Almost all car engines require valve adjustment. The valve adjustment procedure involves setting the gaps between the valve and the pusher. On engines where the thermal valve clearance is adjusted manually, this must be done at certain intervals. This requires a certain skill, so engineers came up with automatic gap adjustment. But there are also problems with this technology - this is the knocking of hydraulic compensators, which will be discussed today.

A hydraulic compensator is a device that allows you to automatically set the gap between the valve and the engine pusher. It is a metal cylinder containing a spring and a check valve.

The principle of operation is to change the length of the hydraulic compensator cylinder to the entire length of the timing gap. This device operates from a return spring and oil pressure.

The hydraulic compensator is a simple cylindrical device that consists of plungers, a reverse valve and a spring.

The huge advantage of hydraulic compensators is that they automatically adjust valve clearances and relieve the car owner from this procedure. But in addition to the advantages, there are also disadvantages of this technology. The main one is a knocking sound when cold or hot in case of a malfunction.

How do hydraulic compensators knock?

The knocking sound of hydraulic compensators resembles a clatter, very similar to the clatter of a loose chain. It comes from the cylinder head. From its top. The knocking of expansion joints can occur when it is cold or hot, or it can always be present, depending on the wear of the expansion joints.

As we know, the operation of hydraulic compensators is directly related to oil. When the engine is cold, the oil simply has not yet entered the hydraulic compensators, so the engine may make a characteristic clicking noise for some time. But after a short time, if there are no other prerequisites, the knocking will disappear.

This symptom is very clearly observed on domestic classic engines that are installed in Nivas of recent years of production. At one time, the happy owners of these engines wrote a collective letter to the VAZ company and demanded a recall company.

Oil is changed during maintenance for a reason

In case of prolonged operation of the vehicle without changing the oil, the following situations may arise that cause knocking of the hydraulic compensators:

- channel contamination

- oil loses its qualities

In the first case, the knocking will occur when the engine is cold. The oil supply channels are clogged and therefore it is impossible to create the required pressure in the hydraulic compensators. As the oil warms up, deposits peel off and oil flows throughout the entire system. After cooling, all the dirt will sit on the walls and re-clog the channels. This will cause a knocking noise every time the engine warms up.

If the oil has lost its qualities due to age, it may begin to foam. Such oil is not capable of creating the necessary pressure and its prolonged presence in the engine will lead to significant damage.

If the oil is old, it must be replaced. You should not immediately fill in expensive oil. It contains high-quality detergent additives that can remove dirt from the walls. This will lead to even more clogging of the oil system channels. Therefore, before filling in good oil, after prolonged use with old oil, it is necessary to flush the system with a special product.

Causes of knocking hydraulic compensators

The main reasons for knocking hydraulic valves include two malfunctions:

- mechanical parts of the hydraulic compensator

- engine supply oil to hydraulic compensator

Mechanical faults include:

- Wear and wear of the plunger spring. Most often this is natural wear and occurs due to the fact that the camshaft lobes leave wear on the surface.

- Clogged hydraulic compensator. Namely, a clogged valve that is responsible for the oil supply. As a result of this malfunction, the hydraulic compensator begins to stick.

- Airing. Occurs when there is insufficient oil supply to the mechanism.

- Carbon deposits and contamination of the main elements of the hydraulic compensator. Occurs when using low-quality oil or additives.

Malfunctions in the oil supply to the hydraulic compensator can be caused by:

- Oil filter malfunction.

- Low oil pressure

- Wrong oil viscosity, or wrong oil

- Overheating of the engine, as a result of which the oil loses its properties.

As mentioned earlier, knocking on hydraulic compensators is possible both hot and cold.

When the engine is well warmed up, a distinct knocking sound from the hydraulic valves appears, which means that there is a problem with the oil. Perhaps the oil has already lost its properties and requires replacement. Or you have filled in oil that is not suitable for your engine according to the regulations. The possibility of a clogged oil filter is also possible.

