Among the many technical devices that help improve the efficiency of a car, an ordinary thermal tape for the muffler can play a significant role. It turns out that with its help you can significantly increase engine power.

How to properly use thermal tape for a muffler

How to wrap a muffler with thermal tape

If you decide that the benefits of thermal tape outweigh the possible negative consequences, follow these rules when wrapping:

- Wet the thermal tape thoroughly before starting work so that it is more securely attached to the metal;

- Wind evenly so that there is an equal number of layers of thermal tape throughout the entire exhaust manifold (or the entire muffler, depending on the chosen winding tactics);

- Use metal clamps to secure the ribbon through a certain number of skeins, this will allow the ribbon to hold tighter.

Remember that you perform any such experiments with a car that are not provided for in the operating instructions at your own peril and risk.

Winding at home

In order for the winding of thermal tape to be as successful as possible, the master must take into account the following basic nuances in practice:

- the width of the source material should not exceed 50 mm, otherwise the processing of the muffler will become more difficult;

- the body of the workpiece must be completely covered with the insulating element;

- To cover the collector, you should first use a special anti-corrosion paint;

- Before direct winding, the thermal tape is wetted under water, and it must remain submerged for several hours.

When winding turns, the master must ensure that the pitch of the surface being processed is even and identical everywhere. And in order to secure the thermal tape more securely to the base, peculiar metal clamps are attached through a certain number of turns.

When treating the muffler with a similar component, the driver must also take into account that the pressure inside the system will become uneven, and this over time can lead to burning of the exhaust valves. And the thermal tape itself perfectly accumulates moisture and various dirt.

But in any case, treating the muffler with thermal tape is an effective step from a practical point of view, which in many cases is completely justified. And if a similar procedure was carried out by a person who knows the intricacies of the technological process well, then its implementation will certainly benefit the entire vehicle.

How to wrap with your own hands quickly and without mistakes

A collector in a car is

an important rule - winding is dense and uniform in width. Pipes must be cleaned and degreased before treatment.

To perform quality work, adhere to some rules:

- individual circles need to be fixed with metal clamps, and at the end proceed in the same way;

- before winding, it is necessary to treat it with corrosion- and high-temperature-resistant paint;

- buy tape from well-known manufacturers, the options presented on ALI are of too low quality;

- the optimal width is 4-5 cm, narrower or wider types will be more difficult to wind;

- Before starting the main steps, soak the tape in water for 1-2 hours.

Usually only the exhaust manifold is wrapped, but if desired, the entire muffler can be treated.

How to wind thermal tape?

Features of boring cylinder head channels with your own hands

After selecting the thermal tape, you need to wind it around the collector. First of all, degrease the surface of the collector and paint it with a layer of heat-resistant paint that will protect it from corrosion. While the paint is drying, soak the tape in water for 3 hours. This action will allow the tape to lie tighter and give it additional stretch. Then wrap the tape over the commutator in two layers.

Speaking of layers. Usually the tape is wound in one or two layers, but this does not prohibit making another layer, since the more layers, the better the thermal insulation properties. Therefore, the choice of layers is yours. However, two layers are the best option and are applicable in any case.

When winding, use only a single strip, as pieces of tape will only reduce its effectiveness.

Once the commutator is completely rewound, press the tape to it using a metal clamp. When fastening, it is also possible to use thick wire.

That's all. This completes the thermal insulation of the collector. As you can see, this is not a complicated process, however, it should be approached as responsibly as possible, since poorly wound tape usually does not last long.

Why do you need to wrap?

What is a downpipe and why is it needed?

Those skeptics who doubt the ability of such thermal tape to increase engine power by several horsepower should give several of the most common arguments regarding what other significant advantages thermal tape provides for the muffler, and why it may be needed:

- This thermal tape helps eliminate the ringing, sometimes rattling sound in the muffler during the exhaust, which is observed quite often in practice. “Cushioning” is similar to how if a rubber lining was placed at the bottom of a metal dish - now when you throw a nut there, sound will be absorbed;

- Thermal tape helps reduce the temperature under the engine hood, which helps extend the life of many parts, primarily those made of plastic, as well as the car battery;

- The main advantage of thermal tape is increased motor power. It can be simply explained using physical laws. The fact is that the exhaust system, by its structure, contributes to the braking of exhaust gases. Therefore, the faster they are retracted, the easier it is for the engine to work, so that it does not spend additional significant effort “pushing” them through the muffler pipe. Having served their purpose, the gases enter the cold pipe of the exhaust manifold, immediately cooling and compressing, thereby reducing their exit speed. Thermal tape on the muffler prevents them from cooling quickly, that is, it becomes a constant assistant to the engine. Due to the fact that he does not have to spend extra effort on running them, the efficiency of the motor power increases, and this is the main argument in favor of why thermal tape is needed.

