What is a CVT and what is its main difference from conventional gearboxes?

CVT transmission - what is it? CVT is an abbreviation of the English name for a variator, i.e. Continuously Variable Transmission, which literally means “constantly changing transmission.” Its main property is the ability to change gears in a different order than we are used to, namely without constant and sequential switching of speeds (steps, gears). In this connection, the variator is rightly called a continuously variable transmission. This is its main distinguishing feature.

The variator belongs to the class of automatic transmissions: it operates in a wide range, gears are switched automatically, and the processes are controlled by an electronic system. Still, the difference between CVT and automatic is significant. What exactly does it consist of?

- A continuously variable transmission is lighter and smaller in size than an automatic transmission.

- It differs from the “automatic machine” in its operating principle. The CVT provides the ideal combination of gear ratio and engine load at every moment (changes occur every second).

The gear ratio is the ratio of the crankshaft speed to the wheel speed. For each gear this figure is individual - gear ratio 4, 5, 6, etc.

CVT saves fuel and increases driving comfort (since the engine operates most of the time at the lowest speeds, while driving at a constant speed).

From an engineering point of view, the variator is the best of all currently existing gearboxes. But don’t rush to make a decision about buying a car with a CVT, not everything is so simple.

Line of power units

The first generation of the model was so popular with domestic drivers that Japanese engineers spent seven years developing the second generation. Only in 2014 was the start of production of the Nissan Qashqai 2 announced. At the same time, the crossover was put into mass production at an automobile plant in St. Petersburg. The Koshak was officially supplied to Russia with 1.2, 1.6 and 2.0-liter power plants. The most widely used is the 1.6-liter gasoline engine, distinguished by its speed and relatively high resistance to adverse conditions.

However, a considerable part of the model’s sales came from modifications with a small-displacement 1.2 engine with 115 “horses”; there were also buyers for a 130-horsepower 2-liter engine. In 2022, the Nissan Qashqai 2 has undergone some changes, mainly affecting the exterior of the model. The variety of power plants remains the same. The engines are combined with a variator and a manual transmission. The maximum speed of the version of the car with a 1.2-liter engine is 160 km, and acceleration to 100 km/h takes as much as 13 seconds. Of course, such indicators of dynamism may seem too weak to many. But the 2.0-liter version of the car accelerates to “hundreds” in 10 seconds, and the maximum speed is 180 km/h. True, the difference between these two modifications in cost is about 200 thousand rubles.

When did it appear and what caused the appearance of the variator?

This development was patented in the 18th century. They began to actively use it in the 1950-1980s. Used in equipment that does not have the same power as a passenger car (with electric generators, in chainsaws, snowmobiles, machine tools, sewing machines). For the vehicle, it was necessary to invent a completely different continuously variable transmission mechanism. And over time, engineers solved this problem.

For the first time, a continuously variable transmission was installed on Dutch DAF vehicles comparable to motor vehicles in 1958. Later, in the late 70s, the patent was “inherited” to Volvo. The concern tried to improve the “modest” variator (taking this path was easier than rebuilding the entire production). The resource of the improved CVT model was only enough for 30 thousand km. Years later, the concern refused to use a CVT in its cars.

CVT automatic transmission for DAF 55, chassis removed from frame

In the 80s, the variator was used on Ford cars (Ford Fiesta model), Fiat (Fiat Uno model), and Subaru. And only Subaru managed to overcome the main drawback of CVTs - their fragility (the concern used a metal-containing pusher instead of an elastic belt in the CVT design). Subaru has equipped many vehicles with its own CVT transmission and still supplies its design to other manufacturers.

In the 90s, they began to install a variator on class C cars (i.e., middle class, before that it was installed on inexpensive and practical class B cars). And all thanks to the ongoing search for a more advanced CVT design.

Engine life 1.2

The joint development of Nissan and Renault has found its application on many French and Japanese relatively small cars. The 1.2-liter engine was designated DIG/TCE by Nissan and Renault, respectively, and by its internal index the engine can be identified as H5FT. It debuted for the first time in 2011 and immediately received many praises from independent automotive experts. Its main advantage is smooth operation and low level of mechanical noise. The Nissan Qashqai 1.2 really works quietly, and virtually no extraneous mechanical noise from the operation of the engine and transmission penetrates into the cabin.

