VAZ electronic throttle: design, diagnostics, flushing and repair.

In this material I want to talk about the design, diagnostics and repair of the Delphi electronic throttle valve (pipe), installed on VAZ cars together with the M74 engine management system.

The reason for writing this article was one very typical malfunction on a VAZ 2115 car with an atypical cause, which I will talk about a little later. I would like to warn you right away that the author of this article does not bear any responsibility for unqualified intervention and repair of the electronic throttle valve in the event of its failure and emergency situations on the road, since repair of this unit is not provided, but only replacement. Design. An electrically driven throttle valve (pipe) is designed to dose the amount of air entering the intake manifold. Changing the amount of incoming air is achieved by turning the damper with an electric motor, which is controlled by a controller. Main parts of the throttle body: All photos are clickable!

1. Housing 2. Damper 3. Gearbox 4. Electric motor 5. Throttle position sensors.

The connection diagram is shown below:

Removing the throttle assembly: 1. Turn off the ignition, remove the minus terminal from the battery. 2. Unscrew the clamps and remove the intake pipe hose from the throttle body. 3. Disconnect the harness block. 4. Unscrew the 4 bolts securing the throttle assembly from the intake manifold and remove it.

Typical faults and their diagnosis. A childhood problem of the first car releases, error P2135 (Mismatch of signals from sensors A and B of the throttle position) manifests itself in the form of unstable idling, speed limit to 2000 and loss of traction. It can be successfully treated by crimping, bending and soldering the contacts of the throttle body block or by replacing the entire electrical wiring harness. On most cars it has been cured for a long time, on new ones it almost never occurs. Floating speed and unstable idle. Here we will dwell in more detail, since this phenomenon is common and appears sooner or later on almost all cars. The main reason here is the mismatch between the throttle opening angle and the amount of incoming air. On most cars it can be treated by washing. It is advisable to wash the throttle valve at least once every 20-30 thousand km. otherwise, deposits of soot and oil particles create obstacles to air movement during idle with all the ensuing consequences. Therefore, the throttle assembly must be kept clean and tidy - this is an axiom. The second reason for floating idle speed is throttle play. How does it manifest itself and how to diagnose it. Below is a screenshot of the SMS diagnostic program. The parameters were taken from a VAZ 2115 car with an M74 engine management system.

Here it is worth paying attention to the high air flow, relative filling and injection time. At the same time, the opening angle of the throttle valve is very small and the controller, trying to stabilize the idle speed, drives the ignition timing into the minus. This happens because the actual angle of the throttle valve does not correspond to the angle calculated by the control unit due to backlash. Moreover, if you initialize the throttle, then the engine may work normally for some time, but after some time or after a restart, the situation with the speed floating repeats. It is worth mentioning here that if the throttle is dirty, the parameters will also differ from the norm, with the only difference being that the valve opening angle becomes larger than usual. As an example, here is a screenshot with normal parameters:

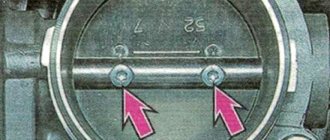

How to eliminate throttle play. To do this, the throttle assembly must be disassembled. From the gearbox side, unscrew 4 screws (Torx 15) securing the cover.

Here we see the gears of the transmission mechanism.

The middle gear is simply removed.

On the other side there are throttle position sensors and an electrical connector. They are fastened with very rare pentagonal Torx screws. Photo below:

We're filming. The electric motor in the housing and the damper axis are visible.

Next, you need to use a press or vice to squeeze out the throttle axis from the TPS side towards the gears.

Remove the axle.

There is no need to remove the electric motor if it is in good condition. You can check it simply by measuring the resistance at the contacts. The resistance should be approximately 10 to 30 ohms.

Below is a photo of all the components of the electric throttle in disassembled form.

The position of the throttle valve, when the electric drive is not engaged, is determined by the position of the spring whiskers between the stops - lugs in the throttle body and is approximately 10% of the opening relative to the closed position.

Play along the axis of rotation of the throttle valve appears due to wear on the aluminum spring stops. Marked with a red arrow:

There are 2 options here: either replacing the throttle assembly, which is not cheap; at the time of writing (September 2013) it costs about 2,500 rubles. Or you can remove the backlash by eliminating the gap between the spring mustache and the body bosses. The essence of the method I propose for eliminating the backlash is to slightly move the spring mustaches by the amount of the gap, by cutting, for example with a needle file, grooves for the mustaches in the plastic stops on the gear itself.