Advantages and disadvantages of processing

It must be understood that if this method provided only “advantages” without any risks, designers would have long ago put it on the assembly line for car production. Since this is not the case, it is necessary to directly note certain “disadvantages” of the innovation. The main thing is that it can cause some problems for the vehicle's exhaust system. Since after the winding the pressure will no longer be one-sided (only towards the muffler), the exhaust valves may come under a certain influence of gases, which increases the likelihood of them burning and premature failure. In addition, thermal tape can become a source of accumulation of moisture, salt, dirt and other foreign mixtures that are unsafe for the metal, and this is a reason for unwanted corrosion to begin on its surface. The third point is financial. We are talking about the considerable price of good quality thermal tape, which sometimes reaches several thousand rubles for 10 linear meters of tape.

Therefore, before you start wrapping, you need to carefully weigh all the pros and cons, and figure out whether there will be a tangible benefit from this or not. Experienced drivers understand perfectly well that an increase in power of 10 percent or more, as is sometimes heard, cannot be achieved based on their elementary physical laws. At best, it will be 3 - 4%.

How to paint if necessary?

If you were unable to find thermal tape for a motorcycle muffler of a suitable color, and you wrapped the exhaust system with the most common (by the way, the cheapest) white stripe, then you can paint it. For this purpose, special silicone heat-resistant paints are used. They are usually sold in 400 ml aerosol cans.

One container will be enough. Price: 420-450 rubles per piece. As a result, thanks to savings on the cost of tape, the overall budget for restoration work will not be affected. In addition, such a coating will create an additional protective layer against moisture, gasoline and oil.

In order to ensure excellent conditions for the functioning of the car, it may be necessary to use thermal tape, which sometimes has to be wound around the muffler. With its help, the driver is able to significantly increase the engine power of the car. This article provides brief instructions on how to use such material, as well as the procedure for its practical use.

Advantages of winding the muffler with thermal tape

The idea of using thermal tape to wrap a car muffler came to drivers for a reason. Basic knowledge of physics is enough to understand how, according to the promoters of this idea, it will be possible to increase motor power by winding tape:

- Since the thermal tape is resistant to high temperatures and retains heat, it reduces the cooling rate of the exhaust manifold through which exhaust gases pass;

- This leads to the fact that the engine has to spend less effort on “pushing” the exhaust gases, since they exit through a warm pipe, that is, they avoid the process of cooling and compression;

- By reducing the effort to release exhaust gases, engine power increases.

This theory is confirmed in practice. Enthusiasts measured the effectiveness of wrapping the muffler with thermal tape to determine whether the engine's power actually increased. There is an increase, but it is at a level of 3-4%; you should not believe information on automobile forums that talk about increasing engine power by up to 10%.

It is worth noting that increased power is not the only advantage that winding the muffler with thermal tape provides. Besides:

- The presence of thermal tape on the muffler reduces the temperature under the hood, which has a beneficial effect on plastic elements;

- Thermal tape can help if the driver's muffler is loose, causing rattling and ringing.

Perhaps these are the main advantages that thermal tape on the exhaust manifold provides.

Adding power

The power here is in the form of an error, namely you can count on +3+4% (maximum). Of course, if you have a properly tuned exhaust + install this tape, then it will be quite good, plus the sound will be deep.

BUT you shouldn’t hope that the increase will be +5+10%; I’ll emphasize once again - as practice shows, the MAXIMUM is 3 percent (I admit 4, no more)

If you just installed the SPIDER and wrapped it with this thermoelement (did not remove the catalyst and did not replace the resonators), then the increase may not be noticeable at all.

Now we are watching the video version.

This is where I end, I think my article was useful and interesting to you. Subscribe to our channel and website, there will be many more useful articles and videos.

( 20 votes, average: 3.85 out of 5)

Disadvantages of wrapping the muffler with thermal tape

Naturally, this method of increasing engine power is not ideal, otherwise all cars from the factory would be delivered with a muffler wrapped in thermal tape. There are disadvantages that cannot be ignored if you decide to use this method to increase engine power:

- Possibility of damage to exhaust valves. Since the outlet will no longer have one-way pressure towards the muffler, there will be a risk of negative impact on the exhaust valves. In particular, they can quickly fail due to burnout;

- Possibility of corrosion. Thermal tape is still a fabric on which moisture settles. The presence of moisture on the fabric in direct constant contact with the metal of the muffler can lead to the formation of corrosion.

