Hydrogen engine is the operating principle of environmentally friendly cars. Which are radically different from the usual cars with an internal combustion engine. Standard cars produce large amounts of toxic exhaust into the air, causing serious air pollution.

The problem of global warming is becoming a real threat to humanity. In addition, oil reserves on the planet have a limited resource, and sooner or later humanity will be forced to switch to other options for energy sources for cars. One such option could be a hydrogen fuel engine.

Operating principle of a hydrogen engine

History of the hydrogen engine

The first attempts to create a hydrogen engine were made in 1806 by the French researcher Francois Isaac de Rivaz. The scientist obtained hydrogen through a physical and chemical process called “water electrolysis.” At the time of the creation of the first hydrogen engine, there was no talk about air pollution, and such an engine was invented purely for scientific purposes, in order to learn how to use hydrogen as fuel.

However, the first patent for a hydrogen engine was received only in 1841, and the first successful device operating with hydrogen and air appeared in 1852 in Germany.

An interesting fact is the use of hydrogen during the Patriotic War, when in Leningrad during the military blockade there was not enough fuel, but there was enough hydrogen. B. Shelishch, a technical military specialist, offered his vision of the process of refueling cars and balloons using hydrogen.

So, not only the internal combustion engines of balloon winches began to run on hydrogen, but also 600 cars throughout the city. After the war ended, this type of fuel was somewhat forgotten. The BMW automobile company began experimenting with hydrogen again in 1979 during the fuel crisis. At the end of the 20th century, other automobile companies also joined the research.

Operating principle of hydrogen fuel

Hydrogen, when generated environmentally correctly, is the cleanest type of fuel. The design of hydrogen engines is quite simple. The fuel tank is filled with compressed hydrogen. This places increased demands on the fuel tank; it must be extremely durable to withstand pressures of up to 300 bar. When driving, the car releases hydrogen into the fuel cells in the form of fuel, enriching it with oxygen. Due to the chemical reaction, electricity is generated.

Operation of a hydrogen internal combustion engine

The distribution of electricity goes to a central unit under the hood, which then distributes it at the required power to the electric motor located on the front axle. Hydrogen fuel guarantees instant reaction speed even at a minimum level of pressure in the fuel supply system. Air does not participate in the production of the fuel mixture, and the steam that ends up in the combustion chamber is converted into water at the final stage.

In cars of this type, two installation options are possible: standard internal combustion engines and engines equipped with hydrogen elements. Each individual engine has its own specifics and set of characteristics.

How to make a hydrogen engine with your own hands

Creating a hydrogen generator is an effective way to significantly reduce fuel costs. The task is to supply a special gas (Brown system) into the combustion chamber. Below are simple step-by-step instructions.

Electrolyte assembly

Use 8 stainless steel electrolytic plates (16x20cm) stacked on top of each other. They should already have a hole at the top. Drill another hole 1 cm thick. Place PVC spacers (3 mm thick) between them. The steel plates must not touch each other. Use a screw connection to secure the structure.

Preparing a plastic container

Prepare the container. Insert two long screws inside the cover and seal the gaps with sealant. Attach a wire to each screw by wrapping it around it and leave it outside the container. Make another hole in the lid and insert a rubber hose there, immersing it in water. The other end of the tube should open into the plastic housing of the car's air intake.

You will need to drill a hole in the housing to insert the tube. For a stronger connection, use PVC fittings on both ends. Pour distilled water to fill half the volume. Add half a teaspoon of salt or a full teaspoon of baking soda and mix well.

Place the stainless steel electrolyte into the container, making sure it is well submerged. Any gaps inside the container should be filled with sealant to prevent gas leakage. Bubbles instantly form inside the container and gas begins to be produced.

How does a hydrogen car work?

An exact example of how a car runs on a hydrogen engine can be seen using the Toyota Mirai. It was this company that in 2013 demonstrated the world’s first mass-produced hydrogen-powered car. Mirai is equipped with an electric motor that includes 370 fuel components, where direct current flows into alternating current, and the voltage reaches 650 V. Moreover, such a car can accelerate to a speed of 175 km/h.