Specifications 1.2 DIG:

- number of cylinders – 4;

- engine type – in-line;

- valves per cylinder – 4;

- power supply system – direct injection;

- boost level – 115-130 forces.

Initially, the 1.2-liter engine was produced in only one boost level with 115 horsepower, but a few years later other variations with 120 and 130 horsepower appeared. The DIG/TCE engine is a four-cylinder with four valves per cylinder. The all-aluminum block is equipped with direct fuel injection and a turbine. A reliable chain serves as a timing drive, and one phase regulator is installed on both shafts. A technological innovation of the engine is considered to be the use by the manufacturer of antifriction materials during the development of the engine, which, in theory, should help increase the service life of the engine.

But during the operation of the Nissan Qashqai 1.2, over time they encounter some problems and “chronic” engine diseases:

- Increased oil consumption. The level of lubricant consumption in some cases increases after crossing the mark of 200 thousand kilometers and amounts to 0.5 liters of oil per 1000 km.

- The revolutions are floating. Another typical “sore” of DIG/TCE, which can be successfully eliminated by flashing the control unit.

- Oil leaks. Often, owners of Nissan Qashqai 1.2 note various leaks of lubricant through various oil seals - the reason is completely unknown.

The manufacturer does not provide any information regarding the rated life of the motor. The guaranteed service life of DIG/TCE is 150 thousand km. The owners, in turn, note that the service life of the Nissan Qashqai 1.2 engine is 300 thousand kilometers.

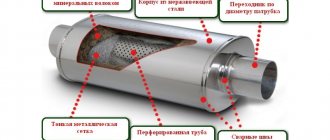

Standard diagram, principle of operation and main elements

A variator in its simplest design (created by Volvo and initially used by the Subaru concern) is a driving mechanism through which rotation is transmitted from one unit to another through an intermediate link. The nodes are two pulleys - wheels with a rim around them, inside which the belt moves. The intermediate link is a V-belt (a type of drive belt) that connects the pulleys to each other. The mechanism is called a “V-belt variator”.

Torque is continuously transmitted to the wheels, and the gear ratio also continuously changes (as engine speed changes, the belt either tightens or loosens).

Cost of work

| Work performed | Average cost, rub | Note |

| Replacing the variator | 18000 | No price per unit |

| Belt replacement | 16000 | Belt cost included |

| Changing transmission oil and filter | 3000 | No consumables |

| Valve block repair | 18000 | |

| Dismantling/installation of the variator | 12000 | |

| Torque converter repair | 5000 | |

| Replacing the step motor of the variator | 3000 |

Diagnostics of the Nissan Qashqai variator is free, provided that repairs are carried out.

Modern V-belt variator

The modern design of the CVT gearbox uses pulleys made of heavy-duty metal, and the belt is not an elastic band, but a composite tape made of wear-resistant metal (assembled from strips that are fastened together with staples). The belt is coated with a special coating that protects it from wear and slipping.

One of the pulleys is the drive one. It is connected to the engine's crankshaft (which converts the energy obtained from fuel combustion into rotational energy). The driven pulley is connected to the wheels of the car. The pulleys have a variable diameter (the edges of the rim diverge and converge, then the belt no longer passes inside, between them, but on top).

At low vehicle speeds, the diameter of the driving pulley has a minimum value, and the diameter of the driven pulley has a maximum value. At medium speed the diameter is the same. At maximum, the size of the master increases, and the size of the slave decreases. By changing the size of the pulleys, we change the gear ratio.

The mechanism is “controlled” by an electronic system, relying on information from numerous sensors (shaft speed, wheel rotation, information from the transmission itself).

Main elements of the variator

The pulleys and belt are only part of the design of modern CVTs and are called V-belt drives. The structure of a CVT (continuously variable transmission) is much more complex; the unit housing contains many other elements.

Let's remember what we already know. Torque from the engine is transmitted to the input shaft and then to the drive pulley. This process may involve a hydraulic transformer (not available on all models). The torque converter disconnects the transmission from the engine and transmits force from the shaft to the pulley.

