Important nuances in work

- When driving the oil seal using a mandrel, do not overdo it. Apply gentle blows and control the depth of the oil seal. If you hit it hard, you can easily damage the oil seal;

- Before installing the oil seal, lubricate the rim and sealing edge with fresh oil;

- Before installation, inspect the flange for wear in the area where the sealing lip of the oil seal meets. If there is a “groove,” the flange must be replaced.

As you can see, the process of replacing the VAZ 2107 gearbox seal is quite simple and does not take much time. The most important thing in this job is to properly tighten the rear axle flange nut.

Steering gearbox - repair, replacement, adjustment

The steering gearbox is a rather old mechanical device that is now used mainly on cars of the classic LADA family. Today you will learn what a steering gearbox is - repair, replacement, adjustment with your own hands.

The steering gearbox is a small mechanism designed to transfer rotational motion to translational motion. This means that the gearbox converts the rotation of the steering wheel into a force that moves the steering rods in the right directions, causing the wheels to turn and change the direction of movement of the car.

The gear used in the gearbox is a reduction gear and consists of two elements - a worm and a gear. In addition, the mechanism has a special lever that moves the steering rods in the right directions.

The steering gearbox of the VAZ 2107 is sealed and filled with oil, which significantly increases its service life and makes it easier to turn the steering wheel, reducing the effort exerted by the driver.

Video - Steering gear repair

https://youtube.com/watch?v=_iGPcODrMRc

In most cases, this unit is not repairable, since it is relatively inexpensive and consists of only two main parts. However, the manufacturer left the option for car technicians to purchase a repair kit.

Before repairing the steering gear, let's determine the malfunctions.

- Firstly, it can be repaired if the steering wheel rotates but the wheels do not. This means that there are defects on the threaded part of its shafts that prevent the two interacting parts from touching.

- The second type of fault is oil seals. If they have reached critical wear, then the oil from the gearbox will certainly leak, which already leads to its accelerated wear. If there are other mechanical damages, the gearbox must be replaced.

First, remove the faulty unit from the car. After this, press the bipod off its shaft using two hammers. Drain the oil from the gearbox through any technological hole. Now unscrew the four bolts that secure the cover and remove it. To access the worm shaft, you need to unscrew a similar cover on the other side of the mechanism. Pull out the remaining parts and replace the faulty ones. These may include oil seals and damaged shafts. After this, reassemble the gearbox in the reverse order. Don't forget to add oil!

How to change the steering gear on a VAZ 2107

If there is more serious damage, the steering gear must only be replaced. To do this, you need to purchase a new VAZ 2107 gearbox and immediately fill it with transmission oil. Now you need to remove the faulty gearbox from the car.

- Disconnect the tie rod ends from the tie rods. To do this, first unscrew them, and then unscrew the fastening nuts using a 22mm wrench. To pull them out, you need to use a special puller, which is available in any auto parts store.

- Go inside the car and loosen the clamp that secures the steering shaft to the steering gear. Pull the shaft out of engagement with the gearbox.

- All that remains is to unscrew the three bolts that secure the mechanism to the engine compartment of the car.

- Install the new gearbox in reverse order. Before you start operating the car, do not forget to adjust it.

Adjusting the VAZ gearbox

Adjustment of the steering gear is carried out to get rid of play in the steering wheel, as well as all kinds of discrepancies when it rotates with the position of the wheels. The car wheels must first be aligned.

To adjust the steering gear, you need to unscrew the lock nut on its cover from above and loosen the special adjusting screw. Ask your partner to sit behind the wheel and rotate the steering wheel in different directions with energetic, but not wide movements, while you gradually tighten the adjusting screw. As soon as the steering wheel begins to rotate tightly and the wheels move with the slightest movement, the locknut is tightened.

This completes the adjustment of the steering gear. As you can see, this procedure is not long at all and can be performed with just a 19-mm wrench and a regular flat-head screwdriver.

Features of VAZ-classic rear axle gearboxes

All VAZ classic cars are rear-wheel drive, the vehicle moves using the rear axle, which is the drive axle. The VAZ rear axle gearbox is the most important part in the transmission; it is where the main gear is located.

A lot depends on the gearbox - if it is faulty and humming, the car can get stuck in the middle of the road at any moment and will have to be towed. The speed of the car depends on the gear ratio (TR) of the main pair in the rear axle gearbox (REA) - the lower it is, the faster the car will move. But too high a speed loads the engine and transmission, so when replacing REM, owners of VAZ 2101-07 vehicles need to take into account the power and volume of the internal combustion engine (ICE), and install a gearbox that optimally matches the technical characteristics of the vehicle.

Device

In order for the car to move, it is necessary to transfer the rotation of the engine to the wheels. But the engine speed is too high, and in order to correctly distribute the torque, a mechanism is needed that changes the gear ratio. Due to the gearbox and different engine speeds, the speed of movement changes, and the main pair of the rear axle takes over the rotation and transmits it to the wheels through gears.

