As you know, cars with an injector differ markedly from versions with a carburetor in terms of the design of the engine power system. This fully applies to both foreign and domestic cars.

As for the popular VAZ 2110 model, the throttle valve on the VAZ 2110 is an important and critical element that requires periodic maintenance.

Next, we will look at how the VAZ 2110 throttle valve works and works and what malfunctions the throttle assembly may have. It is also necessary to pay attention to when you need to clean the throttle assembly, how to properly clean the throttle on a VAZ 2110, etc.

Purpose and design of the throttle valve

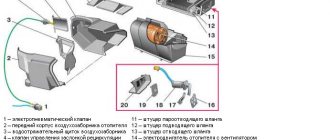

The throttle valve in a VAZ 2110 car is a whole unit that is installed in the air duct system.

At the inlet there is a pipe from the air filter, the outlet is connected to the intake manifold. The throttle must regulate the flow of air that enters the engine. Due to this, the motor power is regulated. The design of the throttle valve (VV) uses an actuator. It can be mechanical or electronic. The throttle position directly depends on the position of the gas pedal.

An important element in the DS is the throttle sensor. On the VAZ 2110 it is made in the form of a potentiometer that produces a signal. It changes depending on the throttle angle. This signal is sent to the engine electronic system. The electronic control unit doses the incoming fuel.

During operation, the throttle valve assembly becomes dirty. Fuel combustion products can settle on the side of the collector, and dust on the other side. The presence of contamination in the throttle valve of the VAZ 2110 affects the stable operation of the engine.

The main signs of contamination in the throttle valve block:

- poor vehicle acceleration dynamics;

- Unstable engine operation at idle;

- The car moves jerkily, there is no smooth ride.

When should you clean the damper?

Symptoms that the VAZ-2110 throttle valve requires cleaning:

- Unstable engine operation at idle.

- Delay when starting the engine.

- Extraneous sounds from the muffler.

- Increased gasoline consumption.

- The car jerks when driving at low speed.

- The crankshaft speed fluctuates.

All these symptoms indicate that there are deposits in the unit body (they can be seen without complete disassembly). Oil dust and gases cause deposits to form. You can clean it yourself using a special aerosol product. According to the technological map, the damper should be cleaned every 35 thousand km. mileage But it is better to reduce the mileage to 15-20 thousand km. The procedure will take a little time, but it will have a lot of effect - the engine will run stably, gas consumption will decrease and power will increase.

Operating principle of the throttle valve

The throttle valve's job is to supply oxygen, which the engine needs to operate properly. It is with the help of this valve that the air supply to the engine is regulated during combustion of the fuel mixture. Air enters the cylinders from the environment when the valve opens, having previously been cleaned through the vehicle's air filter. The flap turns, opening the way for air, by pressing the gas pedal.

Operation of the throttle valve VAZ 2110

At the same time, the number of revolutions on the tachometer increases. In the VAZ 2110 car, the throttle control is electronic, which allows you to perform more useful work than with a mechanical type. The VAZ 2110 throttle valve is located under the hood of the car, in its central part. As a rule, it is located between the intake manifold and the air filter; all these devices interact with each other. In some assemblies of the VAZ 2110 car, it can be located on the passenger side of the car.

Several sensors also take part in the operation of the throttle valve. The main one is the air flow meter sensor. It is he who electronically controls the air supply to the engine. If there are problems with the throttle valve, it is most often the cause of failures. Also, one of the common reasons for poor operation of the throttle valve in a VAZ 2110 car is partial or complete contamination of the valve. This happens due to untimely replacement of the air filter and affects the operation of the engine - of course, for the worse.

Throttle valve of a VAZ 2110 car

Engine performance directly depends on the amount of air that comes with the fuel mixture. If the air supply is limited, the fuel mixture will not be enough for complete combustion.

Functions

In simple terms, without terminology unnecessary for most motorists, the throttle valve is nothing more than the gas pedal of your car.

By pressing or releasing this pedal, you thereby close or, on the contrary, open this damper.

The device provides a path for additional air to enter. When you press the gas pedal to the floor as much as possible, you open the throttle fully, so the engine speed increases.

