24.01.2018 1,

If you find that your gas tank is rotten or you accidentally punctured it, then do not rush to buy a new one. Even buying a used gas tank can cost a pretty penny. First you need to identify the extent of the damage.

We remove the gas tank, dry it and check for rust. For most cars it is located on the rear right side of the car. If necessary, clean it of all deposits. Cleaning can be done either with improvised means (sandpaper) or with special mechanisms (sandblasting).

Soldering the gas tank

After assessing the identified damage, you can begin soldering the gas tank. The most popular method can be considered cold welding. We clean the surfaces where the gas tank is damaged. Mix the epoxy resin and hardeners in a separate bowl. Apply a homogeneous mass to the hole.

It is necessary to apply a fabric patch on top of the homogeneous mass, having previously generously lubricated and soaked it with the same mixture. After the resin has cured, you must ensure that the entire surface of the hole is covered and generously covered with resin and patch. Such a patch may take more than one season, but you should not rely on it for the rest of the time you use the car.

This soldering is suitable in most cases, but for plastic tanks a different soldering method is required. In this case, you need a soldering iron (250 W). If there is major damage, additional pieces of plastic (of the same brand as the gas tank) will be required. Each plastic part must be marked.

Plastics are mainly divided into three types. PP (polypropylene), ABS (acrylonitrile butadiene styrene), PA (polyamide). It is necessary to solder the plastic gas tank only from the outside. If necessary, use reinforcing materials (fine metal mesh). After soldering plastic products, do not allow the soldered parts to cool suddenly.

How to fix a gas tank leak?

There are several ways to fix a hole in a gas tank with your own hands, from the simplest to the most complex. We will look at all the available methods that can really help at least a little. For safety and ease of operation, all fuel must be drained from the tank to eliminate the risk of fire. In addition, it is better to remove the tank itself in order to be able to carry out unhindered repairs. Then, we find the hole and begin to grind it down to bare metal. Sometimes the tank is made of plastic, in which case you need to grind it carefully so as not to create additional cracks in the hole areas.

Once the tank is cleaned, we assess the extent of the damage. It may be possible to get rid of the problem, at least for a while, by using cold welding. We process the tank with cold welding as recommended by the manufacturer and wait a certain time until everything dries. After this, we pour a certain amount of fuel into the tank and check whether it is leaking.

Solder is suitable for soldering a metal tank; it gets perfectly into the middle of the crack and seals it on both sides. This is a budget repair option; ideally, repairing a gas tank leak should be done by conventional welding. If you yourself have not held a welding machine in your hands, contact your neighbors in the garage cooperative. Surely, some grandfather will agree to help you for a pittance.

One way or another, if your gas tank has leaked, it’s better to start collecting money for a new one. The fact is that even the highest quality restoration work has a short-term effect; after a year or two you will have the same problem again.

Gas tank, soldering iron, solder...

To solder a metal gas tank, a powerful soldering iron (500 W) is required. Before soldering, the hole area must be treated with soldering acid. The solder must be fusible; in extreme cases, a copper plate will do. After soldering, it is necessary to cover the entire surface with resin to prevent rust from appearing.

If there is minor damage during the trip, you can use a folk remedy, of course, if you have laundry soap on hand. It is necessary to strongly rub the surface in which the holes are supposed to be made with soap. The soap will clog all the small cracks and thereby help you get to the nearest service station. This method is only intended to help you get to the nearest service station. serving.

All the methods described do not guarantee long and high-quality operation of your gas tank. If a part breaks, the part must be replaced. In our case, we postpone the timing of replacing the gas tank, but in the end, sooner or later, it is necessary to replace the broken gas tank.

Gas tanks that are part of the fuel system of modern cars are most often made of two materials: cross-linked polyethylene (plastic) or metal. However, if something happens to a plastic tank, this material can only be repaired in extremely rare cases; most often it is replaced. As for containers made of metal, the situation with them is somewhat simpler and in many cases it is possible to repair a fuel tank made of this type of material.

How to check a gas tank for leaks after soldering

After completing repair work on the gas tank, it is necessary to perform a leak test. To do this, it is necessary to create a pressure of about 7–15 kPa in the tank, having previously plugged all the holes for the hoses and leaving only one for the pump. After this, soapy water is applied to the container. The absence of bubbles indicates a successful repair and no leaks. If it is possible to immerse the tank completely in water, then the tightness is checked in this way. However, in this case you will have to put in a lot of effort, because completely lowering the tank under water is not so easy.

