Car battery charging voltage from generator

Normally charged battery

– a prerequisite for a comfortable ride.

In the cool season, it is especially important that the battery

ensures reliable starting of the car engine.

Modern cars, especially business class ones, have a battery charging control unit that monitors the main parameters of the process. Economy category vehicles do not have such devices. Experienced drivers do this task without the help of others. Let's look at how to have more complete control over the battery charging

.

Capacity replenishment speed

There is an opinion that for normal battery charging, the charge current should be 10% of its capacity, i.e. with a battery 50 Ampere hours, the charging current will be 5 Amperes. Under these conditions, the battery

will reach its capacity up to 10 hours.

Imagine, you were turned on by the wires of another car in the winter, and in order to fully charge the car battery, you need to drive the car for 10 hours straight, that is, drive about five hundred kilometers.

It is believed that to replenish the battery charge to the nominal value, it is enough to drive 30 kilometers in a normal cycle, and in city traffic jams half that. That is, if your work is located more than 10 kilometers from home, this is enough not to worry about recharging the battery outside the car.

The case is different when work is close to home. You spent the capacity when starting the car, quickly drove to work, and then also home. After a week or two, your battery . And not at all because there is something wrong with the car, it’s just the rhythm of the drive.

In this case, you should think about warming up the engine even in the warm season just to ensure that the battery

was always in a charged state.

Let's return to the charge current. If it is enough to drive a car 30 kilometers to fully charge the battery, and not 500, as in the example, therefore, the charging current of the car generator is not 5 Amperes, but much higher.

Charging time while driving

Now to the question of how long you need to drive your car to charge your car’s battery.

Charging at idle has its disadvantages. Namely:

- fuel is wasted;

- there is no radiator airflow;

- the engine is not blown;

- antifreeze heats up quickly;

- The radiator fan is forced to turn on.

And if there are additional consumers, then the efficiency of battery charge delivery will decrease.

Motorists are interested in knowing how long they need to drive their car to charge a dead battery. The condition of the battery, the health of the vehicle’s electrical equipment, and the weather all play a role here.

It is the climatic conditions that should be discussed in more detail.

Charging in warm weather

Warm weather is most favorable for fast charging of the battery due to the movement of the car. Even if you maintain low speed, after 30–60 minutes the container will be full. But this statement is relevant if the battery itself has not been reset to zero.

If we talk in kilometers about how much a driver needs to drive to charge the dead battery of his own car, then this is an average of 30–50 kilometers.

While driving, try not to increase the speed too much, since the charging current in this mode stops flowing to the battery. And when you are standing at a traffic light, lightly press the gas pedal. Thus, the electrical system will not switch to battery power.

It turns out that if the battery is in good condition, it will take 30–50 km to charge it. It is recommended to keep the speed at average. If the speed is too high, the generator will produce an increased voltage, exceeding the required 14.4 V. This is where the voltage regulator comes into play, cutting off the current supply. Otherwise, the battery may simply burst.

Battery life

battery life is more than five years. Used cars imported from abroad have fully working seven- to nine-year-old batteries on board. charging the battery from the generator how to check the charging process is in progress. There, however, the storage conditions for cars are different, and the temperature in winter is higher.

There are three reasons for the low durability of the battery: violation of the battery charging mode, quality of the battery , human factor, in other words, laziness.

Let's start with the first one. If the battery is not charged to full capacity all the time, the plates undergo a sulfation process. Sulfation, or the formation of lead sulfate on the plates, can be compared to a stomach ulcer in humans, only in humans it can be treated, but a battery ulcer is practically untreatable.

There are various methods of complete discharge-charge, charging with pulsed currents. Maybe there is some percentage recovery, but if the battery

I lay down completely, then alas...

The quality of the battery depends on the manufacturer. How to remove the battery on a Ford Focus 2? Modern technologies only affect the increase in battery capacity while reducing the size and weight, respectively, the amount of lead.

