VAZ-2114 engine operating temperature: indicators

A change in operating temperature is almost always associated with a malfunction of the cooling system. When the operating temperature range is violated, the engine behaves extremely unstable. You cannot use a car with such a fault for a long time, as this will lead to the need for major repairs. But many do not know what is considered the normal operating temperature of the engine on the VAZ-2114. Let's look at this issue.

Normal temperature readings

For all cars the operating temperature is approximately the same. This is due to the fact that in 1992, manufacturers established a single standard. According to it, the temperature at which the engine will operate without failures fluctuates around 90 degrees. The permissible error is 3 degrees in each direction.

In 2004, this figure was revised, as the automotive industry has made great strides forward. Then a range from 85 to 105 degrees appeared, acceptable for many cars. It was he who was guided by when creating the VAZ-2114. The injector of this model can operate at temperatures from 87 to 103 degrees. This range applies to modifications with 8 and 16 valves with a volume of 1.6 liters.

What does an increase or decrease in this indicator lead to?

If the temperature drops below this norm, the engine will lose power and dynamics. As a result, the car will have a harder time picking up speed and consume more fuel. Especially often, a decrease in normal indicators occurs in winter, if the power plant is not warmed up enough or if the stove malfunctions

It is important to maintain the engine regularly to avoid this situation.

In summer, leaving the operating temperature range is more dangerous, especially if the engine overheats, which happens extremely often this season.

An increase in temperature leads to boiling of liquids in the engine, which causes irreparable damage to it.

The main problem with the engine reaching operating temperatures is related to changes in the properties of the oil:

- as it decreases, it becomes more viscous;

- when increasing liquid.

This may result in under or over lubrication of parts. It is much more dangerous if the oil becomes more liquid and loses its properties, since in this case friction occurs between the iron parts, leading to their wear.

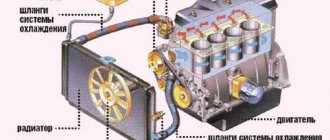

Basic cooling system malfunctions

The reason why the operating temperature range on a VAZ-2114 engine with 16 or 8 valves may change is the failure of parts of the cooling system. Almost every component of it is capable of changing the engine temperature in one direction or another.

- If the radiator is faulty, then most often the temperature rises. First of all, this is due to its clogging. It is enough to clean the grille of this part from debris and dust and the temperature indicators return to normal. If the radiator leaks, then more expensive repairs will be required, including soldering it or completely replacing it. Nevertheless, the radiator is one of the most reliable parts of the VAZ-2114.

- The pipes of this car are the weaker components of the cooling system. An increase in temperature in the engine is associated with wear of the pipes, which causes delamination and cracks to appear in them. Through these damages, coolant leaks out, causing the temperature in the power unit to rise.

- If the water pump fails, you will have to replace it. This unit may produce too little pressure or leak altogether, which will practically stop the circulation of fluid in the system.

- Most often, car enthusiasts are faced with a faulty thermostat. This is a rather capricious part that has to be changed from time to time. In winter, jamming of the thermostat is not so bad; it will be stuck in a small circle, this will be enough for the normal functioning of the engine. In the summer, the radiator fan will work continuously, but it will still not be able to cope with the increase in temperature. The thermostat must be replaced as soon as possible after it breaks. Experienced car enthusiasts recommend installing a more advanced model of this element from a Lada Granta car.

- If the fan installed on the radiator malfunctions, the power plant will boil in almost 100% of cases, especially when the thermostat fails at the same time.

Tips for motorists

The electric motor of the fan, the engine cooling system of the VAZ-2112 car, is switched on through a relay. And it is triggered by a command from the electronic control unit, which receives a signal from the fan activation sensor. It is located just above the thermostat. It should not be confused with the coolant temperature sensor, which works with the temperature gauge located on the instrument panel. It is located below the fan sensor.

If the temperature gauge needle creeps into the red zone of the scale, and the noise of the cooling system fan turning on is not heard, then you will have to look for the cause of this malfunction. To begin, press the horn button, thereby checking whether fuse F7 (20A), which protects the fan’s electrical circuit, is intact. There is a beep sound, which means the fuse is intact, and there is no point in opening the mounting block.

Next we check the fan relay. It is located on the right side of the front console, where the passenger's feet are located. We open the cover, the original relay is the first on the left edge. You can check it by replacing it with an equally good one. And if, by closing contacts No. 85 and No. 86, the fan starts working when the ignition is on, then it is working. The fan motor can also be checked in another way by connecting it directly to the battery.

The most common cause of cooling system fan failure is the fan switch sensor. It is checked by warming up the engine to a temperature of just over 100 degrees, and then turning off the engine, leaving the ignition on. Remove the terminal from the sensor. If the fan starts working, the sensor is faulty. Naturally, first check whether the fan itself is working. If all of the above devices are working properly, the reason the fan does not turn on will be the electronic control unit.

