situation, it is more advisable to replace the entire assembly by first removing and completely disassembling the starter.

Take care of your car, carry out repairs in a timely manner, and it will serve you for as long as possible.

Source

Checking the fuel pump

The part in question has a relatively simple structure. Rotation is carried out using a special pusher driven by a long steel rod. You can check the pumpless pump without removing it from the engine:

- you should remove the fuel pipe from the filter installed after the pump or disconnect the line in another place accessible for clear viewing;

- Then, using a special pedal, you need to pump the fuel.

The back of the part is equipped with a special lever. If you start pumping it, then gasoline should start flowing through the fuel line. Its absence indicates a malfunction. In this case, the easiest way is to purchase a new fuel pump. Its cost is no more than 1 thousand rubles. It is also possible to carry out repairs - but the cost is comparable to buying a new part.

TOP 5 reasons why a car stalls while driving and won’t start

It happens that you buy a new car, and at first it starts up great. Then something wrong happens - everything doesn’t work. The problem when a car stalls while driving and does not start is one of the most discussed problems among motorists today. Five most common reasons:

- lack of fuel;

- pump failure;

- filter contamination;

- ignition failure;

- sensor malfunction.

Some of them can be easily fixed by an experienced driver with his own hands, but some problems can only be solved with the help of repair shop employees.

Carburetor faulty

If the fuel pump works normally and fuel is pumped through the carburetor, then the problem may lie in the carburetor. You can check it if you have an assistant:

- remove the air filter cover;

- press the gas medal and turn the starter;

- Fuel should begin to flow into the intake manifold.

If for some reason there is no gasoline, then the carburetor requires repair. As a rule, the main cause of malfunction is the presence of resins and slag in the jets. To flush it you will need to use a special liquid and a compressor.

No fuel supply

When problems arise with the fuel supply on a VAZ 2107, regardless of the engine type, it simply will not be possible to start the power unit. You will need to understand the reasons and fix the problem.

On the injector

On an injection engine, the fuel pump located in the tank may break down. We check its performance and, based on the results obtained, perform certain actions: repair or carry out further diagnostics. Checking the fuel pump on the injection “seven” is quite simple: just turn on the ignition and listen to the operation of the mechanism. If there are no signs of the node functioning, it is worth understanding the lack of performance in more detail.

On an injection VAZ 2107, fuel may not enter the engine due to problems with the fuel pump located in the tank

On the carburetor

With a fuel pump on a carburetor engine, things are somewhat more complicated: the mechanism will have to be dismantled, disassembled and the condition of its structural elements diagnosed. Malfunction of the pump leads to the fact that fuel does not flow into the carburetor float chamber or does not flow in sufficient quantities. You can try to pump up gasoline manually, and also check the fuel pump:

- The hose is removed from the outlet fitting and lowered into a prepared container with fuel, which is necessary to supply gasoline to the carburetor.

- The prepared hose is put on the outlet fitting, and its other end is lowered into another empty container.

- The assistant starts the engine and keeps the speed within 2 thousand rpm. In addition, a stopwatch is started.

- After a minute, check the performance of the fuel pump by measuring the amount of gasoline pumped.

If the fuel volume is less than 1 liter, the fuel pump is considered faulty.

Preparatory activities

If the VAZ 2107 carburetor does not function well and does not start after heating, then it is worth checking the car for malfunctions.

Technical inspection consists of several points:

- It is necessary to check the fluid level in the engine mechanisms.

- External surfaces should be checked for oil, antifreeze or fuel leaks. Carefully inspect the live wires connected to the spark plugs. The contacts must be free of any burns.

- If the car sits for a long time without moving, then some of the gasoline evaporates. To restore the level, you need to pump it up with a hand pump.

The next step is to turn on the engine. The driver sits behind the wheel and depresses the clutch pedal when the starter is turned on. If it spins more than 10 times and the engine does not start, then you should check for breakdown of the car’s mechanisms.

Prevention of injector breakdowns

Why the injection engine does not start and how to eliminate possible problems is now known to all readers of our resource

However, it is better to avoid such breakdowns, so let’s pay attention to ordinary procedures that, if carried out systematically, will help minimize the risks of all malfunctions. The simplest but most effective prevention consists of the following measures:

- Firstly, refuel exclusively at proven gas stations and only with high-quality fuel. Remember that most fuel system and engine malfunctions are caused by dirty gasoline;

- Secondly, change all consumables on time and only with high-quality products. The most important thing is periodic replacement of all kinds of filters and engine oil;

- Thirdly, periodically check the main components of the machine for stability. The list of the latter, naturally, includes the injector, elements of the fuel system, ignition and engine;

- Fourthly, never neglect routine diagnostics of your car at a service station. Surprisingly, even a delay of a couple of hundred kilometers can cause serious damage, which previously could have been eliminated with very simple actions;

- And fifth, always operate your vehicle properly. That is, you do not need to overheat, overload or negatively impact your car in any other way.

Perhaps this is where the most important information on today’s issue has come to an end. We hope the material presented above was useful and provided answers to your questions. Good luck in operating and maintaining your car!