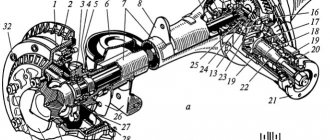

The VAZ rear axle gearbox consists of the following parts:

- flange, it is fixed on the drive gear (shank) of the RZM, and is an intermediate link between the driveshaft and this gear;

- the shank of the main pair, at one end of which there are splines for pressing the flange, at the other end there is a bevel gear with a small number of teeth;

- driven gear (planet gear), it is in mesh with the drive gear, and it is with it that it forms the main gear;

- center differential, allowing the rear wheels to spin at different angular speeds.

The differential design is very simple - the mechanism consists of two axle gears, two satellites and a satellite pin. From the gearbox, the movement is transmitted to the axle shafts, on which the wheels are mounted.

Differences in VAZ rear axle gearboxes

RZMs differ in the gear ratio of the main pair; in total, there are four types of gearboxes on the VAZ classic:

The slowest one is the RZM 2102, its drive gear has 9 teeth, and the driven gear has 40 teeth. To calculate the gear ratio, you need to divide the number of planetary gear teeth by the number of teeth on the drive shaft; for the VAZ 2102 the drive gear is equal to 4.44.

The “penny” gearbox (2101) accordingly has the number of teeth on the gears 10/43, so its IF is 4.3. The next, faster one is RZM 2103 - it has a ratio of 10/41, which means the gear ratio is 4.1. And finally, the “fastest” will be the 2106 gearbox, with the number of teeth 11/43 and an inverter frequency of 3.9, respectively.

Many VAZ 2101-07 owners strive to install the fastest gearbox, but this is not always necessary. If the car often carries cargo, that is, the car is a “workhorse”, high speed is of no use, but high-torque power will be very useful. It should be noted that RZM 2102 was not supplied as spare parts; it was installed only on station wagons.

Gearboxes on machine 2107

The VAZ 2107 is the last car from the rear-wheel drive VAZ series - it began production later than all of them and was in production the longest of all the “Classics”; its production ended in 2012. All types of gearboxes were installed on the machine, except 2102; the choice of RZM depended on the type and power of the engine.

Differential device

The planetary gear is mounted on the differential housing. The differential consists of two axle gears, two satellites and a pin. The main, most common differential malfunctions are wear of the pinion pin (play) and wear of the splines on the axle gears.

On a car, the play of the pin of the satellites can be determined by turning the driveshaft by a quarter or more; if there is no play, then the shaft practically remains in place when you try to turn it in one direction or another.

It's also worth noting that there is never any noise coming from the differential. When moving forward (in a straight line), the differential rotates as one unit and it turns out that there is simply nothing to make noise there.

The cause of noise from the rear axle gearbox when gas is added and the noise disappears after releasing gas is (almost 99.9%) wear of the teeth of the main pair. This is clearly visible on the removed gearbox. The forward side of the teeth has significant wear, while the reverse side shows little wear.

If, after disassembling and troubleshooting the parts of the main pair, wear of the teeth is detected, then no repair will help and it will simply be a waste of time and money. Only the main pair needs to be replaced.

Home-couple

The gears of the main pair are selected at the factory based on contact patch, noise and other parameters and are marked. For example, on the planetary gears it is stamped - VAZ 2103 (model), 10 41 (gear ratio), 4091 (pair number). The main pair number 4091 is also marked on the bevel gear.

After marking these parts, they became the “main pair” and are not installed one without the other, that is, “family”. “- 6” is also marked on the “tip”; this is an amendment for assembling the main pair in the gearbox. When troubleshooting a differential, its bearings are also checked for wear and, if necessary, replaced. Bearing wear is often caused by unprofessional replacement of the gearbox seal.

For example, after replacing the oil seal, tighten the shank nut without observing the tightening torque (pull as much as possible) and the force is transferred not to the spacer sleeve, but to the differential bearings.

These are supports on rotating axes and shafts, which receive loads and transfer them to various structures...

As a result, after a short run after replacing the shank oil seal, noise from the gearbox appears. Only in this case, the “hum” noise in the gearbox is constant and unlike the noise from worn teeth of the main gear. In this case, the hum is constant, regardless of whether gas is added or released.

Rear axle gearbox assembly video

During assembly, the gearbox is adjusted according to 4 parameters:

1. Selection of the adjusting ring

Parameters from 2.6 to 3.5. The ring serves to adjust the depth of engagement of the teeth of the “tip” and “planetary gear”, which is strictly specified. This is where the “correction -6” is needed for this main pair, which was mentioned above. Of course, this amendment will be individual for each main couple.

In this video, the main pair will be adjusted using a special device. It is clear that the vast majority of motorists do not have such a device and this is just a clear example of adjusting the engagement depth parameter. An option will also be given for adjustment without a “device”.

A “device” with a micrometer is also installed on the device, simulating the gear of the main pair. The indicator shows zero. Then the indicator leg is transferred to the bearing bed and in this case the indicator shows a value of 3.25, which is not good, since it should be within the range of 3.0. On the second landing plane it turned out to be 3.45. The arithmetic mean is 3.3. To adjust, we will use the correction at the “tip” - “-6”. In this case (– 3.3) + (-6) = 3.36. The thickness of the adjusting washer required is 3.36 mm. Using a micrometer, select the washer of the required thickness.