The driver of a VAZ-2112 car can independently check the entire electrical circuit for turning on the fan, with the exception of the ECU.

I need help, the cooling fan on the VAZ 2112 doesn’t turn on, tell me what could be the problem? When I close it directly, it works, but otherwise the car starts to boil (the heater works, the thermostat opens

Comments 55

FRIENDS IT WAS ABOUT THE TANK COVER)

The valve on the expansion tank cap is stuck!

FRIENDS IT WAS ABOUT THE TANK COVER)

What temperature does the instrument display while driving?

If you can’t find the reason yourself, then just drive in emergency mode to an auto electrician

Try changing the relay, there was such a problem, it disappeared immediately after replacing the relay. She has a beard, remove the side trim in the passenger's feet, there are 3 of them, or just try to swap them, in case the contact turns sour or something like that

The VAZ-2110 cooling fan does not work. Cooling fan connection diagram

To ensure safe and stable thermal conditions of an internal combustion engine, precise operation of the cooling system is required. The slightest failure will lead to overheating of the engine, which can lead to burnout of the head gasket or failure of the piston group elements.

The radiator fan is one of the key components of the car cooling system. Its role is to promptly force cool the liquid in the radiator. Problems with turning it on are a common occurrence for our cars.

In this article we will talk about possible reasons why the VAZ-2110 cooling fan does not work, and also consider options for eliminating them. But first, let's understand its design and operating principle.

Procedure. Step-by-step instruction

If after completing the next step the problem goes away, further checks are stopped.

- Open the hood.

- Wait for the engine to cool down.

- Perform an initial visual inspection: integrity of the hoses, reliability of the clamps, absence of leaks or cracks.

- Make sure that the expander cover elements are in good condition. Remove scale, rust, clear holes, wipe, assemble. The absence of noticeable damage to parts gives hope that the product will work.

The valve design is elementary. The cover contains a spring. Functionally, it is designed to regulate the pressure in the cooling circuit. A hot engine increases it, a cold engine decreases it.

Compressing at a value of 1.1 atmospheres, the spring relieves excess pressure and prevents the destruction of hoses and the tank. As the motor cools, it creates a vacuum effect. The tank will begin to flatten. The valve equalizes the pressure.

The lid screws tightly on the thread, eliminating distortions. There should be a gap between it and the body. An overtightened valve will not work. It is difficult to test the device's operation in road conditions. You can check by replacing it with a known good one.

Inspect the electrical wiring elements to ensure a reliable connection

Possible factors for damage to electrical circuits:

- vibration;

- oxidation;

- burning;

- breakage, fraying of electrical wires;

- insulation aging, short circuit.

Switch the tester to resistance measurement mode. Remove it with special tweezers and ring the fuse link F7 located in the mounting block.

Fuse box diagram

Replace the burnt-out element with a serviceable one with a rating of 20A. Inspect and clean the nest. Insert fuse.

It was not possible to find out the reason, the protection triggered again - look for a short circuit.

Disconnect the fan plug. Use a tester to measure the circuit of the electric motor windings. Zero resistance or a break indicate the need to replace the radiator blower electric drive.

Interturn short circuits that cause multiple replacements of fuse links cannot be measured with the device.

Sensor check

Start the car. Pull out the coolant temperature sensor connector. The fan starts working - the sensor needs to be replaced. Secure the disconnected wire. Drive to a nearby service station.

Relay test

There is a hatch on the floor at the front passenger's feet.

Below it is a built-in panel with three relays of the same type:

- fan installation;

- fuel pump;

- ignition (main thing).

By replacing each other, try to start the airflow. The VAZ 2110 fan does not work - go to the next step.

Check the electric motor

Winding measurements did not reveal a malfunction. Apply voltage briefly from the battery using additional insulated conductors. The operation of the fan indicates a malfunction of the controller, which does not output a signal to the relay.

- The only correct solution is to turn on the airflow directly and urgently visit a service station.

- Prevention of breakdowns of the cooling system of the VAZ 2110 injector 16 valves.

- Periodically inspect the components of the cooling system.

- Monitor the cooling temperature on the device, listen to the operation of the fan.

- Maintain coolant level. Replace after 2 years or 30,000 km.

- Use the solution to remove rust and scale.

- Signs of a change in the properties of the coolant are a change in color, an increase in fluidity.

- Check the density with a hydrometer.

- Do not mix coolants.

- Every twelve months, rinse the expansion tank cap with water and check it on a stand with a pressure gauge.

- Avoid contact of aggressive liquids with electrical wiring and electric motor windings.