Location

Idle speed

The principle is to supply the required amount of air into the fuel rail to create the mixture in the correct proportion. Air enters through the filter into the throttle valve of the VAZ-2110. When idling, a small amount of air passes through the valve to maintain crankshaft speed at 750 rpm. The damper is completely closed at this moment. As soon as the driver presses the accelerator pedal, the damper opens (the angle of rotation of its axis is recorded by a position sensor and sends a signal to the electronic control unit).

Normal operation

Air enters through the gap formed by the damper, but the regulator does not work. A mixture formation process occurs in the fuel rail - gasoline is suspended (like fog) under high pressure. Its value is constant and is regulated using a sensor and an overpressure valve. After the mixture is formed, fuel is injected into the combustion chambers - the injectors open one by one (in fact, these are electromagnetic valves). They are controlled by an electronic unit. Their operation completely depends on the readings of the sensors and the fuel map (firmware of the microcontroller control system).

Electronic gas pedal

On some modifications of the VAZ-2110, the throttle valve is driven by an electric motor. The idea is simple: a sensor system is installed on the pedal (most often based on a potentiometer - a variable resistor). When you press the pedal, the resistance changes, and the electronic control unit determines the position based on the signal level. Then a signal is sent to the throttle valve actuator, and it opens to a certain angle. Instead of rheostats, encoders are installed - sensors that record the angular movement of the axis. They are more accurate and reliable, but the cost is higher. In general, the reliability of an electronic damper drive is much higher than a cable drive.

Operation of the sensor system

The air flow sensor is of great importance. It allows you to estimate the amount of air that enters the fuel rail through the throttle assembly. Depending on the position of the VAZ-2110 throttle valve, the volume of air passing through it changes. But the air cannot be weighed, felt, touched. Therefore, a more cunning way was invented to estimate its quantity - by heating a platinum filament.

When the ignition is turned on, a platinum filament in the mass air flow sensor heats up (this is why the sensors have a high cost - more than 2000 rubles). The electronic control unit contains the reference temperature of the filament. When air passes through the sensor pipe, the thread cools by several degrees (due to airflow). The control unit records the difference and, knowing all the geometric dimensions of the sensor, calculates the approximate amount of air passing into the fuel rail per unit time.

Remote control position sensor

The remote control position sensor can be contact (supplied as standard) or non-contact. Most often, a non-contact TPS is installed after removing the old one and discovering that it will not be possible to restore it efficiently.

This sensor on the VAZ 2110 is located directly on the throttle pipe, attached to the throttle axis.

The following symptoms indicate that the VAZ 2110 TPS needs to be checked and it needs to be cleaned (and possibly replaced):

- “Floating” idle speed;

- When the gas pedal is pressed during acceleration, the car moves jerkily;

- Increased fuel consumption compared to before;

- It is possible (but not certain) that the "Check Engine" light on the dashboard will light up.

The main danger is that if the TPS malfunctions, it will distort information regarding the position of the damper, then your VAZ will be guaranteed interruptions in engine operation, plus excessive fuel consumption.

Repair work

Now to the question of how the cleaning procedure is performed. For everything to go smoothly and without problems, it is enough to prepare all the necessary materials and tools in advance, place everything at hand and get to work.

To clean the throttle you will need:

- Screwdriver Set;

- 13mm wrench;

- Throttle valve cleaner.

Specialized preparations made from appropriate components are sold specifically for these purposes. Do not spare money on their purchase, since the funds will last for a long time. This is more profitable than changing the damper every time.

Cleaning with special means

Preparation

Let's start with the preparatory activities that will ultimately allow you to get to the throttle body and more and clean it properly.

- Remove the casing that is installed on the power unit.

- Unscrew the cap on the expansion tank. This will allow you to relieve excess pressure from the cooling system.

- Slightly loosen the tension on the mounting clamps, then remove the forced ventilation tube.

- Examine the current condition of the air pipe, which should also be removed and, if necessary, replaced.

- If there are significant traces of oil in the pipe, then you can be 100% sure that the throttle is definitely clogged.

- The problem is most likely in the forced ventilation duct. This is explained by the fact that contaminants in the form of gas from the crankcase and oil particles have no other way than through the ventilation branch.

- Next you need to remove the damper heating tubes. To do this, just loosen the clamps with a screwdriver.

