Depth of recesses for valves, on the piston bottom. 2110, eliminates the possibility of valves coming into contact with the piston if the timing belt breaks.

The piston design of the 2110 and all subsequent models uses a loose fit piston pin. The clearance in the hole in the connecting rod head and in the holes in the piston ensures free rotation of the pin. The pin is secured in the axial direction with locking rings. For this purpose, the piston, in the pin holes, has installation grooves for retaining rings. On the outside of the piston pin holes, in the upper part, there are small recesses that make it easier to install and remove the circlips. In addition, they facilitate the access of oil to the contact area.

This design simplifies the assembly process and ensures uniform wear of rubbing surfaces, increasing the service life of parts. The piston diameter classes and piston pin hole classes adopted for model 21083 correspond to the classes of models 2110, 2112, 21124.

Basic casting markings applied to the part.

1. Product model designation – symbols “21” and “10”, in the area of the finger hole.

2. Designation, on the inside of the skirt.

3. Designation of casting equipment - letters and numbers, on the inside of the skirt.

4. The designation of the casting alloy is “AL34”, on the inside of the skirt.

Basic markings applied to the bottom.

1. Orientation marker – “ ” when installed, should indicate the direction towards the camshaft drive

2. Class marker - one of the symbols (“A”, “B”, “C”, “D”, “E”) determines the deviation in the outer diameter.

3. Piston mass group marker:

“ ” – normal;

“+” – increased by 5 g.

“ – ” – reduced by 5 g.

4. Piston pin hole class marker – one of the numbers (“1”, “2”, “3”) determines the deviation in the diameter of the piston pin hole.

The hole class marking is additionally applied with paint on the inside of the bottom:

blue color – 1st class

green color – 2nd grade

red – 3rd grade

Additionally, for repair pistons.

5. Marker for repair products:

“ ” – 1st repair (diameter increased by 0.4 mm from the nominal size.)

“ ” – 2nd repair (diameter increased by 0.8 mm from the nominal size.)

| PISTON | 21083-1004015 |

| Manufacturer | JSC AVTOVAZ |

| Piston diameter (nominal), mm: | 82,0 |

| Piston diameter (1st repair), mm: | 82,4 |

| Piston diameter (2nd repair), mm: | 82,8 |

| Weight, g: | 335,0 |

| Piston pin | 21213-1004020 |

| Piston pin diameter, mm: | 22 |

| Piston rings | 21083-1000100 |

| Ring height, mm: | 1,5/2,0/3,95 |

The depth of the recesses for the valves, on the bottom of the piston 21083, eliminates the possibility of the valves coming into contact with the piston if the timing belt breaks.

A design feature of the VAZ 21083 piston, which distinguishes it from the 2110 piston, is the method of fixing the piston pin. In the 21083 design, the piston pin (21213-1004020 or 2101-1004020) is pressed into the upper head of the connecting rod 2108-1004045. The tight fit defines the position of the finger and prevents it from moving. The diameter of the holes in the piston bosses provides the piston pin and connecting rod with free angular rotation. On the side surface, on the area near the hole for the piston pin, there are model markings - “21” and “083”. In terms of geometric parameters, there are no differences between the pistons of the VAZ 21083 and VAZ 2110 models.

Main Dimensions

| Piston class by outer diameter | A | B | C | D | E |

| Piston diameter 82.0 (mm) | 81,965-81,975 | 81,975-81,985 | 81,985-81,995 | 81,995-82,005 | 82,005-82,015 |

| Piston diameter 82.4 (mm) | 82,365-82,375 | 82,375-82,385 | 82,385-82,395 | 82,395-82,405 | 82,405-82,415 |

| Piston diameter 82.8 (mm) | 82,765-82,775 | 82,775-82,785 | 82,785-82,795 | 82,795-82,805 | 82,805-82,815 |

| Piston pin hole class | 1 | 2 | 3 |

| Piston pin hole diameter(mm) | 21,982-21,986 | 21,986-21,990 | 21,990-21,994 |

Applicability of piston 21083-1004015.