How to check the fan sensor

To check the functionality of the fan switch sensor, it must be removed from its seat. As mentioned above, it is usually located either on the radiator or in the cylinder block. However, before removing and testing the sensor, you must ensure that power is supplied to it.

Power check

Checking the DVV power supply

On the multimeter, we turn on the mode for measuring constant voltage within about 20 Volts (depending on the specific model of the multimeter). You need to check for voltage in the disconnected sensor chip. If the sensor is two-pin, then you will immediately see whether there is 12 Volts there. In a three-pin sensor, you should check the voltage between the terminals in the chip in pairs in order to find where there is one “plus” and where there are two “minuses”. Between the “plus” and each “minus” there should also be a voltage of 12V.

If there is no power to the chip, first of all you need to check whether the fuse is intact (it can be either in the block under the hood or in the car interior). Its location is often indicated on the fuse box cover. If the fuse is intact, you need to “ring” the wiring and check the chip. Then you should start checking the fan sensor itself.

However, before draining the antifreeze and unscrewing the radiator cooling fan sensor, it is worth conducting another small test to ensure that the fan operates properly.

Checking fan operation

Using some kind of jumper (a piece of thin wire), connect the “plus” in pairs and first one, and then the second “minus”. If the wiring is intact and the fan is working properly, then at the moment of the short circuit, first one and then the second fan speed will turn on. On a two-pin sensor there will be one speed.

It is also worth checking whether the fan turns off when the sensor is disconnected, and whether the contacts in it are stuck. If the fan continues to run when the sensor is turned off, this means that there is something wrong with the sensor and it needs to be checked. To perform this, the sensor must be removed from the machine.

Checking the fan switch sensor

You can check the DVV in two ways - by heating it in warm water, or you can even heat it with a soldering iron. Both of them involve checking for breaks. Only in the latter case will you need a multimeter with a thermocouple, and in the first - a thermometer capable of measuring temperatures above 100 degrees Celsius. If you are checking a three-pin fan switch sensor with two switching speeds (installed on many foreign cars), then it is advisable to use two multimeters at once. One is to test one circuit, and the second is to simultaneously test a second circuit. The essence of the test is to find out whether the relay operates when heated to the temperature indicated on the sensor.

Check the radiator cooling fan switch on sensor using the following algorithm (using the example of a three-pin sensor and one multimeter, as well as a multimeter with a thermocouple):

Checking DVV in warm water using a multimeter

- Set the electronic multimeter to the “diagnosis” mode.

- Connect the red probe of the multimeter to the “positive” contact of the sensor, and the black one to the “minus”, which is responsible for the lower fan rotation speed.

- Connect the probe measuring temperature to the surface of the sensor's sensitive element.

- Turn on the soldering iron and apply its tip to the sensitive element of the sensor.

- When the temperature of the bimetallic plate reaches a critical value (indicated on the sensor), a working sensor will close the circuit, and the multimeter will signal this (in the dialing mode the multimeter beeps).

- Move the black probe to “minus”, which is responsible for the second fan speed.

- As heating continues, after a few seconds the second circuit should close on a working sensor and when the threshold temperature is reached, the multimeter will beep again.

- Accordingly, if the sensor does not close its circuit during warm-up, it is faulty.

Checking a two-contact sensor is performed in the same way, only the resistance needs to be measured only between one pair of contacts.

If the sensor is heated not with a soldering iron, but in a container with water, then make sure that it does not cover the entire sensor, but only its sensitive element! As it heats up (control is carried out with a thermometer), the same operation will occur as described above.

Conclusion

The cooling fan switch sensor is a reliable device, but if there is a suspicion that it has failed, then to check it you need a multimeter, a thermometer and a heat source that will heat the sensitive element.

Source

Basic cooling system malfunctions

The reason why the operating temperature range on a VAZ-2114 engine with 16 or 8 valves may change is the failure of parts of the cooling system. Almost every component of it is capable of changing the engine temperature in one direction or another.

- If the radiator is faulty, then most often the temperature rises. First of all, this is due to its clogging. It is enough to clean the grille of this part from debris and dust and the temperature indicators return to normal. If the radiator leaks, then more expensive repairs will be required, including soldering it or completely replacing it. Nevertheless, the radiator is one of the most reliable parts of the VAZ-2114.

- The pipes of this car are the weaker components of the cooling system. An increase in temperature in the engine is associated with wear of the pipes, which causes delamination and cracks to appear in them. Through these damages, coolant leaks out, causing the temperature in the power unit to rise.

- If the water pump fails, you will have to replace it. This unit may produce too little pressure or leak altogether, which will practically stop the circulation of fluid in the system.

