03/04/2022 1,776 Electrical package

Author: Ivan Baranov

Every car has power windows (SP). Today, almost all modern vehicles are equipped with electric SPs, allowing you to open and close windows at the touch of a button. What elements does the window lift mechanism consist of and what is its operating principle? We will give answers to these questions below.

[Hide]

Electric window device

Window lifters first appeared from the German manufacturer Brose in 1928, and their operating principle was based on a mechanical drive. The first automatic window lifts were developed in America in 1940, using an electro-hydraulic mechanism. Since then, the design has undergone a large number of changes in dimensions, operating principle and drives used.

Window regulator installed in the door body

The end result of the developments was electric windows, which are now installed in all vehicles. The device is used to automatically raise and lower car windows. Electric windows do not affect driving safety, but significantly increase the convenience of passengers and the driver.

Massive demand for electric lifts has made the option quite economical and affordable.

The history of the appearance of electric windows

The first mechanical window lifter was developed by engineers of the German company Brose in 1926 (a patent was registered, but the device began to be installed on cars two years later). Many automakers (more than 80) were clients of this company. The brand is still engaged in the manufacture of various components for car seats, doors and bodies.

The first automatic version of window lifts, which had an electric drive, appeared in 1940. Such a system was installed in the American Packard 180 models. The operating principle of the mechanism was based on electrohydraulics. Of course, the design of the first development was large and not every door allowed the installation of the system. A little later, the Ford auto brand began offering an automatic lifting mechanism as an option.

Premium limousines and 7-seat Lincoln sedans, produced starting in 1941, were also equipped with this system. Cadillac is another company that offered its car buyers a window lift in every door. A little later, this design began to be found in convertibles. In this case, the operation of the mechanism was synchronized with the roof drive. When the top was lowered, the glass in the door automatically hid.

Initially, convertibles were equipped with a drive powered by a vacuum booster. A little later it was replaced with a more efficient analogue, powered by a hydraulic pump. In parallel with the improvement of the existing system, engineers from different companies developed other modifications of mechanisms that ensure the raising or lowering of glass in doors.

In 1956, the Lincoln Continental MkII appeared. This car was equipped with power windows driven by an electric motor. This system was developed by Ford auto brand engineers in collaboration with Brose specialists. The electric type of window lifts has established itself as the simplest and most reliable option for passenger cars, which is why this modification is used in modern cars.

Design features

Automatic window regulators are made up of a number of electrical and mechanical components that control the position of the glass. The actuators are installed inside the door. The structural elements include:

- control unit - receives commands from the driver and passengers and generates control signals for the operation of the lifting mechanism;

- drive - an actuator that consists of an electric motor, gear and worm gear, combined into one module;

- lifting mechanism - connected to the glass and directly performs the work of moving.

Window lifter control unit

For control, special buttons are used that are installed on the doors. To lower or raise the glass, just press or lift the button. Each door has its own control, but only the driver can operate the front and rear power windows.

Correctly removing the window lifter

There should be no problems with how to remove the window regulator. Because everything is simple here:

- we use a screwdriver, unscrewing the fasteners that hold the casing;

- remove the protective film;

- unscrew the motor;

- disconnect the unit, after which the glass should move easily from hand pressure;

- Unscrew the remaining fasteners on the window lift mechanism.

The glass must be supported and removed carefully to prevent it from breaking, cracking or chipping.

Since you had to disassemble the doors and get to the internal system, take the time to lubricate all elements that are subject to friction. Thus, the work of the window regulators will be extended, and preparing the car for winter will be one step shorter.

Types of drives and lifting mechanisms

Previously, mechanical drives with a simple lifting mechanism were used to control the position of the glass. It was enough to twist the installed handle, and with the help of a simple design the movement was carried out. Modern systems use an electromechanical drive system, and lifting mechanisms are divided into:

- lever;

- rack and pinion;

- cable

Cable glass lift

The cable device is considered one of the most popular types of mechanisms due to its simplicity and efficiency. Rollers are used inside the structure, between which a flexible cable or chain and a drive drum are pulled. When an impulse occurs, the drum begins to rotate and the cable begins to wind. In this case, the device is connected to the glass and activates it. The main disadvantage is the rapid wear of the cable and the low strength of the drums.

Lever lifting mechanism

Lever lifting mechanisms are quite reliable, fast and compact. The principle of operation of the device comes down to the operation of an electric motor, which rotates the gear and changes the position of one or two levers attached to the glass. The mechanism operates quietly and has excellent performance properties.