After the torque converter, the force passes to the belt, and from it to the driven pulley. Then, using a planetary gearbox, the torque is transferred to the secondary shaft. And the car moves forward. In order for the car to move backward, the planetary mechanism or reverse mode is activated (changes the direction of rotation of the shaft).

The design also includes a differential, which distributes the load across the wheels (torque is transmitted to the differential from the intermediate shaft).

The electronic system, which manages all processes inside the CVT, reads information from the sensors and changes the operating mode of the CVT. The sensors are installed where you can quickly obtain information about the speed of rotation of the shafts, the temperature of the working fluid, and the position of the selector (gearbox knob). The electronics takes into account the load on the engine, the speed of the car, the position of the gas pedal and much more.

Some CVT models provide the ability to manually change speeds in steps, like on an automatic transmission. In others, only special modes may be present: “sports”, “economical”.

All described elements are placed in one housing.

Working fluid

The diameter of the pulley changes due to the movement of the disks. Movement is possible due to the pressure of the working fluid - oil (hydraulic system). But this statement is only true for the drive pulley. On the driven disks, they move from the belt tension and due to the return spring.

A special oil has been developed for CVT. The fluid exhibits frictional properties (helps reduce friction and wear of rubbing surfaces) at its operating temperature (60-70 degrees above zero).

It is permissible to fill only original fluid (no substitutes).

When driving at a speed of more than 150 km/h, the oil overheats (operating temperature increases to +80 degrees). Overheating should not be allowed; it will negatively affect the service life of the variator (CVT). The liquid is cooled using an additionally installed oil cooler (radiator).

It is necessary to monitor the oil level: if the amount decreases too much, the belt will slip. And, in order to prevent clogging, the fluid must be changed every 60-150,000 km (every five years).

Other types of variators

There are structurally different types of variators: V-belt (the most common), toroidal and chain. We studied the first one in detail because it is the most common. The second is installed on all-wheel drive and rear-wheel drive vehicles. The latter is used on heavy vehicles, since it is the most reliable.

Toroidal CVT gearbox

A toroidal gearbox is a more complex mechanism. In it, the role of pulleys is played by disks elongated in the shape of a cone on one side. The disks are directed towards each other with sharp ends. The one located on top is the leader. Below is the follower.

The role of the belt is performed by rollers. They are located on opposite sides between the disks. And they move along the curves. Synchronously rising up, they increase the gear (the speed of the car increases, the torque decreases). When lowered to the driven disk, the gear decreases. Positioned in the middle, they issue a direct transmission. The force is transmitted due to friction (rollers rub between the disks).

Belt CVT is used more often, but toroidal is more reliable. However, it has a significant drawback: it cannot be repaired (if it breaks, you have to replace it with a new one).

Chain variable transmission

Chain is a type of V-belt, which is practically no different from the “prototype”. In the variator they only replaced the belt with a steel chain. Such a device has a variator called Multitronic, created by the Audi concern. It has an increased service life, an increased level of strength, and the chain variator can withstand loads better. Therefore, it is more often used on trucks.

The chain variable speed transmission is not widely used because it produces a lot of noise (the level is too high).

Modern CVTs

Nowadays, most cars from Japanese and German brands are equipped with continuously variable transmissions. Because their production is cheaper.

The world's leading manufacturers of automatic automatic transmissions, including CVTs, are ZF, Aisin, and Luk. These manufacturers create “automatic machines” for automakers from Japan, Europe and the USA. For example, the Ford concern uses ZF products, and Luk supplies components for Subaru CVTs.

Also, many global automakers have established CVT production at their factories. Their developments are patented and produced under their own names. Some of these CVTs do have unique features that affect the operation of the unit. The essence of others is not too different from what was previously invented.

The most famous CVT models:

- Japanese – X-tronic (Nissan), Lineartronic (Subaru), Multimatic (Honda), Multidrive (Toyota) – Japanese CVTs are less “capricious”, the undisputed leader among them is Multidrive (Toyota);

- German - Multitronic (Audi), Autotronic (Mercedes-Benz);

- American - Ecotronic (Ford) and Durashift CVT (Dodge).

