Causes of failure

To be honest, the bearing is a very durable part of the hub. And to “kill” him you need to try! Most likely, all kinds of racks, rubber bushings and other attached parts will fail, but if you “try” you can also damage this element.

1) Long mileage . No matter how trivial it may sound, a long mileage of a car wears out all the components, and the bearing is no exception. This is the main cause of the malfunction, the rest are secondary. After approximately 70 - 120,000 kilometers, different manufacturers have different ways. You will hear a characteristic crunch. It says that this part needs to be changed.

2) Loss of tightness . The bearing has a little lubricant, which is covered with special casings made of rubber or plastic. If they break, the lubricant comes out and wear becomes much greater. After just a couple of thousand kilometers you can hear a characteristic hum, which indicates a malfunction.

3) Sloppy driving . If you constantly fly into holes at high speeds, this will also wear out this unit a little. Although, as I wrote above, other suspension elements will fail faster.

4) Incorrect pressing . This is a secondary reason; during repairs, the new bearing may be pressed in incorrectly, for example, obliquely. Thus, when driving, it will not stand correctly, which will wear it out quite quickly; after about a couple or three thousand kilometers it will need to be changed again.

5) If you tighten it too much . This happened especially on our domestic cars; the bearing was overtightened during replacement, so it heated up more than usual, which also contributes to a decrease in service life and subsequent breakdown. So you need to take into account the twisting force; it is usually indicated in the instructions.

These are all the main reasons, but as you can see, the last two are the “crooked hands” of the car service. So we only replace them at trusted stations that provide a guarantee on the work. Sometimes it is more profitable to look at official stations.

Causes of beating and its correction

The most likely causes of runout when a vehicle is braking are:

- wear and slight deformation of the surface of the brake disc;

- disruption of the vehicle's chassis;

- wheel nuts not fully tightened;

- deformation of the wheel disc;

- the occurrence of a hernia on the tire.

How to check a car brake disc for runout and fix it yourself?

- The brake caliper is removed without disassembling and secured with wire.

- The brake disc is attached using hub nuts.

- Install the device at a distance of 5 mm from the edge of the brake disc and take measurements.

The value should not exceed: for the front wheel – 0.06 mm, for the rear – 0.08 mm.

If the measurement result is higher than the maximum permissible, the adjustment (correction) should be made in the following order:

- in the place where the beating is heard more clearly, make chalk marks on the hub;

Symptoms of failure

This is where the most interesting thing is - how to determine a malfunction; there are several hundred percent methods.

1) “Dry” crunch . When a wheel bearing fails, a crunching sound appears when driving. These are spherical elements rolling. They broke the clip they were in and are now not evenly distributed. You won’t confuse this sound with anything else; believe me, this sound is perfectly audible in the cabin. This is the very first symptom - as soon as such a sound appears, we immediately go to the service station.

2) Vibration . If the bearing is already well worn, then vibration should appear in both the steering wheel and the body. This suggests that the spherical elements have already worn out the bearing race well, a little more and a “wedge” may occur. We change it urgently.

3) The car is pulled to the side . It is also possible that the part with the faulty element does not work normally - so to speak, it is stuck a little, and therefore the car will pull in one direction or another, as if the wheel alignment .

How to check a wheel bearing while driving

While the car is moving, if there is extraneous noise in the cabin, it becomes a hearing irritant for the driver. Finding the source of noise is sometimes difficult, because many components and parts of a machine can produce sound. Try to accelerate the car. Some tires can create a hum at high speeds, thereby misleading the driver.

You can find out which side the fault is on by maneuvering:

- Turn left, the load on the left axle will decrease, if the sound disappears or weakens, then the problem is on the left side.

- Turn to the right, the load on the left side will increase, a hum will appear, which means the assumption that the fault is on the left side is correct.

- Try varying your speed and alternating turns left and right.

- Listen to how the frequency and tone of the sound changes. It can decrease, increase, and sometimes disappear altogether.

Unbend the car on a flat road, release the gas, and move by inertia. Let the passenger listen to where the hum is coming from. Test your assumptions. Perform diagnostics on the car's wheels hanging up using a jack.

What will happen if you don't change

Many car enthusiasts drive with faulty wheel bearings, and even accelerate at 100 kilometers per hour or more - guys, this is very dangerous, remember this is the connecting element of the wheel, which is responsible for its rotation. If it is broken, it can jam at any moment. And this is a sudden stop of one of the front wheels. Now imagine if your speed is 100 km/h - at that speed you will simply fly off to the side of the road, this is the best case scenario, but you can also fly into oncoming traffic, and then you’re not far from an accident. There have been cases when cars overturned. So guys, the hub bearing is very dangerous, if you don’t want to change it, drive at low speeds, up to 40 km/h, otherwise everything can end very badly.

avtoexperts.ru

When, while driving, in addition to noise from the tires, additional high-pitched noise appears, this is a sign that one of the wheel bearings has “woke up” and needs to be replaced.

Hub and wheel bearing

However, during repairs, a controversial question often arises: which bearing is humming, right or left? In order to determine a faulty wheel bearing yourself, without contacting a car service, there are several ways.

