It's no secret that the operation of gasoline and diesel engines is based on the combustion of a fuel-air mixture. Formed in the carburetor or injector, it enters the cylinders, after which it ignites and the thermal energy pushes the pistons that drive the engine shafts. As a result, the car drives. The engine operation algorithm is very clearly established, but for its proper organization, not only the timely supply of fuel to the cylinders is important. The spark formation process, which is achieved using the machine’s ignition system, is also important in this system. One of the main components in it is a distributor, which supplies a spark precisely to the spark plug of the cylinder where the piston currently reaches the desired position. We’ll talk in more detail about the operation of this particular part of the machine and its features today.

What is this detail?

A distributor is a part of a car engine that runs on fuel such as gasoline. We are talking about an internal combustion engine, and not some other one. So, it is the distributor that is responsible for the timely provision of an electric pulse to the spark plugs, as a result of which the discharge of the latter is ensured and further ignition of the fuel in the chamber where the pistons are located directly.

In other words, a distributor is an ignition distributor in a car. Which is responsible for getting a spark at the right time. It is worth saying that such a part is available on almost all internal combustion engines. The only thing is that the latter may not be located in the same way and its functionality may differ slightly from one another.

It is also impossible not to take into account the fact that diesel car engines do not have an ignition system, just as injection cars do not have a breaker. For a better understanding, it is worth understanding the structure and principle of operation of the distributor, with which we will now try to approach this issue in more detail.

FAQ

What is a distributor?

The distributor is called the ignition distributor. This part is used in the ignition system of carburetor vehicles only.

Where is the distributor located?

You will find the distributor near the engine or cylinder head. The easiest way to identify it is by the round plastic housing cover with five “horns”, to which the high-voltage ignition wires and the central electrode are connected. The cover is placed on a cylindrical metal case in which the distributor mechanism is located.

What is the distributor responsible for?

The distributor is responsible for ensuring that a spark is supplied to the spark plugs individually, in a certain sequence and in synchronization with the operation of the camshaft.

What does a distributor do?

The distributor receives voltage and creates high-voltage pulses in the ignition system, and then distributes them to the spark plugs of each cylinder in a given sequence. When the crankshaft rotates, the gear of the distributor shaft on which the slider is located rotates, which, constantly rotating, transmits part of the voltage to the contacts of each individual spark plug. Every time a piston is at TDC (top dead center), the slider sends voltage to that cylinder's spark plug.

Ignition distributor device

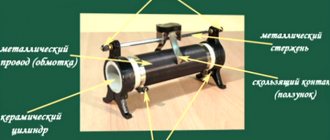

The non-contact type distributor device includes a set of certain elements:

1. Rotor or so-called distributor drive. Which is often represented by a splined shaft that engages with a camshaft gear or a shaft. The difference depends on the design of the motor.

2. Ignition coil, which has a double factory winding.

3. There is also a breaker; there is a cam clutch, as well as a centrifugal clutch and a contact group.

4. A slider that is attached directly to the clutch shaft and rotates when working with it. There is also a distributor cap. It is from this that the high-voltage wiring goes to all the spark plugs.

5. Vacuum-type ignition timing advance regulator. A capacitor is also included in its circuit. It functions as a “lightning rod”, since it is it that takes on a little charge, protecting the group of contacts from melting under the influence of high voltage.

6. Depending on the type of distributor, an octane corrector can also be installed in the lower part of the structure, which controls the speed of revolutions, depending on the brand of gasoline. Have you ever heard of the concept of octane number? This is what it is, only in the classic versions its correction is done with your own hands.

Common distributor malfunctions

The complex design and abundance of small elements cause a wide variety of problems that can arise in the operation of the distributor. Let's look at the most common of them:

- damage to the cover - manifested by instability of the engine, its jerking, drops in speed, and in wet weather - a stalling engine. Problems can be mechanical (cracks, chips, moisture getting inside the cover) or chemical (oxidation of contacts hidden under the cover);

- burnout of the slider fuse - as a result, it becomes impossible to transfer electricity to the ignition coil;

- failure of the capacitor, leading to the supply of excess voltage to the spark plugs;

- violation of the rotation geometry of the shaft, its jamming or deflection, damage to the distributor body are the result of serious mechanical damage and require complete replacement of the failed part.