Purpose of the throttle valve

Not a single car in the world can do without such a unit as a throttle valve. The mechanism is a transverse channel regulator that changes the amount of flowing liquid or gas. That is, at its core, the damper is an air valve. When it is closed, the pressure in the intake system is equal to vacuum, and when it is open, it is compared to external atmospheric pressure.

By pressing the accelerator pedal, the degree of opening of the damper is adjusted. Accordingly, how much air enters the engine cylinders depends on this. Almost every modern car is equipped with an injection engine, where all important responsibilities are assumed by the electronic control unit (ECU).

As some car enthusiasts know, the optimal ratio of gasoline to air is 1:14.7. By detecting the throttle position and the amount of air using sensors, the ECU regulates the operation of the injectors and fuel pump. This knowledge will be useful in deciding how to adapt the throttle valve.

In other words, the computer commands how much fuel needs to be supplied to the engine in order to maintain optimal proportions.

The main “miscalculations” of VAZ

Of course, no matter how much VAZ praises e-gas, this mechanism also has serious drawbacks. For example, if it fails, this device cannot be repaired. A complete replacement will be required, which will be very expensive. Although today there are “traditional craftsmen” who have adapted to repair the device themselves, this is not always effective - driving with such e-gas is even dangerous.

As for the responsiveness of the car, not everything is clear here either. Many motorists claim that the old Kalinas were much easier to pedal and responded better to pressure. E-gas responds to them with a delay, and this can become a critical problem, especially if you need to quickly avoid a collision or simply quickly overtake.

Mechanical throttle

Currently, a mechanically driven damper can only be found in budget car configurations. In such a mechanism, the damper is connected to the accelerator pedal via a metal cable, fixed to the shaft and placed in a housing on which sensors are also located:

All this looks like a separate block. Various pipes also lead to it; coolant is supplied and discharged through one, and through others the crankcase is ventilated and fuel vapors are captured.

Thanks to the IAC, the required number of crankshaft revolutions is maintained when the damper is closed. The regulator itself consists of a stepper motor and a special valve. Together they regulate the amount of air, regardless of what position the throttle valve is in. Usually there are no problems regarding how to adapt the throttle valve in the case of a mechanical drive.

The design and principle of operation of the electronic gas pedal

To understand how it works and functions, you need to roughly understand the general circuit of the mechanical analogue. The functions of these systems are similar, but the simplest unit can only be considered a traditional drive.

The gas pedal is a control element for the throttle and its damper. The function of the throttle is to regulate the amount of air. The more air, the higher the engine speed the crankshaft will rotate. The pedal is connected to the throttle drive via a cable drive or levers. All this significantly reduces the effort required to press the gas.

The operating principle of the electronic unit is more complex, but this makes the process of controlling speed easier. The electronic accelerator is used only on engines with an injection power system. Its device is completely electronic. It is based on electronic modules that convert electrical signals.

Structurally, the unit consists of a plastic lever and a mounting bracket - there are two sensors inside the bracket. All these elements form a single, non-separable structure.

Potentiometers are used as sensors. The movable contact of which is in rigid connection with the axis of the plastic pedal lever.

When the driver presses the accelerator, the electronics sends information about the position of the lever to the unit responsible for converting signals. In the next step, the signal is amplified and the throttle is opened according to the vehicle settings.

If we consider the classic scheme, the pedal axis is aligned with the potentiometer slider. The variable resistor is manufactured on a printed circuit board using sputtering technology. When you press the accelerator, the potentiometer sliders move along the sprayed surface, changing the resistance in the circuit.

New car models use two potentiometers. This approach increases the reliability and accuracy of control. If one resistor fails, the system will use the readings of the second.

Electromagnetic throttle valve

The electronic analog, unlike a mechanical unit, allows you to achieve the optimal torque value in any engine operating mode. The level of fuel consumption is reduced, and driving such a car is comfortable and safe. The main distinctive features (and in this case, advantages) are the following:

- idle speed is controlled by moving the throttle valve;

- there is no mechanical connection between the pedal and the damper.

Due to the fact that there is no mechanical connection, torque can be controlled electronically instead of the gas pedal. The damper module itself consists of the following elements:

- housings;

- the damper itself;

- electric drive;

- return spring mechanism;

- damper position sensors.

