The source of powerful low-frequency sound in sound systems is the subwoofer. This also applies to car acoustics, which is why most car enthusiasts equip their cars with such devices.

You can purchase a ready-made unit, but many people prefer to buy speakers and make a box for the subwoofer with their own hands. This is not as difficult a job as it might seem, but it will require tools and certain skills.

How to make a subwoofer box correctly

Before you start making a subwoofer box, you need to choose a loudspeaker. The volume of the future structure will depend on its parameters. Most often, specialized imported loudspeakers with a diameter of 10-12 inches are used to reproduce powerful bass. Structurally, the subwoofer box can be made in three options:

- Closed box

- Bass reflex

- Bandpass

The quality of the loudspeaker and the design of the box ultimately determine the sound quality of the low-frequency sound system.

Vas indicator

This parameter for speakers can be measured using two methods:

- additional mass;

- additional volume.

In the first case, measurements are made using some weights (10 grams for every inch of diffuser diameter). These could be, for example, weights from pharmacy scales or old coins whose denomination corresponds to their weight. The diffuser is loaded with such objects and its frequency is measured. Next, the necessary calculations are made using the formulas.

When using the additional volume method, the sound emitter is hermetically sealed in a special measuring box with the magnet facing outward. Next, the resonant frequency is measured and the electrical and mechanical quality factors of the speaker, as well as the total, are calculated. Then, taking into account the obtained data, Vas is determined using the formula.

You may be interested in: An astronomer is a scientist who studies astronomy

It is believed that the lower Vas, other things being equal, the more compact design can be used for the speaker. Typically, small values of this parameter at the same resonant frequency are the result of a combination of a heavy moving system and a rigid suspension.

How to make a housing for a subwoofer

The easiest to make is a buried box or box. This is a completely closed structure, the manufacture of which will require a minimum of simple wooden parts. How to make a housing for a sub becomes clear when you see such a device. Essentially, this is a rectangular box with a hole cut out in the front wall for a dynamic head. The box consists of six walls, which are easy to cut out of the appropriate material. A terminal block is mounted on the side or rear wall to connect wires from the amplifier. The closed box (CB) is distinguished by dense and not vague bass, smooth amplitude-frequency response, but has the lowest efficiency among all designs.

The box can be in the shape of a parallelepiped or trapezoid with beveled walls. Due to its characteristics, the closed design is suitable for many musical styles. The sealed, closed design conveys bass well in pop and rock music, classical, jazz and instrumental works. But fans of rap and dubstep will be disappointed, as the closed box is not suitable for playing music that has a lot of heavy bass and where the low frequencies are the basis of the music.

Properties of homemade models

Many music lovers want to bring their sound to a super powerful level. In this case, the speakers should be equipped with a subwoofer. The sound will become tens of times stronger.

Low frequencies differ from high and mid frequencies in that they do not need to be sounded in stereo. And there is no need to make two speakers in a wideband version.

It is only important to choose:

- Speakers, one of the expensive elements;

- Powerful microcircuits that amplify sound;

- One hundred watt pulse power supply.

All remaining spare parts are of low cost. If you do your work efficiently, you can assemble the column yourself. Homemade devices can work for several years. Only microcircuits, diodes and transistors fail.

How to properly assemble a subwoofer enclosure

It is not difficult to make a housing for a subwoofer with your own hands if you strictly follow all the recommendations. The most important thing that a closed case requires is tightness and lack of vibration. The optimal material for a low-frequency speaker is multilayer plywood or MDF. The thickness of the material must be at least 18-20 mm. Thin walls will resonate and these vibration waves entering the car interior will greatly degrade the quality of low frequency reproduction. The most important parameter of any subwoofer is its volume. This parameter takes into account the internal space of the box without the volume occupied by the speaker. The relationship between the volume of the housing and the diameter of the loudspeaker is as follows:

- 10 inches (25 cm) – 15-20 liters

- 12 inches (30 cm) – 25-35 liters

- 15 inches (35 cm) – 40-60 liters

- 18 inches (46 cm) – 70-110 liters

In order to increase efficiency and improve sound quality, all seams between wooden walls must be sealed. It is best to use silicone sealant for this purpose. A closed box for a subwoofer, made with your own hands, has its undoubted advantages:

- Easy to calculate volume

- Ease of production

- Small sizes

- Distinct and clean bass

There are only two main disadvantages: low efficiency, not suitable for listening to “heavy” bass. The internal volume of a closed subwoofer can be filled with padding polyester or cotton wool. If the volume is calculated correctly, then this is not necessary. It is recommended to listen to the work of the subwoofer, both with and without filler, and choose the best option. At different air temperatures, the pressure inside a closed volume changes and to equalize it, a small hole of no more than 1.5-2.0 mm is sometimes left in the subwoofer housing.

