In this article we will figure out how to make heated seats in a car. Let's look at what kits there are for installing heated seats, their advantages and disadvantages. This will help you decide which kit is best to choose for your car. The principle of operation of heated seats, the process of installing and connecting heating elements, and advice on proper operation are given here.

Heated seats are a good addition to a car, increasing comfort, and are installed on expensive cars or on any model as an additional option. If the vehicle is not equipped with heated seats, a kit for installing heated seats can be purchased separately. This can be either a soft substrate with heating elements inside, which is installed on top of the seat upholstery and connected to the cigarette lighter, or a kit for installation under the seat upholstery. In this article we will look at how to make heated seats using a kit that is installed under any seat upholstery (artificial, natural leather or textile). These are very thin heating elements, about 1.5 mm thick, which are not felt at all until they are turned on.

The content of the article:

- What types of heated seats are there?

- How does heated seats work?

- Preparing to install heated seats

- Removing seats and upholstery

- Installation of heating elements

- Connecting the heated seat wiring

- Assembly, installation and testing of heated seats

This article is of a general nature and will be useful as instructions for installing heated seats on any car. In the description of the installation kit you can read that it is intended for professional installation by an experienced specialist. However, the installation process is also accessible to a simple car enthusiast. It is important to carefully study the information provided in this article and do everything consistently and carefully. This can take several hours or two weekends, depending on the skills and efficiency of the installer.

What types of heated seats are there?

There are 2 types of seat heating kits: with a copper heating element and with a carbon fiber heating element (carbon fiber/carbon thread).

Seat heating kits are available in 12V and 24V versions.

Seat heating kit with copper wire heating element

A seat heater with a copper heating element is one long zigzag wire where one end has a positive polarity and the other end has a negative polarity, similar to the filament in a light bulb, which also gets hot.

Heated seats with a copper heating element have the following advantages:

- The copper heating element heats up quickly.

- Heated seats with a copper wire heating element reach a higher temperature than carbon fiber ones.

Disadvantages of heating with a copper heating element:

- The disadvantage is that the rapid heating and cooling cycles will thin the wire and eventually it will burn out.

- Since the copper wire heating element cannot be cut to fit any seat, there are no universal kits that will fit all vehicles. Various sets with a copper heating element are sold for specific car models, or for specific seat sizes. If you are going to install a seat warmer kit with a wire heating element, it must be designed specifically for your car model (to fit), or be smaller than the car seats.

Seat heating kit with carbon fiber heating element (carbon fiber/carbon thread)

The carbon fiber (carbon fiber) heating element has a honeycomb structure. Electrodes (positive and negative) are located at the edges of the heating pad, cells made of carbon fiber are located between these electrodes.

Sets with a carbon heating element have many advantages:

- The heating element of such heating is a carbon (carbon fiber) thread, which is much stronger than copper wire.

- The honeycomb structure makes the heating substrate very reliable. Damage to a single cell does not disable the functionality of the entire heating system.

- Heating elements in the form of carbon fiber can be trimmed with scissors to reduce the size and fit it to a specific seat. This makes the seat heating kit with carbon heating element universal.

Disadvantages of sets with a carbon heating element:

- Carbon filament takes longer to heat up (about 1-2 minutes longer than a copper wire heating element).

- The carbon heating element heats up to a lower temperature (about 5 degrees lower than the copper heating element).

- Heating with carbon wire reaches the highest temperature of 50-57 degrees and the lowest 43-51 degrees Celsius, which is slightly lower than the copper wire element.

As can be seen from the listed advantages and disadvantages, heated seats with a carbon heating element are more preferable, as they are a universal and reliable option. In addition to universal kits, you can also find a seat heating kit specifically for your car on sale. It will fully match the seat configuration of your car, and will have detailed instructions for connecting to your vehicle. The universal kit may need to be adjusted to the location by trimming the lining with heating elements.

Electrical diagram of a heated cape

The heated cape is connected to the vehicle's on-board network using a plug that is inserted into the cigarette lighter socket.