Perhaps these are the main negative aspects of this decision.

Exhaust repair materials – muffler sealant, thermal tape, cement

Many drivers, if there are problems with the operation of the exhaust system, do not think about repairing one or another part, but change it entirely. Sometimes this approach pays off, but most often it leads to unjustified costs.

If, however, you replace it with a secondary production part, you will have to change it every three to four years, although the same sealant for the muffler could easily save the situation.

Damage to the exhaust system can occur for several reasons:

- mechanical damage;

- wear of one of the elements;

- burnout;

- temperature difference (water entering a heated element);

- poor quality previous repairs.

In order to solve this or that problem, there are materials such as thermal tape for the muffler, sealant or special cement. Let's look at them separately.

When is muffler tape used?

Muffler repair. Part 1

The entire exhaust system consists of tanks and pipes. Tanks are more susceptible to burnout, since condensation accumulates in them, gases swirl, and the thickness of the metal is lower than in pipes. But there are situations when the pipes themselves are damaged. This is usually the result of an impact - a stone flying out from under a wheel, hitting a curb, or falling into a hole.

Sometimes it happens that during rain, splashes from under the wheels fall on the pipeline (usually on the exhaust pipe, if it is not protected) and due to temperature changes it cracks. The ideal option is to weld the damaged area, but this is not always possible. It is for such cases that thermal tape is intended.

It can be wrapped around the damaged area and prevent exhaust gases from leaking through. The only drawback of this material is that the thermal tape is unable to impart rigidity, so within some time the damaged pipe will break.

Muffler sealant – repair or service?

Muffler repair. Part 2 Many people consider sealant paste to be a kind of panacea for exhaust damage. It's actually just a substance that is used as an extra layer of protection for connections. The sealant is applied to clamping rings, rigid connections and other places where different elements of the exhaust system are joined. It can be used if the muffler gasket was reinstalled or if non-standard sized connectors were used.

But there is one place where sealant can really help. Sometimes the flanges by which two exhaust elements are connected bend under the influence of temperature changes and not a single gasket or sealing ring is able to ensure a high-quality connection. In such cases, it is necessary to coat the joint with sealant; over time, it becomes coked and ensures a high-quality connection.

How to “treat” small cracks and breaks in the exhaust?

Often, gaps appear in the rolling or welding seams, which cause extraneous sounds. The best option for blocking them is muffler cement. This material does not fade, it can be applied as much as you like, it only gains strength when exposed to high temperatures.

The only “but” is that it is advisable to use cement only when the hole is small and the muffler part or element retains its rigidity. If you use it to seal a crack, the effect will be zero - any pothole on the road and the crack will open again. For such damage, thermal tape is best suited - it covers a large area.

It is advisable to use cement only in places where there are no kinks, or where they are compensated, for example, using a spring-loaded connection or a vibration compensator. Another point worth considering: if a crack appears at the connection between the tank and the pipe, no amount of cement or other materials will save it. In any case, the inside of the tank is very worn out and the entire exhaust element will have to be replaced.

In essence, all the materials considered have one drawback - they are not universal. There are cases of exhaust damage that require professional intervention. On the other hand, when it is not possible to get to a service station right away, and the question arises of how to seal the muffler, such materials are simply irreplaceable. In some cases they can be used as a temporary solution, and in other cases as the most permanent solution.

What is bandage tape for?

Pros and cons of Lada Vesta

Repairing a muffler with bandage tape is a temporary, therapeutic measure that does not replace a full repair or replacement. Using high-temperature tape (also called scotch tape) can help an exhaust system that has worn out over time. Often the muffler, resonator, and pipes—connecting and exhaust—fail. These parts are made of thin steel, which is susceptible to corrosion, which causes holes, cracks, and breaks to appear.

Many car owners are not ready to invest large sums in a full repair of the exhaust system, so they use bandage tape. This is an excellent alternative to welding.

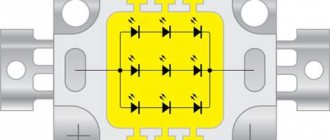

What is thermal tape

To put it simply, thermal tape is a dense fabric that is heat resistant. It retains its properties at temperatures up to 1400 degrees Celsius.