Installing not one, but two damper position sensors in the module will improve reliability. For this purpose, magnetoresistive devices or potentiometers with sliding contacts can be used. It is precisely because of the breakdown of these elements that it is necessary to decide how to adapt the throttle valve on many cars.

If a malfunction occurs in the electric drive, the damper is brought to the emergency position due to the return spring mechanism. In this case, the module itself must be replaced, which can only be done as an assembly.

Replacing the idle speed sensor (video)

Dismantling the IAC

- First of all, before starting the replacement, turn off the engine and open the hood.

- The regulator itself is located on the throttle body, slightly lower than the damper position sensor.

- This photo shows how to find it visually by simply looking a little further under the hood.

The idle speed control is marked with a red marker.

Next, remove the wire block by first unhooking the latch from its body. And then unscrew the two bolts using a regular Phillips screwdriver

(Please note that you should choose a screwdriver with a short blade, otherwise it may simply not fit in a limited space).. Remove the unscrewed screws in a safe place

We put the unscrewed screws in a safe place.

When the bolts are unscrewed, we simply pull the regulator body towards us, and it calmly gives in.

IAC inspection

Now that the device has been dismantled, you can easily determine and decide whether to replace the sensor with a new one or start cleaning it. If there is carbon deposits on the regulator, but there is no mechanical damage, no parts are falling off its body, and its condition inspires confidence in you, then you can easily simply clean it. For this we only need carburetor cleaner and a clean rag. Using it, fill all the holes and niches, clean everything with a rag and let it dry for a certain time.

This is what a “dirty” IAC may look like.

And so after cleaning.

If the IAC has damage to the working mechanism, then it will only have to be replaced with a new one. The catalog number of the factory idle air regulator is 2112-1148300-04. Of course, there are analogues, but you should go to the store with a previously removed spare part.

IAC assembly

After the device has been cleaned or replaced with a new one, we reassemble it in the same manner as removal. Do not forget to connect the wiring harness to it and check that it is securely secured.

Throttle valve clogged and cleaning intervals

From time to time, the throttle valve inevitably becomes clogged, which manifests itself in various ways. In this regard, a reasonable question arises: how often should it be cleaned? It is not entirely possible to answer this unequivocally, since there are no recommendations on this matter. Some car owners visit auto repair shops when they suspect an engine problem.

Some people believe that the damper needs to be cleaned after every 40,000-50,000 km. Others have a different opinion and clean the damper more often, after 30,000-40,000 km.

Typically, black carbon deposits on the valve indicate low quality fuel. When operating a vehicle with such gasoline, there is a risk of oily deposits forming. After this, there should be no question whether the throttle needs to be adapted.

conclusions

The main cause of failures are spark plugs, but they are not the only ones that influence the appearance of this effect. Some car enthusiasts may not be able to cope with the occurrence of such malfunctions on their own, and it is necessary to go to a car service center, where they will carry out high-quality diagnostics and also fix the problem. But it is worth considering that you will have to be generous, since neither computer diagnostics nor repairs will cost a penny.

The brakes, of course, were invented by cowards - any reckless driver will tell you that. But when you realize that there is “something wrong” with them, it becomes scary to get behind the wheel: the trip may be your last. We drive thoughts like “it will do” away: the jokes are over

It is important to determine the type of malfunction - at least in advance

Signs of a clogged damper

When the throttle valve becomes clogged, the engine begins to operate in an unstable mode. Typical signs of a malfunction in this case are:

- increased idle speed;

- delayed engine response to pressing the accelerator pedal;

- while the car is moving, jerks are observed, and sometimes the vehicle changes speed independently, without the driver’s participation;

- abruptly releasing the gas pedal causes the power plant to stop.

In some cases, the CHECK indicator on the instrument panel will light up. Sometimes tar deposits settle on the throttle shaft, causing it to seize. Then the gas pedal is pressed with noticeable force.

Before moving on to solving the problem of how to adapt the throttle valve on a Skoda or any other car, you need to make sure that the diagnosis is accurate by conducting a visual inspection of the mechanism. To do this, you need to remove everything that is possible in order to open access to the module. Be careful not to accidentally disconnect the cooling system pipes.

conclusions

The main cause of failures are spark plugs, but they are not the only ones that influence the appearance of this effect. Some car enthusiasts may not be able to cope with the occurrence of such malfunctions on their own, and it is necessary to go to a car service center, where they will carry out high-quality diagnostics and also fix the problem. But at the same time, it is worth considering that you will have to be generous, since neither the repair nor the repair will cost a penny.