Calculation of the FI box using JBL SpeakerShop and BassPort programs. — DRIVE2

Before you begin calculating the bass reflex enclosure for a specific subwoofer speaker, you need to find out what Thiel-Small parameters the speaker has and understand what they are: For an adequate calculation, three parameters are enough. Fs is the resonant frequency of the speaker, indicated in Hz (hertz). Vas is the equivalent volume indicated in liters.

Qts – total quality factor of the speaker.

1. Calculation of the net volume and tuning frequency of the bass reflex. To do this, you need a program for calculating subwoofer enclosures, there are quite a lot of them, both paid and free, the most popular and easy to use is the JBL SpeakerShop program. In the program, you need to specify the Thiel-Small parameters, selecting the volume of the box and setting the bass reflex port, to obtain the required frequency response graph.

2. Calculation of the bass reflex port. Very quickly and conveniently, and most importantly with great accuracy, you can calculate the port at the desired frequency in the BassPort program.

We enter in the program: The required frequency of tuning the FI port The previously obtained net volume of the box The effective area of the speaker diffuser (measured, the length along the center of the speaker from one middle of the suspension to the opposite middle of the suspension) The maximum stroke of the diffuser in one direction (indicated in the instructions or on the manufacturer’s website as Xmax , can be indicated either in one direction or in both directions at once) Select the port cross-section Enter the dimensions of the port Press the calculate button and get the required port length “L”, as well as other equally important data, in particular - the displacement of the port, which will be added to the volume of the subwoofer enclosure.

3. We calculate the total volume of the FI case. In the JBL SpeakerShop program, we learned what pure volume is needed for a particular subwoofer, as well as what frequency is best to set the FI port. At Bassport, we calculated how long the FI port should be based on its area, and found out how much volume the port would occupy.

Now we add up: net volume + port volume + 3 – 4 liters (volume displaced by the speaker) and we get the total internal volume of the future FI case. If roundings, stiffening ribs are used in the housing, if the housing is slotted, etc., this must also be taken into account in the total volume. Example: *Net volume - 45 liters.

*Slotted port, area 140 cubic cm. at 36 Hz - 8.5 l., plus 3.8 l. on the port wall of 18 mm. plywood. *Displacement by speaker - 3 liters. *Total - 60.3 liters. the total volume of the hull FI. Now, it would seem the most incomprehensible thing is how to obtain the dimensions of the hull based on the known displacement? We have a volume of 60.3 liters.

Advice

We measure the trunk, see what dimensions suit us, for example: height - 40 cm, length - 60 cm, we just need to find out the width. We subtract the thickness of the walls from the height and length (let it be 18 mm plywood) and we get: height - 36.4 cm, length 56.4 cm.

Now we calculate: 60.3 * 1000 / 36.4 / 56.4 = 29.4 - the width of the body, without walls, with walls 33 cm.

This is what the calculation of a bass reflex enclosure for a specific subwoofer speaker looks like. I ask you not to take this article as a clear guide to making a FI subwoofer, there are a lot of points and subtleties that are not taken into account.

Who is interested in car audio, join vk.com/sound_paradise

Making a box for a subwoofer with your own hands

Making a do-it-yourself subwoofer housing is simple and takes a minimum of time. After the speaker has been selected and the internal volume of the closed box has been calculated, you need to prepare the material, fasteners and tools. With your own hands, the subwoofer body is usually made from the following materials:

- Plywood

- MDF

- Chipboard

Moisture-resistant multilayer plywood is considered the best material for making a subwoofer box. There are some difficulties with this. Plywood is the most expensive material and it is difficult to find plywood with a thickness of 18 mm or more. If the volume of the subwoofer is too large, then the plywood walls will emit a “ringing”, which can be eliminated by installing internal stiffeners. A good choice would be to use MDF. It is cheaper than plywood, easy to process and has good moisture resistance. Chipboard has become widespread. It can be found at any furniture company. There the slab will be cut to the specified dimensions. The disadvantages of chipboard structures include very low rigidity, when strong low-frequency vibration at the fastening points causes the material to collapse. In addition, it absorbs moisture well and if water gets into the trunk of a car, the box may simply crumble. This material can be used to make a housing for a home subwoofer. It will not be used in extreme conditions and will last a long time.