An additional battery also stores energy reserves. In this form, the car can travel 350 km. An electric car can last 200 km more on one charge, but there is a drawback to long-term charging - 1.5-2 hours. Mirai produces about 200 ml of water over a distance of several km. Hydrogen engines use rotary internal combustion engines due to the effect of hydrogen on pistons and lubricants.

Hydrogen-powered Toyota

It is almost impossible to convert a standard engine to a hydrogen one; for hydrogen, the design must be extremely strong in order to avoid the process of detonation of materials. Some car companies are developing hybrid versions, where instead of pure hydrogen, a mixture of regular gasoline and hydrogen is used. To prevent overheating, the gas supply is reduced.

This type is used by Mazda and BMW, which produced a limited batch of similar cars. They have the ability to automatically switch to a different type of fuel. But experts could not call such cars ideal, since the hydrogen reserve was only enough for 200 km, and the presence of gasoline prevented the car from being defined as an environmentally friendly vehicle.

In general, the operation of hydrogen cars can be broadly compared to the operation of electric vehicles, with the only difference being the energy source.

Also interesting: Toyota Corolla.

Background: how hydrogen cars work and when they will appear on the roads

In Spain, where I live now, there are quite a lot of electric vehicles - I see them almost every day, both on the roads and at charging stations. And every year there are more and more electric cars (not only in Spain, of course). But there is an alternative - hydrogen fuel cars, which also do not pollute the environment, since their exhaust is water. The topic of today's reference is hydrogen cars, the principle of their operation and prospects.

When did the first hydrogen cars appear?

The hydrogen-powered internal combustion engine was invented by François Isaac de Rivaz in 1806. He obtained hydrogen by electrolysis of water. The piston engine that the inventor created is called the De Rivaz engine.

The ignition was spark, the engine had a connecting rod-piston operating system. Well, the cylinder was set in motion by the detonation of a mixture of hydrogen and oxygen with an electric spark - it had to be generated manually at the moment the piston was lowered. Two years later, the same inventor built a self-propelled device with a hydrogen engine.

But hydrogen began to be more or less widely used to operate automobile engines many years later. In 1941, in besieged Leningrad, GAZ-AA automobile engines were modified by Lieutenant Engineer B.I. Shelishch. The engines controlled the winches of the barrage balloons (they were fueled with hydrogen, and there were many gas reserves in Leningrad), but these were car engines. In addition, several hundred engines in cars were modified.

Since the 1980s, several countries, including the USA, Japan, Germany, the USSR and Canada, have started experimental production to create cars running on hydrogen, gasoline-hydrogen mixtures and mixtures of hydrogen with natural gas.

In 1982, the RAF oil refinery and plant developed the world's first experimental hydrogen minibus, the Kvant-RAF, with a combined power plant based on a 2 kW hydrogen-air fuel cell and a 5 kWh nickel-zinc battery.

Over the years, such cars have been developed in different countries, mostly as an experiment. After the concept of a “green” car became popular, large corporations like Toyota became interested in hydrogen cars. Since the 2000s, automobile companies have begun to develop commercial vehicle concepts.

Where can I get hydrogen?

Hydrogen can be produced by different methods:

- steam reforming of methane and natural gas;

- coal gasification;

- electrolysis of water;

- pyrolysis;

- biotechnology.

Steam reforming is now considered the most economical method of producing hydrogen.

This is the name given to the production of hydrogen from light hydrocarbons (methane, propane-butane fraction) using steam reforming. Reforming is the process of catalytic conversion of hydrocarbons in the presence of water vapor. Water vapor is mixed with methane at high temperature (700–1000 Cº) and high pressure using a catalyst. With steam reforming, hydrogen is produced cheaper than using any other methods, including electrolysis.

The most harmless method of producing hydrogen is electrolysis - producing hydrogen from water using electric current. The purity of hydrogen yield is close to 100%. Apart from the pollution required to generate electricity, such installations are almost harmless to the environment, since only hydrogen and oxygen are released during operation.