Changing the oil and oil filter can help in this case. If the knocking noise persists when hot, it is worth diagnosing other engine components. Perhaps the problem is with them.

As for knocking when cold, there is no need to worry; almost always this knock is not critical.

Noise appears after replacing expansion joints

Another reason for the knocking of compensators is their malfunction, since they need to be changed periodically. Most often this becomes the main reason. If you are replacing a hydraulic compensator, it is recommended to replace the entire set. There is no guarantee that all expansion joints are in good working order and do not create a lot of noise. If the knocking does not disappear after replacement, then you need to find the cause in other external factors.

Most often, new expansion joints do not knock. However, if the knocking continues, then the parts may be defective, or they were not the cause. To make sure that the matter is completely different, you need to check their fastening. Perhaps the parts could not give the necessary shrinkage and create a similar sound. To eliminate the knocking, you need to tighten them, and the knocking should stop. If the knocking does not go away, then you need to go to a car repair shop.

What to do if hydraulic lifters are knocking?

First of all, you need to determine which hydraulic compensator is knocking. For mechanics, determining which hydraulic compensator has failed is usually not difficult. Yes, you can do it yourself. It's simple.

To do this you need to remove the valve cover. You will also need a device called a phonendoscope.

A phonendoscope is a device with a long needle at the end and headphones.

If this device is not at hand, you can try using a stethoscope. I think you already understand the point, you need to listen to where the knocking is strongest, this way you can determine which hydraulic compensator is acting up.

If you find a faulty hydraulic compensator, you can try to eliminate the knocking by cleaning. To do this, you need to disassemble it and wash it in diesel fuel or kerosene. In some cases, this helps eliminate knocking. If not, then unfortunately you will have to change it. Their cost is not that high and it is better to do it as quickly as possible, because otherwise the consequences can be dire.

Choosing the right oil

As we have already figured out, hydraulic tappets can make knocking noises due to poor quality oil. Choosing one that is only suitable for your car is quite difficult. When selecting, it is recommended to read its instructions. It is quite possible that it has the same thickness, but different lubrication properties. This directly depends on the amount of different additives in the oil. You should definitely check the certification of the oil you purchased for your car’s engine brand.

An important point is to select the right brand of oil, otherwise you will have to replace other engine elements, not just hydraulic compensators. Before changing the oil, it is recommended to consult an engine specialist.

Is it possible to drive with knocking expansion joints?

As mentioned earlier, this malfunction cannot be triggered. Dead hydraulic compensators have a very negative impact on the entire gas distribution mechanism drive. Repairing it is very expensive. Also, the knocking of hydraulics leads to faster wear of all cylinder head elements.

Disadvantages of hydraulic compensators

In addition to all the listed positive qualities of this wonderful technology, it has several significant disadvantages.

- There is almost always a knocking sound from hydraulic compensators when the engine is cold.

- Hydraulic compensators do not work well at high speeds.

We changed the hydraulic compensators and they still knock

The knocking sound of new hydraulic compensators after replacement may not always be associated with their malfunction or defect. As mentioned above, the operation of these devices depends on oil. If the new compensators are not filled with oil, they will tap for some time until they are filled.

When installing hydraulic compensators, experts recommend filling them with oil to avoid them running dry.

In order to avoid problems with hydraulic compensators, regular oil changes are necessary, here you can find out about this - how often you need to change the engine oil.

Undoubtedly, the technology of using hydraulic compensators is very convenient. It is used by many different manufacturers in engines for both the budget and premium segments. But some still use manual valve adjustment technology, such as Honda. This is due to the fact that their engines are high-revving, and as we said earlier, hydraulic compensators, there is also very little space in the gas distribution mechanism, since in most cases the proprietary Vtec technology is used there and there is very little space for hydraulic compensators.

Why do you need hydraulics?