In our country, the following car models with a CVT have become widespread: Honda HR-V and Civic, Nissan Primera, Audi models.

Features and differences of the X-tronic Nissan variator

The cars of the Nissan-Renault alliance are equipped with branded X-tronic CVTs produced by the Jatco subsidiary: on the Renault Captur, Nissan X-trail and Qashqai crossovers, etc.

Nissan's continuously variable transmission (CVT) is a type of V-belt CVT, but is a modified version of it. The reason for the modification was the desire of the automaker to deprive the CVT of its typical shortcomings.

Engineers made changes to the V-belt drive design (they made thinner pulleys and reduced the flexibility of the belt). The degree of reliability of the variator is increased by reducing the pressure between the belt and pulleys. Friction losses decreased by a third. As a result of the changes made, a lighter gearbox was obtained.

The main innovation is an additional planetary gear. Unlike conventional CVTs, the X-tronic gear ratio is higher – increased to 7.3/1.

X-tronic works in tandem with powerful engines; thanks to the adaptive electronic control system, the variator “adjusts” to any road conditions. Hence the recognition of experts: the X-tronic continuously variable transmission is a promising development that changes for the better the general idea of CVTs.

In turn, drivers in numerous positive reviews note: CVT from Nissan works quietly, the car with it accelerates smoothly and rapidly, thanks to the variator, the feeling of comfort does not leave during the entire drive.

But there are some drawbacks here: a car with an X-tronic variator slips in difficult road conditions (snow, mud). And in the event of a breakdown, the same difficulties with repair arise.

Lineartronic Subaru is one of the most reliable CVTs

Since 1984, Subaru began to use ECVT CVTs, forgotten since Volvo’s attempts, and significantly improved them. Subaru engineers equipped the CVT not with an elastic belt, but with one made of metal links. The mechanism also received a torque converter, sensors, and an electronic system. In this CVT, only the diameter of the drive pulley changed. The experts were amazed - the service life of this variator turned out to be many times longer. And the automatic mode demonstrated all the advantages of automatic transmission. At one “wonderful moment,” the concern decided to abandon the ECVT installed on the Justy model, and developed a CVT for Vivio, controlled exclusively by electronics. A little later, Subaru engineers tried to improve the performance of their first CVT; the new model was called iCVT and installed it on the Pleo car. An attempt to install iCVT on more powerful cars was unsuccessful.

In 2009, a new CVT model appeared called Lineartronic, based on the developments of the famous auto parts manufacturer - LuK. Today, Lineartronic CVTs from Subaru are installed on the brand’s models: Outback, Impreza, Legacy sedans, Exiga compact van, Forester crossover.

Cars with turbocharged engines are equipped with an upgraded version of the TR690, produced since 2009, and the rest are equipped with a new variator TR580 (New Lineartronic). CVT versions differ in design and size.

Subaru CVTs are considered the most reliable because they use a chain instead of a belt (a type of V-chain variator). The LuK company still supplies Subaru with a chain and guides for the Lineartronic variator. The chain is assembled from 900 plates and is flexible. With it it became possible to use pulleys of smaller diameter.

Due to the difference between the width of the pulleys, the CVT exhibits a record maximum gear ratio of 6.32. Also, a smaller bending radius made it possible to reduce internal stress and minimize the risk of deformation and friction of chain parts.

A smooth but confident start (even when going uphill) is ensured by the operation of the torque converter. It doubles the torque coming from the engine, and then (at 10 km/h) it is blocked (which eliminates unnecessary energy losses).

Despite its impressive potential, Lineartronic has compact dimensions: the entire CVT structure is significantly smaller than a belt drive.

The 4WD system is integrated into the variator housing. “Electronics” allows you to distribute torque between the axles, depending on road conditions; ensures vehicle stability and controllability.

The CVT electronic control unit is located outside the variator, is not subject to vibration or temperature changes, and therefore demonstrates high reliability.