- For a while, come up with plugs for them from improvised means - old spark plugs, some kind of non-hollow rubber bands. In short, anything that fits the diameter of the hole.

- Remove the fuel tank ventilation system hose. To do this, you must first unscrew the clamp, remove the cable and unscrew the throttle mounting nuts.

- Be sure to remove the connectors from two sensors - idle speed and throttle position. They are located on the unit being repaired, so there will be no problems with the search.

Symptoms of pollution

These include:

- It becomes difficult for the engine to switch from high speeds to lower speeds and vice versa.

- The engine stalls while moving with shaking and has great difficulty restoring normal speed.

- The engine stalls at idle speed.

- Cold starting of the engine is difficult. In order to start the engine, you need to turn it with the starter for a long time.

- You will smell gasoline from the exhaust pipe.

- The first few minutes after starting the engine will “triple”.

It is recommended to clean the damper every 50-60 thousand kilometers . You should also periodically perform certain preventive actions.

Causes of pollution

A mixture of dust and oil particles slowly covers the surface of the valve during operation. This is especially noticeable in places where there are air turbulences.

If you do not clean it on time, then over time the thermal gap will become overgrown with such plaque. Also, the valve stroke in the damper, which regulates the idle speed of the car, will decrease.

Cleaning the damper

This work must be done with the engine turned off. You also need to wait until it cools down to avoid burns.

Tools and materials:

Key "13" for removing the throttle assembly

Set of screwdrivers for work

Carburetor cleaner

Ear sticks that can be used to clean the flap

Throttle assembly gasket

- Screwdriver Set.

- The key is "13".

- Rags (you can take ear cleaning sticks).

- Pad.

- Flushing liquid.

Step by step cleaning

Before you start cleaning, you should prepare everything you need so that in the future you will not be distracted by searching for the right tool:

- a set of car keys, sockets and tools;

- regular and Phillips screwdriver;

- gasket for the throttle block, it is advisable to purchase a new element;

- a product that is used to remove contaminants from the carburetor;

- gloves to protect hands.

You may also need ear cleaning sticks and a toothbrush that is not used for its intended purpose.

Cleaning is carried out in the following sequence:

- Having opened the car hood, you need to disconnect the terminals from the battery, using a size 10 key to do this.

- By loosening the clamps on all 5 pipes, the pipe will be carefully removed.

- The connectors are disconnected from the sensor, which is located on the damper and the regulator that controls idle speed.

- The cable that controls the throttle is disconnected.

- Using a Phillips screwdriver, unscrew the idle speed control to remove this element from the block.

- Using a product used to clean carburetors, the surface of the block is cleaned. To clean the dirtiest areas, you can use a waste toothbrush and ear sticks.

- To extend the performance of the idle air regulator and the unit, experts recommend applying high-quality silicone lubricant to the rod. If, during a visual inspection, it was noticed that the condition of the rod is unsatisfactory or there is strong play, the easiest way is to completely replace the rod with a new one, especially since its cost is quite reasonable.

- Before assembling the throttle assembly, which is carried out in the reverse order, you need to replace the old gasket with a new one.

At this stage, the cleaning process can be considered complete, and, as you can understand, this event is not as difficult as it initially seems.

If during cleaning it is not possible to achieve smooth operation, it is recommended to contact a specialist about this problem. To determine the cause of the malfunction, it may be necessary to use special equipment, which is available only at service stations. By following the step-by-step instructions, all car enthusiasts, without exception, will be able to clean the throttle valve from contamination. If difficulties arise, you can visit the Internet resource at any time and watch a video lesson taught by experienced mechanics.

Source

Superficial intervention or deep cleaning?

There are two ways to clean the throttle valve. The first is a superficial intervention that does not require complete removal of the entire device. And the second is a complete cleaning, which must be performed in cases where your car’s engine is not working well.

To perform the first type of cleaning, you will need a pre-purchased cleaning product and a fine brush. Open the hood, remove the corrugation, it goes from the air filter housing to the throttle valve. You will see a valve - it is easy to recognize by its completely round shape. Treat it with a chemical and let it sit for a few minutes, then remove the dirt with a brush. If necessary, use a rag. Repeat the procedure several more times until the flapper valve turns a bright color. This work can be carried out once every 3–5 thousand kilometers, fortunately, it does not take much time.

