The owner of any car is not very often interested in how to check the camshaft.

Tested by many generations: usually this unit is quite durable and can survive even a couple of major repairs without replacement - of course, if by bad luck it was not caught with a manufacturing defect. However, there is no need to be too vigilant. There is always the possibility of trouble. If the camshaft suddenly closes, but you don’t understand it and continue to drive, then along the way you will destroy a whole bunch of spare parts that come into contact with it. So at the slightest suspicion you need to conduct a thorough examination. If the suspicions are confirmed, we catch a tug or call a tow truck and urgently get it serviced. Here your car will receive a final verdict based on more detailed diagnostics.

How to check the camshaft? There are several ways: by hearing, by sight, by touch. How suitable one or the other is for you depends only on your intuition and possession of certain knowledge of auto mechanics.

Let's listen carefully

Anyone who has been driving his own vehicle for quite some time has become quite familiar with the inner voice of his car - the rumbling of the engine and the operation of the corresponding parts.

In normal condition, the camshaft sound is quiet and even, with a frequency that varies depending on the speed. A faulty unit acquires a dull, tapping voice, reminiscent of blows with a hammer. Listening to the engine through the valve cover gives good results

. Inventive people use wooden sticks, inverted glasses, and stethoscopes for these purposes. However, a similar sound is produced by an untwisted valve. Unless you are an experienced motor mechanic, you may not feel the difference.

When removed, the camshaft (complete with the bed) is checked by ear as follows: hold it parallel to the ground with one hand, and tap it on top with the other. If you hear even the slightest sounds, your path lies to the repair shop. Only when checking, you need to make sure that the camshaft itself does not move along the bed: clinging to the limiter, it inevitably makes a knock, which can be taken as a sign of wear.

{banner_content}

Where does knocking come from when the engine is hot?

The reasons can be very different, and the first priority when detecting knocking noises is to understand what parts are causing it. The service life of the engine as a whole depends on finding the cause in a timely manner and quickly solving problems.

- The most harmless reason lies not in the mechanism, but in a decrease in the engine oil level. When the engine knocks when hot, in road conditions the most that can be done is to use a dipstick to find out the current engine oil level. Lack of lubrication provokes friction of adjacent parts against each other, they can be damaged, which causes the appearance of characteristic knocking sounds.

When adding oil to the required level, the knocking should stop.

- It is necessary to listen to the intensity of the knocking noises; if there is a clear increase in them, then it is better to contact a car service center and conduct engine diagnostics. If the knocking in the engine when hot is uniform and is characterized by subsidence with increasing temperature, and no visible malfunctions or problems are detected, the car can be operated for tens of thousands of kilometers before it needs to be repaired.

- The knocking noise may come from the crankshaft. If the engine is under load, and the knocking occurs with increasing force, progressing over time, then the search for the problem is narrowed to the crankshaft bearings. It is dangerous to continue driving with such a malfunction, otherwise the situation will worsen and the engine will need to be overhauled.

- A knock in a hot engine can be produced by the valves when the crankshaft speed increases and the pressure in the lubrication level system decreases at the same time. In order to get rid of the knocking, you first need to normalize the pressure in the system so that the engine functions normally. It is important to select only a motor oil whose viscosity and properties satisfy the climatic conditions of a particular region, taking into account the season.

If the oil pressure is normal and the knocking does not stop, then you will have to remove the valve covers and check the clearances. Increasing clearances is the main reason for knocking and subsequent wear of parts.

This phenomenon is typical for cars with significant mileage, where gaps appear due to long use and natural wear of parts. The gaps must be set correctly; they are adjusted using a special set of feeler gauges that are placed in the spaces between the rocker arm and the top of the valve.

- As engine temperature changes, knocking noises can either increase or decrease. The first case is due to the fact that worn parts may expand slightly when warmed up, thereby reducing the gap, and this in turn leads to the natural disappearance of the knock. This situation is often observed in the cylinder-piston group of the engine. The second case is related to the heating of the engine oil. As you know, when the engine is hot, it liquefies, which can increase knocking in the bearings of the crank mechanism. Continuing to drive a car while the engine is knocking is very dangerous. To avoid serious damage to the engine unit, it is better to call a tow truck and take the car to a service station, where specialists will identify the exact cause and immediately eliminate it.

