High-quality operation of the lighting system plays a vital role for comfortable driving at night and in bad weather conditions. However, even with fully operational equipment, the amount of light can be significantly reduced due to contamination of the head optics. A headlight washer was developed specifically to solve this problem, which allows you to remotely clean the lights without leaving the car and without interrupting the movement. The presence of a washer becomes especially important when using xenon headlights.

What is a headlight washer in a car?

Modern cars are constantly being improved and strive to be as comfortable and safe as possible for drivers. One of these developments to increase driving convenience and safety is a washer, which is necessary to clean the headlight lens from dirt, dust and insects.

BMW standard headlight washer

The driver can activate the function while driving and improve the quality of light by cleaning the headlight lens.

The washer looks like a smaller windshield cleaner (in the case of a brush type). More modern models (jet) are made in the form of small pads under the headlights, which extend after receiving a command from the driver. Install the washer in close proximity to the optics. Depending on the type of design, the device may be hidden in the inside of the car's bumper and activated only after pressing the headlight washer button. There is also a stationary installation option, when the system nozzles are located on the outer surface of the front bumper.

What types of headlights is it used on?

The washer is required to be installed on cars with xenon headlights. For halogen it is available as an option. The fact is that halogen and gas-discharge lamps have the same principle of directing light. But xenon has a stronger luminous flux. The presence of dirt or frozen ice on the headlight leads to scattering of the light beam.

Halogen bulbs simply lose their brightness and deprive the driver of high-quality illumination of the road surface, while xenon can blind oncoming cars, creating emergency situations. Therefore, for cars with standard xenon, a washer system must be installed.

Common Manufacturers

HELLA

Unconditional advantages:

- equal cleaning of low and high beam headlights;

- Possibility of installation on any car;

- service life is designed for 10,000 cycles or 1 year of operation;

- low consumption of cleaning fluid;

- operability over a wide temperature range;

- German quality, development and assembly.

There are two types of washers:

- Stationary. The nozzles are motionless, open and not protected from external factors. They can be mounted on any type of car.

- Retractable. After pressing the button, they move out, release a stream of water and move back into place. The injectors are well protected and do not spoil the appearance of the car. Installation on bumpers not specified by the vehicle manufacturer is difficult or impossible.

SCYTHIAN

There are four modifications of SKIF washers:

- 12P. Installed on cars with a flat bumper, at an average distance between the bumper and the center of the headlight. The insertion is carried out flush with the surface of the bumper. The model is simple, reliable, efficient.

- 12V. The model was created for SUVs, the nozzles are high, capable of “finishing off” a stream of water to the headlights.

- 12-N. Designed for cars with curved flat or spherical bumpers. A special rubber band levels out the curvature of the bumper. Also suitable for SUVs.

- 12-C. Suitable for cars with a spherical bumper or located at an obtuse angle relative to the headlight.

Sho-Me

The product has a number of undeniable advantages:

- A special feature of the design is a powerful pump that allows liquid to be supplied to the nozzles under high pressure. A strong jet knocks dirt off the headlights, cleaning them.

- The pump is connected via a hose to the standard car reservoir, so there is no need to install a separate container for headlight washer fluid.

- Easy to install.

- Reliable relay.

- Versatility, allowing you to choose the type of nozzles for any bumper shape - flat, rounded, off-road.

- Officially certified for installation using xenon.

- It does not spoil the appearance of the car, since the nozzles are small and invisible, and the cleaner is placed inside the engine compartment with a control button leading into the cabin.

There are three types of headlight cleaners from Sho-Me:

- OFS-1D. Designed specifically for SUVs.

- OFS-1P. Suitable for vehicles with flat bumpers.

- OFS-1S. Mounted on cars with a spherical (rounded) bumper.

Types of washers

Depending on the design of the washer, there are:

- brush;

- and inkjet devices.

The difference between them lies in the principle of glass cleaning and the elements that make up the system.

A brush washer is like a smaller size glass cleaner. Water is supplied to the glass under slight pressure, and a special brush washes away dirt using mechanical cleaning. The device is installed for glass diffusers, since plastic is too sensitive to this procedure.

Brush headlight washer

Jet washer is installed on most modern cars. The principle of operation of the device is to supply washing liquid to the headlight lens under high pressure. The quality of cleaning depends on the distance between the nozzle and the optics, the volume of detergent and the degree of spray.