Rack and pinion mechanism

Rack and pinion window regulators are in great demand due to their low cost and simplicity of design. The mechanism consists of a guide plate, which is connected to the glass, and a rack. When a control command is given, the guide begins to move using a drive mechanism. Among the disadvantages, it is necessary to highlight the need for regular lubrication and the low strength of rack teeth in budget cars.

When is it necessary to change the motor?

Most often, the electric motor needs to be changed after several years of using the car (on average after 5-7 years). Typically the following types of problems occur with the device:

- Clogged moving parts. In this case, the gear motor works worse, the windows are difficult to open, and lubrication does not help. If you remove the casing and dismantle the unit, as a rule, you can see a large amount of rust and dried silicone inside the structure. If the damage is not too severe, you can clean the structure, rinse off excess elements, re-lubricate the parts and reassemble the electric motor, placing the cover on a fresh layer of sealant. After this, the windows usually begin to open and close again easily and quickly.

- Wear of parts. In this case, you can replace the gears, since if the teeth wear out, it is not necessary to buy a new unit. The gear motor can also be damaged in the form of abrasion of the brushes, which should be renewed.

- Breaking. If the gears are not worn out, but broken (most often 1-2 teeth break off), the entire gear motor will have to be replaced, since the window lift mechanism will stop functioning or will malfunction.

Features of operation and control of power windows

The operating principle of automatic windows is quite simple. An individual control unit is installed on each device, which also receives commands from the central module. The mechanism processes signals from the buttons and activates the actuators - the electric motor begins to work and changes the position of the lifting mechanism.

Some systems allow you to control automatic lifts after turning off the engine, as well as change the position of the glass using external commands (for example, an alarm key fob).

For control, a direct or electronic system is used. The first option is directly connected to the on-board circuit and consists of a three-position switch. It is enough to change the position of the element, after which the glass will begin to move in one direction. Due to the lack of locks and protective mechanisms, it is practically not used.

Electronic control is one of the most popular methods for adjusting the position of glass. The structure consists of:

- electronic control unit;

- input devices (switches, glass position sensors);

- actuators (electric motor, drive).

Individual control buttons are installed on the passenger doors, and the main module is installed on the driver’s side. With its help you can change the position of any lift, turn on the lock or close all the windows.

Window lift motor repair - VAZ 2110 repair

Recently, we have often heard from VAZ 2110 owners about malfunctions of the window lifter mechanism. In one of the articles we have already looked at the FAULTS THAT MAY NOT WORK FOR THE WINDOW LEFT WINDOW, this time we will look specifically at the repair of the VAZ 2110 window lift motor. Before you start repairing the VAZ 2110 ESP engine, it needs to be removed. There is no need to save time and disassemble it at the door. Since this is very inconvenient and you will end up spending more time than if you dismantle it right away.

1. First of all, you need to remove the cover from the gearmotor; for this you will need a 5.5 wrench. After unscrewing the 4 bolts, remove the cover.

2. At this stage, remove the driven gear from the gearmotor. By the way, check it immediately for the integrity of the teeth.

3. Using a Phillips screwdriver, unscrew the bolts that secure the motor to the gearbox.

4. We remove the wires coming from the engine; it is advisable to remember their connection so as not to get confused during assembly.

5. Now, put the disconnected wires inside the motor housing.

6. Now you can undock the electric motor from the gearbox.

7. Next, you need to knock the armature out of the electric motor. We do this this way: we clamp the armature shaft in a vice (it is advisable to wrap it with something to spoil the worm). And through the spacer we hit the end of the engine housing with a hammer.

8. Once the shaft is removed, remove the plastic plug from its base by using tweezers or pliers to pry it open.

9. Now at the same end of the shaft you need to knock out the bushing. Moreover, it is advisable to spray it with WD beforehand. Then, secure the shaft with the bushing so that the stop is on the bushing, and by inserting a thin punch with a hammer, knock the shaft out of the bushing.

10. Next, clean the shaft from rust (you can use sandpaper). In addition, it’s a good idea to treat all parts with gasoline.

11. Take the motor housing and press the rear shaft bushing into place, using a thin spacer and a hammer.

12. Insert the brushes into the brush holders and secure using wires.

13. Insert the shaft inside the gearbox housing.

14. Having released the brushes, check that there is contact between them and the commutator.

15. We install the previously removed plastic tip on the end of the shaft and lubricate that place well, I used CV joint-4, but in principle any waterproof grease will do.