Note. When the shank bearing wears out, it begins to rotate on the “tip” body. As a result, the bearing end, adjusting washer and shank gear bodies wear out. It turns out that when replacing the shank oil seal, even with the correct tightening torque, the adjustment of the depth of engagement of the teeth of the gears of the main pair is lost and the “howl” of the pair is ensured, as is its early failure.

Let's return to the gearbox assembly...

2. Adjusting the preload of the shank bearings

The shank bearing sits on the “tip” and a NEW spacer sleeve MUST be installed. The video clearly shows that the new bushing is smooth without any deformation, while the previously installed one is deformed. What happens is this: When the shank nut is tightened to the prescribed torque (from 12 to 26 kgf), the bushing takes on the tightening force and, when deformed, works like a spring, creating tension. The tightening force for the VAZ 2107 gearbox nut is significant and the shank must be secured against turning.

In the video we see what kind of “device” the master uses. It is necessary to tighten the shank nut until there is no play. When the nut is tightened correctly, the shank should rotate with a resistance force of 0.3-0.4 kg, therefore, the bearing preload is correct. This assembly rule applies to old (used) bearings.

The differential with bearings is installed and secured with covers (tightening torque is about 8 kgf) and the adjusting nuts of the differential bearings are tightened.

3 and 4. Simultaneous adjustment of the thermal clearance of the main pair and the preload of the differential bearings

For these purposes, another “device” with two indicators is needed. Using the adjusting nuts in the video and everything is shown well, we move the planetary gear towards the teeth of the “cone” to achieve the required clearance. Factory clearance adjustment data is from 0.08 to 0.12 mm. However, such a gap is provided for the new main pair (“tips” and “planets”). The gap is checked in 4 planes by turning the gear. The gap for the working main pair after adjustment is 0.13-0.14 mm.

After making the adjustment, the adjusting nuts are locked with special plates for this purpose, with one or two “antennae”. This completes the assembly and adjustment.

Why does oil leak from the rear axle gearbox of VAZ 2107, 2106?

It is important to understand when the seal is leaking and when there is simple fogging. If after using the machine no drops of oil are visible near the oil seal, we can assume that the oil seal is simply sweating

In a situation where drops of oil or a trail followed by a drop are visible, we can assume that the oil seal is leaking.

Causes of leakage of the rear gear axle seal of VAZ 2107, 2106:

- Wear of oil scraper elements of the oil seal.

- Rupture of the compression spring of the oil seal.

- Oil seal defect.

- Development on the flange.

- Faulty or clogged gearbox breather.

When the oil seal is just sweating on a VAZ gearbox, you don’t have to change it, but if it leaks, then it definitely needs to be changed! But before changing the oil seal, check whether the gearbox breather is working by simply pressing on its head, and it should move a little. If it is motionless, then the breather is most likely to blame for the leak, because. it does not allow gases to escape from the gearbox, which creates excess pressure and presses the oil out of the oil seal. Also try unscrewing and blowing out the breather before deciding to replace the gearbox seal. Let's now talk about replacing it.

Is it necessary to change it?

Of course, there are other ways to solve the problem. Instead of buying a new part, you can repair the VAZ 2106 gearbox. However, doing this in a garage is highly not recommended, since you simply will not be able to set the gap in the gear meshing correctly. That is why the most reliable solution would be to purchase a new element. Fortunately, its cost is not that high (about 4 thousand rubles), so from a financial point of view, your costs will be minimal.

Oil seal replacement process

First you will need to arm yourself with the necessary tools. In particular, you need to prepare:

- flat screwdriver;

- calipers;

- a regular mount or some convenient strong metal rod;

- keys for 13 and 24;

- torque wrench;

- dynamometer;

- durable cord.

On a VAZ 2106, the rear axle oil seal is replaced after the oil is drained from the crankcase. In this case, you must not forget about the oil drain cap, which should be screwed into place.

Removing the axle shafts

Let's get started:

both rear axle shafts will need to be removed from the rear axle beam.

To do everything correctly, you need to strictly follow the instructions. So:

- dismantle the wheel;

- remove the brake drum;

- we see four nuts that will need to be unscrewed (to avoid problems, you will need to turn the axle shaft until the large diameter holes coincide with the two brake shield locking nuts):

- unscrew the nuts;

- remove the spring washers;

- turn the axle flange 90 degrees so that the large-diameter holes and the brake shield mounting nuts coincide;

- We secure the brake drum with two wheel bolts (you can tighten them by hand).

Note. These wheel bolts do not need to be tightened, leaving approximately 5 mm to ensure acceleration of the drum. But you need to be extremely careful not to damage the brake drum.

The axle shaft is abruptly removed from the rear axle beam.

Advice. There is a special impact puller that will allow you to remove the axle shaft much faster.