- Most often, car enthusiasts are faced with a faulty thermostat. This is a rather capricious part that has to be changed from time to time. In winter, jamming of the thermostat is not so bad; it will be stuck in a small circle, this will be enough for the normal functioning of the engine. In the summer, the radiator fan will work continuously, but it will still not be able to cope with the increase in temperature. The thermostat must be replaced as soon as possible after it breaks. Experienced car enthusiasts recommend installing a more advanced model of this element from a Lada Granta car.

- If the fan installed on the radiator malfunctions, the power plant will boil in almost 100% of cases, especially when the thermostat fails at the same time.

Let's sum it up

In this article, we examined one of the most common reasons why the engine does not warm up, may cool down while driving, the engine temperature does not rise above 70 degrees, etc. Let us add that in the latter case, on a car with an unknown history, it often turns out that the previous owner had previously installed a too “cold” thermostat. In parallel with this, other malfunctions of the cooling system may occur, as a result of which the internal combustion engine does not heat up.

It should also be noted that repairing the device is impractical given its relatively low cost. For this reason, instead of descaling the thermostat and trying to eliminate its jamming, it is better to immediately install a new element on the machine.

Source

Refinement of the cooling system

Domestic cars are far from perfect, that's a fact. Lada Priora was no exception in this regard, having inherited many shortcomings from the legendary “ten”. One of them is an unfinished cooling system.

There are several ways to quickly and without financial costs modify the SOD on Priora.

- Installing a 6-hole thermostat (stable maintenance of coolant temperature).

- The use of Kalina SOD on Priora will reduce the pressure in the system and provide quick warm-up at subzero temperatures.

- Installing a larger or additional water pump to improve coolant circulation efficiency.

- Use of multi-speed and silent forced cooling fan.

- Changing the firmware of the control unit so that the fan operates at a lower temperature.

Refining the cooling system of the Lada Priora is a feasible task even for novice car enthusiasts. The SOD has a simple design with a minimal set of components. Thanks to this, the system is relatively reliable.

The VAZ 2170 model received several power plants, but the most popular engine in the Priora is a gasoline unit with 16 valves and a volume of 1.6 liters. On various automotive forums it is called briefly - 126 (number). Responsible drivers spend a long time thinking about which car to buy, and the engine plays an important role in this matter. Service life, operating temperature, price of a new motor, analysis - our review will answer all these questions.

Extraneous noise

When extraneous sounds appear in engine operation, the first thing you need to do is look at the condition of the hydraulic compensators, since they are the most common cause of failure. The solution to the problem of knocking hydraulic valves is replacement. But if they have nothing to do with it, then it’s worth checking the oil pressure in the system. In addition, sounds may come from the pistons, their pins, main bearings or valves. If the problem is with them, then you should contact the nearest service center.

Troubleshooting a vehicle's fuel system || Refilling a car air conditioner

| Repairing a Nissan Almera engine is quite expensive, since Japanese spare parts themselves are expensive. The sooner you notice problems, the more likely it is that... |

Engine operating temperature on the VAZ-2110 - is there a difference?

Despite the fact that 8 and 16-valve VAZ engines have a slight difference in the design of the cooling system, the operating temperature for both engines is the same.

Engine operating temperature on the instrument panel.

The factory provides a normal engine operating temperature ranging from 87 to 103 degrees. Maintaining the temperature within these limits can be greatly influenced by certain issues related to the performance and quality of the cooling system elements. Let's look at each of them briefly.

Cooling radiator

Boiling of the coolant can be caused by a clogged cooling radiator, and it can become clogged both inside and outside.

Clogged honeycombs of the engine cooling radiator.

Cleaning the radiator regularly will ensure normal engine operation and will help prevent antifreeze from boiling.

When checking the condition of the radiator, we pay special attention to the presence of leaks and the integrity of the honeycombs, the absence of cracks in the tanks and the condition of the pipes

The water pump is responsible for the complete circulation of coolant through the cooling and heating system.

Antifreeze leaking from under the pump.

Maintaining the normal operating temperature of the antifreeze also depends on the efficiency of the pump. The main pump malfunctions include bearing failure, leakage and destruction of the pump impeller.

This can occur as a result of both physical damage to the impeller and destruction as a result of cavitation processes. Cavitation is most often caused by the use of low-quality antifreeze or untimely replacement.

Most of the complaints are made specifically to the thermostat, the bypass valve, which directs the coolant in a full or small circle, depending on the degree of heating.

Thermostat location under the hood.

For example, the engine may not warm up to the legal 87–90 degrees due to a stuck valve. However, most often thermostat malfunctions occur due to the quality of the thermoelement. Despite the fact that each thermostat is marked on the body, which indicates the valve response temperature, the indicated temperature does not always correspond to reality.

