The vast majority of modern cars are equipped with fuel injection systems. There are modifications in which gasoline is sprayed by a nozzle in the intake manifold. There are also models in which fuel is sprayed directly into the engine cylinders.

Diesel units operate differently than gasoline internal combustion engines. In them, diesel is supplied to an already compressed environment in the cylinder. In order for a portion of fuel to be sprayed smoothly, a mechanism such as a high-pressure fuel pump is needed.

Let's consider the features of such a mechanism, its modifications and signs of malfunction.

What is a fuel injection pump and why is it needed?

The mechanism, which is abbreviated as injection pump, is part of the fuel system of a diesel engine, but there are also models for gasoline power units. The only difference between the fuel pump of a diesel engine is that the pressure it generates is much higher than its gasoline counterpart. The reason for this is the fundamental features of the unit’s operation. In the cylinders of a diesel engine, the air is first compressed to such an extent that it is heated to the ignition temperature of the fuel.

When the piston reaches top dead center, the injector sprays fuel and it ignites. The injector needs to overcome enormous pressure. For the system to work properly, the pump must create more pressure than in the cylinders.

In addition to the mentioned function, the pump must also supply fuel in portions, depending on the operating mode of the power unit. This parameter is determined taking into account the rotation of the crankshaft. In a modern car, this process is controlled by an electronic control unit.

Checking individual elements

When measuring the pressure in the fuel rail shows a deviation from the norm, the following reasons must be considered:

- the electric fuel pump is unable to develop the required performance;

- the regulator has failed, causing the gasoline pressure in the circuit to decrease or increase above normal;

- the fine filter is completely clogged, preventing the normal passage of fuel;

- Worn injector valves leak – the engine “floods” with fuel.

One way to check the fuel pump is to press the return hose located in the engine compartment with pliers. When the return line is blocked, the pressure gauge should show at least 5 Bar, with a new pump - 6 Bar. A pressure of 4 bar is critically low.

Since the above method does not give an absolutely accurate result and is not applicable to all car models, it is advisable to check the fuel pump by directly connecting a pressure gauge. Other elements of the system should be excluded - pipelines, fine filter and regulator. Remove the back seat of the car, get to the unit and connect the meter directly to the outlet fitting.

If the readings on the ramp and on the pump fitting are equally low, change the pumping unit. Otherwise, the problem needs to be looked for elsewhere, following the algorithm:

- Purge the fuel line and change the filter, then test again.

- Reconnect the pressure gauge to the ramp, start the engine and remove the vacuum pipe (coming from the suction manifold) from the RTD fitting. If the pressure does not change, install a new regulator.

- To make sure that the injectors are working properly, you need to measure and compare two indicators: the pressure on the manifold with the return hose pinched and the maximum pressure created by the pump when connected directly. If the second value is much higher, part of the pressure is lost at the injectors.

If you find problems with loss of pressure on the manifold itself, remove the ramp and check each injector separately. Faulty parts cannot be replaced one by one - you will have to buy and install a complete set.

The easiest way to check injectors for leakage is to test them in operation together with the manifold. Remove the ramp without disconnecting the fuel line, place a rag and turn on the ignition. If the injector valves are worn out and lose their tightness, gasoline will begin to drip from them. The working elements should be checked again - with the return hose crushed.

High pressure fuel pump (HFP) of a diesel engine

is one of the most complex components of the fuel supply system of diesel engines.

History of development and improvement

This device was first developed in the 1930s by Robert Bosch. In passenger cars, injection pumps began to be actively used in the second half of the same decade.

Since the first gasoline engines were equipped with carburetors, only diesel units needed such a mechanism. Nowadays, gasoline engines with a direct injection system also have a pump of this type (a carburetor is already extremely rare - only in older generation cars).