Removing the corrugation from the throttle valve

For more detailed cleaning of the throttle valve in a VAZ 2110, you need to completely remove the entire injector mechanism. It is also recommended to replace the gasket and O-ring, which are included in the throttle valve repair kit, which is easy to buy at any auto store. Before starting cleaning work, remove the terminals from the battery.

Then disconnect all air pipes connected to the throttle body. After this, remove the fastenings of the throttle cable and unscrew the throttle valve itself. It is attached to two bolts that are screwed into the engine housing. Electronic sensors must be disconnected carefully to avoid damaging them.

Disconnecting the air pipes of the throttle assembly

After that, take a chemical and treat the entire body and all the grooves of the throttle body. Do this until you completely get rid of the dirt. You can also clean the air flow meter sensor. To do this, carefully treat its hairs with a cleaning product and remove the dirt with a brush. Give the entire device time to dry completely before reassembling. Do not forget to change the gasket and ring, which are located in the corrugation. Also pay attention to whether all air pipes are intact. Perhaps some require replacement with new ones. For maximum effect, you can also replace the air filter.

Cleaning

Even if the purpose of removing the throttle was to modify it, still do not forget that for stable operation it also needs periodic cleaning. To be honest, there is nothing complicated in this procedure, but it will help the engine run better, which is quite important.

For cleaning you will need:

- short and long screwdrivers;

- toothbrush (soft, or just old);

- cotton buds;

- cleaning agent;

- rubber or cotton gloves.

For cleaning to give the desired result, it must be carried out very carefully. First, you can go through all the cavities with a toothbrush, at the same time cleaning the idle speed control (it must also be removed). Further, more delicate, cleaning is done with cotton swabs. Pay special attention to the area where the throttle valve is located and the place where the XX regulator fits.

Please note that cleaning the crankcase ventilation duct with conventional means is not possible, but it can be easily done using the foot pump available in each trunk. The diameter of the fitting is similar to the wheel one, you just need to add cleaning agent and pump your foot several times.

If you have problems mentioned at the beginning that started recently, cleaning should fix them. If there were problems from the beginning, do not forget about improvements. Sometimes only replacing the throttle assembly helps.

The operation of a gasoline-type engine is based on this: the driver presses the accelerator pedal, the state of which is recorded by the control unit, tilting the VAZ 2110 throttle valve in accordance with the force of pressure on the gas pedal. The damper serves as a conductor of air into the combustion chambers of the cylinders, the control unit records the volume of air and proportionally sends a signal to inject the same amount of fuel. Changing the amount of air and fuel mixture leads to acceleration or braking of the car.

The main point for clear and smooth operation of the power unit is the throttle valve, which is a link in the same chain between the control unit and the driver of the vehicle. The damper device is simple and consists of: a plate fixed to the axis, which is placed in the pipe. Changing the angle of inclination leads to a change in the supply of the combustible mixture, which affects engine operation.

After two or three years of operation, the injector throttle valve on the VAZ 2110 tends to become clogged and needs to be cleaned from the effects of exhaust gas and dust. As a result, the operation of the injector becomes unstable. It is advisable to carry out comprehensive diagnostics of the throttle valve (TZ) systematically - after 60,000 km.

Debugg

If you notice that the throttle has begun to perform its direct duties poorly, do not rush to go to a service station and hand over your money.

The problem with the damper can often be solved with your own hands.

Most often, a problem with the throttle occurs due to contamination, which leads to impaired functionality. To correct the situation, simply clean the element.

When Cleaning Is Required

The practice of "tens" car owners shows that on these cars the throttle becomes clogged literally just a few years after the start of active use of the car.

The biggest “pests” for the damper are particles of oil, dust and gases coming from the engine crankcase.

When the engine is running, dust mixes with air and oil, forming a kind of mixture that enters the throttle valve. Over time, this substance sticks to surfaces and accumulates on the idle rod.

Soon the thermal gap becomes covered with dirt, and access through the idle air regulator channel is significantly deteriorated. If you do nothing, the engine will begin to work incorrectly, the dynamics will drop, and the engine will respond late to pressing the gas pedal.