Good day! Question for those who have encountered this problem. So I’ll start from afar to make the situation more clear. In general, I wrote earlier that I had a problem with the fact that at a traffic light the speed dropped to 500, then rose to 1200, then leveled off and everything started in a circle several times, and if I left it on hot, at idle, it could stall altogether, but it stalled softly, as if they had simply turned the key, and the canister purge valve was also clicking. I went through various diagnostics for a long time, in the end they found an air leak through the rubber bands of the receiver, changed the IAC, washed the throttle, changed the filter and mesh, after this replacement curve the fuel pump whistled, failures seemed to become less frequent, but it still stalled and only when it was hot, when I left it on single. As a result, I got to one diagnostician, he found a bent throttle valve, did the firmware and the car seemed to drive, the fuel pump stopped whistling after a month and a half. Everything seemed to be fine, but over time I began to notice such a thing that when the tank needle is in the red zone, the car seems to have been replaced, it starts to drive very cheerfully with less pressure on the gas pedal, plus there is clearer information from the pedal and less roar of the engine when accelerating. .e. even from the bottom (1.4 engine) it accelerates with a pleasant sound, and not with a fart that is about to die. BUT, as soon as you fill gasoline above the red zone, the car becomes sluggish, when accelerating in second gear, the car does not respond to how much the gas pedal is pressed, whether the pedal is to the floor, or until half the acceleration speed does not change, the speed rises somehow slowly, but if you pump the gas pedal with your foot several times, you can achieve a slight acceleration, but still not as much as on an empty tank (for the difference in weight of 30 liters, I think it’s stupid to say what will affect acceleration). Plus, when accelerating from the bottom, there is an unpleasant, sort of slightly farting sound from the engine (not the exhaust), it feels like it’s missing either air or gasoline. I drove like this for almost a year, I couldn’t find the reason, there were similar topics on the service and on the Internet, but there were no concrete solutions, most people simply don’t believe that the car can drive more vigorously on an empty tank. There is no air or other stuff in the tank. Recently the fuel pump whistled again, but the car drove briskly and on a full tank, so the pump was still original since 2009, I decided that the problem was in it and changed it, it seemed to start running, then I found a topic about the RTD and also changed it to catch up. The car came to life with any tank, drove like that for a week and a half and went to another city on the highway, everything was great, the acceleration was excellent, I didn’t even notice how quickly it picked up to 150. BUT, after driving about 70-80 kilometers, I began to notice that something was wrong again, when I was driving back I had to stoke in third to overtake

In general, now I don’t know where to dig, the car now drives according to its mood, no matter how many liters are in the tank, for example, I leave for work in the morning, it’s dull, the gas is on the floor, and like a pensioner it accelerates slowly, I leave it in the parking lot, in the evening I go out and it drives cheerfully with slipping in second and third gear, as if the engine had been changed. So far I can’t catch any pattern (if before it was based on the level of gasoline in the tank)

I also forgot to write that even after replacing the RTD with a hot one, in half the cases it starts poorly, you have to squeeze the gas. I only drive on gasoline; I don’t have gas equipment. Anyone who has encountered such a problem or knows what could be the reason, please tell me.

www.drive2.ru

Cleaning the remote control

If the cause of unstable engine operation is a dirty damper, you should move on to cleaning it. To do this, you can contact a reliable service station. Among the large number of workshops, you can find one that specializes in specific brands (Audi, Volkswagen, Toyota, Mercedes and others). However, the owner can do all the work himself, since much experience and skills are not required in this matter.

At service stations, the cost of the procedure may depend on a number of factors:

- complexity of the work - for some cars, access to the remote control will require the dismantling of many parts;

- service station service level - as a rule, the larger the organization, the more expensive it is;

- location – in large cities you can leave more money than in the periphery.

Cleaning the throttle valve is a simple procedure, after which you usually need to think about how to adapt the throttle valve on a Nissan or any other car.

Any car owner can perform this procedure independently. No special knowledge or skills are required here. All you need to get to the damper are tools and rags (preferably soft ones). You also cannot do without a special product - mainly the carburetor cleaner “Carb Cleaner” is used.