In light of these features, the Lineartronic chain transmission turns out to be 5% more efficient than a standard V-belt gearbox. Saves up to 8% fuel (compared to an automatic transmission) - this is a serious achievement, considering that 1% savings in the automotive world is already a success. The operating life of Lineartronic is enough for 200-250 thousand km. The CVT can last longer if overhauled.

True, the Lineartronic variator is not intended for aggressive driving (components and parts wear out quickly due to sudden changes in driving modes). Towing on a cable with the engine not running is also not permissible. The service life and smooth operation of the Subaru CVT is affected by the quality of the fluid specially designed for the chain variator.

Features Multitronic Audi

The audio is produced by a variator with so-called virtual gears: each gear corresponds to a certain position of the conical wheels. During acceleration, the CVT maintains high revs. “Automatic” only works when the sport mode is turned on. The gear is selected by the driver.

This CVT has been produced since 2005 under the name Multitronic. Refers to the type of chain variators. Installed in premium class cars - A6, A8.

The design includes a strong chain - assembled from 1025 plates; links of different sizes are used to reduce noise levels. And also pulleys with hydraulic cylinders (the first presses the chain to the pulley, the second regulates the gear ratio). Compressing the pulleys avoids slipping when downshifting (or upshifting).

The Audio clutch device (in CVT) uses a multi-plate clutch instead of a hydraulic system, which makes it possible to combine smooth movement with quick start and acceleration.

Multitronic has a planetary gear (for reversing). The control system allows you to adjust the speed of reversing.

Previous Audi CVTs, produced since 1996, were “famous” for constant failures in the electronic control system. The chain was not very strong. But Multitronic is far from ideal. Audi engineers began to refuse to use it.

Reviews from Renault owners

The Kaptur and Fluence models are equipped with a continuously variable transmission. Let's find out how well the X-Tronic CVT gearbox has proven itself on French cars.

Anatoly, 42 years old, Renault Fluence

I was looking for a stylish, inexpensive to maintain, unpretentious car, a kind of “workhorse”. That is why my choice fell on Renault. I drive a lot in dense city traffic, so I didn’t fundamentally consider a manual transmission. The CVT captivated me with its characteristics and significant fuel economy compared to a conventional automatic.

Arriving for a test drive at the car dealership, I was convinced that the transmission really shifts quickly and smoothly. After the test drive, I definitely decided to take this car. What can I say: in the end I got what I expected. I am completely satisfied with the car I chose. I drive a lot, but carefully, without unnecessary jerks. I'm not a fan of aggressive driving, I've probably already grown out of that age. Therefore, for me X-Tronic is a great option.

I have already driven a little over 70 thousand on my car, and I recently changed the oil in the box for the first time. So far the gearbox hasn't given me any trouble, and I haven't had to spend money on repairing it yet. I hope that the car will continue to reward me with proper operation for my careful attitude.

Vitaly, 35 years old, Renault Capture

This car captivated me at first sight. It is ideal for our, to put it mildly, not ideal roads. In addition, I like to go fishing with friends, so I was looking for a car that wouldn’t turn into a useless piece of hardware when off-road. I understand that the Capture is far from an SUV, but it is quite suitable for the average country road. The only thing that bothered me was the CVT gearbox. But I decided to take a risk and buy this car, because it is relatively inexpensive.

While driving around the city, I was quite satisfied with the transmission characteristics, but with the onset of warm days, it was time to test the iron horse in field conditions. We drove almost the entire way without problems, but a rather steep and long climb separated us from the river. Approximately in the middle, the car stopped and refused to move further. We had to stand for about ten minutes, but then we were able to continue our journey.

Naturally, I went to the service center to fix the problem, but the repairman said that this is a feature of this box - under heavy load it overheats greatly, so the automation simply turns off so that important parts do not burn out. Here's the thing: you can drive a CVT quite comfortably, but you probably shouldn't overload it. I don’t want to part with the car, I’ll drive it around the city, but for outings into nature I’ll look for a more durable option.

How to determine which gearbox is installed in a car

Modern gearboxes, including robotic gearboxes, are very similar in appearance: even a continuously variable one imitates an “automatic” (it has a selector and a standard speed scale). And yet, it is possible to determine whether a CVT or another gearbox is installed in a vehicle. Pay attention to:

- information in the car documents,

- descriptions of your car model from the Internet,

- plate located on the vehicle body.

