If only one shock absorber fails, you will still have to change a pair, so the order in which the work is performed does not matter.

Step-by-step procedure for removing the shock absorber on Kalina

We have already written about replacing the rear shock absorbers.

- First of all, open the hood and, using a ring wrench set to “22” and an open-end wrench to “9”, engage the nut securing the support to the rack and turn it. When the fastening becomes loose, do not unscrew it completely.

- Then, using a jack, we hang the front wheel and remove it. We place wheel chocks under the rear wheels.

- We remove the brake hose from the mounting groove on the rack and move it to the side.

Hoses are marked with arrows

- We apply lubricant to all connections, this applies to the fastening of the strut and steering knuckle, steering tip.

- After waiting a few minutes, you can begin dismantling.

- Having disconnected the cotter pin and unscrewed the nut from the steering end using a pry bar and a hammer, we remove it from the place of fixation.

- At the next stage, it may be difficult that after unscrewing the nut, the bolts may remain in place. This issue can only be resolved by generously applying lubricant, followed by knocking it out and turning it from the installation sites. (As a wedge, you can use a bolt of the smallest diameter - approx.).

- When all the nuts are unscrewed and the bolts are knocked out, all that remains is to remove the three support nuts.

- Of the three nuts, we do not immediately remove only one until the strut is disconnected from the steering knuckle. And after fixing the stand with your hand, unscrew this nut.

- When we have the stand in our hands, all that remains is to disassemble it correctly. And of course you should start by tightening the springs using special ties. (In order to avoid distortion, we tighten the springs evenly in turn on each side - approx.).

- It will be noticeable that the spring no longer rests against the strut support - this is a sign that it is already sufficiently tightened.

- Now you can unscrew the nut securing the support and remove the support itself along with the bearing.

- Then, when the support is removed, we take out the spring.

- Now all that remains is to remove the boot and bump stop from the strut rod. (Although you don’t have to do this if all the spare parts are new).

If you can’t remove the tip right away, you can pry it off with a pry bar

Then we unscrew the strut mount from the steering knuckle using the heads at “17” and “19”.

An air gun will be useful to unscrew these bolts.

The order in which the nuts are removed does not matter

This is what the stand looks like when removed

This completes the procedure for removing the front strut.

Step-by-step assembly procedure for the front pillar

- The first thing we do is put the bumper and boot on the new rack.

New rack, more comfortable to work with new spare parts

The strut spring is in its seat

We take a new support with a support bearing and fix it on the rod, putting on the support fastening nut.

New rack assembled and installed

We carry out exactly the same work on the other side of the car, since the work process is already familiar, everything will go much faster.

Signs of wear

The first signs that it is time to change the front struts will be their so-called “skips” on rough roads, the characteristic noise they will make and, of course, the presence of oil leaks on the body.

Leaks on the strut indicate the need to replace it

IMPORTANT!

Please accept this information as mandatory! After you have carried out work on installing new front struts on the Lada Kalina, you should immediately visit a vehicle technical inspection station to carry out work on the vehicle's wheel alignment, since during the work all the previously established angles were violated. Neglecting this can cause not only rapid and uneven wear of tires and mechanisms, but also lead to a traffic accident.

The support bearing is one of the leading elements of the suspension of any car, and the Lada Kalina is no exception. The movement of a car is associated with constant shocks from the suspension, especially on our roads. This part allows you to absorb the vast majority of loads, taking them upon yourself and distributing them evenly, so that the suspension and body remain in working order.

However, like other components, support bearings wear out over time, after which it is time to replace them. Today we’ll talk about what reasons can lead to a malfunction of this suspension element, how to determine their presence and how to replace it with a Lada Kalina.

000–109

And the second set, with a more significant reduction in ground clearance, allowed not only to improve the result by two seconds compared to the serial struts, but also endowed the car with new qualities. Handling has become a little less interesting: if the Kalina with the standard suspension willingly turns when releasing the gas, then with the St. Petersburg shock absorbers the steering has become slightly understeer. But the potential of tires on this suspension is realized better: the low ground clearance made it possible to set a different camber angle of the front wheels (-2º), and when cornering the inner wheel hardly slips! Reactions have also become more accurate: while previously you had to set the trajectory in advance, with Damp struts the car follows the wheel almost instantly. Not a bad budget option.