- vacuum ignition regulator - becomes unusable when the diaphragm ruptures or becomes dirty.

Please note that these are only the most common faults - in practice, you may encounter other problems that only a specialist can identify.

What is the operating principle?

How does a car distributor work? Everything is banal and simple. When you turn the key in the car, the electrical circuit is closed and voltage is then supplied from the battery directly to the starter. After that, such a starter part as bendix provides engagement with the crankshaft flywheel, and from there the supply continues to the ignition distribution roller drive gear.

A low-voltage current appears on the coil as the circuit closes. This is where the contacts of the breaker are separated and the high-voltage voltage accumulates on the second circuit of the same coil. Then the resulting current goes to the cover due to the graphite contact or brush located in the lower part of the part.

At the same time, the slider is constantly in contact with the central electrode and, when rotating, distributes part of the voltage alternately to the contact of each of the spark plugs. In other words, the voltage is divided equally among all four spark plugs. This is how the general operating principle of the distributor works.

Subtleties of work

Among other things, it is worth knowing important subtleties in the work that the distributor provides. So, for example, it is very important to take into account the fact that the vacuum regulator is inextricably linked with the intake manifold and tube, the so-called throttle space.

This means that it is sensitive to the mode of air supply to the engine and changes the ignition timing itself. The spark is supplied to the cylinder a little earlier and ahead of schedule. In this case, detonation will occur at the moment of gasoline injection into the combustion chamber, thereby pushing the piston down. Of course, Uzbek indicators will change.

Operating principle of the distributor

In many ways, the operating principle of the distributor remained unchanged for many years. In VAZ cars, such as VAZ 2109, 2106, 2107, 2108, an ignition system of this type was used almost until the end of the last century.

The basis of the work is the connection of the distributor with the engine crankshaft. When the piston in the first cylinder takes the position corresponding to TDC, the breaker contacts open, a high voltage appears in the ignition coil, directed through a slider located in the distributor cover to the spark plug of the first cylinder.

There the combustion of the fuel assembly occurs, and the crankshaft continues to rotate. In addition to moving the pistons, it causes the breaker cam to rotate. When in another cylinder another piston occupies a position corresponding to TDC, at this moment the breaker contacts in the distributor open again, and a high-voltage voltage is generated in the ignition coil and supplied to the desired spark plug.

This joint rotation of the crankshaft, the breaker cam and the distributor slider ensures that a spark appears where and when needed. However, this does not cover all aspects of how the distributor works. To understand its operation, it is necessary to touch upon such concepts as the angle of the closed state of contacts (UZSK) and the ignition timing angle (IAF)

UZSK

A concept such as UZSK characterizes the time when the breaker contacts are closed. In essence, this is an indirect characteristic of the accumulation of energy in the coil after the completion of spark formation. UZSK directly affects the amount of energy spent on sparking and, accordingly, on engine operation.

In cases where the distance between the contacts is small, the coil will not accumulate the necessary energy and the spark energy will be low, which will lead to interruptions in the operation of the motor. A large gap also leads to interruptions, since the contact breaking time is reduced and the coil does not have time to fully discharge.

Each ignition system has its own optimal UZSK, to ensure which, if necessary, the distributor must be checked and adjusted.

UOZ

This concept concerns the moment of ignition of a fuel assembly. The fact is that its combustion does not occur instantly, and often, to ensure optimal conditions for such a process, it must begin earlier than the piston reaches the TDC position. The OZ characterizes the time by which the appearance of a spark precedes the appearance of the piston in the TDC position.

It is constantly changing, and its value completely depends on the operation of the motor under specific conditions, i.e. depending on the load, vehicle speed, quality and type of fuel used. To ensure optimal combustion of the fuel assembly, the distributor contains a centrifugal regulator and is also connected to a vacuum regulator.