The valve and camshaft are in constant contact with each other. The problem is that when the engine heats up, the linear dimensions of the parts change. A miniature thermal gap appears at the point of contact. Its size is 0.1–0.2 millimeters.

The appearance of a thermal gap between the valves and the camshaft leads to knocking noise occurring at high speeds and loads. The opening timing of the valves is disrupted and engine power may decrease.

When designing, engineers build a thermal gap into the structure to minimize its size. But still, it is not possible to completely eliminate it in all modes of engine operation.

For older models of power units, every 10 thousand kilometers it was necessary to manually adjust the thermal gap. The car owner picked up a set of feeler gauges and inserted thin plates between the camshaft cam and the valve. Without this, it was impossible to ensure normal operation of the motor.

The urgent task is to minimize manual adjustment. This is how hydraulic compensators appeared.

What to do if the hydraulic compressor is knocking: let’s understand the reasons

According to the laws of physics, metal expands when heated and contracts when cooled. When assembling the gas distribution mechanism (GRM) of an internal combustion engine, this property is taken into account, and the parts are assembled with clearances. The size of thermal gaps is set by the manufacturer and entered into the vehicle passport.

As parts wear, clearances require adjustment and periodic inspection. Deviation of technological clearances from the established norm affects engine operation:

- When the gap decreases or disappears, the tightness is broken (the valve does not close completely), which reduces compression in the engine cylinder and leads to a drop in power.

- If the thermal gap is greater than the permissible value, then accelerated destruction of the parts of the intake and exhaust timing valves occurs. The characteristic knocking of valves when starting the car and on a warm engine indicates an increased clearance.

What is a hydraulic compensator

1.Device. A piston (plunger) is inserted into the cylindrical body of the compensator, resting against a rigid so-called return spring, and a bypass ball valve with a pressure spring is mounted in the piston itself. The lock washer holds the movable plunger together with the filling in the compensator body.

Hydraulic compensators differ from each other depending on their installation location in the gas distribution mechanism:

- If compensators are installed in special sockets in the cylinder head, then the body of the hydraulic pusher is made movable relative to the seat.

- If a hydraulic compensator is installed in the valve rocker arm sockets, the body is stationary, and the plunger has freedom of movement.

2. Operating principle. The hydraulic compensator increases or decreases its size due to the flow of oil and the synchronous operation of the springs and valve. Structurally, the compensator is connected to the camshaft, intake and exhaust timing valves and maintains the specified thermal clearances necessary for proper engine operation. At the same time, it also takes into account its own temperature changes.

Why is the hydraulic compensator knocking?

A faulty compensator makes short, sharp and frequent sounds, similar to metallic crackling. Since the working medium of the hydraulic compensator is engine oil, its quality affects the durability of the device.

1. Causes of knocking compensators related to engine oil:

- The use of so-called dirty oils, in which there are insufficient detergents and dirt-retaining additives, and the acidity level is higher than alkaline. The heating temperature of timing parts reaches 800⁰C. Poor quality oil leads to the formation of carbon deposits, which disrupts the operation of the moving parts of the compensating device.

- The engine oil level is below (above) normal. If the oil is more than normal, then as a result of oil foaming in the crankcase, air gets into it. If the level is low, the oil pump is entraining air as it supplies oil to the hydraulic compensator. The knocking noise is heard only at high engine speeds, and is absent at idle and low speeds.

- Oil pump malfunction. Oil flows slowly or not at all to the hydraulic compensator.

- Untimely replacement of engine oil and oil filter. Dirt in the oil leads to clogging of the gaps between the body and the plunger, “sticking” of the ball in the valve seat and, as a result, to loss of mobility of the plunger.

- Clogged oil passages of the cylinder head.

When applying for compulsory motor liability insurance, you will be required to provide a vehicle diagnostic card. What is it and where to get it - see our material.

Our other article will tell you how to defrost the washer reservoir in several simple ways.