Method N1

It is necessary to either lift the car if it is installed on a lift, or lift each wheel with a jack when working on the site.

Next, wheel chocks are placed under the rear wheels (when checking on the ground), the engine starts, 4th gear is engaged and the drive wheels accelerate to 70-80 km/h, or one of the drive wheels when working with a jack. Then depress the clutch and disengage the gear by shifting to neutral. If the hub is faulty, a clearly audible hum from the bearing will appear, which will “tell” about its malfunction.

If it is a front-wheel drive car, then this way you can check the front wheel hubs; if it is a rear-wheel drive car, then the rear axle hub bearings.

Method N2

The wheels are checked one by one for play. Each of the wheels is lifted on a jack (don't forget by the shoes) and the wheel must be rocked in the vertical and horizontal plane and then rotated.

Checking the wheel bearing

If the hub is faulty, play will be felt, the more, the more the bearing is broken, and when the wheel spins, noise will appear, sometimes with obvious rolling of the balls.

However, wheel play can also be caused by a malfunction of suspension or steering components. An assistant is required for accurate checking. He must press the brake pedal, and in this position, check the wheel bearing play again by rocking the wheel in a vertical plane. If the play remains, then its cause is a suspension malfunction; when it disappears, then it is a sign of wear on the hub bearing.

If the bearing is in good condition, then there is no play at all.

Method N3

Determination of worn bearing when making turns. When making a turn, the car body begins to roll; for example, when turning left, the car rolls to the right. In this case, the main part of the load falls on the right wheel, unloading the left one.

If at a speed of about 15 km/h you make a sharp turn of the steering wheel to the left and the extraneous noise disappears, then the noise came from a faulty left hub bearing. You can check the right side bearing in the same way.

The main signs of a faulty wheel bearing are:

• Vibration on the steering wheel

• Noise when driving

• Wheel play when checking

What is the risk of wheel hub bearing wear?

If you continue to operate the car with a humming bearing, this will lead to its intensive wear with the appearance of a loud crunch and crackling noise. A collapsed bearing will lead to jamming of the wheel hub and, as a result, the suspension arm, ball joint and plus deformation of the drive shaft may suffer.

If this happens at speed, the consequences can be very unpredictable. Therefore, pay attention to the condition of the wheel hubs, the check of which can be timed to coincide with the next vehicle maintenance.

We determine the problem ourselves (at home)

In general, in addition to the crunching noise that you will constantly hear when moving. You can determine by the signs yourself literally around the house.

1) Place the car on a flat, preferably paved area.

2) You need to check the play along the vertical axis. To do this, we take the wheel at the top point and try to swing it with all our might. If you hear clicks and there is play, then this is definitely “hub”.

3) To be completely sure, you can lift the wheel on a jack and rotate it. If you hear a crunching sound, there is a malfunction.

4) There is another method (works only on front-wheel drive), but it is advisable to do it on a lift. You need to lift the car, start it, put it in gear and accelerate the wheels, then turn off the engine and listen. The side that makes noise, crunches and vibrates is faulty.

Now a short video version of the article

Wheel bearing: what is checked at the service station

You can independently deliver the car to a service station, get advice on how to check the support bearing, and even watch how they fix your personal car on a lift and begin to diagnose the condition of the axle and running elements. What will a car mechanic pay attention to?

- He determines for himself the basic method of how to check a wheel bearing and applies it in the process.

- Alternately spins the wheels, first slowly, then faster. At the same time, he listens. If friction, clicking, or howling occurs, the auto mechanic looks at the location of the bearing and evaluates its external indicators.

- Wheel play is also assessed for play. To do this, the auto mechanic grabs the top of the wheel with one hand and the bottom with the other, and begins to loosen the wheel back and forth. If the tire gives way, the bearing is so worn that it requires immediate replacement. But at the same time, you should also evaluate the running parts of the machine, which may no longer operate in normal mode.

About replacement

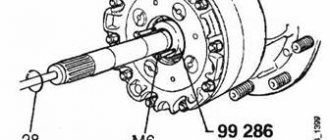

What I want to say is to change the bearing correctly, it’s quite difficult to do it yourself. You need at least a couple of pullers, as well as knowledge of the car's suspension. It’s not for nothing that many automakers change the entire wheel hub.

When replacing it is important:

1) The bearing can be pressed in only with special, even races (ideally, use a housing from an old one). Press-fitting with “rolling bodies” is not allowed.

2) Avoid pressing with sharp tools, which may damage the O-ring, which will then lead to lubricant leakage.

3) When pressing, you need to maintain the correct gap and plane; distortions are not allowed. Incorrect clearance - misalignment will lead to rapid failure.

That's all, in conclusion I would like to say that I myself changed the wheel bearing a couple of times. In a garage environment, and even if you don’t have the skills, it’s very difficult to do this (you can ruin the new one), so it’s better not to waste money and give it to a proven station. Save your nerves, money and energy.

That's all, read our AUTOBLOG.

Similar news

- Speed sensor repair. Using the 2008 Chevrolet AVEO as an example

- Is it worth repairing the steering rack? What's the benefit?

