Design and operating principle of AMT

In general terms, AMT is a conventional manual transmission in which two special actuators (servo drives) are responsible for clutch operation and gear shifting. Each actuator installed on the gearbox is an electric motor with a gearbox and an actuator. The entire system is controlled by an electronic unit that selects and engages the required gear.

New LADA Granta on robot

The electronic unit takes into account the vehicle speed and engine operating mode, as well as information received from systems that monitor traffic safety (ABS, BAS, EBD, etc.). Evaluating and analyzing all the information received, the electronics unit issues a command to change gear.

After receiving the corresponding signal, the clutch is depressed using one servo drive, and the second one at this time engages the desired gear. Then the first servo smoothly releases the clutch.

When operating in Tiptronic mode (manual control), the driver independently moves the selector knob towards higher or lower gear and thereby issues the AMT command.

Note: when using a robot, there is no need for a clutch pedal.

Main problems of DSG7 - video

Weak points of mechatronics

The weakest points are the mechatronics and clutch.

DSG 7 - disadvantages

There are car enthusiasts who are not 100% satisfied with the performance of this transmission. What could they not like and what problems arise in the DSG ?

Is the DSG7 gearbox that good?

— The appearance of jerks and vibrations in the DSG when changing gears. This drawback is caused by the fact that DSG clutch begins to wear out. The result is the same effect if you do not depress the clutch pedal when changing gear in a car with a manual transmission. In a word, the vibration spreads throughout the entire body, depending on the state of the clutch, and progresses until the gearbox completely fails.

— Extraneous noises under the hood. Mainly metal parts when driving over speed bumps.

— Reduced traction when accelerating the car. This problem is known to the developers and they promise to fix it soon.

AMT for LADA Granta. Design Features

Cars of the LADA Granta family (sedan, liftback) have already received a proven AMT, which is installed starting in September 2014. It was developed by engineers of JSC AVTOVAZ together with specialists from the German concern ZF Friedrichshafen AG, which is the author and owner of many modern technologies and innovative solutions in the field of drive systems.

The design of the basic manual gearbox 2181 (modernization of gearbox 2180) was taken as a basis, on which the following were installed:

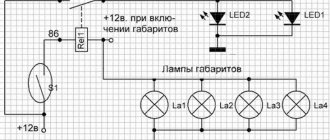

- 1. Electromechanical actuators that control gear shifting and clutch operation;

- 2. Input shaft speed sensor;

- 3. Controller.

2180 gearbox and electronic control unit

In addition, the following were completely removed from the gearbox:

- 1. Clutch drive;

- 2. Internal switching mechanism;

- 3. Cable gear shift drive.

Inside the car, the clutch pedal was removed, and instead of a mechanical (cable) gear shift drive, an electronically controlled selector was installed.

In addition to original design solutions, modern software was developed specifically for AMT, with the help of which the vehicle’s transmission is controlled.

All these changes, together with the electronic motor control controller and the on-board power supply network, made it possible to fully automate the processes of controlling the clutch and gear shifting, as well as ensuring high AMT functionality.

Features of operation

In accordance with the reviews, a list of custom features of the AMT transmission has been compiled:

- Unlike an automatic transmission, AMT does not have such a mode as “parking” or “P”. Therefore, reviews recommend leaving the AMT in gear when parked, turning off the engine in mode “A” or “R”. And with the engine not running, move the lever to “N” mode, but even in this mode the gear will be engaged. When the ignition is turned on, the speed will automatically turn off. Therefore, you need to remember this feature of the AMT, and to prevent the car from rolling, in this case the car is fixed with the brake pedal. Moreover, the car will not start without pressing the brake pedal. Which some car enthusiasts point out as a disadvantage, and others as an advantage that increases the safety of starting the engine when the speed is accidentally turned on, for example, as with a manual transmission;

- Unlike simple mechanics and an automatic transmission, AMT will not move the car at idle speed, that is, driving at idle speed is impossible. To start moving smoothly, you need to add engine speed by pressing the gas. What is indicated as a disadvantage in reviews from residents of megacities, who often find themselves stuck in traffic jams. Therefore, for those who periodically encounter traffic jams, during short stops it is recommended to switch the lever to the “N” mode, because after a minute of parking with the brake pedal not pressed, the switch will disconnect the clutch by pressing the release lever, which can subsequently negatively affect the release bearing . However, some reviews provide examples of the opposite opinion, that this has absolutely no effect on the condition of the release bearing;

- There are many opinions in the reviews about braking using AMT. When braking the engine by resetting its speed, the AMT reacts quite sensitively in higher gears by switching to lower ones, but many recommend doing this in combination with the brake pedal depressed. Regarding smooth braking with the help of brakes, AMT “helps” to brake by switching lower gears. But during heavy braking, the AMT completely disengages the clutch. But in some reviews there are stories about some “sagging” of the brake pedal in these cases.