16. Pull the seal that is on the wires away from the terminals by 5 centimeters.

17. Don’t worry, the repair of the VAZ 2110 window regulator is already coming to an end. There are only a couple of points left to complete. We insert the wires inside the window motor housing and install the seal in its place.

18. Insert the driven gear into the window regulator motor housing. And screw the cover to the body with 4 bolts.

19. Now we connect the housings of the gearmotor and the ESP electric motor. During this, use pliers to hold the gearbox shaft so that it does not turn, otherwise the armature will simply fall out of the gearbox. Don't forget to secure them by screwing in 2 bolts.

20. That's all, the repair of the VAZ 2110 window lifter motor is completed. I suggest checking its operation before installation. Connect the wires directly to the battery.

___________________________________________________________________________

Why do you need the lock function?

Almost all power windows are equipped with a locking function. Its activation does not allow the window to be raised or lowered even when the control button is pressed. The option is designed specifically to ensure safety. It is difficult for the driver to keep track of children while driving, so it is safer to block the operation of the window regulator. The function is activated using an electronic control unit or a special button on the driver's door and its effect applies only to the rear electric windows.

To increase safety, the reverse movement function is also used. If there are obstacles, the lifting mechanism automatically lowers the glass. The system operates by controlling the rotation speed of the drive. If it decreases or lasts too long, the opposite control signal is received.

Electric windows do not affect driving safety, but they can increase the comfort and convenience of driving. You no longer need to use physical force or turn the mechanical drive for a long time - just press a button and automatically adjust the height of the glass position.

Content:

1How does a power window lifter work? 2Cable 3Rack and rack 4Lever 5Impulse

Top best window lifters

If used in heavy duty mode, the window regulator may break. Original spare parts are not always available due to high prices. There are several companies on the analogue spare parts market whose products are comparable in quality to branded ones, but at the same time cost much less.

Budget

In the budget segment there are mechanical windows and universal electric windows for cars. The price of a set for right and left front or rear doors does not exceed 1,500 rubles from different manufacturers.

Russian lifts, "Granat", "DMZ" and "DZS" are installed on domestic passenger cars and trucks and are widely represented on the aftermarket.

Optimal in price

The average price of a set of high-quality window lifting mechanisms with an electric drive is 3000-4000 rubles.

In this segment, you can select cable and rack and pinion window lifts for foreign cars and Russian-made cars.

Inexpensive window regulators

It is considered a recognized leader. The products are mechanisms that work quietly, at good speed, and are distinguished by decent quality and an affordable price. Offers high-precision lifts for the domestic automotive industry.

A large assortment of universal window lifters for Vigilant cars is optimal in price and quality.

The Polish company Polcar has earned the trust of customers with a variety of model options and designs for most car brands. The company uses durable materials and conducts serial tests of products for defects. Prices for Polcar lifts are slightly higher (up to 6,000 rubles), but they are suitable for most foreign cars: Ford, Mazda, Honda, Nissan, Renault and others.

Expensive

The elite ones include lever windows and models with an intelligent control system programmed for different situations, for example, to automatically close windows when the alarm is set. The “smart” system can be purchased separately, its price starts from 1,500 rubles.

How does a power window work?

Such devices are installed inside doors. An electric window regulator consists of three main parts: a lifting mechanism, a control unit and a drive – an electric motor. It sets the lifting mechanism in motion, which is necessary to raise or lower the glass.

The mechanism, based on a worm gear, eliminates the possibility of closing the glass when encountering an obstacle, such as a hand. Rotation in such a mechanism is transmitted exclusively from the worm to the wheel. If, on the contrary, the mechanism is blocked.

There are several types of electrical mechanisms: cable, rack and pinion, lever, pulse. Let's talk about each of them.

Cable

This electric window lifter is the simplest. The cable is driven by an electric motor. The disadvantages include rapid wear of the cable and the possibility of overheating of the motor. On the plus side: it is very easy to repair, and spare parts are cheap. In addition, you can repair it yourself.

Rack and pinion

In such a window lifter, an electric motor drives gears, which in turn transmit traction to the racks. A rack and pinion window lifter is much more durable than a cable window lifter. It is also worth noting the quiet operation and relatively high glass lifting speed.

The downside is that over time the gears will have to re-lubricate, otherwise they will wear out and begin to “skip” teeth, which means they will raise the glass more slowly and make a cracking sound.

Some manufacturers save money and use plastic ones instead of metal gears. They last less than metal ones, but are much cheaper.

Lever

This is perhaps the most reliable and durable type of electric windows. The motor drives a gear, which distributes rotation to either one or two levers at once. Thus, they raise or lower the plate with glass. One of the disadvantages is the uneven speed of glass rise.