Plywood

Wood has been used to make furniture since ancient times, but it was a time when wood was available in abundance, and as wood scarcity increased, plywood was invented for those who could not afford teak, walnut or mahogany furniture. Plywood is made from wood, but every piece of wood is used to minimize wood loss. Plywood has many advantages, such as a variety of sizes and thicknesses. It can easily be covered with paint or laminate in any color or pattern. Plywood production minimizes wood waste, but does not eliminate it.

MDF is an abbreviation for medium density fiberboard. Since the shortage of wood prompted the invention of plywood, MDF is another product that was invented as a wood substitute. MDF is made up of small pieces of wood that are broken down into wood fibers and then compressed in a hydraulic press under very high pressure into a board. MDF boards are manufactured in various thicknesses so that they can be easily used in various industries. These slabs have a very smooth surface and the furniture they make is of very high quality in terms of attractiveness. MDF is easily laminated in a variety of shapes and colors, or painted to your choice. MDF boards are made from wood fibres, hence they have very little screw-driving capacity.

The right subwoofer box

The correct body means a more complex, but also higher quality design. This could be a body with a bass reflex or an even more complex system called a bandpass. Assembling a subwoofer enclosure with your own hands will take more time, but the result is worth it. The bass reflex can be slotted or in the form of a pipe. This design is a small “tunnel”. It rotates or inverts the phase of the signal with its further radiation into space, as a result of which the efficiency of the subwoofer doubles. A bass-reflex subwoofer is distinguished by strong and rich bass, and on its amplitude-frequency characteristic, at the tuning point, there is a large protrusion and At this frequency the volume increases. The tuning peak is regulated by changing the size of the port and the ratio of the working volume of the subwoofer to the size of the bass reflex. This subwoofer design is well suited for playing music with fast and powerful lows. How to assemble a subwoofer box largely depends on its design.

Making a housing for a subwoofer with a bass reflex

As with making a closed box, work on a more complex design begins with choosing a loudspeaker. How to make a box for a subwoofer depends on the type of material and fasteners. Multi-layer plywood is the strongest recommended material. To assemble the subwoofer housing with your own hands, you can use any self-tapping screws. When connecting elements from MDF, and especially from chipboard, you need to use only white self-tapping screws. Black ones do not provide such a strong connection. Sometimes the caps break off when screwed in.

The bass reflex subwoofer must be well sealed. To do this, a layer of sealant is applied to all seams on the inside. The cutting lines must be very even, so it is better to do the work on a special machine, if possible.

When making a slotted bass reflex, you need to ensure that all internal partitions do not have through holes. If the dimensions of the speaker and the box are large, then stagnant zones may appear in the turns of the slot port. To avoid this, all right angles of the bass reflex are smoothed out by installing additional wooden plates. Do-it-yourself subwoofer box assembly is completed by installing external contacts for connecting the amplifier. These places must also be sealed.

Cutting parts

So, you have decided on the shape for the sub box and you have a drawing.

Mark the sheet according to the parts and cut according to the marked dimensions. Use a disk with a large number of teeth; the smaller the tooth size of a circular saw blade, the fewer chips you will get, and their size will be insignificant.

If you use a manual circular saw and your hand is not full, it is better to use a guide so as not to accidentally “fill up” the cut.

It is better to do this work together, since it is quite inconvenient for one person to turn large sheets and hold them while working.

Below is a good video from Rockford Fosgate, albeit in English, but everything is clear here without translation - choosing the shape of the body, lining up the parts, cutting.

Small subwoofer box

Some motorists do not strive for powerful bass, but want to slightly improve the sound picture in the cabin. A small subwoofer is suitable for this. 8" speakers are suitable for this design. Some companies make 6-inch speakers, but they are hard to find. How to make a subwoofer box correctly. A subwoofer for a small loudspeaker has a small displacement, therefore, it will take up little space in the luggage compartment of the car. There is no need to reduce the size of the structure too much, but you also shouldn’t increase it. Increasing the size of the box will lead to the fact that low frequencies will “spread” and the bass will be unclear. If the volume is less than what is needed for a speaker of a certain diameter, then the lows will be too fast and will literally hit the eardrums.

How to properly install and connect a subwoofer in a car

Installing a homemade device in a car, as well as connecting it, will require a certain tool. So, in addition to the fact that you need a subwoofer and an amplifier for it, you will have to worry about the following devices in advance:

- fuse;

- wires (three wires in one winding - for power, for “+” to the battery and a wire to the radio);

- capacitor;

- wire cutters;

- insulating tape;

- plastic clamps;

- set of wrenches.