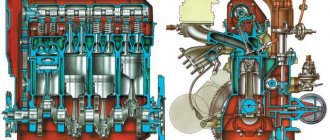

Diagram of the VAZ 21099 piston group: 1 - connecting rod bolt nut, 2 - connecting rod bearings, 3 - connecting rod, 4 - piston pin, 5 - upper compression ring groove, 6 - lower compression ring groove, 7 - oil scraper ring groove, 8 - piston, 9 — connecting rod bolt, 10 — connecting rod cover

For the convenience of selecting pistons for cylinders, cylinders and pistons, depending on the diameter, are divided into five size groups: A, B, C, D, E.

Pistons of nominal sizes of three classes are supplied as spare parts: A, C, E and two repair sizes. The first repair size is increased by 0.4 mm, the second - by 0.8 mm.

VAZ 21083 pistons sizes by letter

Depth of recesses for valves, on the piston bottom.

2110, eliminates the possibility of valves coming into contact with the piston if the timing belt breaks. The piston design of the 2110 and all subsequent models uses a loose fit piston pin. The clearance in the hole in the connecting rod head and in the holes in the piston ensures free rotation of the pin. The pin is secured in the axial direction with locking rings. For this purpose, the piston, in the pin holes, has installation grooves for retaining rings. On the outside of the piston pin holes, in the upper part, there are small recesses that make it easier to install and remove the circlips. In addition, they facilitate the access of oil to the contact area.

This design simplifies the assembly process and ensures uniform wear of rubbing surfaces, increasing the service life of parts. The piston diameter classes and piston pin hole classes adopted for model 21083 correspond to the classes of models 2110, 2112, 21124.

Basic casting markings applied to the part.

1. Product model designation – symbols “21” and “10”, in the area of the finger hole.

2. Designation, on the inside of the skirt.

3. Designation of casting equipment - letters and numbers, on the inside of the skirt.

4. The designation of the casting alloy is “AL34”, on the inside of the skirt.

Basic markings applied to the bottom.

1. Orientation marker - "

» during installation, must point towards the camshaft drive

2. Class marker - one of the symbols (“A”, “B”, “C”, “D”, “E”) determines the deviation in the outer diameter.

3. Piston mass group marker:

«

» – normal;

4. Piston pin hole class marker – one of the numbers (“1”, “2”, “3”) determines the deviation in the diameter of the piston pin hole.

The hole class marking is additionally applied with paint on the inside of the bottom:

Additionally, for repair pistons.

5. Marker for repair products:

«

» — 1st repair (diameter increased by 0.4 mm from the nominal size.)

«

» — 2nd repair (diameter increased by 0.8 mm from the nominal size.)

| PISTON | 21083-1004015 |

| Manufacturer | JSC AVTOVAZ |

| Piston diameter (nominal), mm: | 82,0 |

| Piston diameter (1st repair), mm: | 82,4 |

| Piston diameter (2nd repair), mm: | 82,8 |

| Weight, g: | 335,0 |

| Piston pin | 21213-1004020 |

| Piston pin diameter, mm: | 22 |

| Piston rings | 21083-1000100 |

| Ring height, mm: | 1,5/2,0/3,95 |

The depth of the recesses for the valves, on the bottom of the piston 21083, eliminates the possibility of the valves coming into contact with the piston if the timing belt breaks.

A design feature of the VAZ 21083 piston, which distinguishes it from the 2110 piston, is the method of fixing the piston pin. In the 21083 design, the piston pin (21213-1004020 or 2101-1004020) is pressed into the upper head of the connecting rod 2108-1004045. The tight fit defines the position of the finger and prevents it from moving. The diameter of the holes in the piston bosses provides the piston pin and connecting rod with free angular rotation. On the side surface, on the area near the hole for the piston pin, there are model markings - “21” and “083”. In terms of geometric parameters, there are no differences between the pistons of the VAZ 21083 and VAZ 2110 models.