The supply voltage from the negative terminal of the plug is supplied to pin 2 of the operating mode switch. When the switch knob is in the middle OFF position, no voltage is supplied to the heating filaments and the cape does not heat.

To turn on the heating, you need to move the switch knob to one of the HI (maximum heating) or LO (minimum heating) positions. When the switch is in position HI, the current from contact 2 of the switch will flow to contact 1 and flow from it through the upper terminal of the lower winding to the lower one, then through the trip fuse, a 10 A fuse installed in the plug, and then through the central contact of the plug into the vehicle's on-board network.

The resistance of the lower winding is 3 Ohms, therefore, the heating power will be 48 W. If the switch is set to the LO position, current will flow from terminal 3 to the upper terminal of the upper winding. The total resistance of the heating windings connected in series will be 4 Ohms and the heating power will drop to 36 W.

LED VD1 connected in series with resistor R1 is an indicator of the presence of voltage in the cigarette lighter.

The section of the diagram drawn in blue is the result of a modernization of the cape. VD2 lights up red when the switch is in HI position, and VD3 when in LO position. Resistor R2 limits the current through the LEDs.

How does heated seats work?

- The technology used to operate heated seats is not too complicated. Heated seats work by placing heating elements under the car seat upholstery. Electricity is passed through the heating element. A heating element can be thought of as a resistor because electricity flowing through it receives resistance and produces heat.

- Like many systems in a car, heated seats are activated using a relay switch. A relay switch is a relatively simple mechanical trigger that allows a device to begin receiving power. A relay allows electricity to switch circuits from less power to more power.

- A thermostat is included in the heated seats as a precaution against overheating. If there is no thermostat, then after starting the heating element will continue to heat up indefinitely. This will cause overheating, which may cause fire, injury or damage to the vehicle. As a safety precaution, the thermostat serves as a heat limiter. Once the heating reaches the temperature set on the thermostat, power to the relay is turned off until the seats have cooled to a certain temperature. The thermostat controls both overheating and underheating. The control unit in the form of a mode switch controls the thermostat settings.

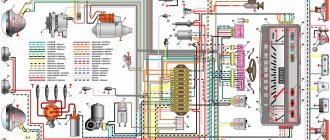

Location of fuses on the diagram for VAZ 2110, 2111, 2112

Today we will look at the location of fuses in VAZ cars of the tenth family, namely models 2110, 21102, 21103, 2111, 2112. We will also show where the fuses and relays are located on the diagram and talk about the purpose of each of them and how to replace the fuses with your own hands. We will also touch on the most common problems with fuses among owners of these cars, diagnostic methods and replacement.

I would like to say that car electrical systems, in particular fuses and relays in the VAZ 2110, 21102, 21103, 2111, 2112, are quite reliable. The service life depends on operating conditions and timely diagnosis and replacement with high-quality components.

Let's figure out why fuses are needed in a car. First of all, they are responsible for the safety of the wiring and other systems of the machine.

It is important to understand that each specific fuse is responsible only for its task and in the event of a short circuit or failure, a fire is practically excluded. A specific fuse blows and this does not cause a chain failure of other systems

Depending on the problem of failure of any component or part of the car for which the electrician is responsible, you need to understand whether the car can be operated with this malfunction or not. The traffic rules contain a list of faults that you cannot operate a car with. If you discover, for example, that the headlights have failed or the wipers are not working at all, you should immediately correct the problem. Well, you can drive a car with non-working power windows. So…

Included in the package

- Pads with heating elements for the two front seats (lower and back), wiring and switches.

- Wiring includes thermostatic regulator, fuse holder with 12v fuse, and relay.

- Zip ties and adhesive tape.

- The kit usually contains everything needed for a standard installation of a heated seat kit. If you need any electrical elements (connectors, corrugation, etc.), you can purchase them in addition.

What tools will you need:

- Phillips and flathead screwdriver

- Ratchet wrench with head for removing seats

- Stripping pliers

- Crimper

- Nippers or metal scissors (for cutting the rings holding the upholstery).

