Motorists know how much nerves are wasted when problems with power steering occur. The steering wheel behaves strangely and turns much more difficult at idle or low speeds. A whistling sound is heard from the pump bearing. Leakage of working fluid onto the engine or onto the road at the location of the unit. The rotation of the steering shaft is accompanied by extraneous sounds.

These inconveniences can affect not only the driver’s nervous health, but also driving safety. What to do if symptoms of a pump malfunction appear? How to replace this power steering part? Is it possible and how to carry out repair work yourself? We'll tell you more about everything below.

Main functions of power steering

Pumps come in different designs depending on what fluids need to be moved and the conditions under which they will operate. They can be a stand-alone unit, for example on a construction site, or work as part of a group of machines or in a production cycle.

By design, pumps are gear, vane and piston. The simplest in design are gear pumps, the mechanism of which consists of two wheels during unwinding, taking liquid into the suction chamber and transporting it to the discharge chamber.

- On the other hand, vane pumps are very sealed, making them ideal for pumping gases. The most popular piston pumps are contaminant-resistant and open-loop tested, making them the most commonly used in practice.

- Screw pumps are also one of the modern designs. They have a long screw mounted inside that works similar to a meat grinder, sweeping up liquid as it rotates and pushing it towards the outlet.

These types of pumps may have only one propeller or several. In some cases, their number can reach up to five, which can significantly increase their productivity.

Screw pumps are used for pumping liquids of very high viscosity. In practice, you can also find several varieties of these devices, for example, radial, inclined piston or peristaltic pumps.

About the device.

Power steering - located in part of the vehicle control system, namely the steering wheel. This device serves to increase the rotational force of the steering wheel and more. The hydraulic booster provides easier and smoother steering. At the same time, this device has a beneficial effect on driving as a whole, greatly increasing the comfort of driving. Also, this device largely ensures good maneuverability of the car and provides confidence in the stability of the car on the highway.

Types of hydraulic pumps

The most common uses of pumps in construction equipment are:

- Hydraulic gear pump;

- Multi-piston hydraulic pump.

Gear pump

An external gear pump consists of two identical gears, which are mounted as tightly as possible in the housing.

- Rotating gears draw fluid from the suction chamber into the interdental spaces, transporting it to the pumping chamber.

- One of the wheels is driven by an external source.

Gear pumps are constant displacement pumps. They are distinguished by their simple design and high reliability.

Axial piston pump

A multi-piston pump consists of several or a dozen small piston pumps housed in one housing. Since a multi-piston pump is a multi-piston pump, each of the pistons of which operates in different phases, the operating characteristics of such a pump are close to constant.

The greater the number of pistons, the less efficiency pulsation.

Dismantling.

To repair the power steering, you need to remove the device from the car. Before doing this, we strongly advise you to thoroughly clean the entire mechanism and surrounding surfaces. This procedure will protect the amplifier from dirt getting into it, in order to avoid subsequent problems when disconnecting the pump. Now it is necessary to pump out as much liquid as possible from the tank. The next step is to remove the screws that secure the steering shaft - to do this you need to climb up the car. Now we can disconnect the tie rods, this will require removable hardware. The next step is to put the car on a jack, set it to the top position, remove the bolts and remove the left wheel. Having a 15 key in stock, unscrew the power steering mounting bolts. Remove the two existing bolts and leave one. Before you move on to removing the hoses, you need to stock up on containers for the pumped out liquid. Afterwards, we close the hoses (you can use improvised hoses) and holding the power steering with your hands, we tighten the last fasteners.

Proper Operating Practices

Replacing oils and filters in the hydraulic system. The pump is supplied with oil directly from the tank, so it is very important that there are no impurities in it.

- Therefore, when filling and topping up oil, do not use old cans or containers of unknown origin.

- Of course, we add oil after installing the filter in the tank, and not before.

- Trouble-free operation of the pump can be extended by changing the oil in accordance with the machine manufacturer's recommendations, both in terms of replacement time and oil specifications.

If the machine has not completed the hours required for replacement within two years, it should still be replaced as it will lose its functionality. The entire hydraulic system has filters that also need to be replaced according to the manufacturer's instructions, called DTR.

Oil level in hydraulic tank

The correct condition (level) of the oil is very important, most often there is an oil level indicator next to the reservoir, and it is the operator's daily duty to check it.

Most tanks are equipped with an oil level sensor, but “visual” monitoring is also important.