Impulsive

In the case of an impulse mechanism, a person has the opportunity to close or open the glass completely without constantly holding the button. A single press is enough and the glass will reach the end. Moreover, the button can take several positions: two up, two down and neutral. By pushing the button all the way, the glass rises without further holding. If you move it to position “two”, you can raise the glass to the desired height.

Electric windows are also installed independently, mainly on VAZ cars, such as “Five” or “Seven”. On sale there are both for a specific car brand and universal window lifters. Installing them does not take much time and effort, especially since there are plenty of videos on the Internet on how to do it correctly. Whether to put it or not is a matter of taste.

The window regulator is used to lower and raise the glass in the car door. Initially, mechanical devices, popularly called “oars” and “meat grinders,” were used for this purpose. Today, they are being replaced by power windows with an electric drive, and manual ones are used, as a rule, on the cheapest cars in minimal configurations.

In addition to the fact that electric windows are convenient to use in themselves, the car owner has the opportunity to improve them in order to insure against his own forgetfulness. We are talking about installing power window closers that automatically close all windows when the car is set to alarm.

Content

How to repair a window regulator yourself

Instructions for independently carrying out preventive or complete repairs of power windows in your car. The entire procedure of disassembling, checking, lubricating and assembling one door takes from half an hour to an hour. If you have minimal skills with a screwdriver and wrench, you can handle this without difficulty.

To begin with, the symptoms:

1. The glass began to rise more slowly

If, after a certain period of operation, the glass begins to rise and fall more slowly than usual, slow down, or jam, then the mechanism needs lubrication. In rare cases, this may be caused by faulty wiring or a poorly grounded circuit. Usually the window regulator at the driver's door breaks first, since it is usually used an order of magnitude more often than others.

2. The glass stopped working completely

If the glass on one of them stops working completely, there are three main possible reasons. Most often the mechanism simply jams. In this case, when you press the button to raise or lower the window, a voltage drop occurs in the vehicle's power circuits. This can be determined using a tester or visually. This is best seen by the slight dimming of the backlight bulbs on the dashboard. It is better to check with the engine turned off, the key should be in the “On” position. In this position, power from the battery is supplied to all circuits of the car. So, if when you try to open or close a window the light bulbs lose a little brightness, disassembling the door and lubricating the window regulator will help you.

If you don't see a drop in voltage when you try to use the power window, the problem may be in the wiring, fuses, or window control panel. The motor itself can also fail, but this happens extremely rarely. Even on 20-year-old cars, the driver's window motor exhausts its service life by 50-70% and can still serve.

If the fuses are in order and the window regulator does not work, in order to further check it or prevent it, in any case, you will have to disassemble the door.

Removing the inner door trim:

In most cars, the inner door trim is secured with 4-8 screws, most often they are covered with plastic caps that match the color of the door trim.

Carefully remove the caps and unscrew the screws.

Inspect the door handles, they also have screws that hold not only the handle but also the upholstery.

Part of the upholstery can be held on by plastic clips. This is usually the lower part. The upholstery is removed from the clips by moving the entire door trim forward, in the direction of travel of the car, by about 2-3 cm. After removing the upholstery from all fasteners, disconnect the wires going to it at the connectors.

Under the top, decorative layer of upholstery there is a layer of sound insulation. This is a plastic or rubber film with slots for handles and wires, glued over the entire area of the door. It is advisable to heat the glue holding the sound insulation layer, for example with a hairdryer. But if this is not possible, you just need to carefully peel the film off the surface of the door.

Having removed the sound insulation layer, you finally gain access to technical slots in the inner wall of the door, through which you can carry out preventative repairs or simply lubricate the mechanism.

Application of lubricants

To lubricate most of the mechanism, a thick lubricant like “Litol 24” is best suited. It will ensure good sliding of rubbing parts and protect them from corrosion for a long time. If there are already traces of rust on the mechanism elements, first treat the mechanism with WD-40 spray lubricant. ITS property of squeezing out rust and creating a protective layer on the surface saved quite a few mechanisms from premature death.

Window regulator does not work well

So, if the window regulator is still working and needs simple lubrication: disconnect the window control panel from the decorative door trim

and connect it to the socket to which it was connected. Lower and raise the window, while inspecting the window mechanism. Apply lubricant to the rubbing surfaces of the mechanism

and raise and lower the window several times. Add lubricant as needed until it is distributed over the entire surface of the rubbing parts. If the window regulator begins to work as expected, you can finish. Remove any remaining grease from the door body, glue the soundproofing material in place, and attach the interior trim. Before screwing in the screws, make sure that all the wires going to the upholstery are connected to the appropriate connectors.