- Bladed knife or scissors

- step drill

- soldering iron with solder and solder paste

- marker

- scissors

- multimeter, 12V electrical tester with light bulb.

The photo shows a universal set of seat heating with carbon heating elements in the form of a cellular structure.

Such sets are sold both on Aliexpress and in other online and off-line stores. Additional accessories and installation kits are not required for most installations, but are used by professional installers.

Preparing to install heated seats

First, disconnect the battery and let the car sit for 10-20 minutes to allow the SRS to fully discharge. Once the airbag (SRS) related connectors have been disconnected, the battery must not be reconnected until you turn on all SRS components again, otherwise an error will occur.

On vehicles with seats that have side airbags, you must follow a certain procedure before removing the seats to avoid an error (may not work on all vehicles):

- Turn off the car and leave the key in the ignition off.

- Disconnect the negative terminal of the battery and insulate it with a rag or plastic bag so that it does not accidentally reconnect. You must wait at least 5 minutes before proceeding to the next step.

- Remove the seats, disconnect the airbags, seat belts, power connectors for the power seats. Do not turn on the ignition while the seat is removed and all connectors are disconnected.

- When the seat is installed and screwed into place and all connectors are connected (the ignition key must be in the off position), connect the negative cable to the battery.

If the seats have side airbags, then before removing the seats you need to disconnect the negative terminal of the battery to avoid an error.

So, let's first look at the brief installation instructions, and then we will analyze each point in detail.

Installing operating mode indicators in the switch

To indicate the supply of voltage to the heated cape in the plug, which, when connected to the vehicle's on-board network, is inserted into the cigarette lighter, there was a red LED. And to indicate the heating power mode or to turn it off in the dark, you had to feel for the switch in the dark, since such an indication was not provided.

Therefore, immediately after purchasing the cape, I installed two LEDs of different colors, red and green, in the switch for indication. On the electrical diagram of the cape, the added elements are shown in blue. Any two LEDs, a 1.8 kOhm resistor and a small piece of wire are all the necessary parts for making an additional indication.

To disassemble the switch, you need to unscrew two screws and remove one of the covers. Next, in the cover with the inscriptions, you need to drill two holes with a diameter equal to the diameter of the optical part of the LEDs. The installation is mounted. One terminal of each LED is connected by soldering to each other and a resistor is soldered to them. A piece of wire is soldered to the second end of the resistor, the second end of which is connected to the black (brown) wire of the cable. One wire is soldered to the remaining free ends of the LEDs, the ends of which are soldered to the extreme terminals of the switch.

For reliable fastening of the LEDs, the place where they are installed and mounted is filled with silicone. As I already reported above, when the lower winding breaks, both LEDs glow in the LO switch position. In this way, you can find out the reason why the seat cover is not working.

The photo shows how the indication occurs in the switch positions OFF (off) - the LEDs do not light, LO (minimum heating, 34 W) - the green LED lights up and HI (maximum heating, 44 W) - the red LED lights up.

Installation instructions:

Disconnect the negative battery terminal.

- Remove the seats from the interior.

- Remove the upholstery.

- Place a pad with heating elements on the back and seat.

- Identify a power resource that is capable of delivering a continuous 10 amps of current. Once you have determined the power resource, wire to that resource.

- Find a suitable location for the switch. Drill a hole in the desired location and pull a connector through the hole, then connect it to the switch and attach it.

- Place the seats in place in the interior and fasten them. Connect all connectors under the seat, along with the new heater connector.

- Connect the battery and turn on the ignition.

- Check heating in all modes.

How to disassemble a cape for repairs

You need to start disassembling the cape by removing the clamp of the current-carrying wire. In order to remove it, you need to unscrew two screws.

Removing the wire clamp did not provide access to the connection of the wires with the heating elements and it was necessary to cut the fabric and foam rubber from the back of the heating cape. It is good to make the cut with scissors or a sharp knife. In this case, you need to be careful and careful so as not to damage the wires and the cut is smooth. Then, after repairing the cape, it will need to be sewn up with thread.