Another environmentally friendly way to produce hydrogen is a biomass reactor.

Source

Hydrogen can be produced both in a large factory and in a relatively small enterprise. The larger the production, the lower the cost of gas. But in the first case, the costs of delivering hydrogen to car refueling sites increase.

How does the fuel system work and what are the options?

It is best to consider the operating principle of such a system using the example of serial hydrogen Toyota Mirai cars.

The basis is a fuel cell, an electrochemical system that converts hydrogen and oxygen particles into water. Inside such an element is a proton-conducting polymer membrane that separates the anode and cathode. Typically these are carbon plates coated with a catalyst. At the anode catalyst, molecular hydrogen loses electrons, cations are conducted through the membrane to the cathode, and electrons are given to the external circuit. At the cathode catalyst, oxygen molecules combine with an electron and a proton to form water. Vapor or liquid is the only product of the reaction.

The advantage of fuel cells based on proton exchange membranes is their high power density and relatively low operating temperature. They heat up quickly and begin producing energy almost immediately after launch.

The Mirai uses fuel cells with a high power density per unit volume (3.2 kW/l), with a maximum power of 124 kW. The direct current produced by the fuel cell is converted into alternating current, simultaneously increasing the voltage to 650 V. The electricity flows into a lithium-ion battery. To move, the car uses the energy stored in it.

Hydrogen in the Mirai fuel cell comes from high-pressure cylinders (about 700 atm). The control unit in the car controls the operating mode of the fuel cell and the charging/discharging of the battery.

According to Toyota, the Mirai requires up to 750 grams of hydrogen per 100 km of travel. Mirai owners talk about about a kilogram of hydrogen per 100 km.

Are these cars dangerous? Why?

Since hydrogen is a flammable gas, it must be transported and stored with care.

We need highly sensitive gas analyzers that can give a signal in the event of a leak. True, hydrogen is a very volatile gas (after all, it is the lightest chemical element) and when it enters the atmosphere, hydrogen quickly rises. It burns out very quickly. The Hindenburg airship burned for only 32 seconds. Due to the rapidity of the fire, not all passengers died; 62 of the 97 people in the airship’s gondola survived.

However, if there are many hydrogen cars, new road safety measures will be required. Cars with internal combustion engines are also dangerous - in the event of an accident and a breakdown of the tank, gasoline or diesel fuel leaks onto the road and can ignite. If the hydrogen tank is punctured, the gas will evaporate very quickly. But if there is a source of open flame or sparks nearby, the hydrogen can ignite.

The Mirai and other hydrogen car models use very durable hydrogen tanks. Toyota has made its tanks bulletproof, with heavy-duty fiber walls that can withstand shots from high-caliber weapons. For tests, the company hired snipers and only a .50 caliber bullet was able to penetrate the tank after being hit twice in the same place.

If you follow safety precautions, hydrogen cars are no more dangerous than cars with internal combustion engines.

What is the service life of fuel cells?

So far, such information is only available for Mirai. Toyota says one cell is guaranteed to operate for 250,000 km. Then, if the cell's performance deteriorates, it can be replaced at a service center.

Which companies are already producing or planning to produce hydrogen cars?

Hydrogen cars are being developed by Honda, Toyota, Mercedes-Benz and Hyundai - these companies already have ready-made vehicles.

Others show only concepts (however, working ones) or simply beautifully rendered pictures. The first include Audi and Ford, the second include BMW (in fairness, it must be said that in 2007 BMW released a batch of 100 experimental “hydrogen” models, which remained an experiment) and Lexus. Only the Toyota Mirai and Honda Clarity have been launched into series so far. They can be purchased in the USA and Europe.

How much does it cost?

At the moment, hydrogen cars are slightly more expensive to operate than conventional cars. So, for a 480 km trip in Europe, fuel costs for the owner of a regular car will be approximately $45, but the owner of a Mirai will pay about $57. And this despite the fact that the government of some countries subsidizes the production of hydrogen for cars. The cost of 1 kg of hydrogen averages $11.45.