How to choose battery ? If there are two different copies with the same capacity, starting current, cost, it is better to buy the one that is heavier, it has more lead, it will last longer.

About the human factor. The biggest mistake car owners make is parking the car in the fall with the battery until spring.

If the battery is

spends it in a discharged, not even fully charged state, and even in the cold with a reduced electrolyte density, it is unlikely to survive until spring.

If you periodically use your car in winter, then regularly (a couple of times a week) you need to start the car and warm it up for at least fifteen minutes, checking the charging voltage.

Visual control

Visual diagnostics can and should be done at least once a week.

In summer, it is imperative to monitor the electrolyte level either through the light or through the electrolyte filling holes. If the battery is maintenance-free, monitor the indicator window.

When it goes

the recharging process (the charging current is too high, it is possible when the generator is faulty),

is

boiling away. This leads to an increase in acid concentration, corrosion of the plates, and an even greater increase in current and temperature.

Video - charging voltage of a car battery from a generator, leakage currents and other checks:

Such an avalanche-like process can destroy the battery.

in a couple of hours. Therefore, if you see any changes in the paint above the battery installation site, foreign deposits, or a change in the shade of the battery case near one of the cans or electrolyte refill caps, immediately determine the cause.

If the battery

during constant operation it is not in the green zone, which means that the charging process is disrupted.

How many kilometers do you need to drive to charge the battery?

The main task of a car battery is to start the engine. It is for these purposes that the bulk of the charge is spent, given that it is not always possible to start the engine “half a turn”. The restoration of the charge level occurs after the power unit has begun to operate, driving the generator.

Many drivers are interested in the question of how quickly the battery is charged from the generator, because with predominantly urban driving, too short trips may not fully charge the battery.

How to measure battery charge (vehicle on-board voltage).

how to measure charging

car battery. VKontakte groups: .

The visual method also includes monitoring the “ battery”

" on the dashboard.

If it does not light up when the ignition is turned on, or does not go out after starting the engine, or flickers depending on the engine speed, then the battery charging is disrupted.

Another tip for visually checking the charging process. In the dark, pay attention to the brightness level of the low and high beams when changing engine speed. This is best done by lighting a white wall. If the brightness increases with increasing engine speed, it means that the voltage-current regulator in the generator is not working properly, you need to check the generator.

Design features of the generator

Structurally, all generators installed on cars consist of a rotor, stator, covers cast from aluminum alloy, voltage regulator, rectifier unit (diode bridge) and brush assembly.

The rotor is a shaft on which the excitation winding is installed between two pole halves - magnetic cores. There are six beak-shaped protrusions on each half of the magnetic circuit. As the rotor rotates, the beaks of the magnetic circuit alternately cross the magnetic field of the stator, inducing a current in the winding.

When voltage is applied to the rotor of the brush generator, the beaks directed towards each other are magnetized. One half is magnetized in the “south” direction, the other in the “north” direction, and when the rotor rotates, the magnetic field changes cyclically from “north” to “south”, exciting an electric current. In a generator that does not have a brush assembly in its design, the beaks of the magnetic circuit are magnetized in a similar way, and at the same time have their own rotation. In practice, such generators have not found widespread use due to their unreliability, complicated design, large dimensions and weight, as well as frequent breakdown of magnetic circuits, leading to the destruction of the entire generator.

Diagnostics using devices

Experienced drivers remember that a garage tool always included a hydrometer and a load fork.

The battery hydrometer is used to measure the density of the electrolyte. Normal density is from 1.23 to 1.28 g/cm3. The lower the temperature, the higher the density must be, otherwise the battery will freeze and fail.

Using a load fork, you can identify a “rotten” can and repair it.

Now the cost of repairs will be more than the cost of a new battery, so these devices are not used in amateur practice.

The most universal device for monitoring battery charging is a multimeter. Sometimes you need to check the battery. Can the battery itself both on the blog and. How can I use it to check the battery charge?