Although the operating principle of the pump has remained virtually unchanged, the mechanism itself has undergone multiple modernizations and improvements. The reason for this is the increase in environmental standards and performance of internal combustion engines. At first, a mechanical injection pump was used, but it was not economical, which led to large emissions of harmful substances. Modern electronic pumps show excellent efficiency, which allows transport to fit within environmental standards and satisfy drivers of modest means.

High pressure pump design

There is a wide variety of modifications of fuel injection pumps for gasoline engines, as well as diesel analogues. However, in most cases, the main elements of a mechanical pump are:

- A filter is installed at the inlet in front of the pump;

- A plunger piston located in a cylinder - the so-called. plunger pair;

- A housing in which recesses are made - fuel is supplied through them to the plunger pair;

- Shaft with cam and centrifugal clutch. This element is connected to the timing pulley using a belt drive;

- Plunger pair drive pushers;

- Springs that return the plunger piston back;

- Supercharger valves;

- Mode regulator – connected to the gas pedal;

- Injection pump return valve (through it, excess fuel is supplied to the return);

- Low pressure pump (pumps fuel into the pump).

As already mentioned, mechanical pumps are gradually being replaced by electronic modifications due to their cost-effectiveness and efficiency. The mechanism itself is difficult to repair and adjust. Electronic pumps are equipped with their own control unit, as well as several electronic valves and sensors.

Most electronic injection pumps have their own diagnostic system, thanks to which the device adapts to any malfunctions and errors that arise. This allows the device to operate properly even if one of the sensors fails. Such a pump stops working completely only if the microprocessor breaks down.

Diagnostic instructions

The first step is to free access to the ramp and fitting installed at the end of the manifold. Remove elements that interfere with measurements - air duct, filter housing, crankcase ventilation pipe, etc. (the list of parts depends on the car model). Proceed to measuring, following the instructions:

- Unscrew the protective plastic cap from the diagnostic fitting on the ramp.

- Place a cut-off plastic container and use a cap to unscrew the spool valves to release the pressure previously pumped up by the pump. You can press the valve or turn the spool 2-3 turns.

- Place one end of the gasoline hose onto the pressure gauge fitting and secure with a clamp. Unscrew the spool from the manifold, pull the second end of the hose onto the pipe.

- Turn on the ignition, and the electric fuel pump will pump fuel into the system. Make sure there are no leaks at the joints of the diagnostic tool.

- Start the engine and record the fuel pressure in the rail using the pressure gauge.

Principle of operation

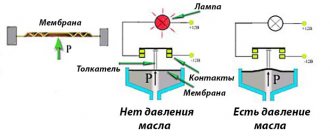

The injection pump operates on the principle of a two-stroke engine. Due to the rotation of the shaft with cams, the plunger piston is driven. Diesel oil enters the sub-plunger space, which then goes into the main line.

The operating principle of the plunger pair is described in more detail in the video:

Plunger pair for UTN

Pressure is created in the cavity, due to which the discharge valve opens. Diesel fuel flows through the fuel line to the nozzle and is sprayed. The pump to the injector supplies only part of the fuel. The remainder is returned to the fuel tank through the drain valve. To prevent fuel from returning from the system when the supercharger is opened, a check valve is installed in it.

The injection moment is determined by a centrifugal clutch. The mode regulator (or all-mode regulator) determines the amount of the supplied portion. This element is connected to the gas pedal. When the driver presses it, the regulator increases the volume of the portion, and when it is released, the quantity decreases.

In electronic models, all processes are controlled by a control unit. Electronics distributes the moment of fuel supply and its quantity, taking into account the dynamics of the car. Such fuel systems have fewer parts, which increases the stability and reliability of the mechanism.

Electronic injection pumps are capable of dividing a portion into two parts, which ensures more efficient combustion and smooth running of the piston group. As a result, there is less exhaust toxicity and increased engine performance. To ensure two-phase injection, the pump control unit records:

- Pressing the accelerator pedal;

- Timing camshaft speed;

- Temperature in the engine cooling system;

- The speed of the car itself;

- The pressure created by the turbocharger;

- Operation of injectors;

- Triggering of glow plugs.