Special impact puller for removing axle shafts

Removing the old cuff

After both axle shafts have come out, you need to do the following:

- holding the cardan from turning with a pry bar (see Repairing the cardan on your own) from turning, unscrew the four nuts securing the hinge flange;

- remove the bolts;

Replacing the rear axle oil seal on a VAZ 2106

- disconnect the flanges using a flat-head screwdriver;

- now you need to wind a strong cord, which was stored in advance, onto the flange of the drive gear (when winding it, you need to make several turns and wind it);

- We use a dynamometer to check the moment of resistance to turning or the RPM of the drive gear (this value must be remembered or written down).

Note. MSP is the product of the dynamometer readings, expressed in kgf, and the force application lever, expressed in cm.

- Now you will need to unscrew the flange mounting nut, holding the drive gear with a special wrench;

- remove the flat washer.

Advice. There is a special wrench to hold the pinion flange. You can even make it yourself from a piece of metal pipe of the required size and two bolts and nuts.

Homemade key for holding the pinion flange

Replacement of the oil seal in the rear axle of the VAZ 2106 continues:

- the drive gear flange is removed;

- we find the drive gear oil seal and remove it from the neck using a screwdriver;

- install a new cuff.

Installation

Note. Before installing a new oil seal, you need to lubricate its working edge with Litol-24.

Light blows with a hammer through a special frame will help to correctly install the oil seal in place.

It is recommended to watch this video, where everything is described in detail.

https://youtube.com/watch?v=_MHYhEGwT84

Note. It must be remembered that the new oil seal should be pressed into the gearbox housing to a depth of 2 mm, counting from the end of the gearbox housing. As a mandrel, you can use some old bearing, or rather its ring, or even a piece of pipe of a suitable size and diameter.

- put the drive gear flange in place;

- put the required washer;

- tighten the flange mounting nut, while holding the drive gear with a special wrench.

Note. The tightening torque of the nut must be equal to a certain value depending on the resistance torque of the drive gear. When tightening the nut, you should start with a smaller torque and periodically check the resistance torque. If, at the moment of tightening the nut, it is discovered that the moment of resistance is too excessive, then this indicates unacceptable deformation. You will have to replace the bushing by disassembling the gearbox and then adjusting the engagement of the main gears. It will be difficult to carry out such work on your own; a highly qualified specialist is needed.

We assemble all the components and parts in reverse order.

The oil seal replacement process is complete. During the process, you should try to compare the methods for dismantling and installing a new oil seal with photos and diagrams. It is not difficult to carry out this operation with your own hands; it will be enough to follow the advice and notes given in the instructions. Replacing it yourself will help you avoid unnecessary expenses and save a lot of time, because at good car services there is now a long queue and the price of services is high.

Replacing bearings. Work plan

Replacing bearings in this case looks like this. Once the unit is removed, you will need the following tools to replace the bearings:

- socket heads for 10 and 17

- ratchet handle

- hammer

- chisel, flathead screwdriver (or bearing puller)

So, the first thing you need to do is unscrew the fixing bracket, which is clearly demonstrated in the photo below:

Then remove it and unscrew the two bolts securing the bearing cover. In terms of their fastening design, all of these are similar to crankshaft covers:

And remove the gearbox bearing adjusting nut:

Next, you will have to try a little to remove the bearing, since its inner race fits quite tightly. I did it as follows: I pointed the impact screwdriver from the inside and knocked out the bearing with hammer blows. Then, when the bearing moves forward a little, you can use a chisel.

And carefully in a circle, turning the gear, we punch through the race until the bearing finally comes off, after which we remove it:

On the other hand, everything is done in the same way. The price of a new bearing is about 150-200 rubles. Installation is carried out in reverse order. It is worth paying attention to the fact that the adjusting nut should not tighten it too much, but at the same time there should be no play!

Source

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at

Why did it happen so?

Perhaps the automatic requests do not belong to you, but to another user accessing the network from the same IP address as you. You need to enter the characters into the form once, after which we will remember you and be able to distinguish you from other users exiting from this IP. In this case, the page with the captcha will not bother you for quite a long time.

You may have add-ons installed in your browser that can make automatic search requests. In this case, we recommend that you disable them.

It is also possible that your computer is infected with a virus program that is using it to collect information. Maybe you should check your system for viruses.

If you have any problems or would like our support team, please use the feedback form.

The front suspension and rear axle assembly are called the main elements on which the so-called “wheel drive” of the vehicle rests. If these units are in working order, the machine will function well.

Reasons for replacing the oil seal and symptoms of malfunction

The seals in the gearbox are changed for one reason: they begin to leak. The oil seal may become old, tear, or be of poor quality from the very beginning, which will inevitably affect its service life. In addition, the tightness of the gearbox may be compromised due to improper installation, as a result of which the seals are compressed too much. The malfunction can be identified by the following signs:

- Small drops of oil appeared on the rear axle, near the gearbox.

- After leaving the parking lot, an oil stain remains on the asphalt.

- A small radial play appeared on the gearbox shank.

It is easy to determine: just move the shank up and down with your hands. As a rule, such play indicates not only torn oil seals, but also worn bearings. It is there that you can detect the backlash

Article on the topic: Do-it-yourself repair and restoration of car batteries

Failure of the steering mechanism

When the gearbox finally fails, the ability to drive the vehicle is completely or significantly lost. How to timely determine the “quick end” of the steering mechanism of a VAZ 2106 car, so as not to encounter this at the most inopportune moment? There are several “warning lights” that indicate that the mechanism in question needs replacement.

| Problem | Causes and consequences |

| 1. Extraneous squeaks are heard when turning the steering wheel | This may indicate that a foreign substance of an abrasive type has entered the gearbox, or an internal breakage of the worm or gear. Possible jamming of the unit, loss of control over vehicle control functions |

| 2. Significant play in the steering wheel | In most cases, play is caused by loosening the adjustment bolt and is eliminated by tightening it. If such a measure does not produce results, therefore, the gearbox of the VAZ 2106 car must be replaced |

| 3. Oil leak | This may mean either a rupture of the sealing gasket or a crack or hole in the housing. This is fraught with high oil consumption, insufficient lubrication of the steering mechanism and acceleration of its inevitable failure. |

| 4. Difficulty turning the steering wheel | The reason is insufficient lubrication, displacement of the engagement angle of the worm and gears, partial jamming of moving parts and mechanisms. It is fraught with increased driver fatigue during a long trip, complete jamming of the unit, loss of control over vehicle control functions |

| 5. Knocks and vibrations in the gearbox, which are felt through the steering wheel | The reasons may be: a loose adjustment bolt, failure of sealing couplings and gaskets, or wear and tear of mechanisms moving in mesh. Possible jamming of the unit, loss of control over vehicle control functions |

Changing the oil in the rear axle of a VAZ 2106

Often, car enthusiasts who own a vehicle such as the VAZ 2106 ask the same question. They are interested in which oil fluid is best suited for the rear axle of their car. At the same time, they ask - what volume is needed and how to change the oil?

There are different opinions. But experts recommend filling the rear axle gearboxes of this machine with transmission oil, which is marked 80W90. For example, this is Lukoil 80W90 GL. This group of oils also includes TAD-17 80W-90 or the so-called TNK.

When we've sorted out the oil, it's time to answer another question. Perhaps he is one of the most important. Namely, how much oil is required? So, the oil volume is as follows - 1.3 liters. At the same time, it is possible to change the oil in the gearbox. True, in this case you will need 1.4 liters.

As for the interval, it is necessary to change the oil fluid after every 30,000 kilometers of the vehicle. If you convert the mileage into a time frame, you get 3 years of operation.

The oil fluid is replaced in accordance with the established procedure:

- First of all, you need to use a lift or inspection hole. You will also need a key for “seventeen” and a hexagon for “twelve”.

- Next, unscrew the drain plug in the bridge and place a special container designed for draining the oil fluid. At the same time, the filler plug is also unscrewed. This is necessary so that the oil fluid flows out faster.

How to change the oil in the rear gearbox of a VAZ. Video

It would be a good idea to treat all components with washing liquid.

- ratchet crank;

- set of heads;

- twelve hexagon;

- two slotted screwdrivers;

- hammer;

- jack;

- wheel bolt wrench;

- mandrel for installing the oil seal;

- penetrating lubricant;

- container for collecting oil;

- torque wrench;

- digital or mechanical scales;

- fresh oil to the rear axle.

- We drive the car into the pit and unscrew the propeller shaft mounting bolts, having previously made a mark on the flank of the cardan and gearbox. After unscrewing the cardan, we tie it with a wire so that it does not interfere.

Using a special wrench, we secure the flange from turning and, using a wrench or a twenty-seven socket, unscrew the nut. The key for fixing the flange is shown in the photo below. You can also screw two universal joint mounting bolts into the flange and insert a powerful screwdriver between the bolts.

Unscrew the plug and drain the oil from the rear axle.

We remove the flange from the slots and take out the thin ring behind it using two screwdrivers.

Using two screwdrivers, remove the inner race of the bearing. We take out the spacer sleeve. This bushing is needed to create the correct tension in the bearings

Please note that the belt of the bushing you removed is barrel-shaped, but on the new bushing it is straight. At the moment of tightening, the belt is wrinkled and the correct tension is achieved.

The photo below shows a new bushing and one that was already working.

We install a new bushing, with the narrow side facing the trunk. We also install the ring.

Let's get started

To begin dismantling the bridge, you must first drive the car onto an inspection pit or overpass. Then you need to drain the oil and disconnect the driveshaft from the gear shank flange.

After this, the axle shafts are removed from the machine and, using an end prick, the 8 mounting bolts that connect the gearbox to the beam are unscrewed. Then you can safely remove the rear axle (gearbox) from the VAZ 2106. At this stage, you can go in two ways - install a new element or try to dig deeper into the old one. In the first moment, the elements are assembled in the reverse order, but we will tell you how to proceed in the second case in the following sections.

Replacing the axle shaft

Let's look at the process of replacing the axle shaft, its bearing and oil seal in detail. Tools you will need:

- wheel wrench;

- a jack and a safety stand (in extreme cases, a stump or a few bricks);

- wheel stops;

- reverse hammer;

- wrenches 8 mm, 17 mm;

- slotted screwdriver;

- Bulgarian;

- round nose pliers;

- hammer;

- chisel;

- workbench with a vice;

- blowtorch or gas torch;

- spacer made of wood or soft metal;

- a piece of steel pipe with a wall diameter of 33–35 mm;

- Litol type lubricant;

- dry clean rag.

Removing the axle shaft

To dismantle the axle shaft, you should:

Place the car on a flat surface and place chocks under the front wheels. Use a wheel wrench to unscrew the wheel bolts. Raise the car body with a jack. Unscrew the wheel bolts and remove the wheel. Using a size 8 wrench, unscrew the drum guide pins. Remove the drum

If it does not come off the blocks, carefully knock it down using a spacer and a hammer. Using a 17mm wrench (preferably a socket), unscrew the nuts (4 pcs) securing the axle shaft. They are located behind the flange, but you can access them through specially provided holes by turning the axle shaft. Using round-nose pliers, remove the spring washers that are located under the axle nuts. Disconnect the axle shaft from the rear axle by pulling it towards you

If it does not give in, use a reverse hammer. To do this, the tool flange must be screwed to the axle flange with wheel bolts. By sharply moving the hammer weight forward, knock out the axle shaft. If you don't have a reverse hammer in your tool arsenal, you can use a removed wheel instead. It needs to be screwed with the back side to the axle shaft flange and struck with a hammer on the tire from the inside until the axle shaft comes out of the casing. Remove the axle shaft assembly with the bearing and its retaining ring. Remove the sealing gasket located between the brake shield and the axle shaft flange. Using round nose pliers or pliers, remove the oil seal from its seat.

About sealing elements and their replacement

Note that on the first Six models, the connection between the bridge and flanges was sealed with a special gasket. A few years later, an oil-resistant sealing agent began to be tried on the assembly line instead. Therefore, in any case, it is necessary to update this seal during reassembly.

What needs to be done next? At the next stage, you need to thoroughly clean the surface of the gearbox connectors from the sealing substance, and then use a rag pre-moistened in gasoline to degrease this surface. If you use white spirit, take extra precautions to protect your respiratory tract. The threads of the mounting bolts and the holes for them located in the can must also be degreased.

All these surfaces are then treated with a new oil-resistant sealant. The threads of the fixing bolts are lubricated with a special fixing compound.

Then the axle gearbox is mounted into the beam and tightened evenly (crosswise) with bolts. Installation of the remaining elements is carried out in reverse order. Finally, you need to pour new oil into the rear axle.

A little anatomy

In the last years of its life on the AvtoVAZ assembly line, the classic Zhiguli remained perhaps the only passenger car in the world with a rigid drive axle. This design is simple and technologically advanced in production, but has serious disadvantages in operation:

- large unsprung mass of the bridge, which negatively affects the smoothness of the vehicle;

- tendency to steer when one of the wheels hits an obstacle - at this time, due to the misalignment of the bridge, both wheels tilt from the vertical and tend to roll in the direction of the tilt;

- reduction in the useful volume of the trunk, because there must be free space between the axle and the car body for the axle to move during the compression of the suspension.

The advantage of a rigid axle, in addition to manufacturability, is its better adaptability to bad roads: the ground clearance under the axle practically does not change depending on the load, and the wheel drive is reliably protected from external influences by the axle housing.

The Zhiguli bridge consists of a stamped-welded bridge beam (such beams are called “Banjo” for their characteristic shape), a main gearbox with a differential, and axle shafts. The gearbox is made in a separate open housing, the flange of which is bolted to the crankcase. A drive gear with a driveshaft mounting flange and a differential with a driven wheel are mounted in the housing on bevel bearings. The main gears are hypoid, that is, their axes are located at an angle of 90 degrees to each other, but do not intersect (they are crossed). The amount by which the axis of the drive gear is offset relative to the axis of the driven gear is called hypoid offset. Such a transmission, if it is precisely manufactured and well adjusted, operates smoothly and with the least noise, but due to the intense sliding of the curved teeth, it is very sensitive to the quality and quantity of oil in the bridge.

The design of the bridge is relatively simple and technologically advanced, although it is not without its drawbacks

Hypoid transmission and the magic of VAZ gearbox numbers

Technologically, it is easiest to transfer rotation from one bevel gear to another when they are on the same axis. But in the gearboxes of rear-wheel drive cars, a gear with axles shifted by 31.8 mm is used. This complication of the design is caused by the fact that, along with the transverse slipping of the teeth, the hypoid gear causes the teeth to slip longitudinally.

The photo shows the rear axle gearbox of a VAZ 2106, the cost of which is 6-7 thousand rubles

And this, in turn, gave the following advantages:

- long gear life;

- quiet operation;

- quick grinding of teeth;

- increased ground clearance.

If both main gears are severely worn or damaged, replace them only in pairs. The fact is that in preparation for sending ready-made sets of spare parts, pairs are selected using special precision equipment, taking into account the tolerance, the correction of which is applied to the drive gear shaft. On the driven gear you can read all the necessary information about the gearbox model - gear ratio (on the VAZ 2106 it is 11/43), model 2106, serial number and production date.

In principle, one of four sets of final drive gears can be installed in the gearbox of any Zhiguli model. They differ only in the number of teeth, and this dictates the gear ratio. There is no need to say what importance this parameter has when choosing a gearbox. It affects both the maximum speed of the car and the implementation of engine torque. As garage tuners say, “it either pulls better or goes faster.” In some ways they are right.

However, as we have already mentioned, there are only four options for final drive pairs:

- VAZ 2101 - 43/10 with a gear ratio of 4.3;

- VAZ 2102 - 40/9, the most high-torque gearbox with a gear ratio of 4.44;

- VAZ 2103 - 41/10, this is the most popular medium balanced version of the gear ratio - 4.1;

- VAZ 2106 - 43/11, is the fastest gearbox, especially when paired with a five-speed gearbox, and its number is 3.9.

This set gives classic car owners unlimited possibilities to customize the car's dynamic characteristics. No “tuning” can change the dynamics of a classic as much as a rear axle gearbox.

So, for certain purposes you can buy a specific gearbox, which will change the maximum speed of the car, acceleration dynamics, fuel consumption, and traction force. The most “cargo” gearbox from 2102, pennies in a station wagon. Its maximum speed is low, about 145 km/h, but the car confidently drags quite serious loads and trailers without overloading the engine. The limit needs to be known, but the fact remains a fact. If you need a small tractor in the back of a Zhiguli, there is a 2102 gearbox with a gear ratio of 4.44 and a number of teeth of 40/9. This gearbox has become a rarity, but if you wish, you can find the main pair both new and used. The other extreme is the gearbox of the VAZ 2106. It will give the car a high maximum speed, but it will not take off from a standstill, because the traction force as a result is less than that of a two.

Defects in the gearbox

Increased play in the RZM can be formed due to wear of the differential pinion pin - if you grab the driveshaft and rotate it clockwise and counterclockwise, this play can be felt. Also, increased clearance can be formed due to wear of the splines inside the differential housing itself.

If the gaps in the main pair of gearboxes are not adjusted, a characteristic noise occurs when the car moves:

- when the load increases (sharp acceleration), a characteristic howl is heard in the bridge;

- When I let off the gas the noise goes away.

The engine can hum in a different way, but the characteristic feature described above can most often be heard on VAZ classic cars. Worn teeth of the main pair are clearly visible on the planetary gear - they become rounded, and they often show traces of rust.

Assembly procedure

After the repair has been completed and all the damaged elements have been replaced, it is necessary to reassemble the rear axle and make sure that the gearbox no longer makes noise when driving.

The process looks like this:

- the new node is fixed in the place intended for it;

- return the axle shafts to the bridge;

- the gear flange is attached to the cardan;

- install wheels and brake drives.

It is necessary to test the car both at low speeds and at high speeds. First of all, leaving the car in neutral gear, press the gas. Then accelerate smoothly, and then turn off the engine. In a situation where the noise is still heard, an unambiguous conclusion should be drawn: you made some mistake or the reason was not in the gearbox.

Let's go to the store

So we did everything we could, but the leak didn't stop. This means it's time to change the seal. Actually, according to GOST, these products are called “Reinforced rubber cuffs for shafts.” Or simply - cuffs. If a store offers you a part with that name, don’t be surprised. Factory part designation: 2101–2402052. Further, its variations can be written through a dash: -01, -02 and so on. All of these products are interchangeable and differ in the nuances of their design and manufacturer.

Perhaps the most important thing when choosing an oil seal is the manufacturer. Choose products from famous factories

No name details, in principle, should not attract your attention, because not only according to ours, but also according to Western standards, the cuff must be marked with the manufacturer’s trademark, cuff size, and type of material. Domestic GOST also provides for marking the year of manufacture. As a rule, these are two digits of the year when the mold was made, and next to them are dots, each of which indicates one year of operation of this equipment. You count the points, add their number with the numbers and find out in what year your part was manufactured. The year of manufacture is important because over time, any rubber compound “ages”, losing its shape and elasticity.

The type of mixture from which the oil seal is made is also important. The most expensive and most durable - fluorine rubber

It works well in aggressive environments and at high temperatures. It is usually marked with the Latin letters FBR. Nitrile butadiene rubber (NBR) is considered optimal in terms of price and quality for automobile transmissions. ACM acrylate polymer seals are also available, but they are usually used in components that should not be directly exposed to water. Chemists are constantly improving their products, so the fundamental differences between mixtures are becoming less and less, due to additives introduced into them that improve the weaknesses of certain recipes. Read reviews on the Internet, listen to the seller’s recommendations and make a decision based on your financial capabilities.

When examining externally, first of all pay attention to the quality of the working edge: it should be even and smooth around the entire circumference. You can use a magnifying glass

It will be a big plus for the gearbox seal to have an external boot - like a second edge, but without a spring and with a hole of a slightly larger diameter. The boot, as the name suggests, protects the work area from dust and dirt. The presence of an inclined notch on the boot or near the working edge indicates that the oil seal is designed for shafts rotating in the same direction.

Lubrication of crankshaft bearing units

Sliding bearings can operate in liquid or semi-fluid friction mode. In the liquid friction mode, the surfaces do not touch, rotation occurs on a layer of oil, and under load a so-called “oil wedge” is formed. In the case of a semi-fluid mode, friction will be liquid and boundary (mixed). With boundary friction, work is carried out on a thin film of oil. Mixed and especially boundary operating modes are dangerous for the engine. Due to friction, the surfaces can heat up to a critical temperature, which will lead to damage to the bearings and shaft journal.

When starting the engine, the mode will be semi-liquid; low speeds will not allow the oil pump to provide the necessary pressure. Further, after starting, with increasing speed, conditions will be created for liquid operation and for sufficient lubrication of the engine.

Signs of gearbox problems

The rear gearbox is one of the reliable mechanisms of classic Zhiguli cars and breakdowns rarely occur with it. However, like any other unit, it may have its own malfunctions, which are determined by characteristic symptoms. They are worth dwelling on in more detail.

Noise when accelerating

If during acceleration there is an extraneous sound from the gearbox installation site, then it can be caused by:

- worn out or incorrectly adjusted differential bearings. It will require dismantling, disassembling and diagnosing parts with subsequent adjustment;

- Incorrect meshing of the teeth of the main pair gears. Eliminated by proper adjustment;

- lack of lubrication in the gearbox. The lack of oil in the crankcase is restored, after which it is checked for leaks at the places where the sealing elements are installed.

Noise when accelerating and braking the engine

If noise occurs both during acceleration and during braking by the power unit, there may not be many reasons:

- deterioration or failure of the bevel gear bearings of the main pair. Eliminated by replacing failed elements;

- Incorrect adjustment of the gap between the tip and the planetary gear. The mechanism needs to be diagnosed and replaced with damaged parts, as well as setting the required gap between the gear teeth.

How to fill the oil?

Before revealing the specifics of the replacement, we note that this instruction can be used not only for cars of model 2106. A similar algorithm for changing the oil can be observed in VAZ cars of models 2101, 2102, 2104, 2105, as well as model 2107.

So what do we need to do to change the oil? First you need to unscrew the drain plug with a hex key. Next, put some container and unscrew the filler element. After the oil has drained well, we screw the plug back in and use a special oil pump (or a large syringe) to pump transmission oil into it. Pour to the level of the bottom edge of the hole. Next, tighten the plug, and now you can safely start operating the car.

Sometimes the substance in the gearbox can be heavily contaminated. In this case, before adding new fluid, thoroughly rinse the gearbox or gearbox housing with a mixture of diesel fuel and oil (not necessarily transmission oil). The proportion is about 300 milliliters of diesel fuel per liter of oil.

Wheel alignment VAZ 2109

The need for wheel alignment can be easily checked.

To do this you need to do a check run. If on a flat section of the road the car constantly pulls to the left or right, then adjustments need to be made. In addition, incorrect wheel installation will lead to rapid tire wear. Before work, it is necessary to check the integrity of the chassis parts: absence of deformation, destruction of silent blocks. There must be the required air pressure in the tires, free play in the steering wheel, and free play in the front wheel hub bearings. In order to check and adjust all this, a VAZ 2109 wheel alignment is performed, for which the car is driven onto a special stand. First, the longitudinal inclination of the axle is checked, then the camber of the wheels, and only lastly is the toe adjusted. The axle tilt is adjusted by changing the number of adjusting washers that are installed at the ends of the suspension braces. To increase the caster angle, you need to reduce the number of adjusting washers in the front or rear, and vice versa, if you need to reduce the angle, you need to increase the number of washers. But they can only be added at the back of the extension; usually the short thread does not allow this to be done at the front. It is worth noting that the number of washers should not be more than 2 in front and 4 in back. The VAZ 2109 camber is adjusted by changing the angle of attachment of the telescopic strut on the steering knuckle. To carry out the work, you need to loosen the fastening nuts and turn the upper adjusting bolt. After installing the required camber, you need to tighten the nuts. If the toe does not correspond to the norm, then adjustment is made. The tie rod tie bolt is unscrewed and the required toe-in is established by rotating the rod. It is necessary to ensure that the planes of the ball joint and the swing arm are parallel. If everything is in order, then you can tighten the coupling bolts. It is recommended that wheel alignment work be carried out in specialized auto repair shops. But if desired, this work can be done in a garage. The main thing is to have a flat surface. Next, all adjustment work is carried out. The correct installation of the wheels can be checked by eye. To do this, tie a weight to a thread and hang it on the wing. If the wheel is parallel to the thread, it means the adjustment was correct. Troubleshooting a vehicle's fuel system || Foreign car gearbox repair