First, before driving with a cold engine, measure the voltage at the battery. It must be at least 12.5 Volts. Turn on the ignition. Normally, the voltage will drop by 0.1 - 0.3 Volts, but still must be at least 12.4 Volts to start the engine.

Useful tips

- It is not advisable to use the capabilities of the on-board PC to measure the voltage on the battery. The result will differ from the true value due to the specifics of connecting the computer to the on-board network. Therefore, errors cannot be avoided. And approximate data, taking into account some variation in parameters, will tell the car owner little.

- the normal operation of the generator and the good condition of the battery. Turn off all consumers and start the engine. What voltage should be depending on this is a sign that the battery is 100% charged. The multimeter should show about 13.6±1. Then, one by one, one of the electrical network devices turns on. For example, headlights, then low beam. Each of the electrical devices “reduces” the voltage

by 0.2. But in total - no less than 12.8. Otherwise the battery will drain quite quickly. - Even if the battery meets all the described requirements, a comprehensive check should be carried out regularly. A good battery should voltage . If the car has not been used, and, for example, after a few days the multimeter shows a value significantly lower than in the previous test, then the battery is already “at its limit.” You need to be especially careful with her.

The author draws attention to the fact that all recommendations are rather approximate and generalized. But it is precisely these simple techniques that allow even inexperienced car owners to understand the condition of the battery, whether the generator is working and how correctly the battery is being recharged. For a more detailed study of all components of the on-board electrical network, you need to contact specialists.

A properly functioning battery will ensure easy engine starting even in the coldest weather. The stable operation of the battery and the entire automotive electrical system certainly depends on the quality of the battery. The battery is supplied with voltage during engine operation by the generator. For this reason, it will be useful to know how to check the charging of the generator.

How to check the operation of the generator

The battery in a car is an important element of the system, which is responsible for providing the car’s on-board network with electricity. The generator is used to charge the battery while it is active. Unstable operation of a device generating electricity causes a voltage drop in the network and failure to restore the capacity of the power source.

Normal generator performance means timely and complete replenishment of the battery charge level, which decreases under load. Checking the battery charge level from the generator is simple and can be done by the car owner himself.

Diagnostics of an automotive energy-generating device includes a visual inspection of the unit, its elements and related parts, as well as voltage and current measurements. At least twice a year, you should check the tension of the drive belt, excessive weakening of which leads to a decrease in the performance of the generator, and sometimes can lead to breakdown of the device. Once a year, you can check equipment elements - fasteners, diode bridge, voltage regulator and others. Timely maintenance of the battery will also guarantee the absence of problems - cleaning the terminals, adding distilled water.

What exactly is the problem?

If your car won't start, the problem is most likely with one of two elements of the charging system: the battery or the alternator. If you come to a car dealership, they may offer you a new expensive battery without conducting any tests. Don't make this mistake! A faulty alternator can ruin a perfectly good battery, putting you even further away from solving the problem. However, no need to worry. Diagnosing car electrical problems is so simple that anyone can do it. To do this, you need to perform the following tests. For tests, you will need a multimeter, which can be purchased at any auto parts store.

What kind of charging should go to the battery from the generator?

It is traditionally believed that 13.5-14.5V should be supplied by the generator to the battery and this is absolutely enough to replenish the battery costs.

It is worth considering that using a battery with a higher power in a car than the manufacturer recommends also requires the installation of a more productive generating device.

It is necessary to take into account the load that the generator must withstand - it is calculated based on the maximum indicators of all electrical appliances and car systems.

Do not forget that the charging current from the energy-generating device will allow you to start the car in the cold season. In order to avoid problems with starting the car, we recommend purchasing generating equipment, the charge current of which will be approximately 10% of the capacity of the power source. That is, a battery of 100 A/h requires a generator that can produce 10A. Please note that for many cars, 100 amp equipment will operate at its maximum capacity, because the power consumption of the automotive system is in the region of 80 amps. Therefore, the choice of a source generating energy must take into account both the battery capacity and network consumption.

For some reason, the car battery is not charging from the generator: what should I do?