Main Dimensions

| Piston class by outer diameter | A | B | C | D | E |

| Piston diameter 82.0 (mm) | 81,965-81,975 | 81,975-81,985 | 81,985-81,995 | 81,995-82,005 | 82,005-82,015 |

| Piston diameter 82.4 (mm) | 82,365-82,375 | 82,375-82,385 | 82,385-82,395 | 82,395-82,405 | 82,405-82,415 |

| Piston diameter 82.8 (mm) | 82,765-82,775 | 82,775-82,785 | 82,785-82,795 | 82,795-82,805 | 82,805-82,815 |

| Piston pin hole class | 1 | 2 | 3 |

| Piston pin hole diameter(mm) | 21,982-21,986 | 21,986-21,990 | 21,990-21,994 |

Applicability of piston 21083-1004015.

Source of the article: https://www.motors-vaz.ru/piston_2110.html

troubleshooting engine parts VAZ 2108, VAZ 2109, VAZ 21099

After disassembling the engine, thoroughly clean, rinse and dry all parts.

1. Clean the piston head from carbon deposits. If the piston has burrs, burn marks, deep scratches, or cracks, replace the piston. Clean the grooves for the piston rings. It is convenient to do this with a piece of an old piston ring.

2. Clean the oil drain holes with a suitable piece of wire.

3. Check the clearances between the rings and grooves on the piston. Nominal piston ring clearance, mm: upper compression ring 1 - 0.04-0.075; lower compression ring 2 - 0.03-0.065; oil scraper ring 3 - 0.02-0.055. The maximum permissible gap for all piston rings is 0.15 mm.

4. The most accurate way to determine piston ring clearances is by measuring the rings and grooves on the piston. To do this, measure the thickness of the piston ring with a micrometer in several places around the circumference, then... 5. ...using a set of feeler gauges, also measure the width of the grooves in several places around the circumference. Calculate the average clearance values (the difference between the thickness of the piston ring and the width of the groove). If at least one of the gaps exceeds the maximum permissible, replace the piston with rings.

8. If the gap is less than 0.25 mm, carefully grind off the ends of the piston ring with a file.

9. Check the clearances between the pistons and cylinders. The clearance between pistons and cylinders is defined as the difference between the measured diameters of the piston and cylinder. The nominal gap between the pistons and cylinders is 0.025-0.045 mm, the maximum permissible is 0.15 mm. If the gap between the pistons and cylinders does not exceed 0.15 mm, you can select pistons from subsequent classes so that the gap between the pistons and cylinders is as close as possible to the nominal one. If the gap between the pistons and cylinders exceeds 0.15 mm, bore the cylinders to the next repair size and install pistons of the corresponding repair size. Measure the diameter of the piston at a distance of 55 mm from its bottom in a plane perpendicular to the piston pin.

Rice. 4.9. Cylinder clearance measurement locations

10. Then measure the diameters of the cylinder in two perpendicular planes (see Fig. 4.9.) (along B and across A of the cylinder block) and in four zones (1, 2, 3 and 4). For this you need a special device - a bore gauge. 11. When replacing parts of the connecting rod and piston group, it is necessary to select pistons to cylinders by class and one group by weight, as well as piston pins to pistons by class and connecting rods by weight. To select pistons for cylinders, calculate the gap between them. For the convenience of selecting pistons for cylinders, cylinders and pistons, depending on their diameters, are divided into five classes: A, B, C, D, E (Table 4.1). Spare parts include pistons of nominal sizes of three classes A, C, E and two repair sizes. The first repair is increased by 0.4 mm, the second - by 0.8 mm. By weight, the pistons are divided into three groups: normal, increased by 5 g and decreased by 5 g. Pistons of the same group must be installed on the engine of VAZ 2108, VAZ 2109, VAZ 21099 cars. For repair size pistons, spare parts include repair size rings increased by 0.4 mm and 0.8 mm. The number “40” is stamped on the rings of the first repair size, and “80” on the rings of the second repair size.