So, at the specified operating temperature of 85 degrees, the thermostat can pass liquid in a large circle already when warming up to 75–80 degrees. As a result, the temperature will not correspond to the norm, the engine will not be able to warm up to the optimal value. The only solution is to test the thermostat before installation. To do this, the thermostat body is placed in a vessel with water and heated to the specified temperature, periodically checking the condition of the valve. A discrepancy between the thermostat response temperature, even by 3–5 degrees, will not allow you to obtain the optimal operating temperature while driving.

Sensors, ECU firmware and fan

The accuracy of the coolant temperature sensor also greatly affects operating temperature.

The temperature sensor is located near the thermostat housing.

The sensor sends an electrical impulse to the electronic control unit, which in turn gives a command to start the cooling fan. The normal temperature at which the fan should start is 105 degrees. If the sensor readings are incorrect, the fan will start earlier (in this case the antifreeze will not warm up to normal) or later

Then the engine may overheat and the antifreeze may boil, especially antifreeze of poor quality.

How does the fan sensor work?

The fan switch sensor itself is a temperature relay. Its design is based on a bimetallic plate connected to a movable rod. When the sensitive element of the sensor heats up, the bimetallic plate bends, and the rod attached to it closes the electrical circuit of the cooling fan drive.

The sensitive element comes into contact with antifreeze, as a rule, directly in the radiator (in the lower part, on the side, depending on the car model), but there are engine models where the fan sensor is placed in the cylinder block, such as in the popular VAZ-2110 car (on injection engines). And sometimes the design of some engines provides as many as two sensors for turning on the fan, in particular, on the inlet and outlet pipes of the radiator. This allows you to both turn on and turn off the fan forcibly when the antifreeze temperature drops.

It is also worth knowing that there are two types of fan temperature sensors - two-pin and three-pin. Two-pin ones are designed for fan operation at one speed, and three-pin ones are designed for two fan speeds. The first speed is turned on at a lower temperature (for example, at +92°C...+95°C), and the second at a higher temperature (for example, at +102°C...105°C).

VAZ-2112 Engine is heating up

- Group: Users

- Messages: 2,472

The message has been edited. ich: 04.10.2006 — 22:10

ordinary user

- Group: Users

- Posts: 467

All-wheel drive

- Group: Users

- Posts: 586

www.del.nah

- Group: Users

- Posts: 1,048

ordinary user

- Group: Users

- Posts: 53

Temperature for turning on the fan on a VAZ211. 102 or 105, depending on the firmware, turn off 95 or 97! So in my opinion it is working correctly for you. You can also look at what color your antifreeze is, if there is a lot of rust in it, then you need to wash it, otherwise there will be problems, perhaps there already are. There are special products for flushing the cooling system. If necessary, I will explain. Write in PM!

Post edited by Porsh: 10/06/2006 - 07:47

recently on the forum

- Group: Beginners

- Posts: 5

Türkiye, kalbimde kalacaksın

- Group: Users

- Posts: 7,594

I'm running_the_rocket_1876km_very scary

- Group: Users

- Posts: 1,885

ordinary user

- Group: Users

- Posts: 467

experienced forum member

- Group: Users

- Messages: 1,410

I have a problem on ten. The car is 5 years old, everything was OK and suddenly it began to overheat. It gets to the point where I’m driving 90-100 and the temperature is about 110 degrees and the fan is running. After the thermostat, all pipes are hot. Should I change the thermostat anyway?

When purchasing a thermostat, do they provide some kind of warranty? I heard that every fifth person often works normally.

And how much antifreeze will be lost (leak out) if you don’t drain all the antifreeze when changing the thermostat?

Post edited by miracle: 05/17/2007 - 11:15

- At work

- Group: Users

- Messages: 22,061

| QUOTE (miracle @ May 17 2007, 09:10) |

| Should I change the thermostat anyway? |

| QUOTE (miracle @ May 17 2007, 09:10) |

| How much antifreeze will be lost (leak out) if you don’t drain all the antifreeze when changing the thermostat? |

ordinary user

- Group: Users

- Posts: 323

experienced forum member

- Group: Users

- Messages: 1,410

Yesterday I bought a new thermostat (membrane type), took everything apart, but it didn’t fit. I decided to assemble without it so as not to overheat. I went to work. But the temperature was about 110 and the radiator was constantly turned on. The pump pumps (antifreeze comes from the steam pipes) The antifreeze is fresh.