The battery is the main source of energy in a car. A serviceable, constantly charged battery will ensure trouble-free starting of your car at any time of the year. It is worth noting that for the newest “iron horses” this is the only way to start the engine yourself without outside help. But where does the battery itself get its charge or, in other words, what charges the battery in the car?

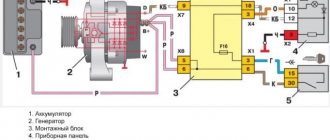

How to check the alternator voltage on the battery

The potential difference can be diagnosed in two ways - directly at the generating equipment and through the battery. The generator is directly connected to the power source with a thick wire, therefore, to check the level of potential difference, you can measure the voltage at the power source. To do this, you will need special devices - a voltmeter, multimeter or load plug.

The wires of the first measuring instruments are connected to the battery in any sequence. The plug must be connected to the battery terminals with strict observance of polarity. It is generally accepted that the normal voltage in the network should not be lower than 12 volts. At idle speed without turning on all the electrical appliances of the car, this indicator should be at the level of 13.5-14V. A drop in voltage values to 13.3-13.8 volts is considered acceptable.

At the same time, using conventional testing equipment, you can check the resistance of the generator elements - rotor, stator and diode bridge. Diagnostics of rotary equipment is carried out by its winding. It is necessary to connect the probes of the device with slip rings. If the multimeter gives readings from 2, 3 to 5.1 ohms, then this element is working. The current consumption of the winding should be within 3-4.5 amperes.

Its normal resistance is 0.2 Ohm. The diode bridge is checked by the presence or absence of resistance, the indicators do not matter. The only thing worth considering is that there should not be a zero dimension. Measurements are carried out in pairs - positive output and all plates on this side or minus and all elements.

We remind you that for normal charging of a car battery, the voltage supplied by the generator must be from 13.5 to 14 volts.

Causes of undercharging of the battery by the generator and ways to eliminate them

Since the generator and the electrical circuit responsible for charging the battery consist of many components, there may be several reasons for the battery to be undercharged. Let's describe the most common of them.

Generator overload

One of the main reasons why the generator does not provide sufficient charging to the battery is that it is simply overloaded. In the standard configuration, this situation usually does not arise, but if you connect gadgets hungry for electricity (smartphone, recorder, navigator, more powerful headlights, etc.) to the on-board network, then the situation may change for the worse.

Installing a more powerful battery (for example, a 70-amp instead of a 55-60 A battery) will also lead to the fact that it will experience a constant deficit of charge current.

So, before increasing the load on the on-board network, do not be lazy, find out the power of the generator and the total current consumption of all consumers - this will protect you from rash actions.

Poor or loose contact

This problem occurs when the slip rings and brushes are heavily soiled. Weakening of the contact can also occur due to a decrease in pressure on the brushes from the weakened spring. Finally, the brushes may simply jam. All these troubles can cause an increase in excitation resistance. The problem can be eliminated by timely cleaning of contaminated elements; if there are oxides on the rings, they are removed with sandpaper.

Breaks in the winding

Another reason why the generator does not charge the battery is the presence of a break in the excitation winding. Such a malfunction is easily diagnosed - just put your hand on the case - in such cases it gets very hot. To clarify the diagnosis, the end of the winding is connected to the generator terminal instead of a brush, and then the current is measured with a multimeter through the battery. If the readings are zero, there is a break. To search for the problematic winding, battery wires are connected to each coil in turn and the measurements are repeated. If the break is external, you can try to fix it with a soldering iron. Otherwise, the entire coil is replaced.

Generator short circuit

Unlike a break, a short circuit in any section of the winding will lead to the inoperability of the entire device. Most often, a short circuit occurs at the junction of the slip rings with the winding. Test method: connect a 5-volt lamp to the rotor core and the slip ring; if there is a short circuit, the lamp will light up. The malfunction is eliminated by replacing the generator (or alternatively, replacing the winding).