Table 4.1 Nominal dimensions of cylinders and pistons Class Diameter, mm piston cylinder A 82.00-82.01 82.00-82.01 B 82.01-82.02 82.01-82.02 C 82.02-82, 03 82.02-82.03 D 82.03-82.04 82.03-82.04 E 82.04-82.05 82.04-82.05

12. On the cylinder block, a group of cylinders is knocked out on the lower plane of the block (the mating plane for the oil sump) opposite each cylinder. 13. The following data is stamped on the bottom of the piston: 1 - piston class based on the hole for the piston pin; 2 - piston diameter class; 3 - arrow showing the direction of installation of the piston; 4 - repair size (1st repair - triangle, 2nd repair - square); 5 - weight group (normal “G”, increased by 5 g “+”, decreased by 5 g “-”).

14. Replace piston pins with cracks. The piston pin should easily enter the piston using the force of the thumb. Insert the piston pin into the piston. If play is felt when rocking the piston pin, replace the piston. When replacing a piston, select a piston pin according to its class

Table 4.2 Classes of piston pins, pistons and connecting rods Size group Engine model VAZ 2108 Cylinder diameter, mm Piston diameter, mm A 76.00-76.01 75.965-75.975 B 76.01-76.02 75.975-75.985 C 76.02- 76.03 75.985-75.995 D 76.03-76.04 75.995-75.005 E 76.04-76.05 75.005-75.015

Size group Engine model VAZ 21083 Cylinder diameter, mm Piston diameter, mm A 82.00-82.01 81.965-81.975 B 82.01-82.02 81.975-81.985 C 82.02-82.03 81.985-81.995 D 82, 03-82.04 81.995-82.005 E 82.04-82.05 82.005-82.015

(Table 4.2). The piston pins are divided by diameter into three classes (1-, 2-, 3rd) every 0.004 mm. The class of the piston pin is marked on its end with paint. The piston pin class is stamped on the piston bottom, the connecting rod pin class is stamped on the connecting rod cap.

15. Replace broken piston rings and oil ring expander.

16. Replace broken or cracked circlips that retain the piston pin. The ends of the retaining rings must be in the same plane. Replace bent rings.

17. Replace bent connecting rods. Replace the connecting rod if there are burrs and deep scratches in the bushing 1 of the upper head. Replace the connecting rod if, upon disassembling the engine, it is discovered that the connecting rod bearings have rotated in the connecting rod. WARNING The connecting rods are processed together with the caps, so they cannot be disassembled.

18. Insert the piston pin into the upper end of the connecting rod. If play is felt when rocking the piston pin, replace the connecting rod. Connecting rods assembled with covers are divided into classes based on the weight of the upper and lower heads (Table 4.3).

Table 4.3 Connecting rod class based on the mass of the upper and lower heads Weight of the connecting rod heads, g Marking upper lower with paint letter 184+2 489±3 F Red 495+3 L Green 501±3 B 188+2 489+3 X 495±3 M 501+ 3 V 192+2 489±3 C 495±3 N 501+3 G Blue

19. In the engine of VAZ 2108, VAZ 2109, VAZ 21099 cars, connecting rods of the same class must be installed. The connecting rod is marked on the connecting rod cover: 1 - connecting rod class by weight (letter or paint), 2 - connecting rod class by piston pin.

20. If there are deep scratches, scratches, nicks on the surfaces on which the oil seals operate, the crankshaft must be replaced.

22. If there are minor scuffs, marks, or scratches on the main and connecting rod journals of crankshaft 1, you need to grind the crankshaft journals to the nearest repair size. It is recommended to carry out the work of grinding the crankshaft journals in a specialized workshop. Then polish the crankshaft journals and blunt the sharp edges of the chamfers of the oil channels 2 with an abrasive cone. Wash the crankshaft and blow out the oil passages with compressed air. The ovality and taper of all crankshaft journals after grinding should not exceed 0.005 mm. After grinding the crankshaft journals, install bearings of repair sizes. 23. If there are burrs, marks or peeling on the working surfaces of the thrust half-rings, replace the half-rings. It is prohibited to carry out any adjustment work on the half rings.