How to identify a malfunction

Are you bothered by some strange sounds in the chassis? Can you clearly hear its knocking while driving? This means that you urgently need to assess the condition of the suspension, since it is possible that you had to deal with:

There can be many reasons for the failure of support bearings, and they are the same for the vast majority of cars, including the Lada Kalina. First of all, we are talking about problems such as:

- Wear of the element (as a rule, the service life of support bearings on the Lada Kalina is designed for 50,000 - 100,000 km).

- Getting dirt and dust inside, which is very important for most of our regions where there are practically no roads.

- Damage due to excessive load on the shock absorber.

- Failure due to damage to the shock absorber itself.

Determining whether a support bearing is damaged is quite simple. To do this, you need to open the hood of the car, remove the “glass” and slightly rock the front of the car. A characteristic sound and vibration will indicate that you urgently need to replace 1 or 2 front support bearings. Of course, it’s better not to let things go wrong and install new components at least once every 50,000 – 70,000 kilometers (depending on the intensity of use of your Kalina). If a knock does appear, you should under no circumstances ignore it, since a new strut will cost you 4 to 10 times more than replacing a bearing, the average price of which is 300 rubles. The cost of work at a service station will also cost no less than 500 rubles. If you make the replacement yourself and in a timely manner, you can save a lot of money, especially since there is nothing complicated in the procedure. Next, we’ll talk about how to change the support bearing on a Lada Kalina car without contacting specialists.

AST SUSPENSION

The Dutch company AST Suspension has been designing and producing suspension components and kits for 35 years; The range has different lines - for ordinary roads and for sports. In Russia, the sale of its products is carried out by the company, which is headed by former rally driver Alexey Kovalchuk. It’s nice that the Dutch are upgrading their kits taking into account operating experience in our conditions.

It was possible to choose the extreme 5200 model - with remote reservoirs and various adjustments, but, firstly, such a design is not allowed by the RHHCC regulations, and secondly, the price of such a kit is a third of the cost of Kalina. Non-professional athletes have no use for this.

We change bearings correctly!

Actually, there are no difficulties in changing the bearing on Kalina. The main thing is to follow the step-by-step instructions that we will give below, and you will be able to deal with this trouble without any problems. So, to replace these components you need:

- Place the car on a flat surface and put it in gear.

- Remove the wheel from the side from which the bearing will be replaced.

- Remove the tie rod end nut. To do this, you will need a 19 mm wrench and pliers for removing the cotter pins.

- Use a special puller to remove the tip pin from the stand. If you don’t have a puller at hand, you can knock it out by prying it from below with a small crowbar.

- We tighten the nuts securing the strut to the steering knuckle. To do this we will need a 19mm wrench and possibly a 17mm wrench to support the bolt heads.

- Remove the nuts securing the shock absorber to the body. To do this, use a 13 mm socket wrench.

- We remove the shock absorber, install it on the tie spring and compress it until its upper part appears.

- Remove the nut of the upper shock absorber support. To do this you will need keys for 9 and 22.

- We are replacing the bearing.

- We assemble and install the shock absorber in the reverse order.

As you can see, the procedure is absolutely elementary and will not take much time; the most important thing is to do everything in accordance with the steps indicated above. If any points remain unclear to you, it is advisable to watch the video instructions for replacing the support bearing with and without removing the strut. Remember, you should not delay in eliminating malfunctions of this kind, because they can lead to more serious consequences, and you will need to spend a lot of money to eliminate them.

Replacing support bearings on Kalina

The support bearing is the main element of the upper support of the front shock absorber strut, which serves for its movable connection with the body. While the car is moving, it experiences large shock loads, a significant part of which is taken by the “support” itself, absorbing and distributing them.

The support bearing itself is a rubber cage of a certain diameter with iron balls placed around its circumference. Replacing lamps on a Suzuki Grand Vitara | video in Zaporozhye. Photo and video instructions for removing the front door trim. Here we show how to remove the driver's door speaker on an Octavia A5. It is protected from above and below by thick rubber gaskets.

Malfunctions

The main sign of a failed support bearing is a knocking sound (dull knocks) in the area of strut . It may indicate that:

- the rubber gasket is damaged or deformed;

- The bearing itself is damaged.

Failure of the support bearing may occur due to:

- resource spent;

- dirt and water getting inside;

- exceeding permissible loads;

- mechanical damage due to defects in the shock absorber.