What could it be? And maybe someone else has a picture of the thermostat assembly 21082-1306010

Megatheronosaurus

- Group: Users

- Posts: 14,452

| QUOTE (miracle @ May 17 2007, 10:10) |

| I have a problem on ten. The car is 5 years old |

| QUOTE (Uclas @ May 17 2007, 13:27) |

| And the day before yesterday I flushed the cooling system and filled it with new antifreeze. It seems that it began to heat up a little less, the fan began to turn on a little less often. |

| QUOTE (miracle @ May 18 2007, 09:25) |

| I decided to assemble without it so as not to overheat. |

| QUOTE (miracle @ May 18 2007, 09:25) |

| the temperature was about 110 |

- At work

- Group: Users

- Messages: 22,061

| QUOTE (Diselist @ May 18 2007, 13:09) |

| You can use the hardware to lower the temperature on the fan. |

Pachimushta Zhrukhot!

- Group: Users

- Posts: 4,578

| QUOTE |

| I decided to assemble without it so as not to overheat. I went to work. But the temperature was about 110 and the radiator was constantly turned on. |

Still would. In this case (without a thermostat), Antifreeze has two paths - in a small circle and in a large circle (through the radiator). Guess which path most of the antifreeze chooses?

The thermostat has two valves. One opens the way for antifreeze to the radiator, the other blocks the short path past the radiator.

experienced forum member

- Group: Users

- Messages: 1,410

Post edited by miracle: 05/18/2007 - 16:07

Domestic 16-valve engines

A little preface. When faced with 16-valve VAZs at the household level, remember that such cars are always equipped with 14-inch wheels, since there are enlarged ventilated brake discs at the front.

So, the “gear” came from an 8-valve engine. In the articles you can find mentions that VAZ wanted to create a powerful and economical engine, and so, the “gear” will never be more economical than an eight-valve engine. Consumption 16 cl. engine 7.5 - 10 liters, depending on the dynamics.

The first engine from the line was 21120 (hereinafter referred to as the 120th

). The volume is one and a half liters, equipped with an ignition module, the valves bend. Visually different is the cast intake manifold. It was developed for cars 2110-2112, installed in various modifications such as “Premier” and 2112 in a two-door hatchback body. It went into production in 1996 and was installed on cars until 2004. If today you buy a car with such an engine, then most likely it has already undergone repairs and a “plug-in” piston is installed on it.

120th: valve bend, cast intake manifold, ignition module, 1.5 liters.

In 2004, the 120th engine was replaced by a new one with the index 21124 (hereinafter referred to as the 124th

). In addition to cars of the tenth family, it was installed on the VAZ 2113 and VAZ 2114.

This engine does not bend the valves, thanks to grooves on the pistons, this is its main difference from its predecessor. It is easy to distinguish by its plastic intake manifold. In addition, the ignition module has been replaced with individual coils for each cylinder. Engine capacity increased to 1.6 liters.

Many people call this engine the most balanced in the VAZ line, and I think this is true. Its service life is at least 200 thousand, if you drive “without fanaticism”.

124th: no valve bending, plastic intake, ignition coils, volume 1.6 liters.

In 2007, the tenth family left the assembly line (the vehicle kits were sent to Ukrainian as punishment) and the Priora was released. This “breakthrough” in mechanical engineering was equipped with the 21126 engine ( 126th

). It was equipped with lightweight connecting rods, pistons, liners, and other parts, which made its service life less than that of a 124 engine. In order to increase power, the grooves on the pistons have been removed and the valves on this engine are bent.

126th or “prioromotor”; oppression, lightweight, volume 1.6.

21128 or 128th

the motor was created and installed on Priora and 2110-2112, which were produced by this company. This is the heir to the 124th engine, the engine capacity has been increased to 1.8 liters, which has a negative impact on the service life. In practice, I saw one such car, which, with a mileage of 90 thousand kilometers, suffered from severe oil consumption. This engine received a lot of negative reviews.

Presentation of the 128th, source https://24techno-guide.ru/images/img575.j

In 2013, 21127 appeared or 127

-th engine, its power was increased to 106 horsepower, an adjustable air intake through the receiver was installed, the mass air flow sensor was abandoned in favor of the DBP (absolute pressure sensor) and the DTV (air temperature sensor). The valves in this engine are bent.

And the last creation we will look at is this 11194

engine. It has a volume of 1.4 liters, installed on Kalina. At one time I drove such a Kalina, and the meaning of such an engine is not clear to me; it drives exactly the same as an 8-valve one. The reviews leave much to be desired, and for its unjustified oil consumption, the engine was nicknamed the “legendary Kalinomotor”, of course, not without sarcasm.

We briefly looked at the "six" from VAZ. In this article I will not touch on modern Vest engines and other creations of AVTOVAZ; to be honest, I’m losing interest in studying the crafts of the alliance of the French and Japanese.