Window regulator jammed

If your window regulator is stuck, spray the mechanism and guide rails with WD-40 spray and wait a few minutes. If after this the window regulator does not work on its own, try manually moving the glass in the desired direction, while simultaneously turning the electric motor on and off. After you have managed to remove the jam and the window regulator has started to work on its own, carry out the operations described in the previous paragraph.

There is no reaction at all to pressing the button

1. Checking the motor

Find the window lift motor and disconnect the wires going to it at the connector. There are two wires going to the motor, there is no plus or minus on them. The polarity on these contacts changes depending on which direction the motor should rotate. Try connecting 12 volt power to it, in random order. To obtain the required power source, you can use a battery by connecting wires to it. Or connect the wires through the cigarette lighter socket using a special plug. Using a tester, make sure there is 12.5-14 volt power on the wires that you will connect to the motor contacts. After connecting the wires to the motor, it should twitch or make a faint humming sound. If there is sound, but the window does not go down, try swapping the wires. When connecting the wires to a working motor, a spark may occur, this is normal.

This is interesting: How to check the legal documentation when buying a car? (video)

If there is no response to connecting the power, the motor itself is most likely faulty. This could happen due to moisture getting into it, or the brushes running out of service life. In this case, the motor needs to be replaced or repaired. This rarely happens, so carefully check the motor and the power supplied to it.

2. Checking power to the drive

This concludes the advice on self-service of window regulators.

Electric window regulator

Electric windows are installed inside the doors either in special subframes or attached directly to the body. In general terms, the window regulator device looks like this. They consist of the following main parts:

- drive;

- lifting mechanism;

- control unit.

The drive combines an electric motor, worm and gear drives. All components are combined into a common block. The task of the drive is to transmit force to the lifting mechanism to raise or lower the glass. Thanks to the worm gear, the possibility of unauthorized lowering of the window glass is eliminated. Rotation in a worm mechanism can only be transmitted from the worm to the wheel; if force is applied in the opposite direction, the mechanism will be blocked.

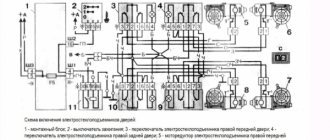

Operating principle diagram

The electrical circuit for activating the ESP is located on the ECU board and is also attached to the mechanism instructions.

In general terms, the principle of connecting a window regulator is as follows:

- It is necessary to connect the electric motor of the joint venture to the power source.

- To do this, the wires from the standard power window kit are twisted: one end of the harness is connected to the mounting block (in the passenger compartment, in the fuse box), the other to the ESP electric drive.

- The wiring is passed through technological holes in the doors and body pillars.

Power can also be taken from the cigarette lighter or standard wiring.

Diagram of the operating principle of the car window lifter:

Types of lifts

The lifting mechanism is an actuator, its task is to raise and lower the glass. Structurally, lifts differ from each other; there are the following types:

- cable;

- rack and pinion;

- lever

Each of them has its own advantages and disadvantages.

Cable

The main advantage that sets a cable window lift apart is its high maintainability . Spare parts can be found in almost any store, and repairs can be done yourself. This advantage offsets the disadvantages of the mechanism, namely wear of the cable, its pulling, low strength of the plastic guide heads and the susceptibility of the electric motor to overheating.

Rack and pinion

Rack and pinion windows are more durable. The principle of their operation is that the rotational motion transmitted from the electric motor to the gears turns into linear motion of the racks. Such window lifters, in addition to being reliable, have a higher speed than cable lifters, and produce less noise.

However, rack and pinion windows are not without their drawbacks. The main one is that the gears need lubrication, otherwise they quickly wear out and stop working normally. The second drawback is inherent in those devices whose manufacturers saved on metal and made the gears plastic. This material is much inferior in strength to aluminum, which has a very significant effect on service life. Finally, rack and pinion windows require more space inside the car door.

Lever

The lever mechanism combines high reliability and small size. The electric motor in such a mechanism rotates a gear, which transmits rotation to one or two levers. The levers move the plate that holds the glass. The operating principle gives rise to the main disadvantage of such a device, which is the uneven speed of glass movement: the higher it is, the lower the speed.

The glass itself, regardless of what types of window lifters are used on cars, moves along guides. Within the doors, this role is played by gutters, and inside there are special rails.

Instructions for self-diagnosis of the drive

We repair the car ourselves

Repairing the window lifter motor is not as difficult as it might seem at first glance.