Self-cleansing procedure

If the damper is electronically actuated, then it is better to remove the negative terminal of the battery. Next, you can do everything according to simple instructions:

- dismantle the air filter by unscrewing the pipe clamp;

- disconnect all connectors of the throttle module and other pipes;

- move the air filter receiver to the side so that it does not interfere, and begin cleaning the damper;

- upon completion, reassemble the damper module in reverse order, checking that everything is in place;

- After assembly, start the engine and check the idle speed.

In some cases, before you begin to adapt the throttle valve on a Toyota, Nissan or Skoda, it is necessary to remove the throttle itself, which allows you to completely clean the valve. To do this, you will need a 5 mm hexagon to unscrew the 4 fasteners. Removing the throttle should be done with great care, as there is a risk of damaging the gasket.

If, after cleaning the throttle body, increased idle speed is observed, it means that the damper needs to be adapted. What this is is further in the topic of the article.

Engine lost power: common causes

- Ignition problems. An ignition timing angle that is too early will mean that the fuel-air mixture is prematurely ignited. As a result, the expanding gases counteract the upward piston rather than pushing it down. Under such conditions, engine power will drop noticeably. The same is true for retarded ignition. Late combustion of the fuel-air mixture leads to the fact that the expanded gases “catch up” with the downward piston, useful energy is wasted. It turns out that in both the first and second cases, the driver intensively presses the gas pedal, fuel is consumed, but the full return from the engine does not occur. Also worth mentioning are problems associated with the vacuum and centrifugal ignition timing regulator. The fact is that malfunctions of these solutions affect the ignition timing and its change in relation to different operating conditions of the internal combustion engine. For example, when the speed increases, the regulator shifts the ignition angle. In other words, the degree of opening of the throttle valve and the increasing speed of the crankshaft at the same speed do not allow the engine to develop full power. On injection engines, a loss of power may be observed after flashing or chip tuning of the ECU in order to save fuel.

- Cylinder-piston group and timing. As mentioned above, loss of engine power is caused by wear of the CPG, failures in timing settings, or accumulation of carbon deposits in the combustion chamber. As for the gas distribution mechanism, improper valve adjustment, coke and carbon deposits can disrupt the normal operation of the valve mechanism. More precisely, the tightness of the combustion chamber is compromised due to the loose fit (adhesion) of the valves to the seats. The fit may be compromised if the valves are too tight. Engine coking also prevents the valve from closing normally. The fact is that the carbon layer prevents normal adhesion. As a result, some gases break through loosely closed valves, causing overheating, burnout of the valve, valve seats, etc. Coke deposits can additionally smolder under the influence of high temperature, causing the effect of uncontrolled ignition of the mixture, that is, glow ignition. All this leads to malfunctions and a decrease in the power of the power unit. As for the CPG, piston ring wear is a common cause of low cylinder compression. As a result, gases break through into the engine crankcase, that is, the energy of fuel combustion is again consumed with great losses. Determining the cause is not particularly difficult. It is enough to remove the crankcase ventilation hose and evaluate the degree of smoke intensity. The presence of strong smoke that pulsates will indicate problems with the rings.

- Filling with fuel-air mixture and mixture composition. Problems with the filling and composition of the fuel charge can reduce engine power even if the engine is in good condition and the ignition is set correctly. The most common cause is a dirty throttle valve or a malfunction of the throttle opening mechanism itself. Let us add that running on a lean mixture will not allow the engine to develop full power. Leaning can be caused by air leaks that occur both at the intake and in the fuel system. Another reason is contamination of the jets on the carburetor or fuel injectors/fuel pump mesh/fuel lines of the injection internal combustion engine. The air intake also deserves special attention. The first step is to check the air filter. Then you should diagnose the fuel system. To begin with, it should be ruled out that the tank is filled with fuel with a low octane number for a particular type of engine. The next step is to check the injectors and their performance, as well as the fuel pump.

Article on the topic: Comparative characteristics of summer tires - what do you need to know when choosing?

The need to adapt remote sensing

This definition refers to the operation (or training) that is carried out so that the ECU “knows” what position the throttle valve is in relative to the degree of depression of the accelerator pedal. This procedure is simply necessary if the engine is unstable at idle.

For most Toyota, Lexus, Mercedes, Nissan, and Audi cars, it is necessary to adapt the throttle valve, as this allows you to eliminate the malfunction. The procedure is performed in the following cases:

- in the event of a critical drop in the voltage of the on-board network (the battery is switched off or completely discharged);

- the ECU was replaced;

- the valve was cleaned and the throttle was removed;

- when replacing the throttle module itself;

- the accelerator pedal was replaced, usually with an electronic one.

It is worth noting that due to the layer of dirt, the gap between the damper and the body changes, and after cleaning the damper, its position has changed. But the ECU “has no idea” about this and continues to control the fuel supply according to previous indications (before the cleaning operation). Adaptation will completely eliminate this gap and restore engine performance.

Refinement of a new electronic gas pedal

The pedal assembly (11183-1108500-01) does not have oval holes, which does not allow adjustment in the manner described above. Instead, it is proposed to cut off the protrusion (by 2-3 mm), which prevents the pedal from moving completely. This modernization made it possible to increase the pedal travel, which made acceleration with “pedal to the floor” more active. It is also noted that there is no hesitation when pressing the pedal sharply. What I don’t like about the pedal assembly (8450008980), which is installed on Lada Vesta:

- tight gas pedal;

- large free play of the gas pedal (about 8 mm at the tip of the pedal).

What was decided to do:

- remove one of the return springs to make the pedal softer;

- Place a spacer to reduce the free play of the pedal.

How to measure pedal free play:

- Let's start the engine.

- Place a ruler at the tip of the pedal.

- Smoothly press the pedal until the engine begins to gain speed.

- We remember the distance on the ruler.

We remove and disassemble the electronic gas pedal:

- Disconnect the connector (by pressing the inside of the upper part of the latch)

- Unscrew three nuts (head “10”).

- Remove the top cover by unscrewing the fastening screws.

- Remove the rheostat slider by unscrewing the screw.

Refinement process:

- Remove the spring (holding them with a screwdriver from the outside).

- Remove the white support spacers, remembering how they were installed.

- We measure the distance between the support pad of the return spring lever and the support rubber in the body, retracting the pedal to the amount of free play (indicated by an arrow).

- We glue the material of the same thickness (in this example we use 4 mm stickers for furniture legs and doors) using glue or double-sided tape.

We assemble the pedal assembly and install it in the car. The idle motion of the pedal should be minimal, about 1 mm. If the engine idle speed is higher than usual, and there is no free play of the pedal at all, then too much has been added. You will have to repeat the adjustment operation, adjusting the thickness of the lining. The same thing applies if the free play after adjustment remains more than 1-2 mm.

When the throttle assembly of any modern vehicle operates, a lot of contaminants in the form of dust, soot, and oil gradually accumulate on the surface of the throttle. They form a layer of dirt, which makes the air gap between the damper and the car's air duct smaller than the established norm. This gap is important for the normal functioning of the “heart” of the car, since thanks to it the idle speed is maintained at the required level.

When it decreases, the vehicle's electronic control unit (car computer) slightly opens the damper by introducing coefficients that take into account changes in its cross-section. Up to a certain point, the ECU manages to maintain the air gap at a constant level, but sooner or later the throttle valve will still have to be cleaned of dirt.

The need for such an operation, which involves bringing high idle speeds to a standard value, arises not only after flushing the throttle assembly, but also in other cases, in particular in the following:

- after the vehicle battery is completely discharged;

- after replacing or removing the accelerator pedal;

- after replacing or reconnecting the vehicle's electronic control unit.

Undoubted signs indicating that the damper needs to be trained immediately are the following phenomena:

- whistling when revving;

- inadequate behavior of the engine at idle;

- lack of power at idle or failures.

It is advisable to adapt these devices before you teach idle speed. If the cable of the sensor that sends the signal about the accelerator pedal position is disconnected, you must perform the following steps:

- Release the pedal completely.

- Turn the ignition key to “ON” and wait at least two seconds;

- Turn off the ignition, wait 10 seconds;

- Repeat the procedure according to point 2, and then according to point 3.

The described procedure (you must admit, it’s not at all complicated) will teach the damper to open correctly. But to adapt the valve to the “Closed” position, the following operations should be performed:

- Release (fully) the accelerator pedal.

- Place the key in the “ON” position.

- Switch the ignition to “OFF” and wait 10 seconds.

- We make sure that the valve lever moves within 10 seconds (a characteristic sound indicates that there is movement).

The simplest way to carry out adaptation

Now the question of whether it is necessary to adapt the throttle valve after cleaning should definitely not arise if there were still doubts. The easiest way to carry out the operation is to simply reset the battery terminal. Just to begin with, it is worth warming up the engine well to operating temperature, for which you should take a short trip. Then, turning off the engine, disconnect the negative terminal of the battery and wait. Depending on the brand of car, the waiting time can be 10-30 seconds or 15-20 minutes.

During this period, all ECU parameters should return to the original (factory) settings. Next, all that remains is to connect the terminal and start the engine - the speed should return to normal.

Lubricating the throttle cable on a Priora at home

To work you will need:

- Flat screwdriver;

- Pliers;

- A syringe and a few drops of motor oil or WD-40.

1. First you need to turn off the engine and let it cool.

2. Next, you need to open the hood and remove the decorative engine cover.

3. To remove the throttle cable, you need to remove it from the plastic bracket; to do this, pull the cable casing towards you and, pushing the rubber ring up, remove the cable.

4. Now you need to disconnect the cable from the throttle valve drive. To do this, remove the U-shaped metal bracket from the throttle actuator by prying off one edge using a flathead screwdriver.

5. We remove the cable from the hook, overcoming the force of the spring.

6. Now that nothing is in the way, you can begin to lubricate the throttle valve actuator; to do this, you need to slide the transparent cap and generously lubricate the cable with a few drops of engine oil or WD-40 penetrating fluid. In the case of oil, prepare a syringe.

Try to pour oil into the housing, then move the housing to lubricate the cable along its entire length. Repeat the procedure several times until the cable is completely lubricated.

Next, put the protective cap back in place and reinstall the cable to the place of further service.

Adaptation using the example of some cars

Another method, which we will consider using the example of one well-known German brand, also involves adaptation without a computer. Here you should warm up the engine to a temperature of approximately 70-99°C. The battery voltage must be at least 12.9 Volts when the engine is not running. The action plan for how to adapt the throttle valve on a Volkswagen will be something like this:

- After warming up and turning off the engine, you should wait a short period (5-10 seconds).

- With the gas pedal released, turn on the ignition and wait 3 seconds.

- After 3 seconds, you need to press the accelerator pedal all the way 5 times and release it back. Act quickly, as you only have 5 seconds to do this.

- After the 5th exercise, you should wait a pause.

- After 7 seconds, press the pedal all the way again and hold it in this position until the “CHEK” indicator starts flashing (≈ 10 sec.), then it should remain on continuously (≈ 20 sec.).

- When the indicator lights up constantly, count to three and only then release the pedal.

- Start the engine (repeat if necessary), wait 20 seconds, then lightly accelerate (2000-3500). If the tachometer shows 700 rpm at XX (+- 50), it means that the adaptation was successful.

Problem with idle float when starting on cold due to sticking of throttle 21127 and 21129.

Dear friends, today I’ll tell you about my experience in resolving problems with the throttle assembly. Very relevant, especially for owners of 21129 engines.

By the way, I have the firmware with the problem already fixed.

The occurrence and solution at the plant level in the case of the M74.5 ECU, it was like this. When the ignition was turned on on old versions of the ECU firmware, the micro-calibration time of the Throttle Unit (hereinafter referred to as the remote control) was, well, long, due to the fact that the owner did not wait for a 10-second pause during the ignition, this error occurred.

This problem can be fixed with firmware.

But not everyone, for example, in cars of 13-14 years, the remote control motor was of an old model, had a certain moment of jamming, then in 15 the remote control became “modernized” and this error went away altogether.

Firmware versions that have this problem:

I427DB02 I427DC03 I427DD04 I427DF04 I427DG05 I427GA01 I427GB02 I427GC03 I427GD04 I427GE05 I427GF06

Firmware versions that do not have this problem:

I427GG07 I427GKA1 I427GKA 2

Here is a photo of how to find out your firmware version, the firmware is interchangeable, at least install the oldest one on the new unit, at least the newest one.

Problem with floating XX when starting on cold

The car sits overnight, in the morning you start the revs, when it warms up, the revs begin to jump, +-300 revs, with the probability of stalling, you need to press the gas pedal lightly and everything returns to normal.

Starting the engine, the rpms are 1200, they begin to jump between 500 and 1400 and hang at 700.

Related problems:

— Jerking during a smooth start in first gear — Thoughts in part-load mode — The feeling when accelerating at 50% throttle that sometimes “as if you’re holding your ass”

How to diagnose physically: when disassembling the throttle, remove the plastic gear, twist the motor gear, if it rotates tightly or sticks, then the manual is for you.

It is necessary to remove the remote control, clean the valve (by the way, it was clean) with carburetor cleaner, then remove the cover, unscrew the motor and wash everything.

Source