According to the recommendations in the operating manual for the domestic ten, the damper should be cleaned after every 50 thousand kilometers traveled. If you clean it in a timely manner, the throttle will last much longer and there will be no problems with the operation of the power unit.

Signs of contamination

Problems with the throttle valve can be identified by characteristic symptoms.

| Signs | Explanation |

| Engine has difficulty returning from high to low speeds | This happens when you take your foot off the gas pedal. Instead of a smooth return to the required parameters, the speed literally drops to the 400 rpm mark. The engine may stall and begin to shake. The speed can return to the desired level, but with difficulty |

| The engine is difficult to start when cold and even when operating temperature is reached | To start the engine normally, you need to turn the starter for a long time. You can identify the problem by smell. The characteristic aroma of unburned fuel will come from the exhaust pipe. Try pressing the pedal all the way down several times. This will open the throttle fully, air will flow in, and the engine will start. But in the first few minutes the engine will still stall |

Troubling the motor is a rather indirect sign, since this is how the engine can behave in various types of failure. But don't rule out problems with the throttle.

Cleaning procedure

In most cases, surface cleaning will help if the contamination is not significant. The spray is used to clean carburetors and injectors.

The process for cleaning the VAZ-2110 throttle valve (injector) is as follows:

- Remove the corrugation from the air filter and throttle valve.

- Apply the solution from a spray can to the valve.

- After 5-10 minutes, remove dirt with a brush or clean rag.

- Repeat cleaning if the dirt is not completely removed.

To completely clean the throttle valve of the VAZ-2110, you will need to dismantle it. When carrying out repairs, it is advisable to install a new O-ring and gasket. Cleaning procedure:

- Disconnect the negative terminal from the battery.

- Dismantle all pipes going to the throttle assembly.

- Unscrew the two bolts securing the damper. Remove it for further cleaning. Pay attention to whether the gaskets and o-rings are damaged and what condition they are in.

- Do not damage the sensors during dismantling. Remove them carefully, being careful not to destroy the housing and power wires.

- Spray all surfaces of the assembly, grooves and holes with an aerosol. Wait until the product gets into all hard-to-reach places.

- Wipe the body with a brush or rag. If necessary, repeat the procedure several times. This will allow you to clean the body and internal surfaces as efficiently as possible.

The platinum thread in the air flow sensor often becomes clogged, dust settles on it and interferes with normal operation. It is possible to clean the thread and grill using an aerosol. But you should not touch it with your hands or foreign objects - this will lead to disruption of the sensor. To prevent contamination of the fuel system, change the fuel and air filters promptly. The less dust gets into the mixture, the longer the fuel system elements will last - the VAZ-2110 throttle valve, injectors, air flow sensors, pressure sensors, idle air control.

Preparation

Let's start with the preparatory activities that will ultimately allow you to get to the throttle body and more and clean it properly.

- Remove the casing that is installed on the power unit.

- Unscrew the cap on the expansion tank. This will allow you to relieve excess pressure from the cooling system.

- Slightly loosen the tension on the mounting clamps, then remove the forced ventilation tube.

- Examine the current condition of the air pipe, which should also be removed and, if necessary, replaced.

- If there are significant traces of oil in the pipe, then you can be 100% sure that the throttle is definitely clogged.

- The problem is most likely in the forced ventilation duct. This is explained by the fact that contaminants in the form of gas from the crankcase and oil particles have no other way than through the ventilation branch.

- Next you need to remove the damper heating tubes. To do this, just loosen the clamps with a screwdriver.

- For a while, come up with plugs for them from improvised means - old spark plugs, some kind of non-hollow rubber bands. In short, anything that fits the diameter of the hole.

- Remove the fuel tank ventilation system hose. To do this, you must first unscrew the clamp, remove the cable and unscrew the throttle mounting nuts.

- Be sure to remove the connectors from two sensors - idle speed and throttle position. They are located on the unit being repaired, so there will be no problems with the search.