Why are hydrogen cars better than electric cars?

Actually, the question is not entirely correct.

The fact is that both a hydrogen car with a fuel cell and a “pure” electric car are electric cars. It’s just that in one case the car is fueled with hydrogen, in the second with electricity. If you compare the cost of most electric vehicles and the Toyota Mirai, they are comparable; it is several tens of thousands of US dollars. The cost of the Hyundai ix35 Fuel Cell is about $53 thousand, the Toyota Mirai is $57 thousand, the Honda Clarity is $59 thousand. The cost of Tesla electric cars starts at $45 thousand (the basic configuration with a price tag of $35 thousand is currently only available for pre-order). Electric cars from BMW cost about $50 thousand.

Hydrogen cars are fast to refuel - it takes only 3-5 minutes, unlike electric vehicles, where it takes from half an hour to several hours to recharge.

The main advantage of hydrogen transport is that fuel cells last for many years and require virtually no maintenance. If you take a “pure” electric car with its huge battery, then its service life is only 1–1.5 thousand cycles, that is, 3–5 years. Moreover, a hydrogen car will operate without problems in the cold (including starting), but the battery of an electric car will lose its charge.

What are the prospects for hydrogen cars and when will they be seen on the roads?

Hydrogen cars are already traveling on the roads of Europe and the USA (perhaps there are single copies in other regions).

But there are not many of them - several thousand, which cannot be called mass implementation. The problem that currently hinders the spread of hydrogen vehicles is the lack of infrastructure (just a few years ago, a similar problem was relevant for electric vehicles). We need specialized hydrogen production factories, hydrogen transport systems and refueling stations.

Hydrogen filling stations in 2022 (source)

In addition, hydrogen turns out to be quite expensive, so if electric cars are bought, in particular, to save on fuel, then in the case of a hydrogen car this is not an option. With the massive emergence of factories for the production of hydrogen for cars, as well as service infrastructure, we can expect many more hydrogen vehicles to hit public roads.

But there is no guarantee that this will happen at all, whether it will happen or not is still unclear. Automakers like Toyota are actively promoting their cars and the benefits of hydrogen in the transportation sector. But the competition is too great, both among conventional cars with internal combustion engines and among electric vehicles.

Internal combustion units

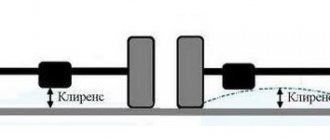

In a standard engine, the time spent on combustion of the fuel mixture is longer than when the engine runs on hydrogen. The fuel mixture enters the cell before the piston reaches TDC. In the case of hydrogen, the mixture ignites instantly. And for optimal engine operation, a pressure of no higher than 4 atmospheres is required.

Hydrogen engines operate optimally in a closed unit, that is, during operation there is no need to obtain oxygen from the outside. As a by-product of the fuel system, steam is produced, which, when passing through the radiator, is converted into water. A special device, an electrolyser, ensures the separation of water from hydrogen. However, most modern hydrogen constructs require the presence of oxygen for the necessary reaction.

Hydrogen fuel cell motor

Hydrogen engines are considered to be not only devices operating on hydrogen, but also engines in which hydrogen fuel components are used. The hydrogen fuel component is analogous to a conventional battery. Such a battery with hydrogen has a significant efficiency of approximately 50%. The mechanism interacts based on chemical and physical reactions.

The body of such a battery is equipped with a membrane; it separates two cells with electrodes: in one, oxidation occurs, in the other, the reduction process occurs. Hydrogen enters the cell with the oxidation process (anode), and oxygen enters the cell with the cathode (reduction reaction).

The electrodes are coated with platinum, this contributes to the function of a catalyst that acts on hydrogen. Similarly, protons arrive at the cathode and are exposed to the catalyst. This creates a bond between protons and outer electrons. The reaction produces a byproduct, water, and the reaction itself creates electricity.