- Sometimes knocking occurs due to the human factor. A simple example: forcing a puddle at high speed leads to water hammer, which can lead to bending of the connecting rod. It happens that the part replaced during repair had a broken geometry, was of poor quality, or was installed incorrectly. The load on such parts increases significantly, which inevitably leads to deterioration of lubrication and an increase in temperature in the area of their operation. The result is rapid wear, increased gaps, and subsequently knocking.

It is important to understand that if a car owner saves on spare parts when overhauling an engine, this will not lead to anything good. If you don’t trust the car service center, you should try to purchase spare parts yourself, choosing the original manufacturer or an analogue with a good reputation.

If, after checking the gaps of the connected parts, it turns out that they correspond to the standard, it can be assumed that the engine is knocking when hot due to intense loads, or due to long-term operation in an overheated state. As a result, strong friction of parts quickly destroys the lubricant.

Visual examination

You need to inspect the removed camshaft from all sides and study all its details. There should be no burrs, potholes, or aluminum leaks from the bearings anywhere. If the surface of the rockers and shaft cams resembles a washboard, this is undoubtedly wear. If, after removing the shaft from the bed, grooves are found on it - the same thing.

Ideally, you need to take the technical documentation for the car and measure all the gaps, but in most cases this will be paranoia. It is enough to listen and look to understand whether your camshaft is alive or not. Based on the visual data received, he develops a strategy and tactics for further actions.

If the shaft still needs to be replaced, any auto mechanic will advise you to simultaneously change the valve levers, called rockers. It’s worth heeding the advice: different degrees of production can lead to premature wear of the new camshaft. If you change it, then it will be as it should be.

What are valve clearances for?

In order for the engine to work at its best and develop all its performance characteristics to the maximum, the valves must move clearly and synchronously. The valves should fit tightly into their seats and open to the maximum.

With correctly set valve clearances, a hot engine works almost the same as a cold one, that is, the loss of power is minimal.

When the car is used a lot, for example, working in a taxi around the clock, the valves quickly lose their settings. Many people have probably heard, they say that the valves are knocking. This is just the time to adjust the valves.

Removing the camshaft

It’s not so easy to get to the bottom of it, but a possible course of action is as follows:

- The air filter is removed;

- The choke cable and gas damper drive are unlocked;

- The exposed valve cover is cleaned of road deposits. The procedure is not mandatory, but desirable, as it prevents sand, dust and other debris from getting inside the engine. The valve cover is removed. At the same time, you get a reason to follow the factory recommendations and change the gasket on it;

- star fastenings become loose

. To prevent the engine from accidentally turning over, it is jammed - for example, with a screwdriver inserted between the chain and the sprocket. The marks on it and on the crankshaft are aligned; - The chain tensioner is removed - it is secured with two tens of nuts;

- The star is carefully knocked off the guide pin. Before doing this, unscrew the bolt that secures it. To prevent the star from jumping off the chain, it is better to tie them with some kind of wire.

All that remains is to unscrew the nuts that hold the part you are looking for and pull it out. Using the folk methods described above on how to check the camshaft, a decision is made: whether it is good or not. If everything is in order with it, the spare parts are mounted in place in the reverse order. If it is bent, a new one is installed.

Why the valve on the VAZ 2106 cannot be adjusted

Then the problem would be the same with other valves.

I think so too. First we combine these marks

Then we look to ensure that the G and A marks match.

If it matches, then adjust the valves as usual. If it doesn’t match, then either the chain is poorly tensioned, the chain is stretched, or the chain is installed incorrectly.

We pull, change or install the chain correctly and achieve perfect alignment of the gear mark and the camshaft mark, the marks of the block cover and the crankshaft pulley. We do not touch the camshaft gear. By tensioning, replacing or rearranging the chain, we catch the coincidence of the lower marks. Then we adjust the valves. A nuance, if anyone doesn’t know. After the marks clearly match, we adjust the gaps, as described above, for 8 and 6 cams. Then we turn the crankshaft 180 degrees, focusing approximately (by eye) Wow! I remembered the old boy: The wolf sells salt - the hare buys. Hare: - Dear, weigh me 300 grams of salt. Wolf: - Hey, oblique, my scales are broken. Let me put some on your eyes. Hare: “To hell with the mound, you gray dog.” And we adjust the gaps of 7 and 4 cams. Another 180 degrees until the lower marks coincide and adjust 3 and 1. Once again 180 (by eye) - 2 and 5. Then another 180 until the lower and upper

marks and do not adjust, but check the gaps at 8 and 6 cams. If everything is OK, then we collect everything and start the engine. If not OK, then adjust it again.