What you need for cleaning

To remove and clean the assembly you will need:

- Screwdriver Set

- Head "13" with ratchet

- Old toothbrush with stiff bristles

- Cleaner

- Cotton swabs

- Latex gloves

Removing the throttle on a VAZ 2110

So that you do not constantly run for the necessary tool, it is better to say in advance that to perform this procedure you will need the following:

- screwdriver with Phillips and flat blade

- 13mm wrench, or rather a socket head with a ratchet handle

- pliers if necessary

First of all, we open the hood of the car and unscrew the clamping screw of the inlet pipe - this is the same thick corrugated “hose” that goes from the air filter housing to the throttle assembly.

And also the second one - from a thinner hose that comes from the pipe:

Now you can slightly move the pipe to the side so that later, when removing it, it does not interfere with us:

Next, unscrew the three screws that are marked in the photo below:

And the fourth one, which is located below:

If for some reason the upper hoses are difficult to remove, you can use pliers, being very careful not to damage the hose.

Then you need to disconnect the plugs with power wires from the throttle position sensor and the idle speed control. This is clearly shown in the photograph below; more precisely, the result is already visible:

And all that remains is to unscrew only two nuts securing the throttle assembly to the receiver, as shown in the photo below:

We move it to the side and the assembly is removed without any problems:

And there are a couple more points - this is disconnecting and removing the throttle control cable. Everything is quite simple here:

- We remove the cable fixing bracket by prying it with a flat screwdriver

- We remove the cable from its engagement with the damper, turning it to the required torque

Cleaning Rules

Before removing and cleaning the throttle valve, you need to buy a special cleaner for it. There are many manufacturers, there is enough choice. Among the inexpensive ones, Abro is effective.

- You need to remove the engine cover (decorative plastic);

- Reduce the pressure in the cooling system by unscrewing the expansion tank cap;

- Loosen the clamps and remove the hose from the forced ventilation air pipe;

- Use a screwdriver to remove the heating hoses for the remote control (it is advisable to plug them for now);

- Disconnect the cable and unscrew the fastening nuts. Now removal of the throttle assembly is possible;

- Use a cleaner to wash everything very thoroughly. Most often, it is necessary to use a needle to check whether the forced ventilation channel is coked, and also to clean it;

- Cleaning is necessary for the idle air regulator, for which it must be removed and inspected. If you find that it is jamming and adjustment is impossible, then it needs replacement;

- After washing, reassemble everything as it was. Please make sure that the gasket is intact and in good condition, then you can leave it. If this is not the case, then only replacement.

Assembly

Installation of the remote control is strictly in the disassembly sequence, only in reverse. A cleaned remote control unit makes engine operation stable at idle, and the engine speed no longer fluctuates. There is a clear response when the gas pedal is operated. Additionally, the throttle assembly may need to be modified, but first study the video on such modifications.

Correction of a factory miscalculation

It is quite common for a throttle assembly to come out of the factory with something that cannot even be called a defect, but can still be attributed to design errors. In theory, air should flow into the space behind the throttle, for which a channel of approximately 2.5 mm is specially made.

But the whole problem is that this channel was pressed against the wall of the receiver, thus blocking the possibility of air flow. A slight modification of the throttle assembly can help in this case.

Bored channel for air flow in the throttle

To do this, just take a file and use it to make a small groove in the indicated place. 2 - 3 mm will be enough. But before doing this, it is necessary to remove the throttle.

On a VAZ 2110, the throttle assembly is removed in the following sequence:

- Disconnect the connectors of the sensor that regulates the position of the throttle valve, its drive cable and the XX regulator;

- We partially drain the coolant;

- Next is the removal of the air hose located on the body of the mass air flow sensor. Why do you just need to loosen the clamp;

- We also loosen the clamps: where the throttle pipe is attached to the air hose; where the hose of the 2nd crankcase exhaust circuit is attached to the cylinder head cover pipe. We remove the connected hoses - the air and 2nd crankcase ventilation circuits;

- Having loosened the clamp, remove the hose of the 1st crankcase gas exhaust circuit from the throttle assembly fitting;

- Having loosened the clamps, we remove the hoses supplying and discharging coolant;

- You will need a wrench with a 13mm head, with which you need to unscrew the nuts securing the throttle assembly to the receiver on a VAZ 2110;

- It is now possible to remove the throttle assembly from the studs;

- It remains to remove the sealing gasket and, if your VAZ 2110 has a system that traps gasoline vapors, disconnect the hose for purging the adsorber.