Accordingly, the engine operates thanks to a hydrogen fuel cell. On one charge, a hydrogen engine can run 200 km. However, fuel components have an increased cost due to the presence of expensive metals in the design. Also, hydrogen chambers must be replaced after 250 thousand kilometers. Therefore, the price of a vehicle with a hydrogen engine is usually higher than that of vehicles familiar to motorists.

What is an ATM transmission?

Currently, American scientists are modernizing the development of a catalyst based on carbon tubes. This development will make it possible in the future to reduce the cost of a car, the production of which can do without such expensive metals as platinum.

Solution two: generate electricity

In this case, hydrogen is not burned in the cylinders. There are no cylinders at all.

The main components of a vehicle are an electrochemical generator (ECG) using hydrogen fuel cells, a buffer battery, an electric motor-generator, control and power electronics - the latter is designed for switching power electrical circuits.

During dynamic acceleration, the battery comes to the aid of the ECG. In addition, it is used to start the generator, as well as to store energy generated during braking (recuperation mode).

In addition to hydrogen, fuel cells require oxygen to function. It enters the ECG along with the air, which is previously purified from carbon dioxide. And the key to success is improving the characteristics of fuel cells.

It would seem that the ideal fuel for vehicles has been found. The consequences of its use are water vapor. In this case, no toxic components or greenhouse gases are generated. And if you produce hydrogen by electrolysis, then it’s generally great - the water cycle occurs.

TE was created back in the 60s of the last century. With their help, electricity, water and heat are obtained on board spacecraft.

One of the first versions of the Honda Clarity fuel cell car

Mercedes GLC F Cell with hydrogen fuel cells

Yes, from an environmental point of view, fuel cells are preferable to hydrogen internal combustion engines, so most research and development goes in the direction of fuel cells. But ECH is still expensive for mass use.

And then, where to get the primary electricity needed for electrolysis? Or rather, what is an environmentally friendly way to get it? Futurologists suggest wind power plants or solar panels, although the latter are more suitable for countries with hot climates.

In addition to the electrolysis of water, hydrogen can be obtained in other ways, for example from hydrocarbon raw materials. Let's say, from the same methane, as is now done in most cases, or even from gasoline. During reforming, i.e. When heated in the presence of platinum or molybdenum oxide to increase the octane number of gasoline, a byproduct, hydrogen, appears. That's what we need.

This is how the idea was born - to install a reformer directly on board the car, and fill the tank with purified gasoline at regular gas stations. However, the power plant turns out to be very complex, three-stage: reformer - fuel cells - electric motor. Moreover, in addition to water vapor, other chemicals will be formed during its operation.

A number of companies are carrying out experimental testing of this technical proposal. Experts hope that, despite the multi-stage energy conversion, the overall efficiency of the power plant will be higher than that of a conventional gasoline engine.

Of course, we must not forget about the hydrogen storage tank. To ensure an acceptable mileage on one refueling, it is necessary that the compressed fuel cylinder withstand very high pressures (several hundred atmospheres), or one must follow the path of using cryogenic technology, which is also technically feasible.

Refueling hydrogen cars

Since the production of cars using hydrogen is not a very developed industry, there are critically few hydrogen filling stations in the world. In 2022, about 150 refills were located in the Americas, and another 150 were shared between Japan, China and Germany.

There are portable mobile units for refueling with hydrogen fuel; they can produce a fairly large annual amount of hydrogen - about 1 ton. With this amount of hydrogen, several cars can be fueled per day. It is produced by electrolysis of water at night, so as not to provoke network overload.

Hydrogen refills can be divided into the following types:

- Small ones. They produce 20 kg of fuel per day, which is enough fuel for 5 standard cars.

- Average. Capable of producing 50-1250 kg of hydrogen, which is enough for 25 trucks or 250 cars.

- Large ones. Production volumes are more than 2500 kg of hydrogen, which is enough for 500 passenger cars.

The cost of such a hydrogen refueling is about $3 million. Given the great complexity, the number of such gas stations is growing at a slow pace.