Information about the transmission is contained in the vehicle operating instructions and technical documentation. You can also find out about the installed device by the vehicle’s vin number (the identification number is indicated in the vehicle certificate and in the vehicle passport). There are special web services that provide information about the vehicle’s equipment using the VIN code.

It is not always worth resorting to paid online services (not everyone will provide the necessary information). It's worth looking up information about the transmission using a search engine. Most models from different brands are described in detail on the Internet. But, if there is no information about the transmission, there is one more option - the designations on the plate.

The designations are a set of numbers and letters, which the sales consultant will help you decipher (if you need to purchase additional spare parts). This information is enough to order components. If suddenly the plate is lost or the letters on it are erased, the same one is located on the body of the device itself. The technician will learn about the transmission when he gets to the housing (in case of maintenance or repair).

Subaru engine compartment plate

Audi engine compartment plate

Nissan engine compartment plate

Pros and cons of a continuously variable transmission

Cars with CVTs are primarily famous for their high efficiency and level of comfort while driving: smooth ride, fast acceleration, imperceptible changes in speed, absence of jerks. CVT ensures optimal engine speed and maximum torque. The engine does not stall at traffic lights or when driving in traffic jams. Going uphill is faster, without slowing down.

These are the main advantages of the CVT gearbox; unfortunately, there are more disadvantages.

- There is an opinion that CVT often fails. However, this is not entirely true: problems with the variator do not arise while the warranty on the new car is valid. CVTs often fail if the car owner violates the operating rules recommended by the manufacturer (subjects the car to high loads, preferring aggressive driving).

- In addition to replacing the expensive original oil, filters are also required (every 30 thousand km).

- Due to their design features, the scope of application of CVTs is limited: they cannot be used in vehicles with powerful engines (no more than 220 hp). It is also unacceptable to operate the car at high speeds.

- Another restriction concerns towing: a car with a CVT can only be towed by a tow truck.

Experts' verdict: savings or reliability?

At the end of the article, I would like to answer the main question of car owners - which is better, CVT or automatic? From an economic point of view, it is more profitable to buy a car with a CVT, since it is the continuously variable transmission that ensures optimal fuel consumption. And the engine paired with a variator runs longer (experiences less load).

But if we take into account other factors (short service life compared to a gearbox, high price of the original oil, cost of possible repairs), buying a car with a CVT no longer looks so rational.

Unfortunately, repairs are expensive. The cost increases significantly if there is a need to repair the torque converter or it turns out that the necessary spare parts are not available (must be ordered). Often there is talk of a complete replacement of the CVT: CVTs are not durable - 150-200 thousand kilometers (hence the low demand in the secondary market). In addition, there are few craftsmen capable of carrying out such complex repairs and complete replacements (accordingly, the cost of their services is higher).

Therefore, both from the point of view of reliability and from the point of view of efficiency, it is more profitable to purchase a vehicle with an automatic or manual transmission (such cars are not sold much more expensive). The only exceptions are some models of CVTs, which are distinguished by an increased degree of reliability and improved performance characteristics (X-tronic, chain Lineartronic, chain Multitronic with adaptive “Sport” mode).

Which car should you prefer? It depends on you: your financial capabilities (are you considering buying a new car or looking on the secondary market, are you ready to invest in expensive maintenance), how long do you plan to drive, how important is it to profitably resell the car, what driving style do you prefer. Cars with CVT are suitable for responsible drivers who prefer measured driving in the city or on the highway, and who highly value driving comfort.

Consequences of ignoring problems

If you do not pay attention to the symptoms indicating the need for repair of the Nissan Qashqai CVT, serious problems may arise:

- The crossover loses power and acceleration dynamics.

- Gears stop shifting.

- Knocks begin to be heard in the gearbox.

- When slowing down and stopping at a traffic light, the car stalls.

- As the driving speed increases, extraneous noise from the continuously variable transmission increases.

Considering the high cost of spare parts, it is beneficial not to cause problems, but to carry out repairs immediately. Delaying repairs will lead to complete failure of the variator.