If the insulation in the stator coils is partially destroyed, the generator will begin to get very hot, and the battery will be fully charged only at high speeds. The same symptoms will be observed when the stator is shorted to the device body. In such cases, the easiest way out is to replace the generator.

Mechanical breakdowns

If the battery is not charging, the reasons may be mechanical. Most often in such cases, the culprit is a loose alternator belt. This problem is easily diagnosed - when the drive belt is stretched, the pulley gets very hot. The problem is solved by replacing the belt.

You should also check the battery terminals - if they are oxidized, this is the reason for the undercharging. The reason may lie in poor contacts in the places where the wires are attached to the generator components, in their breakage, or chafing. Finally, it's worth checking to see if the fuse has blown (although it's recommended to start the diagnosis there rather than end it).

The diode bridge has failed

Since the generator generates alternating current, it needs to be converted to direct current before it is supplied to the on-board circuit. This task falls on the shoulders of the diode bridge, which acts as a rectifier. It is called a bridge because it consists of several diodes. If one of them becomes inoperative, the normal operation of the generator is disrupted. This is also a fairly common cause of undercharging of the battery due to AC leakage. A similar malfunction will be indicated by dimming of the vehicle's external and internal lighting lamps. Diagnosis of the problem is carried out by measuring the voltage and current parameters passing through the battery terminals.

The procedure algorithm is simple:

- start the power unit, let it warm up a little;

- apply the parking brake and shift the gearshift lever to neutral (or to parking mode if you have an automatic transmission);

- switch the multimeter to low amplitude AC voltage measurement mode;

- If the device shows a non-zero voltage, the diode bridge must be replaced.

How many amperes does a car alternator produce per battery?

The current strength required by the electrical system of each car is individual and depends on the number of electricity consumers and their values. And also the charge current must be sufficient to charge the power source.

It is worth noting that ampere readings appear only when there is a load in the vehicle’s electrical system and, accordingly, the battery is discharged. After starting the car engine, the charging current is about 6-10 amperes and drops over time, because the battery is charging, taking on the main energy consumption. If you turn on additional equipment - headlights, radio or heated mirrors, you can see an increase in the charging current values.

When purchasing a generator, pay attention to its technical characteristics, which the manufacturer indicates on the case - that’s where you will find information about the maximum current that will flow to the battery.

In the table below you can see the approximate current values that the generator shows at different loads.

Table 1. How many amperes the generator produces under load.

Signs of a generator malfunction

In modern cars, breakdowns of the electrical system are one of the most common. A large number of electronics requires particularly careful monitoring of the operation and condition of the generator and battery, because their failure can immobilize the car. The most common signs of a generator malfunction are:

- battery indicator light on the instrument panel;

- unstable operation of the battery (its boiling over or undercharging);

- different intensity of headlights;

- extraneous sounds from the generator.

If you notice incorrect operation of the car, then perhaps the battery charging current from the generator is insufficient.

All malfunctions of electrical equipment, which includes the vehicle’s energy-generating device, are mechanical (deformation or breakage of fasteners, housing, malfunction of bearings, pressure springs, drive belt, etc.) or electrical (winding breaks, diode bridge malfunctions, burnout or wear of brushes , short circuits between turns, breakdowns, etc.).

Don’t write off a non-working generator: find out if there are repair kits and spare parts. Replace them if possible. If you cannot carry out repair work yourself, then take the generator to a workshop. Many craftsmen will be able to restore the unit at no extra cost and in the shortest possible time.

However, some breakdowns require the purchase of a new device that generates electricity. For example, a failing bearing that is soldered into the generator housing cannot be restored or replaced in most cases.

Remember that failure of this unit can be caused not only by wear and corrosion, but also by poor quality of elements and components; excessive load; external influence of salts, liquids, temperatures.

Other causes of low voltage

A small potential difference in the system is not always associated with a breakdown of the generator or a bad battery. If the diagnosis of these elements does not reveal any problems, then you should pay attention to the following:

- condition of the battery terminals - connection density and oxidation;

- electrical wiring problems - oxidation, violation of its integrity;

- output contacts to electrical appliances;

- correctly selected energy consumers.