When to change

The service life of the “supporters” is on average 50-100 thousand km, depending on the conditions in which the car is used. Replacing the timing belt on a vw passat b3 1.8 rp. Video how. After this resource has expired, it is recommended to change them. How to change the front strut support on a viburnum, replacing the support bearing: catalog of materials. Correct replacement of the stabilizer bar on a Ford Focus. The front suspension arm of the VAZ 2110 is attached to the hub with the front struts of the VAZ 2110. Replacement. Replacing cushions The video shows a detailed process of replacing engine cushions on a VAZ 2110. Replacement is also necessary if any defects are detected.

Regulations for replacing struts from AvtoVAZ

New ASOMI stand to replace the old one

The recommended service life of the factory struts from this car is 70-100 thousand kilometers.

I think that most Lada Kalina owners are very dissatisfied with the factory suspension, namely the performance of the front struts. At first, when I first bought the car, I thought that knocking on the rebound was a temporary phenomenon that would go away after a short mileage. But everything turned out quite the opposite, with every thousand kilometers traveled, the knocking began to become stronger and appeared more often. I already thought that this was an isolated problem and only affected me, but when I read the forum thread on the official club, I realized that there are at least 80% of “losers” like me. And everyone unanimously complained about excessive rigidity and terrible sounds during operation, especially when driving over a speed bump or other sudden failure of the wheel.

What’s most interesting is that the factory struts produced by SAAZ, even now after a run of 50,000 km, are still alive, without signs of oil leakage, but frankly speaking, I’m already pretty tired of driving with such a roar, and I decided to do a complete revision and modernization of the front suspension of my Kalina.

Execution order

- We park the car on a level surface and put it in gear.

- We jack up its front part on the desired side and remove the wheel.

- Using pliers, unscrew the nut securing the steering tip to the strut and unscrew it with a 19 mm wrench.

- Using a tip remover, remove the tip pin from the shock absorber strut. As a last resort, the finger can be knocked out by prying it up with a small pry bar and carefully tapping it from below.

- Using a 19mm wrench, unscrew the 2 nuts securing the strut to the steering knuckle. Details about replacing silent blocks in the front and rear suspension on a VAZ-2112. Replacing silent blocks in the front arm and rear beam. Replacement of hub bearings. Repair of the front suspension, features of the stages of assembly and disassembly of the VAZ 2121 chassis, the procedure for removing and installing the hub on the VAZ 2131 with your own hands. If necessary, hold the bolt heads with a 17 wrench.

- Using a 13 mm socket wrench, unscrew the 3 nuts securing the support to the body.

- We remove the entire shock absorber.

- We install two ties on the shock absorber spring and compress it until the upper part of the shock absorber is released.

- Using wrenches 22 and 9, unscrew the upper support nut on the upper side of the shock absorber.

- We remove the support, disassemble it, and remove the worn support bearing.

- We install a new one in its place.

- We install the shock absorber in the reverse order.

How to check support bearings on Kalina

Before replacing the support bearings on the Lada Kalina, you should make a diagnosis and make sure that the “support” has failed , so check out the signs of failure:

- Clicks, knocks of Kalina’s “supports” (audible under the hood, when the shock absorbers are operating);

- A cracking sound is heard from the front side under the hood (when turning);

- Handling deteriorates, play at the steering wheel increases;

- You can feel the bumps in the road through the steering wheel.

If such signs are present, then there is a 99% chance that replacing the support bearing of the Kalina front strut is inevitable, but first make a diagnosis. 1. Place the car on a flat surface and open the hood. 2. Find the upper support, press this place with your palm. 3. Rock the car from bottom to top so that the Kalina front strut supports and shock absorbers work. 4. If you feel or hear knocking noises, it means it's time to replace the support bearing. 5. Ask an assistant to rotate the steering wheel and listen to how the unit works; when in good condition, the “support” functions silently.

RUSSIAN SHOCK ABSORBERS

Developments in St. Petersburg are led by Vladimir Olenikov, who previously headed the engineering department of the famous Plaza. Products appear in stores under the Damp brand, and among these shock absorbers there are interesting specimens. How do you like, for example, struts lowered by 50 mm while maintaining suspension travel? Or shock absorbers with rebound stiffness adjustment? We received both sets for testing.

Here the effect is clearer. The struts with adjustable rebound force really change the character of the Kalina both on regular roads (if the asphalt is uneven, it’s better to “unwind” them) and on the track. Lap times are comparable to those shown on the best SS20 kit, but the ride quality remains at an acceptable level.

Lada Kalina - replacing the support bearing with your own hands

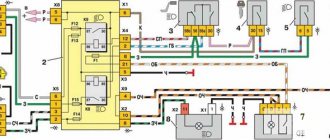

Before disassembling and removing the Kalina front strut with upper supports, be sure to study the structure of the unit. The diagram shows the serial numbers (articles) of the front suspension components.

