Since its invention, the principle of operation of the throttle valve has not changed. Yes, it has been “overgrown” with additional sensors, motors and pipes, is controlled by an on-board computer, and is made from more technologically advanced materials, but its essence has remained unchanged. Just as it previously regulated the air supply to the carburetor, now the throttle assembly supplies air to the engine. However, despite its “stool-like” simplicity, the throttle valve performs an important function, and any failure of it immediately affects the operation of the engine.

What is a throttle valve, purpose, types

The throttle valve is a mechanical valve that regulates the volume of air entering the combustion chamber. The opening angle determines how much air passes through it per unit time and enters the cylinders. Depending on the opening angle, air can flow unhindered, partially, or not at all.

Typical throttle valve circuit

When the driver presses the gas pedal, this is the throttle opening angle control. “Pedal to the floor” - it opens as much as possible and the engine produces full power. At idle, on the contrary, a minimum of air passes through so that the mixture is richer. In other words, it responds to the driver's actions, and the electronic control unit (ECU), in turn, responds to the position of the throttle, supplying the appropriate amount of fuel.

Where is the throttle valve in a car?

As already mentioned, the scheme turned out to be so successful that it has not undergone changes in its basic principle to this day. But, of course, the throttle valve also improved, like the rest of the car. So currently there are three types used on cars:

- Mechanical;

- Electromechanical;

- Electronic.

Mechanically driven damper. Design, features

Let's start with the mechanically actuated damper. This type of part appeared with the beginning of the installation of fuel injection systems on cars. Its main feature is that the driver controls the damper independently using a cable drive connecting the accelerator pedal to the gas sector connected to the damper axis.

The design of such a unit is completely borrowed from the carburetor system, the only difference is that the damper is a separate element.

The design of this unit additionally includes a position sensor (throttle opening angle), idle speed controller (IAC), bypass channels, and a heating system.

Mechanical throttle assembly

In general, the throttle position sensor is present in all types of components. Its task is to determine the opening angle, which allows the electronic injector control unit to determine the amount of air supplied to the combustion chambers and, based on this, adjust the fuel supply.

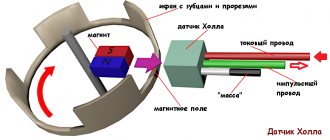

Previously, a potentiometric type sensor was used, in which the opening angle was determined by changing the resistance. Nowadays, magnetoresistive sensors are usually used, which are more reliable because they do not have contact pairs subject to wear.

Potentiometric type throttle position sensor

The XX regulator in mechanical throttles is a separate channel that bypasses the main one. This channel is equipped with an electric valve that adjusts the air supply depending on the operating conditions of the engine at idle.

Idle air control device

The essence of its work is this: at XX, the damper is completely closed, but air is required for the motor to operate, and it is supplied through a separate channel. At the same time, the ECU determines the crankshaft speed, on the basis of which it regulates the degree of opening of this channel with the solenoid valve in order to maintain the set speed.

Bypass channels work on the same principle as the regulator. But their task is to maintain the speed of the power plant when creating a load at idle. For example, when the climate system is turned on, the load on the engine increases, causing the speed to drop. If the regulator is not able to provide the motor with the required amount of air, then the bypass channels are used.

But these additional channels have a significant drawback - their cross-section is small, so they may become clogged and icing. To combat the latter, the throttle valve is connected to the cooling system. That is, coolant circulates through the channels in the housing, heating the channels.

Computer model of channels in the throttle valve

The main disadvantage of a mechanical throttle assembly is the presence of errors in preparing the air-fuel mixture, which affects engine efficiency and power output. This is due to the fact that the ECU does not control the damper; it only receives information about the opening angle. Therefore, with sudden changes in the throttle position, the control unit does not always have time to “adjust” to the changed conditions, which leads to excessive fuel consumption.

Electromechanical throttle valve

The next stage in the development of throttle valves was the appearance of the electromechanical type. Its control mechanism remains the same - cable. But this node does not have any additional channels as unnecessary. Instead of all this, an electronic partial damper control mechanism, controlled by the ECU, was added to the design.

Structurally, this mechanism includes a conventional electric motor with a gearbox, which is connected to the damper axis.