Please note: Initially, thermal tape was used in the construction industry. But due to the highly “chemical” composition and the established harmfulness to humans from constant interaction with it and inhalation of its vapors while working at high temperatures, most countries abandoned it in the construction industry.. Thermal tape, which was used in the construction industry, is not entirely identical to the one that is now sold to motorists

For cars, thermal tape is most often made from silica threads, which makes it less harmful to the environment

Thermal tape that was used in the construction industry is not entirely identical to that which is now sold to motorists. For cars, thermal tape is most often made from silica threads, which makes it less harmful to the environment.

You can now buy thermal tape for the muffler (exhaust manifold) in specialized automotive stores. The price for it varies from 700 rubles to 1500 rubles for 10 meters. Typically, 10 meters in length of standard thermal tape with a width of about 5 cm is enough to wind the muffler.

Which method to choose

So, as it became known earlier, there are three main technologies for repairing a muffler without welding, and you can choose one among them only if you know the operating features of each:

- Cold welding. This is a simple and reliable way to repair the exhaust system. It does not require any special skills and ensures the strength of the connection, which is why it is so popular among car enthusiasts. The main thing is to choose the right composition, and everything else will not cause difficulties.

- Bandages. Most often used for parts that can be wrapped with them. For exhaust pipes, for example. They have a ceramic base and are also impregnated with compounds that can withstand high temperatures, up to 1000 degrees Celsius.

- Sealants. Not durable, but for minor damage, especially in seams - indispensable

If the damage is significant, then only replacing parts will help. This is the best way out of the situation.

It happens that a strange, unusually loud hum suddenly comes from under the car. And then even an ignorant driver understands that there is a problem with the jammer! Most often, burnouts occur; elements of this assembly are less likely to tear apart from each other.

But, fortunately, most breakdowns can be eliminated by repairing the muffler yourself. The main thing is to understand which of the following reasons led to the malfunction:

- hitting an obstacle that damaged the muffling element;

- corrosion, burnout of the unit due to constant exposure to harmful substances in exhaust gases, as well as their heat;

- constant strong exhaust pressure;

- large changes in ambient temperature.

Read also: What is a regular hexagon

If such a nuisance occurs, you should not postpone work on repairing such an important assembly unit, so as not to deafen those around you and yourself with the disgusting noise. In addition, the unit may simply fall apart

Next, we’ll look at how to repair a muffler with your own hands using the example of different cars.

Thermal tape for the exhaust manifold - how to use it correctly?

In order not to bring your car to such a critical state, you need to think in advance about how to wrap the exhaust manifold. In principle, there are not so many options; you just need to choose the right thermal tape. They differ in composition, color, manufacturers and operating temperature, the latter can range from one to two thousand degrees.

Next we proceed according to the following scheme. First, degrease the surface of the collector and cover it with heat-resistant paint. This creates additional protection against corrosion. After the paint layer has completely dried, take the selected tape and put it in water for at least 2 hours. This measure is necessary so that the wet tape fits more tightly and stretches better. Now the only thing left is to wrap the thermal insulation material around the part. It is better to make two layers overlapping, and it is desirable that the strip of tape is whole and not in pieces, this will increase its effectiveness.

Home →

Practical advice → Selection of spare parts →

Thermal insulation

Showing all 9 elements

Sorting

By price

Length

- 5000 (2)

- 10000 (1)

Filler for muffler, flame arrester ceramic 1200C° 1kg

Thermo Tec 11022 thermal tape White 2 in. x 50 ft.

Thermo Tec 11022 thermal tape Black 2 in. x 50 ft.

Thermo Tec 11031 thermal tape Copper 1 in. x 50 ft.

Ceramic thermal tape for exhaust manifold 1200C° 5m

Thermal tape for exhaust manifold ceramic 1200C° 10m

ThermoTape reflective thermal film for intake components 5m.

Heat-resistant paint Rust-Oleum Automotive 1093 C°.

Universal tie clamp Stainless steel

How to wrap it with your own hands

To wrap the tape yourself, you must follow the sequence:

- Prepare the surface thoroughly: clean, degrease and apply heat-resistant paint against rust.

- Select application method: dry or wet.

- For the wet method, immerse the tape in water for a couple of hours. With this method, the material will lie more densely and acquire additional stretch.

- Wind with an overlap of 10 mm. It is wrapped in two covers, three are allowed.

- Metal clamps or thick wire are used to secure the winding.

- It is recommended to also apply a layer of thermal paint to the installed material.