This is done as follows:

It is necessary to remove the trim of the desired door by unscrewing the screws. Unscrew the door handle, as well as the plastic from the inside. After this, you need to carefully pull the casing from the bottom up. Disconnect the speaker that is attached to the door. Through the free holes you need to unscrew the screws that hold the glass. Important: when unscrewing the screws, you must be extremely careful so that the glass does not break.

Remove the glass. Next, you need to unscrew the mechanism and remove it, while remembering where which contact was connected, so that when replacing it, everything should be done in the same order. After removal, you can disassemble the motor to thoroughly examine and clean it. You can also clean the winding, only very carefully so as not to damage the contacts. If the contacts are oxidized, they must be replaced and the mechanism must be reassembled. Replacing the window regulator and reassembling it in the reverse order. Replacing the window regulator

Replacing the window regulator

Price issue

The photos below provide information about the cost of the window lift. In addition, you can see some variants of these devices.

What are impulse windows?

There are two types of power windows: impulse and non-impulse. Pulse window lifters can operate in both pulse and normal modes. Normal mode means that the power window operates only when the control button is pressed. In pulse mode, one short press is enough to completely lower or raise the window.

As a rule, impulse windows are equipped with five-position control keys, which from the neutral position have two positions up and two down. When the key is moved to the first position, the window regulator operates as usual, and the window will go down or up exactly as much as the driver wants. In the second position, a control pulse is sent to completely open or close the window.

The second name popularly given to automatic window lifters is sequential. This term is used incorrectly, since “sequential” means “sequential” (from the English sequence). Everyone knows sequential gearboxes, in which shifting occurs sequentially. What a sequential window regulator is supposed to be remains a mystery. Most likely, someone just really liked the word.

Electrical problems

It is better to start diagnosing a malfunction by checking the condition of the fuse, which is responsible for the operation of the power windows in the VAZ 2110. Usually it is numbered F5. If necessary, the fuse must be replaced with a new one. If it is intact, proceed to the next stage. You will need a 12 volt light bulb with two wires going to its positive and negative side.

Connect the wires to the terminals of the window lift motor and press the button. If the light comes on, the wiring is good, but if not, start looking at the wires for breaks. Also don't forget to check the corresponding relay.

Another problem with the electrical wiring circuit is when the window opens when the button is pressed, but when it is released the glass rises again. In some cases, the button does not work until you turn the ignition off and on. These signs indicate a malfunction of the button, so you can try to remove it and clean the contacts, and if necessary, replace it with a new one.

Do-it-yourself electric window installation

The question of self-installation is usually asked by owners of domestic cars. There are many tutorials on the Internet on how to install electric windows on a VAZ-2107, VAZ-2110, VAZ-2114 and other models.

Stores sell window lifters for specific cars, for example, VAZ-2110 or VAZ-2114, or universal ones that can be installed in almost any car (for example, VAZ-2107). The difference between them is that in order to install a specialized mechanism, it is necessary to completely dismantle the old mechanical one, while the universal one is combined with the existing one.

Since there are no special power windows for the VAZ-2107, the only way to automate the process of opening and closing windows is to install universal power windows. To do this, the “oar” handles are dismantled, an electric motor is installed inside each door, which, through gears, drives the original mechanical window lifter.

”alt=””>

16.01.2015 1 459

Perhaps this article should begin with the words: “ A window regulator is a device designed to raise and lower the glass...”, however, given the fact that most cars, including domestic ones, are equipped with these devices today, I propose to talk about more important and interesting, in my opinion, things.

Many remember, but many did not have time to remember, the “progenitors” of modern electric windows ( ESP ) - mechanical window regulators, which drivers jokingly called “meat grinder” among themselves. Today, the function of a hand is performed by a special motor that quickly and silently raises or lowers the window.

Progress does not stand still and after some time the already seemingly perfect ESPs became even more perfect. They now have mechanisms that can provide timely insurance for a forgetful driver who, while leaving the car, forgot to roll up all the windows. The so-called power window closers automatically raise all the windows after the car is set to alarm or when all the doors are locked, that is, when the central locking is activated.

Price issue

1. Front right rack and pinion lift for VAZ 2109 (price - about 450 rubles)

2. Rack and pinion Forward for VAZ 2107 (price - from 3139 rubles)

3. Lever Katran for VAZ 2110 (price - from 2990 rubles)

ESP device

Electric windows are located in the door cavity or in special subframes. Typically, window regulators consist of:

- Lift;

- Drive (which includes a worm and gear drive);

- Lifting mechanism;

- And also the control unit.

The principle of operation is to transfer force from the drive to the lifting mechanism, due to which the windows are actually raised or lowered. The worm gear serves as a safety device that prevents the glass from lowering spontaneously.

What are the different types of lifts?

Window lifters, in turn, are divided by type of lifting mechanism. The task of this mechanism, as the name suggests, is to raise or lower the glass. There are three main types of lifts, namely:

- Rack and pinion;

- Cable;

- And lever.

Each of the above has its own “pros” and “cons,” which we will talk about now.

The window regulator does not work on Kalina List of possible breakdowns and their repair

- The window regulator on Kalina does not work, then prepare a car tool kit and we will begin. So, in addition to a toolbox, we will need a tester, which can be purchased at any auto store or market.

- Considering that we will have to run, spin, and twirl near the car, we need a spacious place, for example, an area near a garage or house;

- We clearly determine which glass unit is inoperative;

- We open the hatch on the left side of the steering column, as the fuse box is located there. To do this, just pry off the valve with a screwdriver;

- We find under the marking F2 (30), it is he who is responsible for the operability of the double-glazed window chain and remove it;

- We carry out visual diagnostics and test it with a tester. There are two options: either it is intact or it is burnt out. In the first case, the reason is not in him, in the second - in him;

- Based on the decision in point 5, we carry out further actions. Apparently the fuse is intact. Let's move on to the central control unit for double-glazed windows, which is located on the driver's door;

- Using a screwdriver, we very carefully pry off the polymer cover, since it can be scratched and it will lose its aesthetic appearance, and we take out the entire board assembly. We find the switch we are interested in and check the fit of the wire terminals and the integrity of the wiring itself. Using a tester, we ring the switch to make sure it is working properly; if it shows a short circuit, then it is faulty and should be replaced;

- Once the functionality has been confirmed, we move on to the last stage of the search, namely into the doorway. To do this, we remove the door trim, depending on which side we are looking for the cause. We will see a picture in front of us in the form of: the double-glazed window itself, the release and lifting mechanism and an electric motor with a bundle of wires.

AutoFlit.ru

Power rack-and-pinion windows

Rack and pinion window lifters are considered one of the most “long-lasting” compared to others. ESPs operate on the principle of transmitting rotational motion from an electric motor to gears, with its subsequent transformation into linear movement of racks that perform lifting. In addition to reliability, window lifts of this type lift windows much faster and quieter than cable counterparts.

But, like everything in this World, rack and pinion windows are not perfect and have their drawbacks. The main disadvantage is that the gears need lubrication; without it, they very soon begin to wear out, and the power windows themselves cease to function normally. The second drawback especially concerns those devices whose manufacturers decided to “save” on metal parts and gave preference to plastic. The fact is that this material is fragile and is noticeably inferior in strength to aluminum, as a result of which the service life of such ESPs is reduced. Among other things, the rack and pinion mechanism is more bulky, so they are installed mainly in “large” car doors.

Possible motor breakdowns

As a rule, the design of the device is quite simple, and it can be repaired in most cases, however, many motorists simply purchase a new device, since the market offers a large selection of such products. However, in some cases you can get by with less. Main faults that can affect the gearmotor:

- Gear failure. This defect occurs especially often with modern devices: many manufacturers have begun to install plastic parts, which, despite being lighter, have deteriorated strength characteristics. As a result, such elements are more likely to break and crack, and due to broken teeth, so-called sliding occurs when the glass stops at a certain point and does not move further. To improve the strength characteristics, it is better to install a gear made of steel, which can be found in old units or purchased separately.

- Another problem affecting the gear motor is brush abrasion. These elements are necessary to supply the rotor mechanism with current and are a pair of plates equipped with copper plates. Wear of the brushes occurs due to constant friction and the influence of current discharges that form a spark, and a gap appears between the armature and these elements: this also affects the characteristics of the entire device.

- Foreign objects entering the structure, ranging from dust to dirt particles. Usually they get clogged under the winding or get caught on the contacts, and the gearmotor does not work as well as before. In this case, nothing will have to be changed, and you will need to clean the structure, replace lubricants and update the layer of sealing material.

Cable-type electric windows

The main advantage of cable window lifters is their high maintainability. In the event of a malfunction, you can easily repair the mechanism, and spare parts can be found in almost any auto store. This advantage, at first glance, is insignificant, but as practice shows, most motorists choose this type of ESP without paying attention to the disadvantages of the cable mechanism. The fact is that the cable wears out or stretches over time; in addition, due to the low strength of the plastic guides, they often fail, and the electric motor is very prone to overheating.