VACUUM REGULATOR

It is this device that can change the OZ if necessary. As soon as the motor load changes, appropriate adjustments are made to the operation of the distributor device parts.

Important! The load is determined using the throttle valve.

The vacuum regulator of the distributor is a closed cavity. To ensure better performance, the design is divided by a diaphragm. One cavity goes directly to the carburetor.

When a vacuum occurs, the diaphragm begins to move. As a result, pressure is exerted on the movable disk and the breaker cam. The response time of the latter is adjusted depending on the current situation.

Attention! The distributor changes the moment of spark formation, thereby affecting the performance characteristics of the motor.

OCTANE-CORRECTOR

This is a very important element in the distributor design. Without it, the entire system could not function normally. The unit changes the SOP depending on the fuel that is currently being used.

By its design, this distributor element resembles two plates with an arrow. The same arrow is installed on the engine. There are special lines on it, through which the ignition angle is adjusted. It is almost impossible to do without this part when refueling different types of gasoline.

We recommend: Real vehicle ground clearance

CONTACTLESS SYSTEMS

Technologies do not stand still. Every year, the automotive world is rocked by new innovations. This is precisely what innovation became in its time, supplementing the distributor design with switches.

Attention! In switches, the signal is supplied to the control electronic module, and not to the coil.

The second name for non-contact systems in the distributor device is Hall sensors. The simple design of these devices ensures uninterrupted signal supply. The sensors themselves work due to changes in the magnetic field.

Hall Sensor

As you probably already understood, the rotation of parts actually begins to wear them out and malfunctions appear. But an injection engine or even the most modern carburetor engines do not have a slider; instead, a hall sensor is used. Here the device is slightly different and the distribution process is carried out due to the resulting magnetic field.

Of course, such a system is considered to be of higher quality, and there will be less space under your favorite hood. In the most modern cars with an injector and distributed injection, a more modern electronic non-contact type ignition system is used.

A distinctive feature of such a device is that all operating modes are monitored by different sensors. It is from them that all signals are sent to the electronic control unit, and after that the same command action goes to the ignition system switches.

Important

The ignition distributor is a simple and completely manually disassembled unit. You can always easily disconnect it, remove it from your car, disassemble it into parts and find the cause and eliminate it by replacing the faulty part.

Functions of the distributor and a little about its history

To summarize today’s article, we will summarize the entire theory discussed and highlight the main functions of the distributor. In the classical sense of this device, the distributor must:

- Initiate sparking;

- Distribute the spark among the cylinders;

- Adjust spark formation for a specific engine operating mode;

- Ensure the accumulation of excess current in the “bobbin” (capacitor);

- Distribute the accumulated charge throughout the system.

Note that the first distributors appeared in the early 00s of the 20th century. The operating principles of internal combustion engines at that time were quite consistent with the functioning of a mechanical spark distributor. However, over time, approaches to creating cars changed, so conventional distributors with a slider became more and more primitive. At first, in contactless ignition systems they were actively replaced by a Hall sensor, and later microprocessors began to be used in electronic ignition.

In addition, progress in the automotive industry has completely electronicized the fuel supply to the engine. As a result, vacuum octane correctors became useless and were replaced by special sensors in systems with electronic ignition. Considering the rapid pace of development of the automotive industry, it is not surprising that distributors affected only a few generations of cars, no. Most Russian motorists are familiar with a similar spark distributor from the VAZ “classic”. Newer models with electronic ignition are designed fundamentally differently, so you won’t be able to find a distributor in their design.

Perhaps this concludes the most important information on today’s topic. We hope the article was useful to you and provided answers to your questions. Good luck in maintaining and operating your car!

If you have any questions, leave them in the comments below the article. We or our visitors will be happy to answer them

The most common problems

The fact that something is not working correctly in the distributor can be determined by certain signs. So, for example, if there is a spark on the central wire, and there is no spark on the spark plug wires, we can talk about a gap in the integrity of the slider. In this case you will notice:

1. That the car jerks while moving.

2. That the functionality of the engine at idle is very unstable.

3. That the engine does not start at all.

4. That a distinct knocking sound of the piston fingers is heard as the speed increases;

5. That the speed gain has become less;

6. That gasoline consumption has increased.

Causes of malfunction

The distributor may fail for the following common reasons: the slider is burnt out, the piston is stuck, the cover is broken or the contacts under the cover are closed, the sensor is broken, the shaft bearings are faulty, and so on.