This unit works like this: after starting the engine, the control unit calculates the amount of supplied air to set the required idle speed and slightly opens the damper to the desired angle. That is, the control unit in this type of unit has the ability to regulate engine operation at idle speed. In other operating modes of the power plant, the throttle is controlled by the driver himself.

The use of a partial control mechanism made it possible to simplify the design of the throttle assembly itself, but did not eliminate the main drawback - errors in mixture formation. It is not present in a damper of this design only at idle.

Idle speed control

Throttle valve on a car

Using the idle speed regulator, the required crankshaft rotation speed is maintained with the throttle completely closed. For example, if the motor heats up or the load increases, additional equipment is connected to the process.

The regulator is designed as follows: a housing in which a stepper electric motor is attached, connected to a conical needle. While the engine is running at idle speed, the needle, like a piston, regulates the cross-sectional area of the air channel.

Damper adjustment

In order for the throttle valve to work like a clock, its sensor must be periodically adjusted. To do this, follow a few simple steps:

- The ignition is turned off to move the valve to the closed position.

- The sensor connector is de-energized.

- The sensor is adjusted using a 0.4 mm probe located between the screw and the lever.

To check the serviceability of the sensor, the voltage level is measured using an ohmmeter. If voltage is detected, the sensor should be replaced. In the opposite situation, you can continue to adjust the sensor.

To do this, the damper rotates until you see the same indicators that are written in the car's passport. Do not forget to check the tightness of the screws and nuts after adjustment; they could have become loose during the process.

As you know, the fuel system of a car is its vitality. If it is even slightly damaged, the car may unpleasantly surprise you at the most inopportune moment. If the throttle valve or another element of the assembly fails, the consequences can be disastrous. Therefore, it is much better not to skimp on car diagnostics if there is the slightest suspicion of a malfunction. Remember - safety on the road comes first.

Video “Procedure for adjusting TPS”

Typical faults

Experts have calculated how many times a driver presses the gas pedal in 30 minutes during the day - a little more than 100 times. And this happens every day (with regular use of the car). In this case, it is not surprising that over time the remote sensing mechanism begins to malfunction. There are several main faults that will be discussed below. This will allow you to better understand why you need to clean the throttle valve.

Throttle position sensor

This is where most of the problems lie. As a result of its failure, the engine begins to operate intermittently, which is manifested by the following symptoms:

- Problem starting the power unit or it does not want to start at all.

- The engine stalls when idling or the speed is too high.

- There are jerks and failures in the operation of the internal combustion engine.

- Acceleration dynamics and traction drop, and sharply.

- Fuel consumption is increasing.

- The "Check Engine" light on the dashboard comes on.

Only all these listed symptoms do not indicate a malfunction of the damper, and therefore diagnostics should be carried out.

Diagnostics is necessary to identify part malfunctions

Bypass channel clogged

This problem does not cause as much discomfort as a broken sensor. But it shouldn’t be ignored either. Typically, this manifestation is due to improper operation of the engine at idle speed. The reason to check the throttle valve will be dips or sudden engine stops . It's most likely time to clean the damper.

Air leak

And such trouble does occur - this indicates a breakdown of the intake manifold or the very design of the DS mechanism itself is broken, through which air begins to be sucked in. This leads to an increase in the amount of oxygen in the working mixture and the speed increases when this is not necessary. Air entering the cylinders bypassing the filter does not end well.

Violation of the tightness of the unit is usually treated by cleaning. But a breakthrough cannot be ruled out through places other than the valve itself. It is better to contact the specialists of the nearest car service center - perhaps there are other problems that need to be found and eliminated in a timely manner.

Throttle valve adaptation

This term hides the setting of the on-board computer to determine the correct connection between the position of the accelerator pedal and the remote control . The program fails for various reasons:

- disconnecting the battery from the network;

- the throttle valve unit has been dismantled for the purpose of repair or replacement;

- ECU shutdown.

It is better to entrust adaptation to specialists, and such a procedure does not take much time. The cost is also reasonable.

Troubleshooting Methods

Typically, all problems with the throttle body are solved by cleaning the throttle body. To clean the air filter, you can usually simply disconnect the air filter pipe. After this, you need to spray the engine protection with an aerosol to clean carburetors or injectors. This substance will dissolve plaque. And after this, the plaque can be removed with a simple rag or paper napkin.

To solve more serious problems, you need to remove the throttle valve assembly.

, then remove the rubber seals and spray again with the same aerosol. If the remote control is mechanical and does not have built-in electronics, then it would be wise to put it in a container with gasoline overnight.

It is worth remembering that before cleaning the throttle assembly, you need to make sure that cleaning will not harm it, since there are valves that are strictly contraindicated for cleaning!

At any service station you can clean the engine protection quite quickly and relatively inexpensively. The cost of the work may depend on its complexity and the degree of contamination of the system.

If the problem with the throttle concerns not the mechanical control, but the electronic one, then the problems are solved after diagnostics; perhaps the throttle malfunction will be solved after adjusting or replacing the throttle position sensor.

How to adapt and train the electronic throttle of Lada Vesta.

If the electronic throttle body or ECM is replaced, or the controller is reset using the scan tool (Function Test; ECU Reset with Initialization mode), the Throttle Zero Adaptation procedure must be performed.

To do this, with the car standing, you need to turn on the ignition, wait 30 seconds, turn off the ignition, and wait until the main relay turns off.

Adaptation will be interrupted if:

- the engine turns over;

- the car is moving;

- the accelerator pedal is pressed;

- engine temperature is below 5 °C or above 100 °C;

- Ambient temperature is below 5 °C.

If the electric throttle actuator is de-energized, the throttle valve is held in the Limp home position (6-7%) using direct and return springs.

Purpose of the throttle position sensor

This sensor transmits data to the electronic engine control unit about the position of the bypass valve in a certain time period. The operation of this unit is based on the interaction of AC and DC converters.

The highest value of the total resistance of the converters is at the level of 8 ohms. The design of the remote sensing sensor has three contacts. The first and second contacts receive a current of about 5 V, and the third contact is connected to the controller and performs a signaling function.

DPD3 is located on the throttle body. The device receives signals about the opening and closing of the passage channel. The resistance index of the part changes to satisfy the following conditions:

- when the damper is open, the voltage on the third contact will exceed 4 V;

- if the air passage is blocked by the remote control damper, then at the 3rd contact the current does not exceed 0.7 V.

The device controls all fluctuations in contact voltage and thus regulates the supply of fuel necessary for the formation of the air-fuel mixture.

Due to a malfunction of the sensor, the voltage reading most often goes beyond the established limits. This leads to disruption of the normal operation of the internal combustion engine, which can ultimately lead to breakdown of the unit.

Important: a sensor malfunction often causes the transmission to malfunction. Every car owner understands that restoring an engine and transmission is a process that requires a large investment of time and money. If symptoms indicating a breakdown appear, it is necessary to carry out a diagnosis.

Potentiometer

In other words, the potentiometer changes the opening angle of the damper and thereby affects the controller. When the damper is closed, the voltage does not exceed 0.7 V, and when fully open it reaches 4V. This is how fuel supply is controlled.

If the throttle valve stops responding to impulses emanating from the position sensor, the following breakdowns may occur:

- Floating speed when the engine is running. Increased idle speed;

- The engine stalls when switching to neutral;

- Uncontrolled fuel consumption;

- The engine is running at half power;

- The CHEK light is on - check if the throttle valve is working correctly.

Signs of a malfunction of the TPS

Like any mechanism in a car, the throttle position sensor also has this feature and can break down with use. No part lasts forever, so sooner or later it will break. To correctly detect a breakdown, you should know what signs to look out for. Now we list the most basic symptoms:

- First of all, if you suspect something is wrong with the throttle position sensor, first carefully inspect the engine. If you suspect that the speed drops significantly at some moments, then this already indicates that the sensor is not functioning properly. If everything is controlled by an electronic computer, then you should contact the service and do a software reset.

- Also, a breakdown of the sensor is often indicated by a situation when you suddenly release the accelerator, and at this time the engine immediately stalls. If this happens, then this indicates a complete breakdown of the module; it should be replaced immediately so as not to provoke new problems.

- During intense acceleration, your speed drops significantly by 5-10 kilometers per hour. Often drivers think that this fuel is not supplied and go to a gas station, but in fact in 80 percent of cases it is simply a breakdown of the TPS.

- Have you noticed that while driving the car does not respond to movements of the gas pedal. In this case, you need to stop the car immediately, otherwise it may lead to an accident. The problem may be hidden in a complete breakdown of the TPS, sometimes there may be some kind of mechanical damage to the damper, and therefore it cannot close tightly.

- During idle, the speed stops at 2000-3000 rpm and hangs at this level for a long time.

Based on all of the above, we can safely say that all symptoms directly indicate improper engine operation. Therefore, it is worth remembering that if you notice malfunctions in the engine, the first thing you should do is check the throttle position sensor. Below we will describe in detail how to check this sensor, we will look at the example of VAZ cars, their design is identical.

Video about signs of TPS malfunction

Code P0122 Low signal level of the Lada Vesta throttle position sensor.

Code P0122 is entered if:

- ignition on;

- the throttle position sensor signal voltage (ADC parameter “ Throttle sensor voltage 1 ”) is less than 0.25 V for 0.12 s.

The malfunction indicator lights up 5 s after the fault code appears.

Description of checks.

The sequence corresponds to the numbers on the card.

- Using a diagnostic tool, it is checked whether code P0122 is active at the time of diagnosis. If only code P0122 is detected, then the fault must be looked for in the signal circuit of TPS A. If codes P0122 and P0222 are detected at the same time, then the fault must be looked for in the power circuit of TPS A and TPS B.

- The circuit is checked from contact “X1.2/G2” of the controller to contact “3” of the electronic protection device.

- The controller is checked: when you bridge contacts “3” and “5” of the block to the EDS using a probe, the TPS A signal on the diagnostic device should change.

- The circuit is checked from contact “X1.2/E3” of the controller to contact “5” of the electronic protection device.

- The controller is checked: pin “5” of the block to the EDS should receive a reference voltage of 5 V from the controller.

Methods for diagnosing TPD

The most common test of the sensor is to measure resistance or voltage at various throttle positions (closed, half-open, and fully open). We will perform testing using the voltage measurement function.

- Open the hood and remove the air filter assembly where it connects to the throttle body.

- Inspect the throttle plate and the throttle body walls around it.

* If you see carbon deposits on the walls or under the choke plate, clean this assembly using carburetor cleaner (carb cleaner) and a clean rag. The surface must be completely clean. Carbon deposits and dirt can prevent the throttle valve from closing and moving freely.

- Locate the TPS mounted on the side of the throttle body. The sensor is made in the form of a small plastic block with a three-wire connector.

How to fix a problem by cleaning the throttle body

Let's look at how to properly clean the damper step by step:

- First of all, you need to get to the throttle valve. The design of different modifications of the internal combustion engine is different, but, as a rule, it is first necessary to dismantle the air duct running from the damper to the air filter.

- Then you need to remove the throttle valve. You should unscrew the fastening bolts (from 2 to 4 pieces), and then disconnect all the connectors, including the one that goes to the absorber purge valve.

- You can clean the throttle body using carburetor cleaner. Specialized auto chemical stores offer a wide selection of different formulations, so you can always choose the best option in terms of cost.

- Thoroughly wipe the throttle body inside and out using your chosen product and a rag.

- If the car is designed with a protective grille, it also needs to be cleaned.

- Reassemble the assembly in reverse order.

Cleaning the throttle valve is carried out in such a way that its metal surface becomes completely light. Such cleaning will help improve the dynamic characteristics of the engine.

Many car enthusiasts are interested in how to clean the throttle valve without removing it. Some service stations actually offer this service, but it should be borne in mind that effective cleaning of this part can only be done after dismantling the damper.

To clean the throttle valve without removing it, use a special intake tract cleaner. In addition, this procedure can be performed using EGR valve cleaning fluid, as well as WD-40 or solvents.

History of creation

A system for mixing gasoline vapor with air, including a mechanical throttle valve, was invented in 1872 by engineers Gottlieb Daimler and Wilhelm Maybach. In this form, the system existed for more than a century, until the German company Bosch developed an electronic version of the throttle.