Repair dimensions of pistons VAZ 21083 table

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

The marking of pistons allows us to judge not only their geometric dimensions, but also the material of manufacture, production technology, permissible installation gap, manufacturer's trademark, installation direction and much more. Due to the fact that there are both domestic and imported pistons on sale, car owners sometimes face the problem of deciphering certain designations. This material contains as much information as possible, allowing you to obtain information about the markings on the piston and understand what the numbers, letters and arrows mean.

The picture is interactive. When you hover, information about decryption appears

Variety of STK products

In fact, everything is not limited to Prioras, Kalinas and GAZs. The STK company has manufactured many groups of pistons for a wide variety of machines. Today Samara Trading offers pistons for:

If we approach the issue more practically and classify pistons not by models and brands, but by their sizes (diameters and strokes), then STK is ready to offer pistons for virtually all cars.

STK pistons for VAZ cars are suitable for such cars as:

STK pistons for OKA, GAZ, Buran, PAZ and UAZ cars:

STK pistons for ZIL and URAL cars:

STK pistons for Volkswagen cars:

STK pistons for Opel and Ford cars:

Pistons for sporting purposes for VAZ cars:

Information on the piston surface

Discussing the question of what markings on pistons mean, it is worth starting with what information the manufacturer puts on the product.

- Piston size . In some cases, in the markings on the bottom of the piston you can find numbers indicating its size, expressed in hundredths of a millimeter. Example - 83.93. This information means that the diameter does not exceed the specified value, taking into account the tolerance (tolerance groups will be discussed below; they differ for different brands of cars). Measurement is carried out at a temperature of +20°C.

- Installation gap . Its other name is temperature (since it can change along with changes in the temperature regime in the engine). Designated as Sp. It is given in fractional numbers, meaning millimeters. For example, the marking on the SP0.03 piston indicates that the gap in this case should be 0.03 mm, taking into account the tolerance range.

- Trademark . Or an emblem. In this way, manufacturers not only identify themselves, but also provide information to craftsmen about whose documentation (product catalogs) should be used when selecting a new piston.

- Installation direction . This information answers the question - what does the arrow on the piston point to? It “tells” how the piston should be mounted, in particular, the arrow is drawn in the direction of forward movement of the car. On cars where the engine is located at the rear, instead of an arrow, a symbolic crankshaft with a flywheel is often depicted.

- Casting number . These are numbers and letters that schematically indicate the geometric dimensions of the piston. Typically, such designations can be found on European machines, for which the piston group elements are manufactured by companies such as MAHLE, Kolbenschm >

Installation on PRIORU

We will describe the installation of STK pistons on a VAZ (PRIORA), since this particular car is the most purchased in our country and it is this car that most often has problems with the timing belt.

Despite the fact that making a replacement in your yard on your knees is an impossible task, the installation process does not hide any difficulties. First you need to disassemble the engine.

Many drivers sacrifice power for the sake of greater practicality - you can understand them, especially if you look at the aftermarket. If there is a break, you can fly into such repairs that it won’t seem like much, but this way you are protected.

VAZ pistons marking

According to statistics, owners or engine repair technicians of VAZ cars are most often interested in the marking of repair pistons. Below we provide information on various pistons.

VAZ 2110

For example, let's take the engine of a VAZ-2110 car. Most often, this model uses pistons marked 1004015. The product is produced directly at AvtoVAZ OJSC. Brief technical information:

- nominal piston diameter - 82.0 mm;

- piston diameter after first repair - 82.4 mm;

- piston diameter after the second repair - 82.8 mm;

- piston height - 65.9;

- compression height - 37.9 mm;

- The recommended clearance in the cylinder is 0.025...0.045 mm.