2. Mechanical causes of knocking:

- Check valve malfunction. The hydraulic compensator knocks when cold, immediately after starting the engine, but the sound disappears as the speed increases. The same thing happens on a warm engine, when the knock disappears when you press the accelerator pedal.

- Defects in the surfaces of the body and plunger (scores, dents, gouges). A characteristic knock is heard regardless of the speed of rotation of the timing camshaft.

- Wear of the plunger pair. In this case, the knocking noise appears when the engine is warmed up. When the engine has cooled down again, there is no knocking noise.

What are the consequences of operating an engine with faulty hydraulic compensators?

The knocking of compensators is a signal that the thermal clearances in the timing system are not respected, although at first there is no danger to the engine. It’s a different matter if you don’t take any action and continue to use the car for a long time. In this case, breakdown of the gas distribution mechanism is inevitable. The camshaft cams and associated timing parts are the first to suffer from the resulting shock loads when starting the engine.

Design and principle of operation

Over time, engineers developed automation that eliminated the thermal gap. It was called a hydraulic compensator. From the name it follows that the device is intended for compensation. The prefix “hydro” indicates that liquid is used inside. Hydraulics are installed between the valves and the camshaft. In most cases it looks something like this:

Hydraulic compensator device

The operating principle is simple. When the camshaft cam rises, oil is supplied to the accumulator. Then the cam presses on the piston and the fluid allows the pressure to be contained due to the check valve. Excess oil leaves the cylinder and the cycle repeats. While everything works like a clock, there is no extraneous noise. But when a malfunction occurs, a knocking noise occurs.

How to eliminate knocking hydraulic compensators

If the hydraulic compensator is worn out or mechanically damaged, it is replaced with a new one. In other cases, all parts of the compensator are disassembled and washed. The check valve seat is cleaned with a wooden peg from adhering dirt and carbon deposits. If the malfunction of the hydraulic compensator is associated with poor performance of the engine lubrication system, then perform the following actions:

- Changing the oil and oil filter. When choosing oil, preference is given to synthetic and semi-synthetic oils of high quality with low viscosity and detergent additives.

- Checking the operation of the oil pump. If a malfunction is detected, it is repaired or replaced.

- Cleaning the oil passages of the cylinder head. The channels are flushed with gasoline using a compressor.

Repair

Not every hydraulic pusher can be restored to working condition. But sometimes the replacement period can be noticeably delayed. Sometimes you can't do without it. The spare parts catalog does not always contain the required item. There are at least 3 ways to extend the life of the pusher:

- Mechanical cleaning. It will take time and considerable skill to disassemble the cylinder head and remove the hydraulics. But the result will be noticeable immediately. No need to pour chemicals into the engine.

- Changing the filter and oil. During the procedure, the system should be flushed in the traditional way. To do this, you need to fill in the flushing lubricant, hold it, drain and fill the system with regular oil.

- Application of flushing compounds. There are two popular options: Liqui Moly Hydro-Stossel-Additiv and BG103. You need to do everything strictly according to the instructions. Otherwise there will be no effect.

Flushing with Liqui Moly

The second and third options will help to revive hydraulic compensators if the oil channels are clogged. Other types of faults will have to be dealt with point by point. Hydraulics knock when mechanical damage occurs due to a disruption in the circulation of lubricant in the system. The situation can be corrected, but this requires proper diagnosis and repair.

Video guide to eliminating the knocking of hydraulic compensators

See how you can cure old hydraulic compensators

The use of hydraulic compensators reduces fuel consumption and increases timing life. The engine runs quietly and produces maximum power. The manufacturer guarantees reliable operation of hydraulic compensators for 30 thousand kilometers, after which it is recommended to replace them. In reality, expansion joints may fail sooner or last longer, depending on the oil used in the engine. Increased requirements for oil quality are the main and only drawback of hydraulic compensators.

How to get rid of the knocking of hydraulic compensators with your own hands

Increased engine noise may indicate the presence of serious malfunctions, which can lead to complete inoperability of the unit.