Yes, I forgot. If new

If you don’t catch the chain and don’t align the marks, then this means severe wear of the gear teeth. We change the gears and catch again.

Source

Operating principle

The peculiarity of these shafts is their shape. So, on a regular metal cylindrical shaft there are cams and journals. The product is manufactured by casting and machining. The shaft rotates, which means it must be equipped with a bearing. The latter has the shape of a sleeve or liner. The bearing is forcibly lubricated.

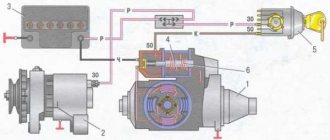

The camshaft of the VAZ-2106 rotates together with the crankshaft. But for every two revolutions of the crankshaft there is one revolution of the distributor. To transmit rotation from the crankshaft, a chain, belt, or gear drive is used. Due to the shape of the cams, gas distribution phases are formed. The inlet and outlet valves will open and close exactly at the right moment. By changing the geometry of the cams, you can improve the performance of the motor.

Through pushers, rockers (sometimes directly and through hydraulic compensators), the camshaft cam presses the valve. The last one opens. Then, as the shaft rotates, the top of the cam presses on the valve, and it opens completely and closes just as smoothly. The geometry of the cams allows for very smooth interaction with the valve lifter. The overall characteristics of the shaft also depend on the shape of the cams.

On the camshaft, the cams are cast at certain angles, due to which the gas distribution phases are formed. The phase angles may differ on different engine models. So, if we compare the gasoline camshaft of the VAZ-2106 and the diesel one, designed for driving in the city, they will be designed almost identically.

Sports camshafts will have a wider profile. This allows the intake valve to open earlier and keep it open longer. This improves dynamics, but reduces efficiency.

On more modern engines, the operation of which is controlled by the ECU, there is a camshaft sensor. It constantly monitors the position of the camshaft. This makes it possible to synchronize the fuel supply with the operation of the timing belt.

Repair and diagnostics

A faulty camshaft will cause noise during operation. Experienced specialists identify a worn bearing among the causes of noise, which requires replacement.

If there are knocks from the camshaft, then, most likely, the working surfaces have worn out and, as a result, critical backlash has formed. There are often tolerances for wear and distortion. When knocking, take measurements and see if the VAZ-2106 camshaft needs to be replaced. Installing a new one is not always necessary. Now these parts can be restored.

A decrease in pressure in the oil system can also be a consequence of critical wear of the mechanism.

Where is it located?

There are two types of motors. These are units with an overhead camshaft, as well as with a lower one. On older cars before 1950, mainly lower valve engines were installed. The camshaft was located at the bottom, the valve plates were directed upward. Motors of this design were cheaper to manufacture, but their performance was low. Then it was decided to move away from this scheme, and as a result, engineers and designers switched to the classic engine scheme with an overhead timing mechanism. However, it must be said that lower camshaft engines are still produced today.

The difference between the bottom-mounted internal combustion engine and the traditional one is that the timing mechanism additionally has rods to compensate for the distance from the shaft cams to the valve tappets in the cylinder head.

Timing gears

This is worth talking about separately. The gas distribution mechanism requires very precise gear adjustment. Often it is enough to align the gears according to the camshaft marks on the VAZ-2106. But for more precise adjustment there is a special split gear. The teeth in it are fixed with bolts to the base. If the bolts are unscrewed, the position of the gear can be adjusted up to 10 degrees. You can find its most optimal position.

More expensive cars have modern engines where this process is automated. Instead of a camshaft gear (as on the VAZ-2106), hydraulically controlled clutches are used. The sensor knows the current shaft angle as well as the engine speed. In this way, the gas distribution phases are adjusted for different engine operating modes.