Additional information can be printed directly on the piston body. For example:

- “21” and “10” in the area of the hole for the finger - designation of the product model (other options - “213” indicates the VAZ 21213 engine, and for example, “23” - VAZ 2123);

- “VAZ” on the inside of the skirt is the manufacturer’s designation;

- letters and numbers on the inside of the skirt are a specific designation of foundry equipment (you can decipher it using the manufacturer’s documentation, but in most cases this information is useless);

- “AL34” on the inner side of the skirt is the designation of the cast alloy.

The main marking symbols applied to the piston crown:

- The arrow is an orientation marker indicating the direction towards the camshaft drive. On the so-called “classic” VAZ models, sometimes instead of an arrow you can see the letter “P”, which means “in front”. Likewise, the edge where the letter is depicted should be directed towards the direction of movement of the car.

- One of the following symbols is A, B, C, D, E. These are diameter class markers that show the deviation in the outside diameter value. Below is a table with specific values.

- Piston mass group markers. “G” is normal weight, “+” is weight increased by 5 grams, “-” is weight decreased by 5 grams.

- One of the numbers is 1, 2, 3. This is a piston pin hole class marker that determines the deviation in the diameter of the piston pin hole. In addition to this, there is a color designation for this parameter. So, the paint is applied to the inside of the bottom. Blue color - 1st grade, green - 2nd grade, red - 3rd grade. The following provides additional information.

For VAZ repair pistons there are also two separate designations:

- triangle - first repair (diameter increased by 0.4 mm from the nominal size);

- square - second repair (diameter increased by 0.8 mm from the nominal size).

Please note that for different brands of cars (including for different engines), the difference between repair pistons should be found in the reference information.

VAZ 21083

Another popular VAZ piston is 21083-1004015. It is also produced at OJSC AvtoVAZ. Its technical dimensions and parameters:

- nominal diameter - 82 mm;

- diameter after first repair - 82.4 mm;

- diameter after the second repair - 82.8 mm;

- piston pin diameter - 22 mm.

Lightening the VAZ crankshaft

We have already written about how to lighten a flywheel, but a flywheel alone is of little use. In this article we will look at lightening the crankshaft and other parts of the crankshaft.

Lightening the VAZ crankshaft:

For a standard crankshaft, you can also make it lighter; it has a large margin of safety. But this must be done after weighing all the pros and cons.

So the advantages of crankshaft lightening:

- Inertial masses, which negatively affect the crankshaft journals, are reduced, increasing their wear

- The motor is lighter and revs faster

Disadvantages of relief:

- If the crankshaft is lightened incorrectly or excessively, idle performance may deteriorate, and under high loads the crankshaft may simply burst.

- Additional costs for tuning (well, how could we do without it?)

Marking of ZMZ pistons

Another category of car owners interested in piston markings have ZMZ brand motors at their disposal. They are installed on GAZ cars - Volga, Gazelle, Sobol and others. Let's look at the symbols on their bodies.

The designation “406” means that the piston is intended for installation in the ZMZ-406 engine. There are two markings stamped on the piston crown. According to the letter painted on the new block, the piston is matched to the cylinder. When repairing with cylinder boring, the required clearances are made during the process of boring and honing for pre-purchased pistons with the required size.

The Roman numeral on the piston indicates the correct piston pin group. The diameters of the holes in the piston bosses, the connecting rod head, as well as the outer diameters of the piston pin are divided into four groups, marked with paint: I - white, II - green, III - yellow, IV - red. On the fingers, the group number is also marked with paint on the inner surface or on the ends. It must match the group indicated on the piston.

The group number should similarly be marked with paint directly on the connecting rod. In this case, the mentioned number must either coincide or be next to the number of the finger group. This selection ensures a situation where the lubricated pin moves with little effort in the connecting rod head, but does not fall out of it. Unlike VAZ pistons, where the direction is indicated by an arrow, on ZMZ pistons the manufacturer directly writes the word “FRONT” or simply puts the letter “P”. During assembly, the protrusion on the lower head of the connecting rod must coincide with this inscription (be on the same side).