When should measurements be taken?

The operation of the power system is structured as follows:

- An electric fuel pump located in the tank pumps fuel along the line into the fuel rail and further to the injectors.

- The regulator limits the gasoline pressure at a certain level, releasing excess into the tank through the return pipeline.

- The injector mixes fuel with air, then the mixture is directed to the nozzles, which open at the command of the controller.

When the wear of the regulator (abbreviated as RTD), pump or injectors reaches a critical level, the pressure in the gasoline circuit will change towards a decrease or increase. There are 2 possible scenarios: there is not enough fuel mixture for normal engine operation, or there is an excess of it - the spark plugs are literally flooded with fuel.

In both cases, checking the pressure in the fuel rail located next to the cylinder head will help identify the problem. The element is a manifold with branches for injectors, to which the main gasoline line is connected.

The fuel pressure in the manifold should be measured if the following symptoms occur:

- the car accelerates poorly, after sharply pressing the accelerator pedal, jerking and deceleration are felt;

- the engine of a loaded car “does not pull” and starts poorly when cold;

- shots are periodically heard in the exhaust manifold;

- a warm engine does not start after a short period of parking (especially in summer); the starter needs to be turned for 20–40 seconds.

The first two signs indicate a clear lack of gasoline, resulting from a drop in pressure in the ramp. The third case is unburnt fuel entering the exhaust manifold with subsequent combustion (a popping sound is heard). The fourth symptom indicates leaking injectors when the cylinders are filled with pure gasoline during parking. Until the pistons release excess fuel, the engine will not start.

Types of injection pump

Fuel systems come in three types:

- Single injection. This is the very first modification. The representative was originally a carburetor. In its cavity, the fuel-air mixture was prepared and supplied to the intake manifold. A little later, such systems, instead of a carburetor, received one nozzle, which injects fuel into the intake manifold, where it is mixed with air;

- Multipoint injection. This is already a type of injection system. An individual injector is installed on the intake manifold for each cylinder. Injection is also carried out into the intake manifold, only as close as possible to the intake valve;

- Direct injection. As the name of the system suggests, fuel is sprayed directly into the cylinders at a time when the air in them is already compressed by the piston.

There are three types of similar mechanisms that can be used in these types of fuel systems:

- Row;

- Distribution;

- Mainline.

In-line injection pump

An in-line injection pump consists of several pumps housed in one housing. Each of them serves a separate injector. This modification was used in old diesel engines. The operation of the entire mechanism strictly depends on the timing drive.

The in-line modification has been used for quite a long time. Even some modern cars (trucks) are equipped with such pumps. The reason is their high reliability and unpretentiousness to diesel quality.

The row system works as follows. The plunger pair is driven by turning the crankshaft. One revolution of the pump camshaft corresponds to two revolutions of the engine crankshaft.

The plunger mechanism, through the fuel shut-off valve of the injection pump, separates part of the fuel from the common line and compresses it in the pressure part of the system. The portion volume is regulated by a gear bar connected to the gas pedal. In cars with an ECU, it is regulated by a servo drive that responds to signals from the control unit.

The injection moment is determined by the crankshaft rotation speed. The mechanism has two coupling halves, which are separated by springs. When the engine speed increases, the springs are compressed, causing the pump shaft to rotate slightly, which leads to a change in the injection advance angle.

Distribution type injection pump

Unlike the previous modification, this model is smaller in size. It is also characterized by stable operation. There are several modifications of distribution pumps. There are plunger and rotary types. They also differ in the type of drive - internal, end or external arrangement of cams.

A drive with an external cam arrangement is not stable or reliable. Therefore, if possible, it is better to focus on the other two types.

Such pumps wear out faster, since one plunger mechanism in them serves all the nozzles of the group. In this regard, in-line analogues have advantages. Due to their small size, distribution injection pumps are installed in fuel systems of passenger cars and small trucks.