- Do I need to change springs when replacing shock absorbers (struts). Sort it out...

Add a comment Cancel reply

Tips for maintenance and operation of bearings

- How to lubricate a wheel bearing.

- Keep dust away from grease and bearings. Lubrication of external surfaces prevents corrosion. For external lubrication, perform the following operations:

- First, you need to cleanly rinse the seat of the clip with kerosene, wipe it dry, then lubricate the seating surface with a thin layer of lubricant. Put on a clean rubber glove, apply lubricant to your palm and rub it into the bearing, then insert the part inside and additionally wipe the surface with a rag moistened with lubricant.

- You can use any anti-corrosion lubricant; specialized lubricants for bearing units are sold on the market. When applying, observe the amount of lubricant - there should be no leaks from the unit.

- Lubrication of the bearing inside is possible if it is open or has rubber seals. Add lubricant inside, but here you also need to follow an important rule - there should be no excess lubricant (turn the races repeatedly, excess lubricant will come out, it should be removed).

Recommended lubricant is presented in the table:

Lubricant brandsManufacturersThickenerBase oil

| RareMax AF-1 | Kyodo Yushi Co., Ltd. | Urea | Mineral oil |

| 6459 Grease N | Showa Shell Sekiyu, KK | Urea | Mineral oil |

| Pyronoc Universal N-6C | Nisseki Mitsubishi Oil Corporation | Urea | Mineral oil |

| HB-1 | Kyodo Yushi Co., Ltd. | Urea | Mineral oil |

| Ronex MP | Exxon/Mobil | Lithium | Mineral oil |

- How to extend service life.

Tighten the axle nut to the recommended torque. Excessive tension will cause excess friction, the lubricant will heat up, dry out, and the rubbing parts will become deformed. Insufficient fastening torque will cause more play than is permissible, which will lead to premature wear. Use original spare parts (nut, cotter pin, retaining ring, etc.) to repair bearings.

Which wheel bearing to choose based on manufacturer, and what to look for when purchasing.

The original number is indicated on the case; the manufacturer recommends installing it. If it is not possible to get the original, there are replacement brands. The main thing is that the dimensions and technical characteristics match. On the packaging, look at the inscriptions, barcode, stamped number on the case, and the package contents.

Wheel bearing kit - what it includes.

The repair kit includes consumable parts: wheel nuts 1 or 2 pcs., wheel bolts - set, lock ring 2 pcs. cotter pin Possible oil seals, outer races and even lubricant.

What to use a press or puller.

For high-quality work, use a press, remove the assembly, take it to a service station, and for a small fee they will replace the assembly parts in 1-1.5 hours. The puller is used when replacing independently, purchased or rented. An assistant's hand will be useful for holding the key.

Important point: Do not put pressure on the inner race of the bearing, as this can lead to damage to the elements of the bearing assembly.

ABS bearings.

The presence of an impulse ring can be easily checked by placing a metal object on one side of the seals. The magnetized side is placed inside the hole of the fist to the connector of the reading sensor.

Curvature of brake discs and how to solve this problem

This phenomenon occurs due to overheating of the surface of the disk material. This is caused by poor operation of the car: prolonged and strong braking of the car, as well as frequent driving around the city in a dense stream of vehicles. When a car drives through water with an overheated brake disc, it begins to cool quickly and the disc itself becomes distorted.

If the discs are not yet very worn out, then a qualified turner can correct the situation.

However, after such processing, a significant part of the metal surface will be removed, which entails rapid wear of the part. There is another way to avoid turning work - to purchase used discs, but this option may not bring a guaranteed effect. The most effective method for correcting curvature is to purchase completely new parts and then replace them, and doing the work yourself will not be particularly difficult.

You need to choose a product depending on the power unit of the car, since they differ in size from each other.

Navigation by instructions

Rear wheel bearing

|

Front wheel bearing

|

Temperature

Like a living creature, a sick car may develop a fever. But not in general, but locally, at the location of the worn part. For example, a wheel bearing.

A faulty rolling unit operates with increased friction, which means it generates more heat. Simply measuring the temperature is unlikely to help here, but comparing the left and right sides of the car will be useful. Just don’t use the brakes before doing this, and you might get burned and won’t be able to feel the difference.

Replacing the rear wheel hub bearing

Work carefully. Minor movement during assembly of installed parts often leads to failures in the assembly process.

- Keep it clean. Dirty mating surfaces can render your work unusable. Always have a clean rag and a degreaser on hand - gasoline, kerosene or white spirit.

- Repetition doesn't make much sense. The procedure for performing the necessary operations is largely the same as described earlier. The differences will be as follows:

- You do not need to remove the tie rod.

It is not necessary to remove the constant velocity joint of the drive axle.

If you need to use a press and the machine is equipped with a linkage suspension, you will need to remove not the strut, but the arm that the hub is mounted on.

Therefore, replacing a rear wheel bearing is a little easier than replacing a front wheel bearing.

In all-wheel drive vehicles the difference will be minimal. Taking into account the design specifics of the car, sometimes it makes sense to unscrew the drive shaft from the gearbox and leave the shock absorber lever or rack in place.