Even if the purpose of removing the throttle was to modify it, still do not forget that for stable operation it also needs periodic cleaning. To be honest, there is nothing complicated in this procedure, but it will help the engine run better, which is quite important.

For cleaning you will need:

- short and long screwdrivers;

- toothbrush (soft, or just old);

- cotton buds;

- cleaning agent;

- rubber or cotton gloves.

For cleaning to give the desired result, it must be carried out very carefully. First, you can go through all the cavities with a toothbrush, at the same time cleaning the idle speed control (it must also be removed). Further, more delicate, cleaning is done with cotton swabs. Pay special attention to the area where the throttle valve is located and the place where the XX regulator fits.

Please note that cleaning the crankcase ventilation duct with conventional means is not possible, but it can be easily done using the foot pump available in each trunk. The diameter of the fitting is similar to the wheel one, you just need to add cleaning agent and pump your foot several times.

If you have problems mentioned at the beginning that started recently, cleaning should fix them. If there were problems from the beginning, do not forget about improvements. Sometimes only replacing the throttle assembly helps.

Now directly about how to clean the throttle valve of a VAZ 2110

1. Take the previously prepared cleaner and thoroughly clean the throttle valve, including all channels of the assembly. Pay SPECIAL attention to the calibrated positive crankcase ventilation duct; as a rule, it is so coked that you have to use a needle or a steel spoke to clean it.

2. Unscrew the two bolts and remove the idle air control (IAC). Properly rinse its channel in the throttle body, pay attention to its condition, the service life of the IAC is approximately 100 thousand km. If during the inspection you find that the idle air control rod is very dirty, sticks, has a lot of play or wear, I recommend replacing it with a new one.

3. If the gasket in the throttle assembly has a “human” appearance, there is no need to change it, but if it is damaged, replace it.

For those who like photos in the “before and after” style, I specially compared two images for greater clarity and demonstration of the work done.

Assembly is carried out in reverse order. That's all there is to cleaning the throttle valve , put everything back together and check the result. The result will be incredible, I can say from personal experience that after I cleaned the throttle valve the car seemed to have been replaced, everything changed, the engine performance, idle speed and sound changed so much that it seemed to me that the engine of my car had been replaced, or I had done something wrong » in the adjustments. While driving, an unprecedented throttle response and sensitivity came from somewhere, the engine began to gain speed faster and “eat” less fuel. The idle speed has stabilized, in short, the result is simply stunning. I hope your throttle valve cleaning also did not go without a trace... Thank you for your attention, take care of yourself and your car.

Checking the functionality of the sensor

With the ignition on, use a voltmeter to check the VAZ TPS voltage between the “minus” and the slider contact (it should not exceed 0.7 V). Open the damper by turning the plastic sector and measure the voltage again.

This time the sensor should output at least 4 V or a little more. With the ignition off, you need to pull out the connector and check the resistance between any terminal and the slider contact. As you turn the sector, watch whether the voltmeter readings change smoothly.

If they “jump,” then a replacement is necessary, preferably with a non-contact TPS.

As evidenced by the practice of a huge number of VAZ car owners, a contactless sensor will last much longer, it does not require additional adjustments, modifications, and inspection will be needed much less often.

Tuning by replacement

The standard valve (throttle assembly) usually has a diameter of 46 millimeters; many fans of various tunings decide to replace this part with an alternative one:

- VAZ 2112 throttle valve 52 has a larger diameter (there are also valves of 54 and 56 millimeters)

- Is there any benefit from such tuning?

- In various online stores they often offer to replace the standard 46 mm throttle body (DU) and install 52, 54 or 56 mm

- The product description says that an enlarged throttle body (also known as the throttle body) leads to a decrease in air flow speed, which improves the performance of the air intake system

- The effect of installing an alternative damper will be clearly visible when using a zero-resistance filter in the system

- We recommend installing a unit with a diameter of 52mm, because... the diameter of its air inlet for a standard receiver is 53mm

The valve is standard (standard) on the left and new (increased flow diameter) on the right

- In order to install a remote control of a different diameter, as a rule, nothing needs to be modified

- The maximum necessary action is a small trimming of the gasket (this is most often necessary when installing a 56mm throttle assembly)

The following positive effects are noticed after such an installation:

- The car becomes more agile

- Problems with idle speed disappear

- The gas pedal also becomes more responsive.