Main fuel injection pump

Unlike the two previous modifications, the main pump creates pressure in a single line - the so-called fuel rail. It serves as an accumulator in which constant fuel pressure is maintained.

Thanks to the smaller number of distribution mechanisms, this modification has proven itself to be the most reliable. Repairing main-line injection pumps is not particularly difficult. The portion volume is controlled by an electromagnetic dosing valve. Such pumps are found in Common Rail fuel rail systems.

Is there a fuel injection pump on a gasoline engine?

Although the main use of fuel injection pumps is in diesel engines, many modern gasoline engines also operate by supplying fuel under high pressure. These mechanisms are used in internal combustion engines with direct injection.

GDI gasoline engines require the installation of such pumps. In fact, this system is a hybrid version that combines the design of a gasoline internal combustion engine with the operating principle of a diesel unit. The only difference is that ignition does not occur due to the temperature of the compressed air, but thanks to the spark plugs. Such engines use an in-line modification.

Basic faults

Although injection pumps differ in their design, there are several important rules that the car owner must follow in order for the pump to serve its allotted time:

- Most pumps are sensitive to fuel quality, so it is necessary to comply with the requirements set by the manufacturer for a specific pump;

- Due to the complexity of the design and the loads placed on the mechanisms, high-pressure pumps require regular maintenance;

- All rotating and rubbing parts must be well lubricated, so it is extremely important to follow the manufacturer's recommendations for choosing lubricants.

If these rules are not followed, the device will quickly become unusable, which will require replacement or expensive repairs.

The following factors indicate a malfunction of the injection pump (if other systems are working properly, faults in which may have similar manifestations):

- Black smoke in the exhaust and, as a result, more toxic emissions into the environment;

- Increased fuel consumption (due to fuel leaks);

- Decrease in engine power;

- While the engine is running, noises from the pump are heard;

- Difficulty starting the engine;

- The timing belt often slips;

- Unstable engine speed.

The most common malfunction in such elements of the fuel system is failure of the plunger pair. Most often this happens due to low-quality fuel - plaque accumulates on surfaces, impeding the movement of parts. Also, the cause of mechanism failure is water, which often condenses in the fuel tank. For this reason, it is not recommended to leave the car with an empty tank overnight.

Signs and causes of fuel pump malfunctions

As mentioned earlier, the injection pump is one of the most complex and expensive components of a diesel engine. In most cases, the cause of malfunctions is the use of low-quality fuel and oil. If foreign particles, dust and dirt, or combustion products get into the injectors or plunger pair, the latter very quickly fail. The following signs indicate this:

- Difficulty starting the engine.

- Increased fuel consumption for no apparent reason.

- Dips in the power of the power unit.

- Smokiness.

- Extraneous sounds and noises when starting the engine.

Another cause of breakdowns is the natural wear of the plunger pair, which leads to an increase in micron gaps, carbon deposits getting into them and failures in the system.

As practice shows, the reasons for interruptions in the supply of fuel to the combustion chambers can be:

- Critical wear of valve teeth or rack.

- Mechanical defects and damage to the bushing.

- Piston abrasion.

- Reducing the throughput of fuel atomizers.

You can read more about the malfunctions in the article.

Repair of high pressure pumps

If repairing a regular fuel pump is not difficult - just buy a repair kit and replace worn parts, then repairing and adjusting a high-pressure fuel pump is a very complicated procedure. It is even impossible to determine the cause of the malfunction without additional equipment. Often self-diagnosis of modern control units does not help.

It often happens that the symptoms of a fuel pump failure are identical to malfunctions in the gas distribution mechanism or exhaust system. For these reasons, it is not recommended to repair the injection pump yourself. To do this, it is better to seek help from a specialized service center.

Additionally, watch the video on troubleshooting and repairing fuel injection pumps:

part 1 Repair of fuel injection pump ve 1.6 diesel disassembly troubleshooting