Each contact must be tightly adjacent and intact, that is, there must be no formations (for example, sulfation) that will disrupt the flow of current. Incorrect connection of contacts leads to accelerated battery discharge even when the car is not running.

To improve the connection of the elements of the car's electrical system, it is necessary to clean all contacts and restore the integrity of the wires by replacing them or connecting them and wrapping them with insulating tape.

In conclusion, I would like to repeat that stable operation of the car requires constant monitoring of all elements, and the generator should attract special attention. The battery is charged from it and provides electricity to the entire car system. Pay attention to all elements: generator brushes, slip rings, voltage regulator, equipment winding.

The most correct measurements should be carried out when the battery is fully charged and in various modes. Remember that the manufacturer links the characteristics of the generator to the number of engine revolutions - they help produce a certain current.

Detailed video on how to check the generator:

Do you have experience diagnosing an alternator and solving problems in a vehicle's electrical system? Please share your experience and opinion with our readers in the comments. If you have questions about the topics covered, we will be happy to answer them.

Well, not so long ago I wrote an article about checking the battery with a load fork , actually this happens for two reasons: when the battery is already dying and needs to be checked, and when the battery is new, it also needs to be tested before purchasing. But is it always the battery? Why might it suddenly fail? It’s one thing if it’s winter and it’s really difficult for him to work, but another thing if it’s summer and he’s not “purr-murr” at all. AND even on the instrument panel, the battery sensor begins to blink occasionally, or is constantly on! In such situations, you should not run headlong for a new battery; first you need to establish the reason why it failed, because in 50% of cases it can be the generator. Moreover, the check is quite easy to do without removing it from the car, let’s read more...

Why does the generator fail?

The generator itself has a simple structure; if you want, it’s a regular electric motor (only made to allow for large current generation), try to spin a regular electric motor and attach a light bulb or LED to it, it will start to light up - and there you have it, an elementary current generator.

Someday I will have an article in which I will tell you what the generator consists of. BUT today it is simple and exaggerated - this is the rotor (moving part), stator (fixed part), brush assembly, relay regulator , and of course the housing in which the whole thing is located.

And now the actual breakdowns.

- The bearings are jammed. This is a fairly common problem with already worn-out generators, the rotor in the housing spins on bearings, from time and moisture (dirt), they wear out and simply jam or wedge. If there is a wedge, then this is one thing - the rod stops rotating. But if wedging occurs, it is difficult to notice; the rod may or may not rotate. In any case, with such symptoms, the belt that turns the generator from the engine is more likely to break. THIS IS THE FIRST CALL.

- The winding on the stator or rotor has burned out. It is there in any case and most likely will be on the stator, so - also from moisture (salt on the roads), it can be corroded and it will simply short out or simply burn out, since copper wires are used there. Accordingly, current generation will stop.

- Failure of the brush assembly. This is also very common, brushes are graphite (often square) rods that run along the stator tracks. So, from time to time they simply wear out and need to be replaced.

- Failure of the regulator relay. This relay prevents the generator from recharging the battery, bringing the voltage and current within the desired range. Often it also fails and the battery does not charge at all! Need to watch.

In general, for these 4 main reasons, the generator may not work, so it must be checked before purchasing a new battery. It's likely that this is what you're dealing with.

Types of relay-regulator

To exaggerate, there are only two types, but each works on the same principle, namely, “cuts” or increases the voltage to the desired level.

Combined with brush assembly. Usually it is mounted on the generator itself, in the housing where the brushes are located, there is also a relay regulator.

Separate. Usually it is mounted on the car body, the wires go from the generator to it, and only then to the battery.

The housings are non-separable and tight and of a different type (often filled with sealants or special adhesives), that is, they cannot be repaired. To be honest, they are quite cheap, especially for our VAZs, so it’s easier to buy a new one than to tinker with an old one.