Installation disadvantages:

- Fuel consumption increases, although many believe that the BC gives incorrect readings and consumption does not change

- Some owners see the effect exclusively on 16-valve engines

The picture we described above may appear completely different:

- All the positive effect that many people notice when installing a larger diameter remote control usually appears because the old remote control already needed cleaning and naturally the motor was not working correctly

- After installing a (clean) new remote control, the engine starts working in its normal mode, this seems like a “new breath”

- In other words, all the described effects appear after regular cleaning of the remote control.

- And besides this, after replacing the remote control, with a larger diameter you will have new problems with the operation of the motor that did not exist before

- This is due to a violation of the ratio of gasoline and air, which the ECU is no longer able to correct.

- And instead of simply returning the remote control to the standard diameter, the owners are recommended to replace the firmware, the price of which is higher, but there is no point

- There is also an opinion that a remote control with a diameter of 52, 54 or 56 millimeters is a completely useless thing, and only installed in combination with other engine tunings produces a noticeable effect

- It remains unclear whether this effect is caused by remote control or other modifications to the engine

- After all, if on a turbo engine with a power of no more than 200 horsepower, standard 46mm dampers are left and their work is quite enough

How to remove the throttle valve on a VAZ 2110

1) Before you begin, remove the plastic cover covering the motor (if you have one).

2) Unscrew the expansion tank cap - this will help reduce the antifreeze pressure in the cooling system.

3) Loosen, but do not remove, all clamps indicated by red arrows (see photo).

4) Remove the hose that provides forced ventilation of the air pipe. Then look inside it, carefully examine it and touch it with your finger - if you feel or see an oil film, this means that the thin forced ventilation channel in the carburetor is already clogged, and the crankcase ventilation is carried out through a large branch.

5) Now loosen the two clamps and remove the throttle body heating hoses. Don't let anything get into them. You can plug them with a clean cloth or, for example, broken spark plugs.

6) Unscrew another clamp and remove the fuel tank ventilation hose.

7) Remove the cable and carefully unscrew the throttle mounting nuts. Done, you can now remove the throttle assembly and get ready to clean it.

Let's sum it up

Taking into account the above information, it becomes clear that the throttle valve is an important element of a fuel injection engine. At the same time, it is a mistake to believe that the throttle assembly does not require regular maintenance.

Moreover, although the manual recommends cleaning the damper every 35 thousand kilometers, it is important to make allowances for the operating conditions of the vehicle. As a rule, even in cities, roads in the CIS countries are not clean, and the air is quite heavily polluted. If a car drives on dirt roads, air pollution increases significantly.

It should also be noted that VAZ 2110 car owners often do not install the best air filters. The result is active and rapid contamination of not only the filters themselves, but also the throttle assembly. For these reasons, it is optimal to change the air filter every 15 thousand km, and also clean the throttle valve (at least superficially) every time it is replaced.

It is also necessary every 30-40 thousand km. completely remove the throttle assembly, deep clean it, at the same time clean the sensors and electrical connectors, check the condition of the corrugations, pipes, etc.

Finally, we note that you need to constantly monitor the condition of the throttle and regardless of whether there are any problems with the engine. This approach will allow not only to achieve stable operation of the internal combustion engine, not to lose engine power and not to consume excess fuel, but also to increase the service life of the power unit. “Turn the Engine” is dedicated to one of the greatest blessings of civilization - the piston internal combustion engine. Everything about the operation, service and preventative maintenance of gasoline and diesel internal combustion engines. Useful information on engine and attachment repairs, methods and techniques for carrying out diagnostic procedures. Tuning, engine tuning and competent selection of technical fluids.

Signs of a clogged element

You can independently verify that the damper needs cleaning based on several signs:

- car acceleration dynamics decreases;

- engine operation becomes unstable;

- when moving, peculiar jerks are observed;

- there is no smooth running.

If the above symptoms appear, the damper should be cleaned of dirt as quickly as possible. Cleaning, as we noted earlier, is quite simple, and besides, it will be much cheaper than purchasing a new element.