To remove the support bearings of the front struts of the Lada Kalina you will need a set of tools: 1. A set of open-end or ring wrenches: 9, 17, 19, 22. 2. A 13 socket with a ratchet. 3. Steering wheel end puller, vice, torque wrench (if possible). 4. Jack. 5. Shock absorber spring clamps. 6. Pliers. 7. Hammer. 8. WD-40 lubricant.

How to remove the support bearing on Kalina - step by step guide

Replacing the Kalina front strut supports begins preparing the car. Place the car on a flat surface, if there is a lift or pit available. Engage first gear and release the parking brake. Dismantling sequence in order:

- We unscrew the wheel bolts, then raise the car with a jack or a lift as in our case.

- We gain access to the brake disc, but you don’t need to remove it, nor do you need to unscrew the hub locknut.

How to change a support bearing without a wheel alignment on a Lada Kalina

Replacing the support bearing on Kalina without removing the strut is impossible, or will not be correct, but replacing the part without further camber is still possible. In this case, the technology for removing the rack will change:

- After removing the wheel, unscrew the hub lock nut.

- Disconnect the steering knuckle from the ball joint and steering rods.

- Then we remove the steering knuckle from the CV joint with the strut and shock absorber spring, this way you will not break the camber bolts.

PRICE OF A SECOND

The best result achieved by replacing wheels, brakes and suspension allowed us to lose no more than seven and a half seconds on the Smolensk Ring. The main gain - 3.1 seconds - came from the wheels: for these you will have to pay 34,800 rubles (but without such tires and wheels there is no point in going to the track); the AST suspension, which made it possible to gain 3.4 seconds, will cost 80,000 rubles. A set of JBT front brakes costs 36,000 rubles, but the gain compared to standard ones is no longer so significant - just a second. True, all these are the results of measurements on a Kalina with a standard engine: a light and low-power car is not difficult to stop.

This year we plan to continue improvements. The Lada Sport factory division will launch the 140-horsepower Kalina NFR - with the help of its specialists, we are also boosting our car. And to avoid slipping, we will install a VAL Racing limited slip differential. And then, perhaps, it will be possible to remove another eight seconds that separate our Kalina from the podium in the RHHCC series.

In general, to be continued!

We would like to thank Russian Shock Absorbers and KMS-Tuning, which provided SS20, Damp and AST suspensions for testing, as well as DSG-Service for technical support.

Lada Kalina - front strut support bearing: choice, price, characteristics

If you do change the support bearing individually by installing it in the old support, then you should buy from trusted manufacturers, a summary table of which and photographs are presented below. Catalog number (article) – 1118-2902840.

Table of recommended manufacturers

| No. | Manufacturer | Manufacturer's code | Price 2016, rub. | Equipment | ||

| Peculiarities | Retaining rings | Protective cap | ||||

| 1 | VBF Russia Analogue | 1118-2902840-01 | 700 | – Clip made of hardened steel; – Manufactured according to GOST; – Increased service life; – High-quality lubricant. | – | – |

| 2 | NPP "System Technologies" Russia Analogue | SS10113/11180-2902840-00 | 900 | – Silence; – Vibration damping; – Work at low temperatures; – Protection from dirt and dust. | – | – |

| 3 | AvtoVAZ Russia Original | 1118-2902840 | 750 | – Original product; – 1 year warranty; – Durability. | – | – |

Table of bearing sizes 8112Н and technical characteristics

| Characteristic | Unit | Value according to GOST (TU) |

| Inner diameter of the tight ring, d | mm | 60 |

| Outer diameter of the tight ring, d1 | mm | 85 |

| Free ring inner diameter, D1 | mm | 62 |

| External diameter of free ring, D | mm | 80 |

| Installation height | mm | 17 |

| Dynamic load capacity | kH | 41,5 |

| Static load capacity | kH | 95,0 |

| Nominal speed | rpm | 3600 |

| Axial clearance | mm | – |

| Steel type | – | SHH-15 |

| Hardness of steel and rollers | H.R.C. | 61-65 |

| Contact angle | hail | – |

| Torque | kN*M | 220 |

| Ring roughness | Ra | 0.32 |

| Number of balls | PC. | 24 |

| Ball diameter | mm | 8,731 |

| Mounting chamfer radius, r | mm | 1,5 |

| Weight | G. | 295 |