There are different ways to restore a gas tank; the specific one you choose depends on the nature of the damage and its extent. Repairs do not require extensive experience or special equipment. Using a tool that almost every motorist has, restoring the tank is possible in a garage. The main thing is to follow the rules and follow the algorithm exactly.

During the operation of the car, the gas tank, which is part of the fuel system, gradually wears out. The easiest way is to replace it with a new one if a tank leaks, but this is expensive. If the crack is minor, then you can deal with this problem yourself, regardless of whether your car has a metal or plastic gas tank.

Material and characteristics of the metal tank

We will be considering a container made of metal, because as mentioned above, such a gas tank can be repaired. As for the material from which this container is made, in 95% of cases it is a soft steel sheet. This sheet has additional treatment, usually a secondary lead coating, which slows down irreversible corrosion processes.

The advantage of this material and the reason why it can be repaired is that when deformed, it is possible to level the metal sheet. If for any reason a gap appears in such a gas tank (for example, a breakthrough due to an accident or thinning of the material due to rust), then it can be soldered or welded.

Causes of gas tank damage

Naturally, there can be many reasons for mechanical damage. However, it is worth mentioning the most common ones:

- Corrosion;

- Bloating due to high blood pressure;

- Deformation or ruptures due to an accident;

- External mechanical factors.

All reasons except the last one are obvious; as for the fourth point, it is due to the location of the fuel tank. This means that in many cars the gas tank is located under the car and one of its sides is perpendicular to the ground. In this case, stones flying out at an unpleasant angle, the bottom touching bumps or debris on the road can lead to some damage to the fuel container, but even in this case it can be repaired, for example, by soldering it.

Fuel tank repair

First of all, before you begin, you need to understand that although the process of repairing a fuel tank is not very complicated, you must adhere to the mandatory precautions and be extremely careful at some stages of the work, so you can avoid possible troubles and reduce the risk to life .

First of all, when starting repairs, the owner must drain all the fuel from the tank, to the last drop. To do this, you can use a regular rubber tube, but if the process is inconvenient, use a jack, tilting the car in the desired direction.

Soldering the fuel tank

Now it is necessary to assess the degree of destruction, and this degree is divided into two points:

- Normal dents, no fuel leaks. In this case, you can level the walls of the tank by supplying compressed air inside.

- Damage to the tank with fuel leakage. Let us dwell on this point in more detail, since it poses the greatest threat.

So, the first thing to remember is that under no circumstances do you weld immediately after draining the fuel. The tank can also be sealed only after time has passed. This is due to the fact that explosive fuel vapors are stored in the gas tank, which detonate when heated, and this is extremely dangerous.

To seal the tank, you need to rinse the tank thoroughly and fill it with water. Rinse with hot water and detergent. If you decide to solder the tank using tin solder, then you don’t have to fill it with water, since the temperature will not be high. However, such soldering is suitable only if the damage is small.

If the gaps are larger and hot soldering with fire is required, be sure to fill the tank with water, but in the place where you want to solder the gap, you must leave a small pocket of air by tilting the gas tank accordingly. At the same time, when carrying out soldering, do not close the lid of the fuel container under any circumstances, since the gas formed during heating must escape freely.

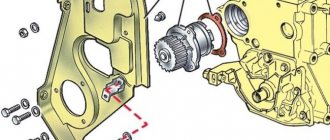

Vehicle power system design

Some advice on whether it's worth installing

gas equipment for a car.

In most cases, fuel tanks of the power supply system consist of two parts, obtained by drawing and roller welding along bent sides. The metal for fuel tanks is a soft steel sheet coated with lead (or tinned). In new car models, there is a trend of using composite materials for the manufacture of gas tanks. The use of composite materials helps reduce the weight of vehicles, as well as reduce the cost of fuel tanks.

reasons for damage to fuel tanks. Since the tank is installed under the car, its upper part is at floor level. On some car models, the fuel tank is installed vertically in the luggage compartment on the side. Tanks located under the vehicle can be damaged by impacts from stones. Tanks installed in the luggage compartment are damaged by corrosion resulting from moisture condensation.

Now let’s ask ourselves how to repair a gas tank? Is it difficult to repair a fuel tank? Repairing a fuel tank is not a complicated procedure, but be careful, this malfunction is very dangerous and it is not recommended to drive with it. Don't put off repairing your gas tank until tomorrow.

DIY gas tank repair

To repair a steel fuel tank with your own hands, you first need to drain the fuel (you can use a tube to drain the gasoline; if draining the fuel is not convenient, tilt the car with a jack), and then remove the tank .

If the repair boils down to straightening out the dent and no fuel leaks are observed, then the operation consists of supplying compressed air to the tank through the filler neck or through the hole connecting the tank to the fuel pump.

To do this you need to do the following:

1) plug one of the two holes in the tank;

2) insert a conical rubber tip drilled through into the open hole of the tank to ensure a tight connection between the tank and the compressed air pipeline;

3) supply compressed air to the tank and restore its size and shape.

If the tank is damaged, it cannot be welded immediately.

inside the gas tank , which mix with air and form an explosive mixture. The flame may cause the tank's mixture to explode, causing the tank to rupture and injure nearby people.

To carry out soldering work, you need to rinse the tank, then fill it with water or inert gas. Washing can be done with a solution of detergent in hot water, shaking the tank vigorously and then pouring out the contents. Subsequent flushing of the tank is carried out by completely filling it and draining it.

If the tank is soldered with tin solder using a soldering iron, you can solder without filling the tank. If the repair requires heating the tank with a flame, for example, to perform hot soldering, then you must first fill the tank with water , and then install it so that there is a small air gap inside, under the soldering point.

When carrying out this work, the tank must not be hermetically sealed ; the gas formed during soldering must freely come out or squeeze water out of the tank. To do this, first connect a flexible hose to the filler neck, which, after turning the tank over, is at the bottom. At the same time, to maintain the desired level, the hose is bent.

The power supply system of a modern car is designed to supply fuel to the engine.

Repairing a gas tank with a large hole:

– cover the edges of the hole with resin, then place fiberglass on the hole and cover it with resin;

– Apply another 2-3 layers of fiberglass in the same order, coating each layer with resin.

Note that the layers of fiberglass and resin combined together have strength characteristics comparable to those of the metal of a gas tank. In all tank repairs, you must ensure that there are no leaks in the fuel tank before installing it.

Repairing a gas tank using cold welding is an effective and reliable method!

Today , repairing a gas tank by cold welding is very popular due to its prevalence, accessibility and ease of use. The essence of repairing a gas tank by cold welding is mixing two active components, which must be thoroughly kneaded together for better weldability. Carefully apply cold weld to the crack and leakage area and wait 20 minutes. Before cold welding a gas tank, be sure to clean the weld area and wipe it clean with a rag.

Conclusion

So, as you can see, there is nothing complicated in repairing a tank, and although this text presents only one of the methods that allows you to solder a tank, the other methods are also not particularly difficult. The main thing in this matter is to follow the precautionary rules prescribed above, otherwise the consequences can be severe for both man and machine.

A leak in the gas tank occurs as a result of physical wear or due to damage with collapse of the housing. Fuel vapor accumulates in an empty tank, so welding and heating can cause an explosion. Many motorists ask how to properly seal a gas tank. There are several repair methods: argon arc and cold welding, soldering. Let's look at each of them in more detail.

Checking the repaired gas tank for leaks

After repair work is completed, the tank is checked for leaks. To do this, close all the holes and use a manual or electric pump to create a pressure in the gas tank, 7–15 kPa is enough. Then cover the tank with soapy water and carefully inspect it. It is possible to place the tank completely in water, but this will not be easy. If air does not pass anywhere, then the work has been done efficiently and the tank can be installed on the car.

Close all the holes, pump air into the tank and use soapy water to check the quality of the repairs performed.

If damage to the fuel tank occurs, you can fix such a malfunction yourself, without the involvement of specialists. Depending on whether this happened on the road or was discovered on site, one of the available restoration methods is used. In any case, you can do everything yourself; this does not require special equipment or professional skills. To perform the work efficiently, you must follow the developed repair technologies and follow the recommendations of specialists.

A leaking gas tank is a serious problem that can happen to anyone. Since the gas tank on many cars is located on the bottom of the trunk, it is no wonder that many motorists have no problem damaging it during operation. The tank was damaged as a result of an impact from a foreign object, or from corrosion - it doesn’t matter, because if this has already happened, there is no time to waste, since with every minute there is less and less gasoline in the tank. You will learn further how to repair a leak in a gas tank.

General rules for repairing a gas tank

The presence of a leak is indicated by increased fuel consumption and a specific smell in the cabin. Even a minor crack is dangerous for the life of the driver and passengers. The leak area ignites when struck by a spark. Damage occurs as a result of cracking of the body during driving and exposure to corrosion. Defects occur when there is a malfunction in the vehicle's fuel system. The discharged pressure contributes to the gradual cracking of the walls. Microcracks gradually increase, causing leaks. Before welding the gas tank, you must follow the safety rules:

- be sure to drain gasoline or diesel fuel from the tank;

- thoroughly dry and dismantle the tank, inspect for damage;

- wash inside using specialized detergents;

- After washing with household chemicals, rinse thoroughly and dry.

Washing the tank allows you to completely remove explosive vapors. The repair method is selected based on the material from which the tank is made. Argon arc welding of a fuel tank is only suitable for metal containers; it is recommended to repair plastic products using cold welding; hot soldering is a universal method. Let's take a closer look at how to seal the gas tank yourself.

Causes of gas tank cracks

On most cars, the gas tank is located in the rear (right, left, under the rear seat). This design feature is explained by safety for passengers and the driver. In addition, vehicle handling is improved. However, the rear part of the body is quite often exposed to external damage during the operation of the car, as a result of which the gas tank also suffers.

The most common cause of cracks is mechanical stress leading to holes in the container. Considering the quality of Russian roads, sometimes even a slight impact is enough to cause a hole to form.

Significant causes of damage also include metal corrosion, which is an inevitable process. The more mileage a car has, the higher the likelihood of this type of problem. Less common are power system faults. Since a rarefied pressure is created in the middle of the tank as fuel is consumed, this affects the condition of its walls. During operation, small cracks may appear on them, and as a result of their enlargement, leakage occurs. This situation indicates the need to repair the gas tank.

One of the reasons for gas tank damage is corrosion.

What to do if your tank leaks

The appearance of a crack, hole or any other type of damage to the gas tank is typical not only for domestic cars, but also for foreign cars. When the seal of the tank is broken, it is necessary to fix the problem as soon as possible. Operating a vehicle with such a malfunction can lead to disastrous consequences, and danger threatens not only those in the car, but also those around them. Due to the fact that the fuel tank is a simple structure, restoring the tightness will not be difficult. However, much depends on the degree of damage and the feasibility of such an event. Since gas tanks are made of different materials, different repair methods are used.

Cold welding gas tank repair

Cold welding is suitable for containers with hard plastic walls or for metal tanks. Glue does not adhere well to thin-walled tanks, so such repairs will be ineffective. The adhesive composition is selected in accordance with the type of container material. It is recommended to wear gloves when repairing a gas tank using cold welding. The crack is cleaned of contaminants and degreased with nefras.

Two-component mixtures are combined in the proportion specified by the manufacturer. The prepared solution must be used within 10-20 minutes depending on the brand name. The glue is applied to the damaged area in layers and smoothed, pressing it to the surface. 2-3 hours after repair, the tank is ready for use. The glue in the form of a bar is thoroughly kneaded with a damp hand and the crack is covered.

Cold Welding Selection

When choosing a cold weld, it is necessary to take into account that it must be resistant to gasoline. Only minor damage can be sealed with it. Moment superglue or similar special compounds from other manufacturers are perfect for eliminating leaks on the road. The rags are cut into patches, soaked in glue and attached to the hole in several layers. This repair method is temporary; it allows you to get home or to a service station and completely solder the holes.

Repairing a cracked metal gas tank

In order for gas tank repair to be not only competent, but also safe, certain rules must be followed. They boil down to the fact that all additional equipment will need to be dismantled, the fuel drained and the container washed.

When repairing a cracked gas tank, it is necessary to drain the fuel, remove the container and wash it.

How to remove the gas tank

Removing the gas tank involves removing the hatch, cable, neck, fuel sensor and pump. The list of certain elements, as well as the process of dismantling them, depends on the specific car.

Tools you may need:

- pliers;

- side cutters;

- screwdriver;

- wrench or socket of appropriate size.

Sequence of actions during dismantling:

- First, the remaining fuel is drained. For this purpose, the design of the tank has a special hole in the lower part. To prevent fuel from spilling on the ground, prepare the container in advance. If there is no plug, gasoline can be drained using a hose and a pump bulb.

Before removing the gas tank, it is necessary to drain the remaining fuel.

- After emptying the tank, disconnect the connector, which is responsible for connecting the wires to the fuel level sensor. This connector may be located under the rear seat or in the luggage compartment. The element can be separated by snapping off the special tab. After this, disconnect the ventilation hose located at the bottom of the tank.

After the fuel has been drained from the tank, remove the connector with the fuel sensor wires, as well as the power supply to the fuel pump.

- Using a screwdriver, loosen the clamp of the fuel supply hose and tighten the tube. If the hose does not come off, try turning it in different directions.

One of the stages of dismantling the gas tank is the removal of the fuel hoses, for which the fastening of the clamps is loosened

- Removing fasteners. To do this, unscrew the nuts that secure the clamps securing the gas tank to the body, and then remove them from the studs. The free side is lowered, then the second side of the fastening is released.

To dismantle the tank fastenings, unscrew the nuts securing the fuel tank clamps

- Remove the gas tank filler cap by simply unscrewing it. After this, the tank is moved to the side to release the neck from the rubber seal.

To remove the gas filler neck from the seal, you will need to remove the plug.

- The ground wire is disconnected from the tank body. It is secured with a nut, which must be unscrewed with a wrench of the appropriate size. There are no longer any elements holding the fuel tank in place and it can be removed from the vehicle.

When nothing interferes with dismantling the tank, it is removed from the car

Cleaning the gas tank

After the fuel has been drained from the tank, it will need to be cleaned of contaminants, for example, by washing under running water using detergents. After drying the tank, it is necessary to clearly indicate the places of future work and understand whether there is a need for its dismantling or restoration is possible directly on site. Is it possible to repair a gas tank without draining the fuel? You need to understand that doing quality work, even with the slightest leak, is problematic. When all the preparatory aspects have been resolved, they proceed directly to the repair procedure.

To reveal the extent of the damage, the container must be washed and dried.

Necessary tools and materials to repair a cracked metal gas tank

Depending on the chosen repair method, the list of tools and materials used will differ. In general, you will need the following:

- tire pump for supplying compressed air;

- hose connected to a hot water supply;

- special cleaning liquids;

- petrol;

- drill;

- bolts and nuts;

- file;

- degreaser;

- sandpaper;

- primer paint.

How to solder a gas tank

One common method of repairing cracks in a metal fuel tank is soldering. To carry out the procedure, you will need a soldering iron with a power of more than 200 W, soldering acid and tin. Leave the tank neck open during operation. Let's start restoration:

- We determine the location of the leak.

- If any deformations are found, we straighten them out.

- We carefully clean the soldering area and degrease it, for which you can use any product (acetone, solvent, gasoline).

Before soldering, the damaged area is cleaned to bare metal.

- Apply soldering acid to the soldering area.

- To make it easier to tin the problem area, heat it with an incandescent lamp or hairdryer.

To apply tin, the damaged area must be heated

- We tin the metal. If the crack is large, we fuse tin in several layers until the damage disappears.

For large crack sizes, tin must be deposited in several layers

- When the soldering area has cooled down, clean it of rosin with a solvent or other means.

After soldering is completed, the area is cleaned of rosin with a solvent.

On old gas tanks, in addition to eliminating the crack, it is appropriate to clean the tank from corrosion, and then apply primer and paint.

How to brew a gas tank with a semi-automatic machine

To carry out welding work on the fuel tank, you will need to pour water inside to prevent ignition of gasoline vapors. The welding site is cleaned to bare metal, removing corrosion using a wire attachment on a grinder or drill. If a large area is damaged, it is cut out, a metal patch of similar thickness is applied, and then scalded. After cooling, the container is covered with primer and painted.

Cold welding repair

When repairing a crack in a fuel tank using cold welding, the same preparatory measures are performed as for soldering (draining fuel, washing, drying, cleaning). If the damage is in an accessible place, the container does not need to be removed from the vehicle. When working with cold welding, you must take care to protect your hands, i.e. use rubber gloves. Then cut off the required amount of the composition and knead it well in your hands. As a result of the chemical process, the product will begin to soften. At this moment, it must be applied to the damaged area with great force, and then leveled.

One way to repair a gas tank is to use cold welding

For greater reliability, a piece of fabric is placed on top of the first layer, then the second layer is applied. Depending on the type of cold welding, it may require dilution with various means. In this case, it is recommended to perform the kneading procedure in a metal container.

Sealing a crack with epoxy resin

Repairs using epoxy resin are resorted to when it is not possible to carry out a full restoration by soldering or welding. All epoxy components are mixed according to the instructions. The damaged area of the gas tank is thoroughly cleaned and a layer of resin is applied to it, after which it is covered with a piece of fiberglass or a clean rag soaked in the same substance. Several such layers are applied. When the patches are dry, you can fill the gas tank with fuel and continue driving. It is worth considering that epoxy resin, as well as cold welding, has an excellent expansion coefficient and low bending strength compared to metal. This suggests that repairing a fuel tank using such materials is a temporary measure.