The knocking of hydraulic compensators when cold does not belong to this category, but if this part is not adjusted, the engine will consume more fuel, develop less power and the comfort of driving the car will sharply decrease. The wear of the piston group will also increase due to incorrectly selected gaps in the gas distribution system.

This article will tell you in detail how to eliminate the knocking of hydraulic compensators, as well as how to do this work efficiently and with minimal time and financial costs.

Knocking of hydraulic compensators: reasons

To understand how to get rid of the knocking of hydraulic compensators, you need to have a good understanding of the operating principle of these parts. The thermal expansion of the metal as a result of heating was the reason for the invention of this type of mechanism.

In old-style cars, instead of hydraulic compensators, adjusting bolts were installed, with the help of which the thermal gap was manually adjusted. This method of eliminating increased gaps in the gas distribution system required the car owner to spend a significant amount of time and money, because the need for manual adjustment arose every time the car traveled 10 - 15 thousand km.

In modern cars this function is fully automated using small inserts between the rocker arms and the valve stem. The operating principle of this part is quite simple:

- Oil from the lubrication system enters the cylindrical cone of the compensator under pressure when the camshaft cam does not apply pressure. Inside the part there is a plunger pair, with the help of which the filling of the internal cavity with oil is regulated until the moment when the pressure part of the mechanism extends to a distance that completely compensates for the existing gap between the part and the valve stem.

- At the moment when the camshaft rotates to the angle required to start applying pressure to the valve, the oil supply is shut off and, taking into account the fact that oil is a practically incompressible liquid, the compensator maintains the required length and transmits the force from the camshaft to the valve stem without delay.

- After the valve returns to the closed position, the entire cycle of operation of the hydraulic compensator is repeated again.

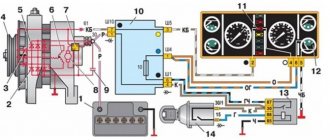

Click on the picture to enlarge

Considering the fact that the internal volume filled with oil can vary depending on the size of the gap, it is possible to completely avoid delays in valve opening and, as a result, increased noise of the gas distribution mechanism.

Unfortunately, hydraulic compensators, like any car part, can fail. A malfunction of this part will inevitably lead to the formation of a characteristic knocking sound during engine operation. Most often, hydraulic compensator noise is caused by the following reasons:

- Wear.

- Manufacturing defects.

- Internal valve jammed.

- Air in the internal cavity of the part.

- Valve mechanism clogged.

All parts of the car are subject to wear, including hydraulic compensators. Therefore, if the car is many years old, it may require a complete replacement of all elements.

Factory defects are not common, but such a malfunction occurs in the first months of car operation. If this reason for the inoperability of hydraulic compensators is identified, repairs are usually carried out at the expense of the manufacturer.

Jamming of the internal valve can occur if low-quality oil is used or non-certified parts have been installed. This malfunction can be eliminated by replacing parts or cleaning them.

Air can enter the internal cavity of the hydraulic compensator if the oil level in the engine crankcase is too low. Also, such a nuisance can await the driver if the oil line through which the oil is supplied is clogged with various deposits.

If the hydraulics are knocking, then it is not necessary to contact specialized workshops to eliminate the problem. You can completely get rid of the noise of hydraulic compensators yourself, if you have minimal knowledge and skills in repairing and servicing internal combustion engines.

Once the causes and consequences of the noise are clear, you can begin to troubleshoot the problem.

Methods for eliminating increased noise of hydraulic compensators

There are several effective ways to eliminate the knocking of hydraulic compensators. One of the most budget-friendly options is to clean these parts.

To perform this operation you must:

- Remove the engine valve cover.

- Remove the rocker arm axles.

- Remove the hydraulic compensators.

- Clean the outside of the parts with a non-natural bristle brush.

- Place each part one by one in a container with kerosene and press the ball valve and plunger several times with a wire.