Ventilation holes

The tanks are equipped with vents, which also need to be replaced every time the oil is changed; their blockage causes air pockets to form in the hydraulic system.

Compliance with operating rules

Following the instructions when filling and replacing filters will not keep the entire system clean, so it is recommended to periodically flush the reservoir, where most of the contaminants, other than the filters, settle.

Despite all precautions, after many years of operation, the pump sometimes fails and requires replacement.

Content

- 1 About the device.

- 2 Dismantling.

- 3 Pump repair.

- 4 Pump disassembly.

- 5 Replacing hoses.

In order to service and repair a broken power steering pump with your own hands, special care and a lot of patience are required. We will tell you how to check and restore the power steering on most modern cars.

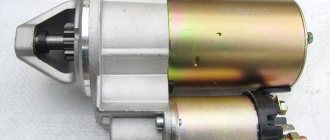

The power steering pump has a fairly simple design and its adjustment does not require special skills or long-term experience in the field of mechanics. The power steering is removed from the car, and a repair kit is used to repair it. After adjusting the hydraulic booster system, it is necessary to install it in its previous position and check it. The cause of a power steering malfunction is not always the pump; it could also be hoses, a shaft nut or other parts of the hydraulic system. To identify the exact cause of the problem, let's take a closer look at the hydraulic system.

The most common breakdowns of hydraulic pumps

A pump is simply a mechanical device made up of components and connections, filled with hydraulic fluid. Years of operation mean that many components wear out and will leak if the pump loses seal.

Less oil means less labor and reduced machine efficiency.

These specialized designs also require specialized repairs to ensure that damaged devices can be restored to full functionality.

Typical problems with hydraulic pumps are related to the oil they contain. This could be due to contamination, leakage, improper pressure regulation or so-called cavitation, i.e. air bubbles getting into the oil.

- Pump malfunctions also represent mechanical damage resulting from improper installation, improper use of the device,

- The effect can be, for example, jamming of the bypass valve, freezing of the liquid if the pump is used at low temperatures, damage to the plain bearings, running dry, that is, if the oil level in the tank is too low, the cross-section is too small. pipeline sections, etc.

Some parts of hydraulic pumps can also be subject to physical wear and tear, requiring replacement or regeneration. The latter method allows you to restore the functionality of the device without the need to invest large sums of money.

Replacing the hydraulic pump

When replacing a pump, certain rules must be followed. After disassembly, it is necessary to drain the old oil from the tank and rinse thoroughly, then replace all hydraulic filters in the machine.

Before assembly, fill the pump with oil (if possible) so that it is not “dry”, also replace all seals and O-rings on the pump, then install the pump and fill the hydraulic oil into the tank. Mandatory after installing the filter in the tank.

- Of course, we can loosen the hydraulic hoses at the outlet of the pump (before they overflow) and then tighten them.

- When we are sure that everything is in order, we start the machine for a few seconds and do this three or four times to completely remove air from the hydraulic system.

- We then start the machine again and let it run for a few minutes. After this, nothing will prevent us from starting to activate individual machine functions.

New pumps are already set to the appropriate values at the factory, so we don't need to adjust them.

Power steering: what is it and what does it consist of?

Hydraulic power steering is a part of the steering mechanism that makes it easier to control the car when turning or hitting uneven roads. The hydraulic booster reduces the effort the driver puts on the steering wheel while driving. If you have a working hydraulic booster, it is much more comfortable for the driver to drive, there is less strain on his hands, and the parking process is easier.

We recommend: Advantages and features of din 933 bolts

Power steering components:

- Pump . The main part of the system. The belt connecting the booster to the crankshaft drives the pump, so the whole mechanism works when turning;

- Distributor . A high-pressure pump supplies oil to a distributor that is sensitive to the level and degree of contamination of the oil. If the tie rods are on the sides of the rack, then the piston is in the center of the body. There may be a different type of distributor. When the piston is on the side and the rods are in the center of the rack;

- Steering gear;

- Steering bipod . It's also a connecting rod. The main part of the mechanism, which performs the function of transmitting force from the sector shaft to the longitudinal thrust;

- Connecting hoses . They are responsible for the circulation of fluid throughout the entire mechanism. Connect the reservoir with hydraulic fluid to the pump, distributor and hydraulic cylinder;

- Hydraulic oil reservoir . From the oil tank it enters all components of the mechanism, lubricating all parts, and then returns to the reservoir.