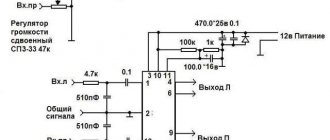

The wires are connected according to the following diagram:

- Initially, the subwoofer wire is routed to the amplifier.

- From the amplifying device, the wire is connected to the car radio.

- The “+” power cable must be protected from damage - for example, wrapped in corrugation.

- The fuse is placed on the same “+” wire at a minimum distance from the battery.

You can connect the subwoofer yourself, based on the parameters of this circuit

Video: connecting and setting up a subwoofer

Independent design, manufacture and connection of subwoofers in a car is available to almost every driver. The key to success will be both a competent calculation of the dimensions and volume of the product, and careful assembly of the case. At the same time, the car enthusiast can independently select the desired size of speakers in order to create in the cabin the low-frequency sound that suits him most.

Home →

Tuning →

How to make a housing for a subwoofer with your own hands

If you need to make a good box for a subwoofer, then it is best to focus on the most complex design. This system is called a bandpass. It comes in fourth order and sixth order. The fourth-order system is a two-chamber box, where one chamber is a closed box, and the other plays the role of a bass reflex.

A sixth-order bandpass is a design with two bass reflexes. The most difficult thing here is the calculation of the second port and the relative relationship of the settings of each bass reflex. The two chambers have different sizes and are capable of limiting the frequencies reproduced by the loudspeaker. The box for two subwoofers is the most difficult to design, but it has the maximum efficiency. To determine all sizes of such sound systems, special utilities are used. The universal WinISD program is suitable for calculating any subwoofer design. It does not have a Russian-language interface, but it is not difficult to understand. To make a drawing of a box for a subwoofer, just load the parameters of the speaker you are using into your computer.

Subwoofer housing drawings

If you don’t have the time and desire to calculate the subwoofer box yourself, you can take ready-made calculations and drawings. If you need to make the bass very deep and powerful, you can make a subwoofer box for two speakers. In this case, the design can be in the form of a closed box or bass reflex. Both speakers must be of the same type and with the same resonance frequency, otherwise it will be difficult to adjust the bass reflex. If you have no experience working with car acoustics, then it is better to make your first subwoofer using a closed box design. A bass reflex subwoofer with one loudspeaker is also easy to make with your own hands. You should not, without experience, take on a system such as a bandpass. In any case, the result will not be satisfactory.

Option No. 2

First of all, guided by Fig. 1 and the table, it is necessary to make a “standard volume” - a sealed plywood box, all joints of which are carefully adjusted, glued and coated with plasticine to avoid air leaks.

rice. 1

| Speaker diffuser diameter, mm | Dimensions, mm | ||

| A | IN | WITH | |

| 200 | 255 | 220 | 170 |

| 250 | 360 | 220 | 220 |

| 300 | 360 | 220 | 270 |

| 375 | 510 | 220 | 335 |

Next, the natural resonance frequency of the loudspeaker located in free space is measured. To do this, it is suspended in the air away from large objects (furniture, walls, ceiling). The measurement diagram is shown in Fig. 2.

rice. 2

Here ZG is a calibrated sound generator, V is an alternating current tube voltmeter and R is a resistor with a resistance of 100–1000 ohms (at higher resistance values the measurement is more accurate).

By rotating the frequency adjustment knob of the sound generator in the range from 15-20 to 200-250 Hz, achieve the maximum deflection of the voltmeter needle. The frequency at which the deviation is maximum is the resonant frequency of the loudspeaker in free space Fв.

The next stage is to determine the resonant frequency of the loudspeaker Fв when it is operating at a “standard volume”. To do this, the loudspeaker is placed with a diffuser on the hole of a “standard volume” and pressed lightly to avoid air leaks at the junction of the surfaces. The method for determining the resonance frequency is the same, but in this case it will be 2–4 times higher.

rice. 3 fig. 4

Knowing these two frequencies, the dimensions of the bass reflex are found using nomograms. Depending on the diameter of the loudspeaker diffuser, select the nomogram shown in Fig. 3 (for diameter .200 mm), in Fig. 4 (for diameters 250 and 300 mm) or in Fig. 5 (for diameter 375 mm). Using the selected nomogram, the volume of the bass reflex is determined by connecting the points corresponding to the found frequencies on the “Resonant frequency” axes with a straight line.