We recommend watching the video instructions:

What is thermal tape for a muffler?

It came into use thanks to the construction industry. In it, and then in other industries, dense asbestos fabric with colossal heat-resistant characteristics was widely used. So, she was able to easily withstand temperatures up to 1500 degrees Celsius! This fabric became widespread, but then the process of its use began to noticeably slow down and fell to a minimum due to its obvious harmfulness to humans and their environment.

However, it is produced in a different way, using different silicon compounds (for example, silica filaments), original LR technology and other modern know-how. Despite a fundamentally different technological approach to their production, they have the same excellent heat-resistant properties and reliability. Ordinary thermal tape, widely used today in the car industry, is a strip approximately 5 cm wide of a thick black color, similar to graphite.

Content

- Why wrap?

- How to wrap it correctly?

- Flaws

- Adding power

This material came to the automotive industry from construction. It was the builders who began to primarily use it for their needs. Originally it was asbestos tape

, which could withstand heating up to

100-150°C

.

At the moment, asbestos is not used for the production of tapes, as it is harmful to humans. But it is worth remembering that some cheap Chinese thermal tapes can be made using asbestos. Manufacturers of thermal tapes now, in most cases, use silica filaments or other types of graphite as a base.

Some manufacturers claim to produce the material by sprinkling molten silicon onto preformed filaments. All the described options can withstand heat well and are also quite durable. When choosing, look at the color of the ribbon; it should be black. If you run your hand over the tape, a black mark will remain on it, like graphite.

Exhaust system coating options

There are two main methods for solving this problem:

- Thermal insulation tape. The use of thermal tape, which is wrapped around the exhaust manifold and other elements of the exhaust system. During wrapping, it is necessary to maintain the tightness of the exhaust pipe and slightly overlap the previous layer with each turn. Small gaps do not affect the overall effectiveness of this tuning method. The thicker the layer, the better the insulation.

- Ceramic coating. Ceramics do not conduct heat well, so they are ideal for our purpose. Ceramic coating is sold in powder form, which is applied by spraying at high temperatures.

Ceramic coating and thermal tape significantly improve the thermal insulation of exhaust gases. How does this affect the air temperature under the hood? Manufacturers claim a reduction in this indicator by 30-40% for ceramic coatings and about 60% for thermal tape. This means that the real figure is approximately 50%. Agree, the result is quite significant.

How to wrap a manifold or muffler with thermal tape - tips and tricks

We have reached the most difficult stage. There are several recommendations that will simplify the wrapping procedure.

Water

It is recommended to make the thermal tape softer using water. You can use a sprayer or simply dip the tape in water and squeeze it thoroughly. This will greatly simplify the wrapping process. After drying, the material will hold its given shape much better.

An extra pair of hands

Wrapping heat tape around long, straight pipes is easy, but when it comes to making connections, you'll need another pair of hands to get the job done. Bends and intersecting pipes are not easy to wrap, so have a helper hold the material in these areas while you pull and stretch the tape around the pipes.

Intersection places

Another difficulty is pipe branches. You will not be able to wrap such areas with one piece of thermal tape. You need to wrap each smaller diameter pipe individually first, and then wrap the larger pipe to overlap the tape on the smaller pipes. The tape will help hold the insulation tape in place until you complete the wrap. Then don't forget to remove the tape.

Installation nuances

Thermal tape is secured using special stainless steel clamps. Usually you practice on the first connection, and starting from the second it turns out fine. Therefore, we advise not to secure the first connection with clamps until the second is completed. Sometimes it becomes necessary to make adjustments at the first node.

Examination

Thermal tape increases the thickness of the pipes, so before final fixing the clamps, we advise you to check the compliance of all elements by installing the manifold on the engine. Sometimes the gaps are very tight and additional difficulties may arise.

Rule 1/2

It is recommended to wrap the exhaust manifold or muffler using the 1/2 principle. Each next layer should overlap the previous one by half. After reaching the end of the pipe, fold the thermal tape inward so that the edges do not stick out.

By adhering to the recommendations listed above, you will be able to do the job efficiently and achieve the desired result. At the end, be sure to secure the thermal tape with stainless steel clamps and enjoy your work.

Choosing what to wrap the exhaust manifold with - types and functions of materials

As you know from a physics course, the volume of a gas is directly proportional to the temperature, that is, the higher the latter, the greater the first parameter will be. It follows from this that heated exhaust gases will exit the car engine much faster. But in the engine compartment the air does not heat up above one hundred degrees, while the temperature of the car’s exhaust manifold is more than a thousand.