Hydrogen for the heavyweight

The last two years will be remembered for important “hydrogen” news. Let's talk about the famous Nikola One electric truck project, presented by the American company Nikola Motor in 2016. This story was continued.

So, Nikola One. An electric cargo vehicle, a tractor with electric drive and a battery with a capacity of 320 kWh. On board there is its own autonomous power plant. Electricity is generated by a hydrogen fuel cell system.

Nikola One for the American market

According to the manufacturer, this truck has an autonomous range of almost 1200 miles, in our opinion – 2000 km. And it moves with zero emissions of exhaust gases - there are simply no such gases.

Initially, they planned to equip it with a “stroke extender” - an on-board gas turbine generator, but then they settled on a fuel cell. True, for some markets the possibility of using a gas turbine generator was still left.

The declared characteristics of the tractor significantly exceed those of most electric vehicles, but there are also doubts - will the energy of the power plant be enough to move 35-ton loads? Operational practice will answer this question. But here another problem arises: where to get hydrogen in sufficient quantities for the Nikola One fleet?

Layout of the Nikola hydrogen tractor: 1 – cooling system; 2 – two electric gear motors for driving the front wheels; 3 – high-voltage and control electronics unit; 4 – traction battery; 5 – receiver of the pneumatic brake system and tank of the battery cooling system; 6 – electrochemical generator (300 kW fuel cells); 7 – tanks with hydrogen; 8 – rear axle with electric motor; 9 – saddle Photo: https://www.automobile-propre.com

Nikola Motors Chief Executive Officer Trevor Milton said the Nikola One electric truck concept will rely on its own hydrogen infrastructure. It will spread throughout the United States, partially capturing Canada. The company intends to build electrolysis plants and transport hydrogen to gas stations.

Not long ago, Nikola Motor found a partner - Nel ASA. The firm supplies equipment to Nikola, helping to create the largest hydrogen fuel network in the world. Suffice it to say that it will have 16 electrolysis stations operating using H2Station technology.

Mr. Trevor Milton, already familiar to us, stated that Nel ASA is already fulfilling the order for the supply of the first two stations based on alkaline electrolysers. The remaining 14 stations will receive a start in life in the near future.

Scott Perry, one of the leading specialists at Nikola Motor, said that Nel ASA has been supplying hydrogen to more than 80 countries since 1927. “We are confident that with such an experienced partner our project will be successful,” he concluded optimistically.

Initially, each station will produce up to 8 tons of hydrogen per day. However, the production volume can be increased to 32 tons per day. By the way, each Nikola truck will consume about 50–75 kg of hydrogen daily.

An interesting detail: Nikola Motor intends to provide its refueling stations for all hydrogen vehicles, and not just its own brand of trucks.

A little time passed, and Nikola announced that it would produce not one, but two tractors - Nikola One and Nikola Two. The second model differs primarily in its cabin. If Nikola One has a sleeping compartment, then Nikola Two is equipped only with a compact cabin for transportation, but not for relaxation.

From an energy point of view, Nikola Two is no different from Nikola One. Behind the cabin there are hydrogen cylinders to power the electrochemical generator. It generates electrical energy for geared motors with a total power of more than 1000 hp. With. According to the manufacturer, acceleration to 60 mph takes no more than 30 seconds, and the range on one hydrogen charge is 1,200 miles. Refueling will take no more than 15 minutes.

Nikola Two is also aimed at the American market

At the end of November 2022, the company introduced the third model of a hydrogen truck. It’s called Nikola Tre (“three” in Norwegian). If Nikola One and Nikola Two are addressed to the American market, then the cabover Nikola Tre will work in Europe.

Nikola Tre for the European market

The technical characteristics of Nikola Tre are practically no different from the first two models. Power plant with a capacity of 500 to 1000 hp. sec., torque up to 2000 Nm, range up to 1200 miles, refueling time approximately 20 minutes.

Problematic issues in operation

Currently, hydrogen engines are not a significant alternative to traditional gasoline engines and cannot fully replace them. One of the reasons is the difficulty in producing gas, as this process is quite expensive. The storage procedure, which requires a temperature of minus 253 degrees, is also difficult.