These are the most common types, of course, previously there were so-called ones combined with terminals, but they didn’t catch on because the device is not very convenient, so I won’t talk about them.

If your relay is “broken” and is constantly recharging, then it’s worth changing it, but first you need to make sure that this is the problem. Now there are only two ways to check: - without removing it on the car itself, and checking an already removed relay. Let's look at both options.

Car tips

Actually, I already told you about them from above; if the generator refuses to work, then it is easy to notice even inside the cabin.

- All modern cars will be signaled by a warning lamp - “red battery” on the instrument panel. If it lights up or even blinks, then there is nothing good about it, you need to react immediately, otherwise a discharge is just around the corner.

- Weak glow from all instruments. The “warning lamp” may burn out, but if you notice that the instruments begin to glow dimly, this means that the car is running on the battery, and not on the generator. Again you need to check.

- Belt break. If you crawl under the hood and there you see a break in the belt that spins the generator, then you MUST CHECK THE OPERATION! Otherwise, again, you can kill your battery.

These are all obvious malfunctions, but it happens that the battery is dead and everything seems to be fine, but something inside is “gnawing” - maybe it’s the generator? How to check easily and quickly on a car without removing it? Question? And everything is quite easy here

Check without removing from the car

There are two 100% ways that I personally recommend to you.

1) Check with a multimeter . Of course, not everyone has it, but in fairness it’s worth noting that this is a fairly common device and let’s say your father, neighbor, friend will have it “anyway.” To begin with, we measure with the engine not running, at the battery terminals, the normal voltage should be about 12.5 - 12.7 V, ideally.

We start the car, do not accelerate, and do not turn on any electrical appliances - with the engine running, we measure the voltage, it should be within 13.8 - 14.5 Volts.

However, on modern cars, where a lot of electronics are crammed, manufacturers assure that 14.8 Volts IS ALSO NORMAL. More on this below. Next, we connect the load - headlights, heater, heated rear window, foglights, radio, after that the voltage should drop a little - but not lower than 13.7 - 14.0V. If it is lower, say 12.8 - 13V, then the generator is not working, you need to check it.

Normal battery voltage is 12.5 - 12.7V

After starting the car - 13.8 - 14.5V, on some modern cars - 14.8V

After turning on the maximum load, it should be - 13.7 - 13.8 V

If the voltage is below 13V, urgently CHECK THE GENERATOR

2) The old grandfather's method . You can check this on almost all machines, and this method works 100%. But everything needs to be done very carefully. So - we start the engine, turn on a small load (for example, headlights or heated rear window). And on a working engine, we need to remove the negative terminal from the battery, everything is unscrewed with a key to “10”. We remove it and put it to the side, you can simply lift it above the terminal.

If the car continues to work confidently, the headlights have not dimmed, then your generator is 100% working. If the car stalls immediately, it means that the generator is 100% not working and it urgently needs to be looked at. So I tested it on a VAZ 2101 and now it works on my AVEO.

Battery overcharge

However, often it is not “undercharging” and “overcharging”. The electrolyte from the battery boils away and the battery also fails; there is nothing good about this either.

The first sign will be white streaks on the top of the battery, which means the electrolyte simply boils and evaporates. That is, the battery is charged, but the generator still “craps” charging it. The relay regulator has most likely failed here.

The check here is also elementary - you need to connect a multimeter or tester (whatever they call it) with the car running, and look at the charge. If it greatly exceeds 14.5 - 14.8 V, but is within the range of 15 - 15.2 V, it means that it is overcharging. We urgently change the relay-regulator, otherwise you will constantly boil your battery, ALSO NOTHING GOOD. It’s trivial that the plates may crumble.

Now let's watch the video version.

That’s all, he told me, exactly the methods without removing it from the car, and of course give it to a good auto electrician for repairs.

This is where I end, sincerely yours, AUTOBLOGGER.

(

36 votes, average: 4.42 out of 5)