And again, returning to physics and the laws of heat transfer, it can be argued that the gases, due to such a low temperature in the engine compartment, are cooled, which means that the process of their release slows down. Thermal tape can solve all these problems by creating excellent thermal insulation of the manifold; it will retain heat in the exhaust system and at the same time prevent the engine from overheating from the heat released from the exhaust.

There are three main types of such tapes on the automotive market, differing in composition and color. The most common among car owners are black and white thermal tapes. In principle, they are at the same consumer level and are identical in their properties. Bronze is considered more effective; its thermal insulation properties are better than those of previous options by as much as 30%, and all thanks to a different composition.

Thermal insulation of the exhaust manifold - when to act?

The design of the exhaust manifolds includes a steel screen, which also acts as thermal insulation. If, as a result of tuning or for some other reason, it is missing, then you cannot do without thermal tape. The temperature of the collector, as mentioned above, can reach as much as 1600 °C, and after stopping the engine it cools down quite quickly. Thus, condensation forms in it.

The following signs will help you understand that thermal insulation of the exhaust manifold is urgently needed. First of all, your “iron horse” will lose power, and problems with starting the engine are also possible, especially when the car stalls. Sometimes there are even cases where black smoke comes out of the exhaust pipe. In addition, a special light will light up on the instrument panel in the cabin, indicating that the engine is overheating.

Properties and selection

The material is made from harmless silica filament and graphite compounds. Available in the form of a tape of a certain width, heat-resistant.

The use of such material for the muffler winding guarantees the following:

- Increased engine power.

- Increased ventilation of the combustion chamber.

- Thermal insulation.

- Reduced temperature under the hood.

When purchasing, some points are taken into account:

- Heat resistance up to 1500 degrees.

- The width is selected depending on the convenience of the winding. 5 cm is enough.

- Tone: black, white, bronze.

Black and white ribbons are considered popular. Well suited for cars with low power. Black thermal tape absorbs heat from outside more than others, while white helps insulate the temperature under the hood.

Bronze material is more thermally insulating and is suitable for cars with more powerful engines.

We recommend watching the overview video:

Varieties

Thermal tapes for the muffler are made on the basis of silica, expanded clay, basalt, carbon or ceramics. Such materials can withstand temperatures from 850 to 1100 degrees. These products are produced with a strip width of 25 mm or more. For motorcycles, the most convenient to use tape is 50 mm wide.

Until recently, it was possible to purchase stripes in only two main colors: white and black. Nowadays, such products appear on the market in a variety of colors. You can choose a ribbon that best matches the color of your motorcycle.

Depending on the material and manufacturer, a skein 10 m long costs from 1000 to 3500 rubles.

Other uses.

In principle, thermal tape for muffler winding can be used in many cases, helping to solve a lot of problems with the exhaust system:

- Protect elements from minor mechanical damage;

- Act as a sealant at joints;

- Ensure operation in case of minor defects - fistulas, burnouts, cracks.

Of course, if the exhaust manifold burns out, it will not be possible to restore the unit’s functionality. For thin-walled elements - resonators or pipes, wrapping with thermal tape will be a good option for a quick repair, allowing you, if you do not restore functionality completely and permanently, to get to a garage or service center without problems.

Thermal tape for a motorcycle muffler has become a tuning classic. The exhaust system of a car is hidden from prying eyes; for bikers, taking care of the exterior of a motorcycle is one of their priorities. The owners highly appreciated the quality of the tape, its ability to both combat minor defects and give the muffler a stylish appearance. Thermal insulation characteristics are also important, thanks to which they provide reliable protection of the legs from burns.

Purpose

The main purpose of thermal tape for a muffler is to improve the appearance of the motorcycle. Over time, the components of the exhaust system rust, chrome elements lose their shine (and sometimes this coating is damaged or peeled off). By wrapping parts of the motorcycle with special tape, you will not only hide all defects, but also give it a brutal look. The second useful function of this material is to protect the motorcyclist’s feet from parts of the exhaust system that heat up to very high temperatures.

From a technical point of view, according to experts, tape winding reduces the cooling rate of exhaust gases, and, as a result, increases the rate of their release to the outside. This leads to an increase in engine power (albeit insignificant, only 2-3 l/s).

This coating increases the sound insulation of the exhaust system, although it is unlikely that any biker is embarrassed by the roar of the engine of his “two-wheeled friend.”