Sources

- zen.yandex.ru/media/tec/otechestvennye-16klapannye-motory-5da93b67028d6800ac761e55

- dvigatels.ru/russia/dvigatel-vaz-2112.html

- carprofy.ru/dvigatel/vaz-2112/

- drom.ru/catalog/lada/2112/specs/engine_capacity/

- drive2.ru/b/1827090/

Operating temperature of VAZ 2110: diagnostics and replacement of the coolant temperature sensor

Drivers who regularly drive on country roads often see the following picture: a car is standing on the side of the road with the hood raised, and steam is coming from the engine compartment. The cause of this situation is most often the temperature sensor. In one case, the motorist himself is to blame for the breakdown; he did not notice the temperature increase, and in the other, the electronic element was worn out. The coolant sensor (DTS) rarely breaks, but if this happens, then urgent replacement is required. After studying this material, the reader will learn what the operating temperature of the engine is, why the VAZ 2110 engine gets hot, how to check the DTOZH and how to replace/install a new element in a car where the injector is located.

This happens if you do not notice a malfunction of the engine temperature sensor in time.

How to check wiring

Finding a broken conductor in a car's electrical circuit yourself is not at all difficult. The cooling fan does not turn on, but it works. Fan on grant. It is necessary to check (ring) all wires in the indicated areas with a tester.

For carburetor engines:

- from the switch on sensor to the fan;

- from the fan to the mounting block (fuse);

- from the mounting block to the relay.

For injection engines:

- from the main relay to the fan switch relay;

- from the switching relay to the fan and controller;

- from temperature sensor to controller;

- from the fan to the mounting block (fuse).

If a wiring break is detected, it must be restored, as well as the possible cause of the circuit break must be identified and eliminated.

kokika 26.11.2009 — 12:32

I just went through a friend and got a diagnosis, they said 450 rubles.

or a dead thermostat that opens a wide circle at 100C

My thermostat did not open at all, the symptoms were the same. Moreover, last fall and winter I traveled normally, I got used to the operating temperature being about a hundred. But in the spring, when the sun warmed up, it began to boil. The thermostat blew, six months passed - again, bitch, I died. Now it starts to open immediately after starting the engine and the engine only heats up above 60 degrees in traffic jams.

QUOTE

(Nadezhda1979 @ November 26, 2009, 11:23)

The sensor is lying and displays the temperature incorrectly. for example, when the temperature was 70 it showed 90. The fan was constantly working.

Are both sensors lying at once? There seem to be different sensors for the fan and the dash.

QUOTE

(kokika @ November 26, 2009, 12:04 pm)

No one named what kind of work they should be?

About 90 degrees. More precisely, from 80 (depending on the thermostat) and up to 105 (depending on the fan sensor). In hot traffic jams it can reach 110-115, in winter in severe frosts along the highway it can drop to 70.

QUOTE

(kokika @ November 26, 2009, 12:04 pm)

And how much does diagnostics cost?

You can do basic diagnostics yourself: start the cold engine and feel the upper and lower radiator hoses under the hood with your hands. One (upper) should heat up as the engine warms up, the second should remain cold until it warms up to 85 degrees, after which the thermostat opens and the lower hose should heat up. If the engine heats up to 100, the fan turns on, and the lower hose is cold, then the thermostat is definitely stuck in the closed position.

QUOTE

(omkc1 @ November 26, 2009, 12:25 pm)

The thermostat opens at 90-95 degrees.

Like 80-85. On Kalina the thermostat marking is exactly 85 degrees, on dozens it’s probably the same, there’s only one engine.

QUOTE

(*Fantik* @ November 26, 2009, 1:19 pm)

in our city it’s 350 rubles.

It depends where. Garant-N charges 400 rubles, despite the fact that diagnostics should be included and maintenance should be done free of charge. At Autofan they gave me diagnostics for free, although I didn’t go there for maintenance, but to change the struts; I just complained about the “dzhekichen” along the way.

What should the engine operating temperature be?

Engine operating temperature shown on the instrument panel

If we take the information from the international convention of automobile manufacturers dated December 1, 1992, the uniform standard for engine operating temperature is considered to be 90 degrees Celsius. With such indicators, the engine operates as efficiently as possible and does not create residual negative effects.

When switching to more advanced engine manufacturing technologies in 2004, it was accepted that a specific indicator of this indicator cannot be held in one position, and therefore they made a gradation of acceptable standards, which amounted to 85-105 degrees Celsius.

Engine overheating shown on the instrument panel

According to data from the manufacturer AvtoVAZ, on a 16-valve VAZ-2112 engine, the operating temperature of the engine is considered to be 87-103 degrees Celsius.

At this temperature, all systems function normally, and the motor is not subject to negative factors and consequences.

Reasons why the motor does not heat up to 90 degrees

If you begin to notice that during a trip the power unit does not heat up to the required temperature, you should check the functionality of the elements of the engine cooling system and find out why the engine temperature does not rise. Most often, the internal combustion engine does not reach the required temperature for several reasons.