Jet headlight washer for Tiguan

The jet washer is also called a retractable washer because it is located entirely in the body of the car's bumper. The elements of the feed system are visible only after it is put into operation.

Classification of design control systems:

Automatic - triggered by holding a special lever for a specific period of time. Most often used in jet washers.

Forced - involves manually turning on the washer using a button specially designed for this, which is located on the dashboard of the vehicle. Thanks to the use of a forced system, the driver can easily control the volume of washer fluid. An obvious disadvantage of this system is that it can distract the driver’s attention during fast driving.

Design and principle of operation

The design of the headlight cleaning system resembles a windshield washer in the number and type of elements used. The main devices included in it:

- Tank with cleaning fluid. Provides up to 25 operating cycles. During one activation, the system uses up to 200 ml of detergent. The total tank capacity is 2.5 liters for one and 4 liters for two nozzles.

- Motor. Used in a telescopic system to move the nozzle.

- High pressure pump. Designed to supply detergent to the nozzles.

- Nozzle block. Provides liquid spray onto headlight lenses.

- Connecting hoses.

- Control block. Controls the optics cleaning process.

Components of a high-pressure jet headlight washer

The operating principle of a headlight washer is quite simple. It can be divided into three main stages:

- opening of linings with nozzles;

- watering the headlights with cleaning fluid;

- return to standard position.

The driver activates the cleaning function, putting the system into operation. After this, the process of rinsing the glass with washing liquid under high pressure begins. The control unit commands the motor to extend the nozzles. The liquid is supplied from the tank using a high pressure pump. Connecting hoses transfer the detergent to the nozzles, after which it is sprayed onto the diffuser. When the process is completed, the motors return the device to its original position.

Types of nozzles

Depending on the installation method, the nozzles are:

- stationary;

- telescopic.

Stationary ones are installed directly on the car bumper. This is a simple device in design and design, which is characterized by reliable operation. The only drawback is that the injectors are always visible.

Static nozzles

Telescopic nozzles are installed inside the bumper, leaving a special hole for outward movement. When the cleaning system is activated, a special motor pushes out the elements, adjusting the spray range and angle. Although the basic principle of how both types of injectors work is very similar, telescopic units are more popular due to their ability to be integrated into the bumper.

Telescopic nozzles

Kit selection

And so, your car does not have a headlight washer system from the factory. It's okay, this is a fairly common phenomenon that many people struggle with with their own hands. That is, the corresponding device is installed independently

By the way, washers are an important component when installing xenon and bi-xenon cars.

Some recklessly try to simplify the scheme by using a pump from a windshield washer designed specifically for the windshield as a headlight washer. In practice, this is a dubious solution, since in reality the efficiency will be too low. The liquid will be supplied under slight pressure. Therefore, the equipment will not be able to cope with dried or frozen deposits. The only solution is to turn on the windshield washer for a longer time. But in the end, you will still have to spend extra money on constantly topping up washer fluid.

If you want your headlights to be cleaned quickly and efficiently, you will need to organize a system using a high-pressure pump.

Lucky are those who have such a device installed on their car from the factory, but it is not specifically included in your configuration. This makes it possible to buy the original kit. It will be extremely easy to connect, since the design places for installation are already provided. The only problem will be the high cost, because of which not everyone decides to buy factory kits.

Therefore, more often the choice falls on universal kits. They are divided into 2 categories:

- Telescopic. Before turning the devices on or off, the special spray nozzles included in the headlight washer kit begin to extend and then slide back out of the holes made in the bumper. As a result, the washer fluid is supplied under pressure through the nozzles, and the process of cleaning the surfaces begins. Upon completion of cleaning, they return to their original position, hiding in the bumper;

- Jet. Everything is a little simpler here. Sprayers or nozzles are simply mounted on the bumper. The location and distance are chosen so that the liquid pressure falls directly on the headlights, while maintaining a sufficiently high pressure. They are static, do not hide anywhere and do not fold. That is, the sprayers always remain visible.

What should you choose? Let's talk about this further.

Jet vs telescopic

Judging purely by external characteristics, then the objective advantage is on the side of telescopic devices. They look more original and more expensive.