An autopsy showed that the heating winding was connected to the current supply wire by twisting followed by soldering. For insulation, insulating tubes are put on the solder joints.

A thermal fuse is included in the gap between the black wire and the lower end of the heating element for fire safety. This fact caused a pleasant surprise.

I removed the insulating tubes from the junctions of the ends of the heating windings with the current supply wire and checked the reliability of the connections. I found no defects. The rations were brilliant and high quality. I rang the windings again with the tester. The resistance of one of the heating windings, the bottom one in the electrical diagram, instead of 3 Ohms, was infinity. I had to start looking for the break point.

First, in order for the current-carrying wire not to interfere with work and not to break the ends of the heating windings with its weight, it was necessary to disconnect it from the windings by heating the joints with a soldering iron. In order to get to the heating conductors, I had to literally turn the car seat cover inside out. The following picture opened before my eyes.

On a sheet of foam rubber about two millimeters thick, the heating wires are neatly laid in a snake on glue in an insulating tube. The conductors are covered on top with a translucent sheet of thin, fragile elastic material with a sticky layer. There was full access to the wires to find the break point. All that remains is to find this place.

Removing the seats

Disconnect the battery terminal before disconnecting the seat. Otherwise, the airbag error will light up (if the seat has one). Disconnect power from the seat last.

The seat is attached to the car floor with 4 14 mm bolts. The rear bolts are covered with plastic covering.

The plastic needs to be removed and the bolts unscrewed.

To make it easier to remove the seats, remove the headrests, seat belts and anything else that prevents the removal of the seats.

The removed seat is easy enough to stick out of the cabin. Start pulling it out from the back. Be careful as the metal runners have sharp edges that can damage the plastic. It is better to place the seat on some kind of elevation (a bench or table) to make it more convenient to work with it. Lay or place something under the seat as the metal runners can damage the surface. Remove all side plastic covers.

Dismantling works

To install heating elements, you first need to carry out a dismantling procedure. It includes the following activities.

- Unscrew the plastic fasteners that connect the seats to the body of your car.

- Remove the skids. Two pieces are located in front, and two more are located in the back.

- Remove the chairs from the interior, otherwise it will be extremely uncomfortable to work.

- Separate the back from the chair. To do this, there are bolts on the sides, which can be removed with a 10 mm wrench.

- On the back there is a plug for the headrests, which can be removed.

- The upholstery is removed from the hooks below. To do this, the hooks are slightly unbent.

- Now you can completely remove all the trim.

- Carry out a similar procedure with the second seat if you plan to install heating on it too.

Read more: Car tinting with llumar film

While you are installing the heating, throw the upholstery into the washing machine. This will not harm her, and the interior will look newer and nicer.

Removing the seat upholstery

To install a seat heater, you need to gain access under the seat upholstery and backrest. To begin removing the upholstery from the seat, you need to remove all the metal rings (hog rings) that hold the upholstery. Start at the bottom back of the seat. Turn the seat over for better access and start cutting off the rings with wire cutters.

The instruction manual, which can be purchased or downloaded on the Internet, may be useful during disassembly. The service instructions may contain information about disassembling the seat (removing the upholstery), the location of all fasteners.

When disassembling the seat, take a photo before you remove anything, so that later, when reassembling, you can look at the photo as a hint.

Once the edges of the upholstery are free, lift up the edge of the upholstery to gain access under the upholstery and begin cutting away the fasteners (rings) that secure the center section of the upholstery. Instead of fastening rings, you can use small ties. Clean the surface of the soft part of the seat, as the heating will stick to the seat.

The seat back may have 2 brackets for attaching the headrest. There is no need to remove them, as they will not interfere with the heating installation. They may also break when removed.

Installation of heating elements

- The installation process for the driver and passenger seats is the same, with the exception of one feature, which we will discuss below.

- After installing the heated seats, the only visible thing should be the heating mode switch.

- The heated pad is placed between the seat upholstery and the seat cushion.