Most often, such unpleasant moments will require replacement. But there is also a pleasant moment: more often than not the entire distributor as a whole needs replacement, but only a failed part. And this will certainly cost much less in terms of the amount of payment to the master.

As you can see, there can be a lot of reasons. But in any case, this often happens because the car owner pays very little attention to his iron horse.

Pollution usually occurs every 10 thousand kilometers. Therefore, checks are needed precisely at the specified kilometer rolled.

Even an owner uninitiated in the subtleties of the car’s functionality can visually assess the condition of the slider, contacts and roof and judge the operation of the distributor as a whole. But what about the hall sensor?

In models of non-contact operating principle, inductive and hall sensors often fly. To diagnose the ignition systems and the distributor itself, it is worth tracing the spark on a spark plug that was turned out in advance, while first starting the engine. In a garage environment, you can also arrange a check. To do this, you will need measuring instruments or conventional indicators.

The distributor capacitor can also be included among the spare parts that are out of service. It helps increase the voltage on the spark plugs when the engine starts. You can easily check it by disconnecting it and touching the ground. When you hear a clear crackling sound and the voltage drops, the capacitor is alive, but if this does not happen, the part will have to be sent for replacement.

How the distributor works and how it works

This mechanism includes many components for various purposes. The main ones among them are the following:

- rotor - provides traction with the rotating camshaft gears;

- breaker - a module with a cam clutch, which is connected by special contacts to a centrifugal clutch;

- ignition coil equipped with double winding;

- a runner rotating simultaneously with the shaft, located on the distributor cover and transmitting voltage to the spark plug;

- a cover through which current-carrying wires extend to the spark plugs;

- a vacuum-type regulator that ensures the operation of the ignition advance function;

- non-contact type equipment - used on the most modern models of distributors.

In addition, many devices are equipped with an octane corrector, which changes the operating mode of the distributor in accordance with the quality of gasoline.

The operating principle of the distributor may have individual characteristics depending on the specific car model. However, the general specifics of the action of this element are almost the same in all engine models. When the crankshaft is cranked, the pistons act on the distributor cam, as a result of which its contacts open. This leads to the emergence of high voltage, which is transmitted through a special slider to one or another spark plug. This process is continuously repeated while the engine is running, only the spark plugs to which voltage is applied change.

A clear relationship with the crankshaft and pistons ensures high precision of the distributor, which, in turn, increases the efficiency of the entire car engine.

Replacement

How can you replace the distributor of your car yourself and is it possible? Yes, this really can be done even in a garage. To dismantle such a part, you will need to remove the negative terminal from the battery. Now you need to completely remove the high-voltage wiring leading to the cover and disconnect the hose from the vacuum corrector. Then remove the bracket, carefully supporting all the wires.

Please note that the installation of the new distributor is carried out in a certain position. For example, in the VAZ nine, it is possible only in one rotor position, which certainly greatly simplifies the whole process. And no notes are needed, this is a banal myth that car owners come up with.

In other words, installation simply involves placing the new part in its rightful place. Of course, all the nuts need to be tightened thoroughly to ensure proper fixation to the engine. That's all the replacement is.

Invest or sell cheap?

Today, the existing systems used to ignite fuel are not all and not always good. Almost all of them have their own pros and cons. But creating a particularly complex system in your own car is very expensive. It will be much more accessible to use simpler and cheaper systems.

Thus, it turns out that there is no direct need to install a cool, expensive ignition system in your inexpensive car. Why? Yes, because this way you will increase the cost of the car itself, but not the quality of ignition itself. Therefore, if the original ignition and distributor, including those, do not let you down when driving a car, why change anything.

Now you know all the most important and important things about this automotive element, we hope that this information will help you in communicating with your iron friend.

Share information with friends: