The abundance of monitoring and control electronics still does not allow protecting modern injection engines from various malfunctions and problems. Periodically, the engine idles unstable, starts poorly and does not allow you to move away.

You should not always rely solely on electronics, sensors and the car's on-board computer. If, the next time you try to start the internal combustion engine, you clearly hear the fuel pump (pump) working, but the engine itself does not start, you need to check your ignition system to ensure its functionality.

Practice clearly shows that quite often the reason lies in the lack of a spark on the spark plugs. It is with their inspection that experienced motorists and repairmen recommend starting the inspection. Only when deciding to deal with the problem on your own, be extremely careful. There are several methods for checking spark, but each of them requires mandatory compliance with safety rules. Otherwise, you may suffer from an electric shock, as well as damage the car itself.

Bringing the car back to life

As for why a spark disappears, everything is probably very clear. Now, it would not be amiss to consider the order of her return. The reality is that in most cases, getting the spark back is a simple matter and just involves carefully checking the broken car. To be more precise, to normalize sparking it is required:

- Firstly, check the spark on the injector using the method described above, make sure that it has disappeared, and, at least indirectly, try to determine the cause of the malfunction;

- Next, it is enough to assess the current circumstances and act based on them. As typical situations, we suggest considering solutions to the following problems:

- the spark plug is wet, the presence and strength of the spark are unimportant, the carbon deposits are correct (brick color) - wipe the part and screw it back in;

- the spark plug is wet (not always) and the carbon deposits are incorrect (white or black) - clean, dry the part and try to start the engine, if there is no result, change the spark plug and deal with problems in the fuel system (cleaning the injector, checking the ECU, etc.);

- the spark plug is wet, there is no spark at all, the color of the soot is not important - we try to change the part, if there is no result, we check the ignition system and the operation of the injector.

In principle, in theory there are no particular difficulties in repairs of this kind. Despite this, it often causes difficulties in implementation for inexperienced motorists. To solve these, you need to act in the order described above, but if something doesn’t work out, it’s better to turn to professionals at a service station. This approach to repairs will not only save time, but also guarantee trouble-free operation of the car in the future.

Perhaps this concludes the most important information on today’s issue. We hope that the material presented was useful to you and provided answers to your questions. Good luck in operating and maintaining your car!

Troubleshooting

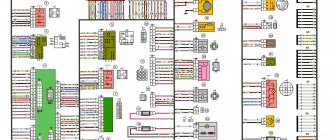

Troubleshooting in the ignition system of the VAZ “Six” should be carried out using the method of elimination, checking element by element sequentially. This is worth dwelling on in more detail.

Battery check

Since when starting a car, the power source is the battery, it is by checking this device that diagnostics should begin. Malfunctions with the battery appear when you try to start the engine. At this moment, the indicator lights on the instrument panel go out. The reason could be either poor contact on the terminals themselves, or simply a weak battery charge. Therefore, the condition of the terminals should be checked and, if you need to clean them, tighten the fastening. To prevent future oxidation, it is recommended to cover the contacts with a graphite coating. If the battery is discharged, it is charged using an appropriate device.

Spark plug wires

The next elements that require mandatory checking in case of problems with sparking are explosive wires. Upon external inspection, the cables should not show any damage (cracks, breaks, etc.). To assess whether a spark passes through the wire or not, you will need to remove the tip from the spark plug and place it near a ground (5–8 mm), for example, near the engine block, and crank the starter for a few seconds.

Signs that you need to check the spark plugs for a spark

An unscheduled check of spark plugs is always associated with incorrect engine operation. We carry out an inspection if we notice the following signs during vehicle operation:

- The engine starts to start after a long rotation of the starter or does not start at all.

- The engine idles intermittently, idles, and jerks while driving.

- Fuel consumption increases.

- The dynamics deteriorate, the engine loses power.

A negative consequence of a malfunctioning spark plug is the accumulation of the fuel mixture in the combustion chamber and its detonation. This will lead to deformation of the connecting rod, breakage of the pistons, crankshaft and other components of the power unit.

Diagnostic methods

In many vehicles, access to the ignition system components is free and not cluttered with third-party parts. Therefore, the driver can easily check the spark plugs at the initial stage to ensure they are working properly. The main thing is to maintain consistency and not to confuse them when unscrewing them from the cylinders. Checking the ignition module is always carried out with obligatory observance of the order in relation to the group of cylinders. Mixing will lead to incorrect final conclusions.

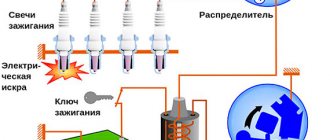

Initially, you should turn off the power unit, one by one disconnect the wires from the conductors themselves and the distributor. If the sound does not change when starting the engine, then there is a problem. Otherwise, continue your search further.

How to check spark on spark plugs?

The following engine parameters directly depend on the quality of the spark:

- fuel consumption;

- throttle response of the power unit;

- engine wear.

Timely checking of spark quality is necessary during vehicle operation.

Causes and signs of incorrect sparking

The main reasons for the violation of spark formation in gasoline engines are:

- spark plug wear;

- incorrect setting of the ignition angle;

- malfunction of the ignition system (coils, high-voltage wires, distributor, crankshaft and camshaft sensors);

- reducing compression in cylinders;

- suction in the air intake system;

- refueling with low-quality gasoline;

- incorrect operation of the gas distribution mechanism;

- malfunction in the engine control system.

The main signs indicating the need to check the spark:

- misfires;

- "triple" of the engine;

- reduction in throttle response of the power unit;

- changes in the color and composition of exhaust gases;

- engine error message on the dashboard.

In any of the above situations, you must first check the spark.

Control methods

There are several methods to check spark quality:

1. Visual control method. To carry it out, it is necessary to dismantle the spark plug. It is advisable to do this on a warm engine. After dismantling, the quality of the soot is visually assessed. If there is a light gray or light brown small deposit, sparking is probably occurring normally. A “wet” working area indicates a lack of spark. Large black deposits are a sign of incorrect ignition angle setting. At the same time, the size of the gap in the working area and the integrity of the structure are checked.

2. Checking spark formation without dismantling the spark plug using a practical method. This method is used by experienced professionals with special precautions. To do this, start the engine. Next, the high-voltage wires are disconnected and connected one by one. In the case of individual ignition coils, the connectors to them are disconnected. If after switching off the character of the engine operation has changed, then the spark plug is working. If the quality of the engine has not changed, most likely the device is inoperative.

3. Check by replacement method. With this method, adjacent candles are swapped. If the misfires are also “swapped”, the device does not work.

4. Parametric control. The high-voltage pulse on the spark plugs reaches 20 thousand volts. It is problematic to measure it directly with conventional measuring instruments. You can evaluate the quality of the pulse using a neon light bulb connected through a resistor.

5. Checking the spark in operating mode. To do this, use an additional candle, which is installed in place of the one being tested. The candle being tested is dismantled and connected to a high-voltage wire (individual coil). Establish reliable contact between the spark plug mass and the metal base of the engine. The engine is started. Control sparking visually. It is better to carry out such a check in the dark, taking maximum safety measures.

6. Computer diagnostics of modern cars allows you to determine misfires in specific cylinders.

Checking the spark

If the engine suddenly begins to misfire, that is, to run unevenly and twitch, and other signs of problems with the spark appear (power is lost, the color of the exhaust changes), then you need to check if there is a spark. The first step is to unscrew the spark plug and visually inspect it; a light gray or brownish coating indicates normal operation of this cylinder. If there is carbon deposits on the spark plug, it means there are problems with ignition - the spark plug will have to be replaced.

You can check whether there is a spark in the cylinder without unscrewing the spark plugs. To do this, it is necessary to pull off the caps of the high-voltage wires from the spark plugs one by one while the engine is running. By pulling off the cap, we turn off this cylinder from operation, the engine should start. If nothing happens, then we have found a problem cylinder in which there is no spark.

You can check the spark the old fashioned way. You need to unscrew the spark plug, put the cap from the high-voltage wire on it and bring it to the engine housing. In this case, the assistant must start the car. If a spark appears between the spark plug contact and the motor, then it is working properly.

With any method of ignition diagnostics, you need to be extremely careful not to receive an electric shock from high-voltage wires.

How to check the spark on a fuel-injected engine

One of the most important parts of your car's electrical system is the spark plugs. These parts ignite the fuel, and if the spark plugs stop working properly, the engine will experience certain problems. The spark plugs themselves do not break so often; most likely, other factors are to blame for the lack of a spark.

However, sometimes a candle that has already exhausted its service life cannot properly perform its working functions. Therefore, it is advisable for every driver to know how to check spark plugs on the road without special tools and diagnostic equipment.

The best way to check spark plugs is through timely maintenance and regular servicing of the machine.

The first symptoms of faulty spark plugs and lack of spark

The reasons for the failure of spark plugs in a car can be very different. But the symptoms are similar in most cases. The main indicator of the failure of one spark plug is that the engine begins to stall. When such an unpleasant aspect occurs, the power of the unit decreases, consumption increases, and the car shakes a little at idle. All this allows us to conclude that one of the cylinders is not working, in particular because there is no spark at the spark plug. The following symptoms of non-functioning spark plugs are also distinguished:

the car does not start, when you try to start the engine, the starter spins smoothly, there is no progress in the ignition; after starting, 2 or 3 cylinders work for some time, then the fourth one is connected - this is an indicator of the failure of the spark plug; the car constantly becomes difficult to start, the engine only starts on the third attempt; the car has lost power and responsiveness, pressing the gas pedal does not produce the desired effect; the car stalled during the trip, starting it is difficult or even impossible;

From time to time, during startup, strong pops are heard in the exhaust pipe - this is the fuel that has been pumped up but not burned.

When all the spark plugs do not work, this situation should alert the car owner. Most likely, the reason is not the spark plugs. But if one spark plug refuses to work, you should look at the spark plug itself, as well as at the wire that connects it to the coil. This will help you find out what exactly caused the problem in your car. And if testing sensors, switches and coils in the field is not an easy task, then testing spark plugs is quite possible.

How to check spark plugs without special equipment?

On the road, we often don't have any equipment to test spark plugs. Therefore, you have to make do with traditional methods to check all the subtleties of the car. In particular, in the case of candles, you can use one of the proven testing methods. First, you should unscrew the spark plug and take a closer look at it, obtaining information about its condition. If the spark plug is wet, it floods with gasoline and does not work. A dry spark plug means there is no fuel getting to it or everything is working properly. A black candle wick also indicates a problem. You can check for spark as follows:

unscrew the spark plug and put a high-voltage wire on it so that you can give a spark; grab the rubber part of the wire with your hand, but in no case grab the metal parts of the spark plug; place the spark plug wick at a distance of about 0.5 centimeters from the engine body - any metal parts; ask another person to turn the ignition key and try to start the engine for four seconds; if a spark appears and breaks through to the engine body, then everything with the spark plugs is in perfect order, you need to look for other problems;

if there is no spark, the spark plug does not work, and other not very pleasant problems are also possible.

If there is a spark, then the engine starting problem is related to the fuel system. If there is no spark, the culprit of your problems is the vehicle's electrical system. These will not necessarily be spark plugs, because the electrical system of a car contains quite a few different elements that can damage the spark plug assembly. You need to check everything to fully ensure that the equipment is working properly. By the way, the easiest way to check whether the spark plugs are working is to replace them with ones that are known to work.

What else could cause the spark plugs to not spark?

If there is no spark, many drivers confidently say that they need to change the spark plugs. But this is not always true. In particular, there are other modules that can affect spark production, so you need to check all the features of the vehicle's electrical system. If we are talking about the fact that the ignition system does not produce a spark, it is necessary to pay special attention to those modules that are responsible for this spark. Among them, you will have to check and suspect a malfunction of the following important machine modules:

high-voltage wires - often this element is the reason for the lack of a spark, the wire can pierce; ignition coils or distributor on old cars - frequent candidates for replacement and repair; switch - a part that rarely raises doubts about its operation; it breaks not so often, but very unexpectedly ;ignition switch - one of the contacts may move away and not give normal commands to the car engine;

an on-board computer that controls the actions of the vehicle's electrical system, including the ignition.

If one of these elements fails, the symptoms will also be similar to a simple spark plug failure. But replacing the spark plugs will not have any effect. If the switch or on-board computer breaks down, you will have to contact specialists and carry out quite expensive repairs. You cannot solve such problems on your own. It is also difficult to replace ignition coils in the field. However, this list of problems is not exhaustive.

Candles

There is another option, how you can check for the presence of a spark on the injector yourself by testing the spark plugs themselves. It happens that the ignition system distributor is in fully working condition, but for some reason a spark still does not appear on the spark plug itself.

But before you check the spark yourself, make sure that the fuel mixture is entering the injector and there are no problems with the air filter clogging.

Diagnosing sparks on candles is not a complicated or time-consuming procedure. You can even do it yourself, without outside help.

- First, check the current condition of the wires that go to the spark plugs from the distributor. If you notice insulation problems, there is probably a problem with the wiring;

- Then remove all the spark plugs with a special tool. Check their condition, assess the amount of accumulated carbon deposits. If there is one, it is recommended to clean it and get rid of dirt;

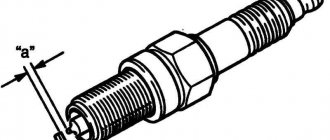

- Check the distance between the electrodes. Normally it is from 0.7 to 0.9 millimeters. If the distance is different, you can simply try to bend or bend the electrode to the desired value. But this is an old method that is advised to be abandoned;

- There is another option. It consists of replacing the spark plugs with new, better quality and more durable ones. Here, iridium elements perform well;

- Having dismantled all the candles, combine them into one row, connecting them using steel wire;

- One end of the wire remains long for further grounding to ground;

- Having secured it to ground, you need to turn the starter while watching the spark plugs;

- If a spark does not form at all, or it is dim, very weak, then the switch is probably out of order.

It also happens that sparks of varying intensity are formed. There may be the following reasons:

- the wires going to the spark plugs are damaged;

- the distributor runner is damaged or worn out;

- the wires are poorly connected to the spark plugs;

- There is damage in the spark plugs themselves.

As you can clearly see, there is nothing difficult in checking candles. This work is performed in 30-50 minutes in a garage without the use of any diagnostic stands, special measuring instruments or professional tools.

How to check the spark on a spark plug

Even modern cars with injection engines and an abundance of on-board electronics are not immune from periodic problems. Quite often there are interruptions in the engine idling, or difficulties in starting the engine are noted, regardless of the ambient temperature. If you hear the noise of the fuel pump when you try to start, the first thing you should do is check the functionality of the entire ignition system, without relying on the on-board computer and sensors.

First of all, as practice shows, you will need to check the spark plug spark, since its “disappearance” is the most common cause of poor starting and unstable engine operation. It is necessary to understand that when checking it yourself, it is important to take special care, since in addition to the possibility of receiving an extremely unpleasant electric shock, you can damage the ignition module or controller. Therefore, it is advisable to carry out the test using a special spark gap, which you can make yourself.

Conclusion

You can simplify the work with spark plugs by following a simple recommendation - change spark plugs according to schedule and service life. This is usually about 30 thousand km for gasoline internal combustion engines.

One of the methods for checking candles on video.

General recommendations for using candles.

When problems with spark plugs appear in cars, this immediately affects the normal operation of the engine, friction appears, and the engine stalls. You can find out whether the problem is really with the spark plugs by externally assessing their condition and checking whether there is a spark.

How to check spark on ignition coil

The ignition coil is not one of those units that constantly breaks down and causes other troubles, but in some cases problems are still noted. The most common cause of problems is winding damage. The subsequent breakdown of the insulation layer leads to a short circuit. The coil can also be damaged as a result of overloads caused by faulty spark plugs, or defects in the high-voltage wires themselves.

Before checking the spark on the ignition coil, it is advisable to drive the car into a dry garage. All work can be done independently, without the use of special equipment. The algorithm for such a check is standard.

- After cleaning the distributor cover from dirt, it is removed.

- By turning the crankshaft on the engine, it is necessary to achieve the closure of the distributor contacts.

- After turning on the ignition, the high-voltage wire coming from the distributor is brought to the ground of the vehicle. Particular attention should be paid to the distance - it should be 5 mm.

- To ensure the accuracy of the coil test, from time to time you will need to manually open the contacts of the distributor.

- You can say that the coil is working properly if a bright blue spark appears. If it is weak, uncertain, appears only periodically or is completely absent, the coil must be replaced, since its repair, as a rule, is simply impossible. When installing a new one, the polarity must be strictly observed, otherwise the new coil will also fail. At specialized service stations, coils are checked on a special stand, which allows testing the performance of the device in various operating modes. A very simple way to quickly check is shown in the video:

Ignition coil: how to understand that there is no spark in it?

Before you begin to understand this issue, it is important to understand exactly what this node actually is. In principle, its main purpose is to convert current from low to high voltage. Well, if this element has any problems, then it will be impossible to start the vehicle. However, this mechanism, in the presence of disturbances, has its own characteristic symptoms. You can recognize that there is no spark in the coil by the following signs:

- There was a decrease in engine power;

- There were problems starting up;

- Fuel consumption has increased sharply;

- Periodically there are interruptions at idle.

If the motorist has identified the problem, and it turns out to be related specifically to the coil, then the next step is to begin repairs. It is quite possible to solve this problem yourself, without resorting to the help of service center specialists. First, the driver needs to inspect the element for any possible violations. Next, if, for example, dirt is found on the coil, it will need to be removed with a dry cloth. It is also very important to pay attention to the wiring itself. There should be no accumulation of moisture and various breaks on it.

More details about checking the ignition coil for functionality will be described in this video:

Coil

In the case of the coil, it can be characterized as a fairly reliable and durable element of the ignition system. It rarely fails and causes trouble for the car owner. But sometimes problems appear and need to be fixed.

Most often, problems with the coil are caused by damage to the winding itself. If this happens, a breakdown occurs in the insulation, which can cause a short circuit that is dangerous for injection engines.

Another reason for damage to the coil is considered to be overload caused by malfunctioning spark plugs or damage to the high-voltage wiring (high-voltage wires).

Before you start checking the spark on the coil, be sure to make sure that the room where the diagnostic work is being carried out is dry. You can do the test yourself, and no special devices or professional equipment are required.

Diagnostics is carried out according to a standard scheme, which involves performing several sequential procedures:

- Thoroughly clean the distributor cover from accumulated dirt. Only after this can it be opened and removed;

- After turning the engine crankshaft, it is necessary to close the distributor contacts;

- The ignition is turned on;

- The high-voltage wire coming from the distributor is brought to the ground of the car. It is important to ensure a distance of 5 mm;

- To increase the accuracy of the test, it is periodically necessary to manually open the distributor contacts.

How to check spark strength on the ignition module

Most car owners understand that when the engine starts to stall or has trouble starting, the problem is often a lack of spark. Therefore, checking the spark on the injector is a manipulation that should not cause any difficulty for the driver, who often has to deal with the need for repairs in the field. Naturally, you should always have a set of several new, or simply working, candles with you.

Since the lack of a spark is the most common cause of the engine stalling or difficult to start, as well as unstable idling, checking the spark on the spark plugs is carried out by motorists first. In order not to turn out all the spark plugs at once, you can check them one by one - removing one by one from the cylinder head, putting caps on them with a wire from the coil and grounding each spark plug to ground. Rotating the starter should produce a nice, bright spark. If it is missing, you can replace the wire (it is advisable to carry a spare one with you) or use one that is known to be working.

When removing high-voltage wires from the module, it makes sense to number them first - this will avoid confusion in the future. Problems caused by the spark plug or wires become obvious in this way. If a spark does not appear on the spark plug, the problem lies in the module itself. In order to accurately determine this, the “replacement” method will help - the working module can be temporarily “borrowed” from another car of the same model. If replacement fixes the problem, you can safely go to the auto store for a new one.

Main symptoms

The malfunction of these elements can be determined by the nature of the car’s behavior. The main symptoms are difficult ignition, unstable engine operation, floating engine speed at idle. One of the signs of a malfunction is increased fuel consumption. It does not burn in the cylinder because there is no spark. At the same time, the car’s power decreases, since it runs on three (if we consider modern passenger cars) cylinders. Difficulty starting is also the cause of failed spark plugs. The spark may disappear or be completely absent. As a result, the crankshaft rotates, but the ignition power in the remaining cylinders is not enough for its normal operation. Moreover, this occurs even on a warm engine. Sometimes the lack of a spark in one of the cylinders provokes breakdown of the catalyst. The mixture that was prepared and fed into the combustion chamber does not ignite and enters the catalyst, where its elements are oxidized.

Checking the ignition coil for spark

To diagnose the performance of the coil, remove the wire from the distributor-breaker. Next, the test is carried out similarly to testing high-voltage wires, that is, the wire is brought to a metal surface and turned with a starter. The presence of a spark will indicate in this case a problem with the ignition distributor; if there is no spark, then the problem lies in the coil.

First you need to check the distributor contacts. These contacts may oxidize, insulation damage is also possible, and the rotor itself may be faulty. Detecting problems with the rotor allows you to eliminate the problem by replacing it. When checking the ignition coil, you should identify possible defects in the integrity of the winding, burnouts and other signs that a short circuit is occurring inside. If such signs are found, the coil should be replaced or the ignition coil should be repaired.

Let us add that the presence of a spark on the spark plugs does not mean that the car must start. This is especially true for injection engines, where the failure of certain sensors or ECUs can make it very difficult or completely impossible to start the power unit. In such cases, there is a spark, fuel is supplied, but the engine still does not start. The ignition switch also deserves special attention, since malfunctions can occur in this place.

Now let's take a closer look at ways to check the main elements of the ignition system. To do this, let's go back to the coil. As already mentioned, the most common cause of a malfunction is a damaged winding. Then an insulation breakdown occurs and a short circuit occurs. It is also important to understand that the coil can fail due to overload. Such increased loads occur as a result of problematic spark plugs or spark plug wires. For diagnosis you should:

- put the car in a dry parking, repair or other box. You can also use the garage. The main thing is that the humidity is not too high;

- Next, you will need to clean the distributor cover from dirt, after which the specified cover must be removed;

- then you need to turn the engine crankshaft so that the distributor contacts are closed;

- Now you can turn on the ignition and bring the high-voltage wire of the distributor 3-7 mm to ground;

After evaluating the spark, you can decide whether the ignition coil needs to be replaced. Please note that repairing this element is often impractical. Also, when installing a new spare part, you should strictly adhere to the required polarity. If this is not done, then the new part will quickly become unusable after unqualified installation. Please note that car service centers use a special stand to check coils. Such equipment allows you to check the coil taking into account various operating modes.

To check the spark on the spark plugs if the distributor is working properly and there are no problems with the condition of the high-voltage wires, you need to unscrew the spark plugs from the engine. In addition to the contacts, you should look at carbon deposits, the degree of oiling of the electrodes, etc. For normal sparking, contamination must be cleaned. You should also check the gap between the electrodes, which is usually between 0.7 and 0.9 mm. If the gap is broken, then you can carefully bend the side electrode. This method is a temporary measure, but in some cases it allows you to drive from several tens to hundreds of kilometers without tripping the engine in case of problems with the spark plugs.

We also add that there are special pistol devices for checking spark plugs. Typically, such solutions are available from spark plug sellers in car dealerships or automotive markets. If there is such a possibility, then the spark plugs can be checked on similar equipment.

Verification methods

If there is no spark, you can use several self-diagnosis methods. The procedures are performed as follows:

- checking for weight;

- multimeter;

- arrester (tester with piezoelectric element).

In the case of the first method, which involves checking for weight, it is strongly recommended to use it exclusively on carburetor types of internal combustion engines. You need to take the spark plug and carefully bring it to any suitable metal component of the engine. Usually brought to the cylinder block. At the same time, the assistant should try to start the engine by turning the key in the lock. This allows you to determine which spark plug is being supplied.

But it is strongly not recommended to use this method on injection engines, since there is a high risk of damaging the electrics and expensive electronics.

If you use a multimeter, you can check the spark plugs themselves. There is nothing complicated in diagnostics, but there are no threats to the ECU. The check is carried out according to the same principle as in the first case.

Another option is to use a spark gap. This method is also suitable for carburetor types of engines. Such a tester allows you to find out exactly where in the ignition system of your car such problems have arisen.

When there is no spark in all working cylinders, the culprit is the controller, the coil, or the ignition module itself, as well as the central electrical wire. Here you should start by checking the important fuses. Next, the mass and current condition of the high-voltage wires are checked.

If there is no spark on the coil itself, then you need to check the central power wire. If breakdowns, insulation failure and other damage are detected there, they should be immediately eliminated by replacement.

Don't forget to check the spark plugs themselves. This is important to do in a situation where it has been established that the spark definitely reaches them, but still does not form. It is also important to take into account what color the spark is. Normally it is white with a slight blue tint. If there is a weak spark, you need to check the contacts.

The most universal tip is to always have a set of spare candles on hand. They can come in handy at any time.

It is necessary to separately consider the procedures for checking the spark on the coil, the spark plugs themselves, and the module used in the ignition system.

Checking the Low Voltage Circuit Condition

This is also not a superfluous event when it comes to the absence of a spark on the candles. To carry out such a diagnosis, you will need a test lamp. Moreover, choose a device with a power of 2-3 W and a voltage of 12 V.

One contact from the control unit is connected to the low voltage contact of your distributor, and the second goes directly to ground. Now you need to close the distributor contacts and start the ignition. If there are no problems in the circuit, then at the moment the contact closes, the lamp must go out. In this case, it lights up only when the contacts open.

If, after opening the distributor contacts, nothing happened, that is, the control lamp did not light up, the cause of the malfunction most likely lies in the breakdown of the primary winding of the coil, or in the low voltage wires.

There are situations when the control lamp shines constantly during diagnostics, without interruption, regardless of the opening or closing of the contacts. Here you should consider one of several potential reasons for this behavior of the warning light:

- the contacts on the distributor have oxidized, which need to be frequented and, if possible, lubricated with graphite lubricant;

- the wires that connect the movable disk of the distributor and its body are damaged;

- other wiring located between the distributor terminal and the lever was damaged.

The test should always be carried out in stages, starting from the most likely faults, and ending with those that are much less likely to cause a lack of spark.

Do not rush to make the worst and most unpleasant diagnosis for your ignition system. It often happens that the reason lies in banal carbon deposits on spark plugs or blown fuses.

High voltage wires

After the spark plugs have been checked and it turns out that they are not the problem, you need to test to see if anything has happened to the high-voltage wires. Diagnosis is carried out in four simple steps.

- If there is no spark on only one cylinder, swap the wires

- Let's check if the problem is resolved after this action

- If a spark appears on a cylinder, but it disappears on another cylinder, then the problem is definitely in the wire.

- The faulty wire must be replaced with a new one.

Likewise, it would not hurt to check whether the central wire that supplies current to the ignition coil is working properly. Sometimes a spark appears after this wire is pressed harder against the transformer, which is located on the distributor cover.

Useful tips

Experienced car enthusiasts are well aware that spark plugs can fail at the most inopportune moment. For this reason, it is recommended to carry a spare set with you. The same can be said about the spark plug wires.

When working on the ignition system, extreme caution should be exercised as you may receive a severe electric shock. Insulated tools must be used.

Since spark plugs fail more often than other elements of the ignition system, checking for a spark always begins with them. Diagnostics can be done one by one. The procedure is carried out by unscrewing the spark plug from the cylinder head, then putting a cap and a wire from the coil on the spark plug, after which it is grounded to ground. The main indicator when checking while the starter is rotating is the spark itself and its quality.

When removing the spark plug wires from the ignition module, it is advisable to mark each wire. This will allow you to check and subsequently connect in a strictly defined order without the risk of mixing up the wires.

Signs of malfunction and checking injection nozzles without dismantling. Diagnostics of injector power supply, performance analysis. Tips and tricks.

Why does the starter turn normally, but the engine does not catch and does not start? Main causes of malfunction, checking fuel supply and ignition systems. Adviсe.

How to check engine performance using spark plugs. The main signs of engine malfunctions: the appearance of black, gray, red and white carbon deposits on the spark plugs.

Signs of malfunction or breakdown of the high-voltage spark plug wire of the ignition system. How to check car armored wires with your own hands.

Engine trouble: symptoms. Why does tripping occur and how to find the reason why the motor starts to trip. Checking power, ignition, compression, etc.

What does the color of carbon deposits on a spark plug indicate, and why does carbon deposits of one color or another form? How to clean spark plugs from carbon deposits with your own hands, tips.

When the spark is lost, you will, of course, never start the car, and in such a situation, first of all, you need to check the ignition system.

The vehicle's ignition system plays a key role in its operation. If in case of many other malfunctions the car can be taken under its own power to the service station, then in case of problems with the ignition it is unlikely that it will be possible to start the engine at all.

Diagnostics using a special gun

This is a rather interesting technique. And it is often used for home diagnostics. This requires a special gun to check the spark plugs. This device has been used in global automotive practice for quite a long time. But domestic car enthusiasts began to widely use it relatively recently.

This technique involves testing under special pressure. Algorithm for this operation:

- The candle is placed in a special slot in the gun. Then the cap is attached to it.

- After securely fixing the spark plug, you should pull the trigger of such a pistol. After pressing, the greatest concentration is required.

- If after this pressing a spark is formed and a light appears on the gun itself, it means that the part being tested is operational.

The indicated technique has not gained great popularity among Russian car enthusiasts, since it does not guarantee absolute confidence in the good working conditions of the spark plug. In addition, the test is carried out under pressure. And in a pistol it differs significantly from the pressure in automotive technology. But thanks to this technique, the driver can have absolutely no doubt that the spark plug will break. Moreover, if this fact was determined during the verification process.

Typical causes of spark loss

Depending on the type of powertrain, there are several factors that can cause the spark plugs to fail to spark. In most cases the reasons are as follows:

- Low battery.

- Damage or failure of spark plugs. They can also be filled with gasoline or oil.

- Malfunction of the module, switch or ignition coil.

- Poor contact or damage to the insulating layer of high-voltage wires.

- Malfunction of the crankshaft position sensor (CPS).

- Malfunctions in the operation of the distributor.

- Problems in the low voltage circuit.

- Poor ground contact.

- Malfunctions in the operation of the engine ECU (electronic control unit).

Implications in practice: catalyst

Misfires cause premature failure of the catalyst. The low quality of materials used in the production of the insulator and resistive filler leads to accelerated degradation of the spark plug. Even if its characteristics meet the manufacturer’s requirements at the beginning of operation, over time, the spark energy may not be enough to reliably ignite the air-fuel mixture, resulting in misfires and an increase in the content of unburned fuel in the exhaust gases. Part of the air-fuel mixture burns out in the exhaust manifold and catalyst, which leads to an increase in temperature inside these elements. Overheating leads to failure of the catalytic converter and oxygen sensors installed in the exhaust system.

External signs and corresponding malfunctions of the contactless ignition system

| Signs | Malfunctions |

|

|

|

|

Let's sum it up

Spark plugs play a vital role in the performance of a vehicle. If at least one spark plug fails and does not produce a spark, accordingly, one of the cylinders will not work, the car will have increased fuel consumption and will be less dynamic. Finding the reason for the disappearance of the spark is a very difficult task, since several units may be “to blame” for this. However, for normal functioning this is simply necessary.

Good day everyone) This is the situation: after a short circuit (I removed the voltage regulator because it burned out and the wire touched the body), the spark on the VAZ 2106 disappeared. The ignition is electronic. The ignition coil is working, I checked it on another car. No current flows to the coil. I checked the fuses. What could be the reasons? Maybe the switch, since the red-blue wire that goes from the switch to the coil has melted? The photo shows a melted wire, replaced it.