We recommend: What to do if the starter turns, but the car does not start?

Soldering

Compared to cold welding, fuel tank soldering is more resistant to mechanical stress and external factors. To eliminate a leak, prepare a patch 4-5 cm larger than the area of damage. Repair of plastic products is carried out on the outer part of the walls of the gas tank with a 250-watt soldering iron. When sealing, you need to select a patch from the same material. The type of plastic is indicated on each part. Most often, gas tanks are made of ABS, polypropylene or polyamide.

For high-quality adhesion, a substrate of fine reinforcing mesh made of metal or copper is required. The substrate is fused into the wall of the gas tank, evenly distributing liquid plastic over the entire surface of the defect until a new uniform coating appears. The procedure is performed quickly so that the plastic does not harden, otherwise sagging will form.

In metal containers, you can seal the hole with a thin metal or copper patch. You can heat the case using a blowtorch or iron. The patch is attached with low-melting solder along the entire perimeter using a 500-watt soldering iron, having previously treated the joints with soldering acid. After soldering, you need to let the body cool, then cover the patched area with bitumen mastic or paint. The coating will protect the patch from corrosion.

How to solder: basic rules

Metal tanks can be repaired using tin-lead soldering technology:

- Remove the container from the car, wash it, dismantle all plastic or rubber elements (a metal container without additional components is required for work).

- Level out the dents using a handy tool.

- Clean the surface around the damage with an abrasive tool (for example, sandpaper or a wire brush clamped in a drill chuck).

- Degrease the cleaned area with gasoline or acetone, and then apply soldering acid to the metal. It is necessary to pickle the steel sheet by repeatedly treating the surface with a reagent.

- Warm up the metal using an external heat source (for example, a working incandescent lamp with a power of 100-150 W, laid on the surface of the tank for 30-40 minutes). The ease of soldering depends on the quality of surface heating.

- Apply tin-lead solder to the cleaned surface using a soldering iron with a power of 75 W or more. Surfacing should be carried out in several passes, additionally heating the tank metal with a tool tip. Small cracks should be filled with solder, large holes (for example, from stones or resulting from corrosion) should be sealed with a piece of tin from a tin can. To improve solder spreading, it is recommended to use rosin.

- Wash the repaired area with alcohol or gasoline to remove traces of rosin, and then cover with primer and anti-corrosion material.

- Install the removed components in their original places, and then mount the tank on the car.

- Fill the tank with fuel and make sure it is leak-tight.

Repair using electric welding

Welding a fuel tank using a argon arc welding machine and tungsten electrodes is considered the most reliable method. It reliably connects non-ferrous metal with alloy steel. Most gas tanks are made of aluminum, so inverter welding is not suitable for repairs. The repair area is cleaned of oils and dirt. The patch is welded around the entire perimeter, trying to maintain a homogeneous gas environment. The seam is smooth and durable. After cooling, the repaired area is painted or covered with bitumen mastic.

Semi-automatic or argon arc welding

To restore the integrity of steel tanks, it is possible to seal cracks using a semi-automatic device with the supply of shielding gas to the welding zone. The container is pre-washed, filled with water, or a continuous supply of carbon dioxide is provided (to prevent the formation of explosive mixtures). The welding site is pre-cleaned of traces of dirt and oil; cleaning the seam from scale is not required.

It is recommended to apply a layer of primer and cover the tank with paint or mastic that reduces the rate of external corrosion (it is impossible to protect the tank from the effects of water from the inside).

Plastic gas tank repair

Repair using epoxy glue is the fastest. This is a temporary measure to fix a leak along the way. You can patch the hole using a plastic welder - an extruder. Welding tanks using this method requires certain experience and knowledge of technology. It is recommended to practice on a small piece of plastic before welding. To correctly calculate the productivity of an extruder, you need to know the size of the cross-section of the crack. Welding begins from the edge of the fracture, laying the molten plastic welding wire evenly across the entire width of the hole with a small margin. For thorough welding, movements are made across the crack, completely filling the hole. In order for the seam to lie evenly, it is necessary that the hot air gun and the shoe of the device are evenly heated.

Leak test

For testing, it is necessary to close all holes in the tank and create an excess pressure within 1.2-1.5 atm. The sealed tank does not allow air to pass through; the parameter is checked using a pressure gauge.

You can apply a soap solution to the outside of the tank; in case of leakage, bubbles will form on the surface.

In automobile facilities, tanks are tested by filling them with kerosene; the tank is considered sealed if there are no signs of leakage when the tank is kept filled for 10-12 hours.