- For the longevity and reliability of the heating elements, it is important that they are positioned correctly. Heating elements can only be placed in the middle of the seat. They should not go into the lateral support. Heating elements must be installed without folds.

- The pads can be trimmed slightly in length (the edge opposite the edge with the wiring) so that they fit well in place. Seal the edge using the adhesive tape included in the kit. You cannot cut the heated pad too wide. You can see how the long wire along the edges shows through - it cannot be cut. It is allowed to trim the edges a little to this wire. This may need to be done so that the heating elements do not come into contact with the side seams.

- Place the heating element intended for the seat and align it on the soft part of the seat. Use a marker to mark the location of the upholstery attachment points (rings or others). Using scissors, cut holes in the heating pad for these fasteners. Cut several strips of tape and cover the exposed ends of the heating elements around the hole.

The pad with heating elements has a double-sided adhesive tape for fastening under the upholstery, on the soft part of the seat.

- If the seat has recessed channels, then the heating element cannot be pushed into them. You need to cut out a heating lining for them in the places where the heating elements are located, having previously marked these places with a marker. After this, the exposed edges of the heating element must be insulated by gluing the tape from the kit.

- Never cut holes in an area covered with tape. Areas with adhesive tape should only be applied to a flat seat surface.

- The heating element should not touch any conductive surfaces (metal rings - upholstery fasteners, seat frame) to avoid a short circuit.

- The old, classic fastenings are metal rings, while the new, more modern ones are Velcro fastenings. For older fasteners, apply the included tape around the rod to insulate it. Velcro fastenings can be sewn onto the lining with heating elements. Thus, there is no need to cut heating elements for this type of mount.

- The soft seat backing must be clean before installing the heating.

- Peel off the protective layer from the back of the adhesive part of the heated pad and carefully apply it to the seat in the desired position. The strength of the heated adhesive joint is achieved by applying sufficient pressure. The heating element cannot be separated and rearranged after gluing.

Universal heating elements must be cut out at the places where the upholstery is attached. Exposed edges must be sealed with adhesive tape included in the installation kit.

- The passenger seat may have a sensor that responds to the passenger's weight to activate or disable the passenger-side airbags in the event of an accident (Occupant Detection System). After removing the seat upholstery, you need to determine whether there are sensors located on top of the seat. Toyota, Kia and Hyundai usually place the sensors on the surface of the seats (bottom). Honda usually places the sensors on the back of the seat. Heating cannot be installed on top of this sensor. In this case, you can install heating only on the part of the seat where there is no sensor (the back or vice versa, only the seat). Also made at the factory. When you buy a Toyota car with such a sensor, from the factory it only has heated backrests of the passenger seat. When you purchase a Honda, from the factory it only has heated seats, and the backrest is not heated (since the sensor is located on the backrest).

- It may be necessary to cut a channel for the temperature controller and wire with a knife in the soft part of the seat so that it is not noticeable after installing and assembling the seat.

Popular

Since the relay is open, turning the ignition on again leaves the heating off and you must press the button again to turn it on. I didn’t take photographs of this process - everything is done locally anyway.

When they are inserted, a toothed metal plate is clamped on top with pliers and cuts through the insulation.

How to install heated seats in a car yourself? By the way, don’t be lazy and install other heating units.

Now you can put the rear trim element on the hooks. In this case, the on-board network will not be affected if the heating fails. Experts recommend choosing the standard ones provided for the VAZ. The connection of control, indication and button illumination was carried out with a two-core wire.

We recommend: Pue frequency of grounding checks

Simple universal heated seats and a diagram of connecting it to the car

I plopped down on the icy seat for a couple of seconds, started the car, pressed the heating button, and within a couple of minutes the seat was already warm. Element Explanation Heating elements These are required for the backrests and seats.

Do you use heated seats? This arrangement of switches will be the most successful from the point of view of ergonomics and comfort. The best opportunity for self-installation of heating elements remains in cars that already have a system installed, but not installed by the manufacturer.