- after sharp braking, the clutch remains open until the engine speed is increased by the gas pedal;

- When you apply emergency braking using the brake pedal, the Brake Assist System (BAS) is activated and the clutch is instantly released.

Advantages and disadvantages of AMT

Among the many advantages of the “robot” are:

- 1. Cost-effective;

Fuel consumption in a car with an installed robot depends on driving style and is 6...6.5 l/100 km in mixed mode, which allows saving up to 30% of fuel compared to a sedan or liftback LADA Granta AUTOMAT and up to 10% compared to cars , equipped with conventional “mechanics”.

- 2. High reliability;

AMT is based on a manual gearbox, which is much less susceptible to breakdowns than an automatic transmission. In addition, the optimal operating modes of the robot are determined electronically (there is no “human factor”), which significantly increases the service life of the engine. Repairing an AMT is practically no different from repairing a manual transmission. In addition, it is much simpler and cheaper than automatic transmission.

- 3. Simplicity of design and unpretentious operation.

Electromechanical structural elements do not require maintenance or adjustment during operation. All connectors and electronic components are reliably protected from dust and dirt. The robot is adapted to difficult operating conditions and ensures operation when exposed to temperatures ranging from -40...+50 degrees Celsius.

- 4. Vibration comfort.

There is no mechanical connection between the selector and the gearbox, so there is no vibration of the mode shift handle.

LADA Granta on a robot

Existing disadvantages of AMT:

- When starting to move, LADA Granta with AMT may roll back a little.

- Unlike an automatic transmission, the robot cannot change gears without losing traction torque. This results in barely noticeable jerks during gear changes.

DSG 7 reviews

Car enthusiasts who switched from a car with a manual transmission to a DSG note that there are no problems using the transmission. The ability to manually change gears allows them to quickly adapt to the new gearbox. Drivers especially emphasize the efficiency of this gearbox. about the DSG are most often positive. Almost all negative reviews are related to the high cost of spare parts for the gearbox and the impossibility of overhauling the DSG. But there are some nuances that lead to the box breaking. Negative factors such as traffic jams, slippage, sudden starts from traffic lights contribute to rapid wear of the clutch and mechatronics.

Real reviews from DSG 7 owners | Video

We went through well-known forums and car clubs, but we won’t be able to parrot you with good reviews about the performance of the DSG 7. Unfortunately, this unit, according to the owners, is damp. Moreover, many (including the editor of this article) had mechatronics or clutch kits changed at low mileage, but this did not exclude further problems. The prospect of ending up with 80-150 thousand rubles worth of repairs is not encouraging.

AMT management

During operation, the “robot” is much simpler than automatic transmission and classic “mechanics”. The electronic selector allows you to use 4 operating modes:

- neutral - N;

- automatic - A;

- reverse - R;

- manual control - M.

Before you start driving, you need to set the selector lever to position “A”, then press the brake pedal and only then put your foot on the gas pedal.

Attention! The engine of a LADA Granta (sedan, liftback) equipped with a “robot” will not start if you forget to press the brake pedal.

The car's acceleration time to a speed of 100 km/h is 12.5 seconds, which is 1.6 seconds inferior to models with a manual transmission (10.9 seconds), but 0.8 seconds better than the LADA Granta with automatic transmission (13. 3 sec.). In this case, gear shifting occurs at 5000 rpm for aggressive driving or 2500 rpm for quiet driving.

The time to switch from one gear to another in automatic mode is no more than 2 seconds. Because of this, AMT may seem “thoughtful” to some drivers, but when switching to manual control mode, the gear shift speed is comparable to the speed of a manual transmission.

Granta 1.6 16v AMT (robot)

I wish you all good health! Reading reviews is of course pleasant and useful, now you also need to make your contribution, so don’t judge harshly, especially for mistakes (I was in a hurry, and I want to write more + no, the beech is stiff and the buttons are small).

Lada Granta (luxury equipment)

ICE: 1.6; 16th grade; 106 l/s, gearbox: 5st. robotic.

Equipment: ABS; 2PB; 4ESP; Climate; Heated front seats; Rain sensor; Two rear parking sensors; Fogs; Wheels R15; Radio with touch control; Standard alarm.

Over 11 years of driving experience, I personally owned: the first was my grandfather’s Moskvich 412 (whatever this car couldn’t stand from me), then the VAZ 2105 1.3 85 onwards. on gas (after Moskvich, a comfortable and stable car), VAZ 2106 2006. (drove for about 2 years), then an almost new 2105 (injection 5-speed, also drove for about 2 years), Toyota Platz 2001. (I got the car in excellent condition, drove it for 3 years, didn’t know any problems, but I wanted more and lost it), Nissan Cefiro 1998. 2.5 210 hp Neo-Di engine which does not run on gasoline below 95, the car is cool but already old and it eats gasoline normally + expensive insurance, taxes (drove for 2 months and sold it), Honda Civic 2000. 1.5 (8 valve automatic - I was shocked myself) right-handed sedan made for the Emirates, no ABS, no airbags, terrible heater. but there is a leather interior and climate control (the car was received in poor technical condition. I thought I’d do it little by little, but it didn’t work out due to financial difficulties, I thought it was about to break down BUT! the car was almost unchanged in technical parts, traveled 3 -and years... low bow to her, the car is really very reliable and durable, although it is designed for good roads and active driving, so the chassis is quite harsh). All cars are worthy of special attention, but we are not talking about them now. And now. TA-DAM! New Lada Granta))

Differences between AMT and other types of gearboxes

Unfortunately, there is no “preload” mode, which is available in conventional automatic transmissions, when the car starts to move from idle.

There is no way to overcome small hills by releasing the gas pedal - a car with a robotic transmission must in such situations put on the handbrake or apply gas. During the development of the transmission, foreign analogues equipped with a recoil mode were studied. As a result, we decided not to include this feature in our robotic transmission, since the electronics only notice a steep climb, and a small hill for a momentarily distracted driver can cause a rollback and, in urban conditions, cause an accident. The same danger comes from releasing the brake on a car equipped with a classic automatic transmission with “drive” turned on. At first, the robotic transmission requires the driver to get used to and control his actions. You need to be especially careful in urban environments that require frequent difficult operations: starting, making a U-turn, turning off the engine, parking. But all the required actions are intuitive and logical, so getting used to the new product happens very quickly. By the way, both CVTs and conventional automatic transmissions need to adapt to them. It is much more difficult for a beginner to get used to ordinary mechanics.

The undoubted advantage of the robotic version of the device is the complete elimination of errors and breakdowns caused by subjective factors. At the same time, it will not be possible to engage the wrong gear, for example, reverse while moving forward, in such a gearbox. In addition, the “robot” makes it possible to control the temperature in the gearbox. A special lamp signals critical overheating. This option is not available in either manual or automatic transmissions.

Users of automatic transmissions notice the moments when gears are changed in AMT. Indeed, in the Japanese automatic transmission Jatco, gear shifting occurs very smoothly without obvious power breaks, and the “robot” needs a short time to change speed. AMT is a relatively simple design: in a classic VAZ gearbox, shifting is controlled by two ZF actuators - German-made electrical actuators. One of them helps the driver to depress the clutch, and the second is responsible for engaging a specific gear.

Impressive result of good work

As a result, we can come to the conclusion that the VAZ team managed to create a good “robot”. What is especially impressive is that the project initially included unification, allowing the design to be quickly adapted to a number of models. The new AvtoVAZ product is in no way inferior to its analogues. From what is known, no unit with a “robot” has such elastic and smooth operation of the power unit.

Therefore, the “traditional” Jatco “automatic” has been replaced by a new product. This happened because VAZ’s “robot” is really quite good and is capable of satisfying the needs of the most demanding drivers. But the partnership with the Japanese continues, because it is necessary to give potential buyers maximum choice.

Today, cars equipped with automatic transmission and automatic transmission practically do not differ in price. But a price increase is coming for currently inexpensive Japanese-made automatic machines. After all, automatic transmissions are imported from Japan complete with a cooling system and require Japanese wheel drives. For AMT, everything was developed at AvtoVAZ. The only exceptions are actuators, control unit and selectors. The difference in price between a manual transmission and a “robot” is only 20,000 rubles. Jatco, even without taking into account drives and cooling, costs more than twice as much as a “robot”.

Pre-production tests

However, the Granta, equipped with an automated manual transmission, is now on the agenda; sales begin in February. To approach this date fully armed, a number of tests were carried out. One of the pre-production cars immediately went to Germany so that AvtoVAZ's partners from ZF, for their part, could conduct their own tests and allow the car to be put into production.

Starting with the Priora platform, cars have undergone a huge number of tests in various climatic zones and under a variety of programs. Tests took place in the Alps and Altai mountains with the participation of partners from Germany, at low temperatures reaching -55°C, in the Far North in Surgut. Speed tests were successfully carried out at the Porsche test site with humidity of almost 100 percent and temperatures exceeding +30°C. These tests were followed by accelerated road tests of 80,000 km and 100,000 km. Difficulties that arose during the testing process were resolved promptly, quickly and professionally.

The new gearbox is a product of Russian engineering, since the burden of solving most of the problems fell on VAZ’s shoulders. Engineers from Russia have demonstrated that their level is not inferior to the quality of engineers in the best European companies.

In general, the design of the new box consists of 80% Russian parts, and this says a lot.

Even during the period of joint work with the Germans on adapting the gearbox for the Priora, it was VAZ engineers who managed to quickly achieve smooth switching, which other companies cannot achieve for a long time. It is difficult in foreign boxes and with quick engagement - the transmission resource is insufficient.

An important advantage of the VAZ AMT is the ability of the system to adapt to the driver’s driving style - both calm and aggressive driving is possible. What else distinguishes the box from a traditional automatic transmission: at -40°C outside, the box makes it possible to start moving as soon as the engine is started. But fuel economy is, of course, the biggest plus.