Other breakdowns and their elimination

If the engine does not start when the ignition is turned on, then, first of all, you need to turn off the ignition system and try to start the engine again after a few seconds. If all this does not give any results, perhaps it makes sense to check the correct installation of the spark plugs - it could very well turn out to be incorrect. If all these actions do not produce any results, then the entire system will have to be thoroughly checked. It may also turn out that the cause of the malfunction is in the distributor cap. It must be carefully dismantled and both sides thoroughly checked. In addition, it is necessary to examine the graphite coal - it could well have been worn off. If the cover is worn out, when its surface is cracked or covered with soot, it is better to replace the cover; it cannot be repaired. The same should be done with graphite coal. Attention! All wiring must be well fixed, because if it comes into contact with other components, its insulation will wear out very quickly. A short circuit can occur due to working fluids getting into the wiring. Therefore, when diagnosing the condition of the ignition system, you should pay special attention to the condition of the wiring. If you find moisture on them, you should definitely wipe it off, because this may well be the reason for poor engine starting. If scratches or other mechanical damage are found on the wiring, it must be replaced. If this is not possible yet, you should wrap problem areas with electrical tape. The ignition coil is checked with an ohmmeter. The resistance must be within the specified range, otherwise the coil will have to be replaced. It is highly not recommended to repair the ignition switch on your own. You can only check the contacts and clean them if oxidation is detected.

It is also worth thinking about the switch, because breakdowns in this unit are quite often the cause of incorrect operation of the ignition coils. The switch is checked with a portable lamp. This is done as follows: the wire that comes from the switch terminal is disconnected from the coil, and then its end is connected to the carrier. The other carrying wire is connected to the coil terminal. Then the ignition is turned on and the car starts using the starter. To do this, the crankshaft will have to be rotated a couple of times. If the light in the carrier lights up continuously, it means that the switch is indeed faulty. Then the problem can only be solved by replacing it. It may also happen that all the wiring is working properly, but the pulses still do not arrive at the switch. Most likely, the contactless sensor is faulty here. It is checked with a voltmeter. This is done as follows: with the ignition off, they begin to carefully turn the crankshaft. In this case, you need to monitor the devices. If the sensor is working properly, then their readings will change sharply. If this does not happen, it can be stated that the sensor is faulty, then it must be replaced. Spark plugs are checked with a “spark”. To do this, you need to remove the wire from the spark plug and bring its end to the ground at a distance of 5-6 mm. After this, you should rotate the crankshaft and look at the gap. If a spark is visible, it means that the system itself is working, and all that remains is to change or clean the spark plugs. During this procedure, it will not be possible to do without an assistant who will have to turn the crankshaft. In this way, the distribution system covers can also be checked. The central wire is disconnected from it, and its end is brought to ground, leaving a gap of 5-6 mm. In this case, you also need to rotate the crankshaft. When a strong spark appears, it can be stated that the circuit is operating normally, and the problem may be in the cover or rotor. It is no longer possible to repair the rotor; it can only be replaced. But if the resistor burns out, the problem can be completely solved with a piece of wire. You can use aluminum and copper wire. A jumper is made from it, which is inserted between the contacts of the router. Of course, this measure is temporary, and you should resort to it only when it is not possible to resolve the issue by installing a full-fledged resistor. For example, this can happen while driving. Do not forget also that a piece of inserted wire causes radio interference, which can spread not only in the cabin, but also near it. The reason for the lack of a spark may also be poor contact of the breaker. Poor contact is quite often the cause of cylinder failure. When checking the contacts, you need to ensure that they are in close contact with each other. Any contamination of the contacts with rust or carbon deposits will certainly reduce the tangent area, and this will certainly cause a complete loss of contact. Sometimes the contacts need to be cleaned non-aggressively. A needle file is used for this. You can clean the contacts with a rag. After cleaning the contacts, rotate the crankshaft until they are completely closed. If any contact does not fit tightly, you need to bend its stand. As you can see, a variety of breakdowns in the ignition system can be eliminated on your own. But if you do not feel completely confident in yourself, then it is better to seek help from specialists who will do everything professionally. Video about checking the ignition system:

Post Views: 1,136

Can it be cleaned?

If there is a characteristic carbon deposit on the electrode and base, this is a sign of engine malfunction. If you simply clean the spark plug and put it back, the carbon deposits will reappear. The color of deposits can indicate many things. This is an incorrectly prepared mixture, the presence of oil in the combustion chamber, etc. By the way, lubricant gets into the cylinder due to existing scuffs or a worn oil scraper ring. Pay attention to this.