When working with hydrogen, the following problems should also be noted:

- High explosion hazard. Even a minimal energy source can detonate an explosion. Therefore, you need to use hydrogen extremely carefully, because even too warm air can be dangerous.

- Storage nuances. This substance requires large containers to avoid volatilization, which becomes problematic for use in the field of passenger cars.

- Damage to pistons and cylinders. Due to the negative effect of hydrogen on the cylinder-piston group, it is necessary to use special expensive materials for engines.

But researchers in the use of hydrogen in the automotive industry do not stop and continue to fight for the development of such an alternative power source.

Is everything so rosy in hydrogen technology?

The service life of a single hydrogen fuel cell is up to 10 years. There is no noise or vibration characteristic of an internal combustion engine during engine operation. The motors are absolutely clean from an environmental point of view. However, criticism of hydrogen fuel transport research is extensive. Apologists for traditional energy sources for wheeled vehicles and developers of conventional electric motors are pushing for hydrogen, pointing to a number of intractable issues in the field of infrastructure and technology.

Critics of hydrogen transport point to a lack of standards for the production, storage, movement and use of hydrogen. The large volume of fuel tanks for long trips reduces the capacity of the cabin and trunk. There are purely technological factors associated with the danger of improper handling of equipment for storing and injecting hydrogen. It is extremely volatile: the slightest gap in the design of tanks and hydrogen supply systems to the site of the chemical reaction can lead to closed filling of the car interior and ignition.

In short, there are enough problems to be solved on the way to the safe and economical mass use of hydrogen for refueling vehicles. The main question is whether the owners of automobile corporations are ready to invest significant funds in the development of new infrastructure, further theoretical research and practical development. Indeed, today refueling cars on the road (that is, without visiting special gas stations) is impossible.

Models with a hydrogen engine

Currently, the range of hydrogen vehicles on the market is expanding significantly. The most famous models include the following:

Mazda with hydrogen engine

Pininfarina H2 Speed

This Italian machine has the ability to:

- Accelerates to 100 km/h in a record 3.4 seconds.

- The maximum acceleration capability is 299 km/h.

- But the cost of such a car is more than $2 million.

Mercedes-benz GLC F-CELL

The car has a combined system that combines a battery and a hydrogen design.

- Electric driving reserve – 50 km,

- On hydrogen – 430 km.

- A special feature of the car is the ability to charge from a regular electrical outlet.

Classification of Mercedes-Benz by class

Mercedes-benz GLC F-CELL

Toyota Mirai

Japanese made car:

- Travels 502 km without refueling.

- Additionally equipped with touch screens for navigation control.

- The ability to accelerate the car is up to 178 km/h.

Toyota Mirai

Honda Clarity

This is a 5-seater family car.

- The range for a trip without refueling is a record 600 km.

- At the same time, refueling only takes a couple of minutes.

Video 22:00 minutes. Review of “Klara Hondovna” Honda Clarity

Advantages of hydrogen cars compared to electric cars

This comparison is often disputed by experts, since hydrogen cars are also included in the category of electric vehicles. Hydrogen components, unlike batteries, are more durable, because the service life of the engine in a conventional electric car is short.

Hydrogen has shown itself to perform well during cold car starts at subzero air temperatures, when the electric vehicle engine cannot cope with the effects of temperatures. Refueling hydrogen cars is also considered an advantage as it can be completed in a few minutes. But electric cars have a lower cost compared to hydrogen cars.

Pros and cons of a hydrogen internal combustion engine

Advantages and disadvantages of hydrogen engines

Hydrogen engines have advantages that other types of engines do not have:

- performance without creating extraneous noise;

- high efficiency of a hydrogen engine;

- increased environmental friendliness (by-product only water);

- good power level;

- simplicity in functional design.

Among the negative characteristics are the high costs of hydrogen production and complex storage levels. During production, the design requires an increase in the weight of the vehicle. The high explosiveness of hydrogen components is also noted.