With a correctly assembled circuit, the heating will function only when the ignition is on. Didn't find the information you are looking for?

Bend back the cover at the passenger's feet and remove the cover of the ECU box. The ideal option is either the center console if there is space for installing buttons, or in the space between the gearbox rocker and the handbrake. This option is quite rare on budget class cars. Unclip the trim on the dashboard where the various buttons are located. ✅ INSTALLING HEATED SEATS ON A CHEVROLET NIVA WITH YOUR OWN HANDS. HOW TO CONNECT SEAT HEATING.

Connecting the heated seat wiring

- It will be more convenient to conduct wiring from the seats to the power source when the seats are removed and located outside the cabin.

- The wiring must have a reserve length and be stretched so that you can change the position of the seat without any difficulties. The cable should not touch sharp edges, bend or be strained to avoid damage.

- Think about where you can hide the heating wiring. The most suitable places are under the center console, which is located between the front seats, under the carpet, at the edge of the footrest, or in the place where the threshold is located.

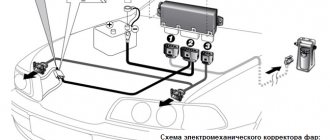

- Study the heating connection diagram, which is in the instructions, as well as the wiring diagram of your car. You need power for the heated seats that will turn off completely when the ignition key is removed.

Simplified connection diagram for seat heating

- The positive (usually red wire) can be connected to the positive ignition power supply.

- Securely connect the ground (black wire) with a small terminal to the body negative (ground). Improper grounding may cause the heating to not work.

- Select a suitable location for mounting the switch that is easily accessible to the driver and passenger, and ensure that there is enough space behind the switch for the wiring and switch bracket. This could be on the side of the seat, on the front of the dashboard, or on the panel that runs between the driver and passenger seats. Mark the location and drill approximately a 20mm hole to install the switch. The hole should not be too small or too large. This is important for securely attaching the switch. The most suitable place for the switch is on the plastic trim located on the side of the seat.

Select a location that is easily accessible to the driver and passenger to install the switch.

Location of fuses on the diagram for VAZ 2110, 2111, 2112

Today we will look at the location of fuses in VAZ cars of the tenth family, namely models 2110, 21102, 21103, 2111, 2112. We will also show where the fuses and relays are located on the diagram and talk about the purpose of each of them and how to replace the fuses with your own hands. We will also touch on the most common problems with fuses among owners of these cars, diagnostic methods and replacement.

I would like to say that car electrical systems, in particular fuses and relays in the VAZ 2110, 21102, 21103, 2111, 2112, are quite reliable. The service life depends on operating conditions and timely diagnosis and replacement with high-quality components.

Let's figure out why fuses are needed in a car. First of all, they are responsible for the safety of the wiring and other systems of the machine.

It is important to understand that each specific fuse is responsible only for its task and in the event of a short circuit or failure, a fire is practically excluded. A specific fuse blows and this does not cause a chain failure of other systems

Depending on the problem of failure of any component or part of the car for which the electrician is responsible, you need to understand whether the car can be operated with this malfunction or not. The traffic rules contain a list of faults that you cannot operate a car with. If you discover, for example, that the headlights have failed or the wipers are not working at all, you should immediately correct the problem. Well, you can drive a car with non-working power windows. So…

Assembly and installation of seats

To install the upholstery on the lower part of the seat, you can use vinyl ties instead of cut rings. Insert the zip ties into the places where there were rings holding the upholstery, but do not tighten them yet. Pull the zip ties through the holes. Starting at the back, connect the zip ties and tighten them a little so they don't come apart again. Once all the zip ties are connected, tighten them and cut off the remainder. To install the upholstery on the backrest, turn the upholstery inside out and begin to gradually tighten it, unrolling it down onto the backrest. Disassembling and assembling a car seat is also described in the article “do-it-yourself seat reupholstery.”

After assembly, the seats are installed back into the cabin, all connectors are connected, including the new one going to the heated seats. Next, you can connect the negative terminal of the battery, turn on the ignition and test the heated seats.