But in terms of operation, inkjet ones are better. Or rather simpler. In winter, the cover that covers the telescopic nozzle may become covered with a layer of ice. Because of this, it self-locks and does not extend. Plus, the mechanism can jam during active use due to low temperatures. If the cap becomes blocked, the pump will still supply fluid at high pressure. Excess pressure, due to the fact that there is pressure, but the liquid does not come out, the hose can break, and the entire washer fluid will leak out. Plus, retractable options are more difficult to install, since they require an individual bracket.

But when it comes to connecting to a power source, there is no difference between them. So here you can choose any option you like.

A fairly impressive number of universal headlight washers are offered for sale, which differ in appearance, design features and installation nuances. Among the manufacturers, the most popular are Skif, Sho-Me and Hella.

Having visited Drive2 and a number of other thematic resources, I noticed that most often universal headlight washers are installed on such cars:

- Nissan Qashqai;

- Toyota Avensis;

- Toyota Corolla;

- Mitsubishi Pajero;

- Volkswagen Jetta;

- Mazda 3;

- Mazda 6;

- UAZ Patriot;

- Chevrolet Lacetti;

- Chevrolet Cruze;

- Mitsubishi Lancer;

- Skoda Octavia;

- Mitsubishi Galant, etc.

You can look for suitable washers for yourself in the nearest car stores, or just go to Aliexpress. Although it is not recommended to buy frankly cheap Chinese kits. Otherwise, you will soon need a replacement, or you will already be thinking about how to remove these devices.

How does the washer turn on?

Depending on the vehicle, there are two ways to control the system:

- automatic;

- manual.

The device operates without driver intervention after activating the glass wiper and turning on the low beam. This option is considered economically unprofitable because it consumes a large amount of liquid.

Premium segment cars are equipped with an intelligent control system. The electronic unit analyzes the frequency of activation of the glass cleaner and, based on the information received, washes the headlights.

The most convenient and economical option is to use a button on the instrument panel. During manual operation there are no problems with how to turn the headlight washers on or off, and the cleaning fluid is used only when necessary.

Standard universal set

Typically, a standard car headlight washer kit consists of the following components:

- hoses;

- pump;

- tee with valve;

- power unit;

- connectors;

- wires;

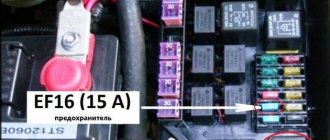

- fuse;

- adjusting key;

- clamps;

- self-tapping screws;

- relay;

- control button;

- seals;

- installation and power connection diagram.

Can be connected to the windshield washer reservoir system. But then you will have to make a hole in it. Or take a new tank separately and install it in the engine compartment.

Main disadvantages

Despite the simplicity and obvious need to use headlight washers, car owners also note a number of disadvantages:

- Poor cleaning properties at high speeds.

- Increased consumption of detergent.

- Constant problems with how to turn on and activate the headlight washers in winter. The device does not operate correctly and may not fully return to its original position.

If the washer fluid is frozen, it is recommended not to use the cleaning system. Otherwise, the driver risks breaking the device due to the increased load on its elements.

The use of a headlight washer made it possible to simplify the process of cleaning the optics and improve visibility on the road without driver intervention. Although the solution does not directly affect traffic safety, it increases the operating comfort of the vehicle. We can only hope that in the future the shortcomings with the operation of the system in winter and the high consumption of washing liquid will be eliminated.

DIY installation instructions

You can install the headlight washer yourself. The work will not take much time and will not require special tools.

Required tools and materials

The working set includes:

- pump;

- hoses;

- nozzles;

- wiring;

- relay;

- fasteners;

- buttons.

Additionally, prepare masking tape, a cutter or drill, fine sandpaper, and a fluid reservoir.

Sequencing

Work order:

- The installation of the washer begins with the installation of nozzles. To do this, mark the holes for the holes with masking tape. The nozzle should be located in the center of the head optics - this guarantees maximum coverage of the glass area with the water jet.

- The hole is created using a cutter or drill. Drilling should be done from the outside of the bumper, otherwise the coating may swell.

- The sharp edges of the plastic are treated with sandpaper.

- Nozzles are inserted into the holes, then tubes are connected to them. Both tubes are laid towards the tank, where they will be connected to the pump through an adapter.