- At the next stage, the hydraulic compensators are placed in a second container with clean kerosene, after completely removing the liquid remaining from the previous flushing.

- At the third stage, it is necessary to check the performance of the hydraulic compensators by adding flushing fluid to them. After which the part is held in a vertical position, with the plunger facing upward. If you press the plunger with your finger, it should not move, and no flushing liquid should be released from the internal cavity of the hydraulic compensator.

After checking the functionality, the parts are installed back, and after installing the rocker arms and valve cover, the engine is test run.

Despite the apparent simplicity of restoring the functionality of hydraulic compensators in this way, the time required to perform such an operation will be very significant.

In some cases, it is possible to eliminate indiscriminately the increased noise of hydraulic compensators.

In order to clean parts without removing them from the engine, you must:

- Remove the intake manifold and fill each cylinder with decoking fluid.

- Crank the engine with the starter.

- Remove the valve cover and spray the hydraulic compensators with carburetor cleaning fluid.

- Leave the car for 2 hours.

- Install the intake manifold and valve cover.

- Start the engine.

It is necessary to keep the engine speed at a high level for several minutes until dark smoke comes out of the chimney. If the knocking of the hydraulic compensators does not appear when hot, then the car can be operated in normal mode.

This method of troubleshooting is the simplest, but it allows you to restore the functionality of hydraulic compensators only if the parts are slightly contaminated. If the engine oil was not changed on time, then the hydraulic compensators can only be cleaned using the first method using special fluids.

Additives and fluids for flushing hydraulic compensators

Replacing hydraulic compensators in a car repair shop is too expensive, so many motorists, trying to prevent the formation of dangerous deposits in the engine oil line, use special additives.

The most popular and inexpensive means used for this purpose:

LIQUI MOLY

Stop the knock of Liqui Moli hydraulic compensators, reviews of which are even published by reputable automotive publications.

It is a high-tech additive to oil, which significantly improves its lubricity, cleans the smallest channels of hydraulic compensators, and eliminates oil deposits on the walls of the line.

The additive can be used for both gasoline engines and diesel units with or without turbocharging.

Hado

Restoration additives from a famous Ukrainian manufacturer of automobile oils. The products are not inferior in their effectiveness to the Liqui Moly additive.

Wagner Windigo

German additive for hydraulic compensators.

The product copes well with its function when used in engines that already have problems with the operation of these parts, and also serves as a good preventive measure.

Any of the listed additives allows you to do without complex and lengthy cleaning by washing the parts, of course, provided that the hydraulic compensators are suitable for further use. If the malfunction is caused by excessive wear of parts, then it is necessary to purchase and install new products.

Debugg

Among experienced motorists, the most dangerous cases are when the tapping does not stop after the engine warms up or the sound increases noticeably when entering operating mode. Finding and troubleshooting engine problems in such a situation is more difficult, since, unlike the option with a cold internal combustion engine, the range of potential causes is much larger.

Before troubleshooting, you will need to clearly determine the location, because there are different types of noise. It is worth considering that when the engine is warmed up, possible oil deposits in the channels soften and have the ability to move, accumulating in some place and thus clogging the channel. It will be necessary to carry out preventive measures:

- hydraulic compensators are being replaced;

- the used oil is drained and new fluid is added;

- it is necessary to clean the engine after partial or complete disassembly;

- The dirty oil filter is removed.

One of the restoration measures is flushing. The motorist can carry it out independently. Before washing the hydraulic compensators, it is necessary to remove them from their seats by removing the rocker arm axles.

Next, immerse the parts in a deep container filled with kerosene or diesel fuel. Gasoline will also work. We clean the parts one by one from contaminants by pressing the valve ball and moving the plunger. We continue the movement until the move becomes as easy as possible. We repeat the operation with each part in a new container filled with a cleaner washing liquid.

After cleaning, we return the HA to its place. Assembly is carried out in the reverse order of disassembly.