Replacing the fan and heater motor on a VAZ 2114. Actually, nothing new

- Failure may be caused by a blown fuse. Fuse F7 is responsible for fan operation. It is designed for a current of 30 A. Also connected to it are a headlight washer motor, a glove compartment light, and a heated rear window. If these systems fail at the same time, the problem is in the fuse. Be sure to check all these systems for shorts;

- Poor contact in the mounting block. Sometimes the contacts in the wire block oxidize, in which case it is enough to simply move it. This usually helps;

- Switch failure is a fairly common problem. Check the functionality of this element.

- Disconnect the battery. This will protect you from short circuits and failure of some electronic systems of the machine;

- Remove the side heater casing on the driver's side;

- Under the instrument panel you need to find and disconnect the positive wire going to the fan;

- Unscrew the lowest heater mounting nut. The negative wire of the motor is removed from the stud;

- The hood opens and the seal is removed. Remove both screws securing the fan casing;

- The casing is removed;

- Unscrew the fan mounting screws. There are only 2 of them, for this you will need a Phillips screwdriver;

- Unscrew the 5 screws securing the air intake grilles. They are located in front of the windshield. Next, remove them;

- The fan is slightly lifted and removed from the mounts by sliding it forward (towards you);

- The fan housing is rotated 90° and removed;

- Before installing a new motor, you should thoroughly clean the compartment from any dirt accumulated there;

- Assembly is carried out in reverse order.

- We remove the impeller. She will have to be shot down;

- Remove the cover; to do this, unscrew the screws;

- We inspect the brushes, in most cases the problem is in them;

- To replace them you will need a soldering iron and a screwdriver. First, we unsolder the wiring of the old brush and unscrew the screw that secures it.

- Do this carefully, do not lose the springs. Install a new brush;

- We put everything back together in reverse order.

AutoFlit.ru

Lever type electric windows

Lever-type ESP successfully combines compact dimensions and a high degree of reliability. In such power windows, the motor turns a gear, which transmits rotation to one or more levers. In turn, the levers move the plate on which the glass is mounted. The main disadvantage of this mechanism is the uneven speed of glass movement; the higher it is, the slower the lifting will occur.

As for glass, regardless of the type of mechanism, it moves along guide channels or special rails.

Window lifter malfunctions and ways to eliminate them

The operation of the window lifter is configured and adjusted by the manufacturer, so you should interfere with it extremely carefully and carefully, otherwise the mechanism may jam, crackle and crackle.

From personal experience, I advise you to carefully study the device and read the detailed troubleshooting instructions before starting to independently repair the window lifter mechanism. Even though many of them seem quite possible to fix with a screwdriver and a wrench, in some cases it may be necessary to completely replace the window regulator.

Before you begin self-repair, you need to study the structure of the window lifter and the principle of its operation.

Window lift creaking

At first glance, the creaking of the window regulator does not seem to be a serious malfunction, but you should pay attention to this signal, since this is the first sign that the mechanism is wearing out and may soon break. Methods to combat this symptom are extremely simple, accessible to everyone and do not take much time:

- lubricate the window lifter - lubricants from any manufacturer, widely available in car dealerships, are suitable for these purposes;

- Replace the rubber bands in contact with the glass. When the window is open, dust and sand inevitably enter the car interior, which scratches the glass and rubber bands, resulting in a squeaking sound. The entry of dust and moisture through the gap between the glass and the seal can subsequently lead to jamming of the mechanism, so it is necessary to regularly monitor its cleanliness.

Window lifter jammed

The main reasons that the VAZ 2107 window lifter is jammed are as follows:

- failure of the welded joint connecting the cable bracket and the glass strip to which it is attached. In this case, you need to disconnect the window lift cable and weld the bracket;

- The cable is tangled or twisted inside the window lift mechanism. You can try simply removing and reinstalling the cable. In case of failure, the entire mechanism will have to be replaced;

- wear of the window lifter gears indicates a clear need to replace them.

Glass falls

It happens that the glass falls and does not stay up. The reason for this may lie in the weakening of the tension roller, which creates the proper tension in the cable. To fix the damage, it is necessary to restore this mount. Another cause of the malfunction may be that the end of the cable has come out of the fastener. Then you need to remove the window regulator and try to wind the cable again.

It’s easy to check whether you carried out the repairs properly: in good condition, the window lifter handle rotates freely and effortlessly, the glass rises easily, without getting stuck and without any extraneous sounds.