There are five groups, with a pitch of 0.012 mm, which are designated by the letters A, B, C, D, D. These size groups are selected according to the outer diameter of the skirt. They correspond to:

- A - 91.988...92.000 mm;

- B - 92,000...92,012 mm;

- B - 92.012...92.024 mm;

- G - 92.024...92.036 mm;

- D - 92.036...92.048 mm.

The value of the piston group is stamped on its bottom. So, there are four size groups, which are marked with paint on the piston bosses:

- 1 - white (22.0000...21.9975 mm);

- 2 - green (21.9975...21.9950 mm);

- 3 - yellow (21.9950...21.9925 mm);

- 4 - red (21.9925...21.9900 mm).

Pin hole group marks can also be applied to the piston bottom in Roman numerals, with each digit corresponding to its own color (I - white, II - green, III - yellow, IV - red). The size groups of the selected pistons and piston pins must match.

The ZMZ-405 engine is installed on the GAZ-3302 “Gazelle Business” and GAZ-2752 “Sobol” vehicles. The calculated gap between the piston skirt and the cylinder (for new parts) should be 0.024...0.048 mm. It is defined as the difference between the minimum cylinder diameter and the maximum piston skirt diameter. There are five groups, with a pitch of 0.012 mm, which are designated by the letters A, B, C, D, D. These size groups are selected according to the outer diameter of the skirt. They correspond to:

- A - 95.488...95.500 mm;

- B - 95.500...95.512 mm;

- B - 95.512...95.524 mm;

- G - 95.524...95.536 mm;

- D - 95.536...95.548 mm.

The value of the piston group is stamped on its bottom. So, there are four size groups, which are marked with paint on the piston bosses:

- 1 - white (22.0000...21.9975 mm);

- 2 - green (21.9975...21.9950 mm);

- 3 - yellow (21.9950...21.9925 mm);

- 4 - red (21.9925...21.9900 mm).

Thus, if, for example, the letter B is written on the piston of a GAZ engine, this means that the engine has been overhauled twice.

In ZMZ 409, almost all dimensions are the same as in ZMZ 405, with the exception of the recess (puddle), it is deeper than in 405. This is done to compensate for the compression ratio, the size h increases on the pistons 409. Also, the compression height of 409 is 34 mm, and for 405 it is 38mm.

Replacing piston rings

On VAZ cars, as well as on all other models of passenger cars, it is advisable to change only the piston rings only if:

If the liners are significantly worn, they need to be bored, and if the last size was already used before, the cylinder block needs to be relined. You can replace the PC on any VAZ engine without removing the internal combustion engine; this will require removing the cylinder head and oil sump. PCs are replaced if the gap at the joints does not exceed 1 mm.

For example, let's consider replacing piston rings on a VAZ-2114 car with an 8-valve internal combustion engine; such work must be carried out on a pit or a car lift:

- turn off the ignition, put the gearbox in neutral, disconnect the negative terminal from the battery;

- drain the antifreeze, remove the air filter housing along with the pipe (injector corrugation);

- remove the valve cover, camshaft, loosen the timing belt and move it to the side;

- disconnect the wires and cooling system pipes from the cylinder head, unscrew the head bolts;

- unscrew the nuts of the exhaust pipe of the muffler;

- We completely free the cylinder head from all fasteners that prevent it from being removed, and we remove the cylinder head;

- if there is protection under the engine, remove it;

- place a container under the engine sump, unscrew the plug on the crankcase, drain the oil;

- remove the lower hatch of the gearbox housing (three bolts);

- Using a 10 mm wrench or a socket wrench, unscrew all the oil pan bolts;

- dismantle the pan, remove the oil receiver;

- Unscrew the connecting rod nuts, remove the lower connecting rod caps, and carefully knock the pistons and connecting rods upward. Pistons should be knocked out through a soft metal drift or through a wooden block. First, you need to carefully knock out the connecting rod bolt without damaging the threads on it, then place the drift on the end of the connecting rod - in no case should you hit the bearings or the seat underneath them;

- It is recommended to remove the connecting rods one at a time, and immediately attach the caps to them; the caps should not be confused with each other, they are placed back strictly in their places, and a lock to the lock is required;

- remove the PC from the pistons, use a piece of the old ring to clean the piston grooves to bare metal. Be sure to check the cleanliness of the groove all around; there should be no coke left in it;

- We install new rings in the grooves, start with the lower MPC, then install the middle compression PK, and lastly the upper one. For installation, you can use a special device, but it is still more convenient to install the rings by hand. If the MPCs are cast iron, they cannot be bent along their axis, they can only be carefully moved apart. Compression rings also need to be bent carefully, to a minimum;

- we install the piston in place using a special mandrel, hammer it in with a wooden hammer handle or a brass or bronze drift;

STK against the Chinese and Americans

Engine piston: design, functions, causes of wear and ways to prevent it

Plugless pistons (we will tell you what they are a little later in this article) manufactured by Samara Trading Company LLC (STK company) are the most popular among experienced and competent mechanics and are considered the most effective.

We have already discussed this topic here, but there is every reason to delve deeper into this issue. Chinese pistons turn out to be quite adapted to our fuel, but they are too unreliable, the quality of the alloys leaves much to be desired: it seems that someone whispered to the Chinese engineers that duralumin slag is better than Soviet steel, cast iron and aluminum. This is wrong.

American pistons, including the famous Federal Mogul, are made a little better, unlike Chinese products. They even provided different groups, but they do not have repair sizes at all. The factory did not provide for this, so they are virtually useless in solving many problems.

A test drive of domestic cars with pistons proved that the dynamic characteristics of cars after replacing the piston group are most productive precisely after replacing them with STK pistons. In other words, torque, compression, exhaust gas quality, oil level, acceleration dynamics, speed and speed of engines on STK remain the same 30-50 thousand kilometers after replacement. No brand of pistons has yet shown such a result.

Let's talk a little more seriously about STK plugless pistons. What are their design and main advantages?

The most unpleasant thing that has probably happened to every motorist is a torn timing belt. There is only one sure way to protect yourself from such a nuisance - replacing the piston group with a good group and setting it up correctly. How to protect yourself from belt breaks and, as a result, bent valves? There is one trick - these are special grooves on top of the pistons, which the people (and then in official car services) began to call “stickless pistons”.

Tubeless pistons

Let's talk in more detail about the grooves on the top of the piston group, which are used by the manufacturing team from STC. So, how does all this work and is there a need to install such pistons on your car? Or can you go with the usual ones and not bother yourself with innovations? Well, let's describe the STK piston itself.

Housing and structure

Such pistons are an almost exact copy of a regular car piston, with only one distinctive feature - in the upper part, instead of the usual “mirror,” special recesses appear to increase the service life of both some timing parts and the pistons themselves.

Recesses of plugless pistons

Toyota pistons markings

The pistons on Toyota engines also have their own designations and sizes. For example, on the popular Land Cruiser, the pistons are designated by the English letters A, B and C, as well as numbers from 1 to 3. Accordingly, the letters indicate the size of the hole for the piston pin, and the numbers indicate the size of the piston diameter in the “skirt” area. The repair piston has +0.5 mm compared to the standard diameter. That is, only the letter designations change for repair shops.

Please note that when purchasing a used piston, it is necessary to measure the thermal gap between the piston skirt and the cylinder wall. It should be within 0.04...0.06 mm. Otherwise, it is necessary to carry out additional diagnostics of the engine and, if necessary, carry out repairs.

Source of the article: https://post1.su/neispravnosti/razmery-porshnej-vaz.html

How to understand when it's time to change piston rings

When the car's oil consumption increased significantly, compression in the cylinders dropped. Before quickly rushing to the garage, you need to measure the compression, first on dry cylinders and then fill the cap from a bottle of oil and measure again and compare the results. If dry cylinder performance is lower, the piston rings must be replaced.

If not, then the rings have nothing to do with it, and you should pay attention to the caps and valves. Also, if low-grade oil is used, the piston rings may become stuck. This phenomenon usually occurs in cars whose engines have not been used for a long time, or have been used for very short distances.