The pipes are not tightened sufficiently, resulting in air leaks. In this case, minor leaks of coolant may be noticeable. To eliminate all these flaws, you need to check the tightness of the connecting tubes and how tightly the clamps are tightened on them, which, if necessary, should be tightened tighter.

The thermostat has failed - this element directs the flow of coolant circulating through the system: at first, when the engine warms up, it is closed and releases antifreeze or antifreeze only in a small circle; when the engine operating temperature approaches 80-90 degrees, the thermostat begins to open, releasing coolant into a large circle. When a thermostat fails, it means that it is stuck in a certain position that does not allow the power unit to reach normal temperature conditions. Replacing the thermostat will help get rid of this problem.

The coolant temperature sensor (abbreviated as DTOZH) is not working correctly - this is a rather complex thermoelement, thanks to which the coolant temperature readings are displayed on the information block on the car’s instrument panel. Thus, due to the incorrectness of the readings transmitted by the sensor to the dashboard, one may get the impression that the engine does not heat up to the required temperature, but in fact it operates in the correct temperature regime.

In order for the information transmitted by the sensor to correspond to reality, it is worth replacing it with a new one.

Car owners often encounter a problem where the engine does not heat up to operating temperature.

Usually they do not pay attention to it right away, since not everyone knows why low engine temperature is dangerous. 100 degrees required for normal operation

The question is why the engine does not heat up well and becomes hot when cold weather sets in, when it is not comfortable to be inside the car due to the low temperature. In addition, consumption increases significantly, the engine wears out faster, the car drives worse, and the level of toxic substances in the exhaust gases increases.

Checking the Thermostat

To diagnose the malfunction, you should contact a service specialist. However, you can check the thermostat yourself. The cold engine is allowed to idle for approximately 10 minutes. After this, you need to check the radiator pipes. If the thermostat is functioning properly, the hoses will not become hot. The temperature rises only at the moment when the coolant begins to circulate in a large circle.

The coolant enters the large circle only after reaching operating temperature. If the pipes begin to heat up before the specified point, you should immediately contact a technician for further diagnosis and troubleshooting. There are also more professional diagnostic methods using special sensors. Such a check can be carried out at a service station.

If the device does not open and close completely, partial overheating may occur or the temperature will rise, but very slowly. Also, the wedge can be observed only periodically.

Any specified defect requires careful examination and repair. If you do not have the necessary skills and minimal knowledge about the internal structure of a car, you should contact qualified car service specialists.

To remove the thermostat, you must first get rid of the liquid in the system

It is important to wait until the entire system has cooled down before replacing the part. Removing the thermostat is quite simple; to do this, just unscrew the three bolts located on the cover and remove it together with the thermostat

Taking into account all the design features of this model, it can be replaced with an identical or suitable analogue. Well-known brands produce units that can be interchanged, so there are no difficulties with selection. In any case, all manipulations must be carried out by a person who knows exactly what needs to be done, takes into account the make, year of manufacture, and mileage of the car.

It is very important to consider that the cost of this part is quite low, so it would be more appropriate to replace it than to repair it. Thus, you can get rid of problems with low engine temperature for the entire winter season

Since when replacing the thermostat you will have to drain the fluid, it is worth checking the engine for performance before the start of the winter season. Many car owners pour antifreeze into the system and then face the need to replace the unit, therefore paying twice for the coolant.

Diagnostics using ODB-2 scanner

The general technical condition of the car can always be checked using a personal diagnostic car scanner.

Of the options available on the market, we recommend paying attention to the Korean-made scanner Scan Tool Pro Black Edition. This model is perfectly compatible with most domestic and foreign cars

A special feature of the device is comprehensive car diagnostics. Unlike analogues, this auto scanner is capable of diagnosing not only the engine, but also ABS, gearbox, transmission, airbag, air conditioning system, etc. The device is also great when used as an on-board computer: in real time it displays speed, revolutions, readings from all available sensors, oil pressure, temperature and much more.

conclusions

The operating temperature of the 16-valve VAZ-2112 engine is 87-103 degrees Celsius.

If this indicator increases, the engine may boil, which in turn can lead to serious negative consequences, such as bending of the cylinder head or major engine overhaul. It is worth carefully monitoring the condition of the components and parts of the cooling system, because they ensure normal cooling and operation of the power unit.

Didn't find the information you are looking for? on our forum.

Airlock

In addition, an air lock in the cooling system can greatly interfere with the circulation of coolant.

A plug may occur after the liquid boils, as well as due to improper replacement of antifreeze or depressurization of the system. As a rule, air is removed from the cooling system through the throttle body pipe, as the highest point of the closed cooling system. After removing the plug, the engine will warm up to rated temperature and will not overheat.

Air is removed through the throttle body pipe after the engine has warmed up to operating temperature.