The damper mechanism of the electronic throttle assembly needs periodic cleaning, as fine dust gets into it, which even a very high-quality filter cannot filter out.

For the first time, an electronic throttle was used for a racing car. Back in 1985, Volkswagen was experimenting with the second generation Golf, trying to make it a racing car. To achieve this, the Golf was equipped with two engines at once, and the E-Gas system was used to synchronize their powers. The throttle on one of them was controlled mechanically, and for the other an electric drive was used, which synchronized the position of the damper. As a result, it was possible to achieve a total engine power of 500 horsepower, and acceleration to hundreds took 3.4 seconds. Not a bad result for 1985!

Electronic throttle became available for civilian vehicles at almost the same time. Manufacturers such as Saab, Mercedes-Benz and BMW equip their vehicles with electrically operated dampers. However, they have not yet been able to completely displace the mechanical drive, which is simple and cheap to produce.

How to Replace a Throttle Position Sensor

The process of replacing the throttle position sensor consists of three stages: removing the old sensor, installing a new one and resetting the error about the malfunction of the device from the memory of the electronic control unit. To replace the TPS, you must perform the following steps:

- Turn off the ignition, but you do not need to remove the terminals from the battery, since the sensor will be de-energized;

- Next, you need to remove the connector from the sensor and unscrew the mounting screws (most often two);

- After this, the procedure for installing a new sensor begins. Carefully connect the end of the damper axis to the sensor seat;

- By turning the sensor in a circle, you need to align the holes and screw in the screws;

- Next, put on the connector;

- To reset the error from the controller’s memory, remove the battery terminals overnight (more than 8 hours), during which time the memory should be reset. If you cannot remove the errors, you can try to continue operating the machine in a “gentle mode”, waiting until the electronic control unit resets it on its own. A more reliable option is to contact a service technician to reset the error using a motor tester.

It should be noted that some modern sensors require not only replacement, but also adjustment. For example, in AvtoVAZ cars, adjustment of the throttle position sensor is not required, but in many foreign cars it is necessary.

Recommendations for choosing TPS

Quite often, car manufacturers install a cheap film-resistive throttle sensor. Such a mechanism will not work for a long time, and very soon symptoms of its malfunction will begin to appear.

Therefore, when replacing, it is recommended to use a non-contact sensor, which is more expensive, but is more reliable in operation and has a long service life. Its working principle is based on the magnetoresistive effect.

Sources

- https://autoleek.ru/sistemy-dvigatelja/vpusknaya-sistema/drosselnaya-zaslonka.html

- https://VazNeTaz.ru/drosselnaya-zaslonka

- https://seite1.ru/zapchasti/drosselnaya-zaslonka-ustrojstvonaznacheniechistkaremont/.html

- https://avtozam.com/elektronika/sensor/kak-proverit-dpdz/

- https://tolkavto.ru/raznoe/drosselnaya-zaslonka-eto-chto-takoe.html

- https://seite1.ru/zapchasti/datchik-drosselnoj-zaslonki-prednaznachenietipyvidyneispravnostifoto/.html

- https://avtoskill.ru/remont-obsluzhivaniye/kak-proverit-datchik-polozheniya-drosselnoy-zaslonki-dpdz.html

- https://AvtoNov.com/%D0%BF%D1%80%D0%B8%D0%B7%D0%BD%D0%B0%D0%BA%D0%B8-%D0%BD%D0%B5% D0%B8%D1%81%D0%BF%D1%80%D0%B0%D0%B2%D0%BD%D0%BE%D1%81%D1%82%D0%B8-%D0%B4%D0 %BF%D0%B4%D0%B7/

- https://autofakty.com/proverka-datchika-polozheniya-drosselnoj-zaslonki-dpdz/

- https://rad-star.ru/pressroom/articles/neispravnosti-datchika-drosselnoj-zaslonki/

- https://okeydrive.ru/datchik-polozheniya-drosselnoj-zaslonki-kak-proverit-zamenit-otregulirovat/

- https://motorsguide.ru/system/datchik-polozheniya-drosselnoj-zaslonki