The module for controlling internal combustion engine parameters on any car (VAZ 2114 as an example) requires a lot of data for processing. For example, to correctly formulate the composition of the fuel-air mixture, the following information is required:

- ambient temperature;

- engine temperature;

- the volume of air passing through the intake manifold;

- oxygen saturation of air flow;

- vehicle speed;

- degree of opening of the throttle curtain.

The VAZ 2114 throttle sensor is responsible for the last point. It determines how open the channel for fresh air entering the intake manifold is. When the driver presses the gas, the throttle assembly opens.

How to get data about the throttle opening angle?

Why is it needed?

The throttle position sensor is responsible for determining the current throttle position. Depending on this, the fuel supply system changes the amount of fuel supplied under one or another operating mode of the power unit.

If problems arise with it, you can contact a service station so as not to waste your energy and nerves. But in practice, changing the TPS yourself is quite simple, plus you will save a decent amount of money.

The desired regulator is located on the side of the throttle pipe on the throttle valve axis.

Regulator location

Features of work

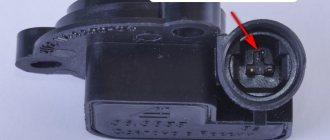

The TPS is essentially a variable resistor, one output of which is supplied with 5 Volt power. The second contact is connected to ground, and the third is connected to the controller.

When you press the gas pedal, the voltage changes. The sensor monitors the output voltage on the controller, thereby regulating and monitoring the quality of the supplied air-fuel mixture. This directly depends on the opening angle of the damper itself.

If for some reason this regulator fails, a catastrophe will not occur, since another sensor, the mass air flow sensor, will temporarily take over its functions.

This does not mean at all that the TPS can not be changed. Each regulator has its own functions, so there is no point in transferring the tasks of the TPS to the MAF.

Throttle sensor diagnostics

You can perform diagnostics yourself without calling technical assistance for help. Testing the effectiveness of the 2114 throttle sensor requires a voltmeter and two insulated wires. Next, the block with wires from the TPS is released, the “plus” on the voltmeter is connected with a wire marked “A” on the block. “Minus” - with a car body.

Turn the key to “ignition” and look at the voltmeter reading:

- a value close to zero or “zero” means that the TPS is in good condition and you need to look for the cause in the electrical circuit or in the electronic engine control unit.

- voltage reading is close to 5V - faulty sensor.

The cause of a part malfunction may be corrosion or incomplete closure of the damper. Before changing the TPS on a VAZ 2114, there is an option to check the mobility of the damper (it is possible that due to microcracks, the dynamics at the tip disappear).

Malfunctions

There are several telltale signs of trouble that may indicate that there is a problem with the throttle valve control.

- High idle speed;

- When the gear is switched off, the engine may stall;

- When the car picks up speed, the car jerks and jerks are felt;

- Acceleration dynamics deteriorate significantly;

- Floating speed occurs at idle.

It should be noted that similar symptoms may also be characteristic of the failure of other components - the idle speed control or the ignition module, for example. Therefore, you first need to check the TPS.

Checking the status of the regulator

Next, let's talk about how you can check this throttle valve sensor. The event is necessary because it allows you to understand whether all the troubles are really due to it, or whether the problems arose due to the failure of other elements of your car.

It’s not uncommon for novice car owners to make hasty conclusions based on the primary signs of a breakdown. This results in unnecessary repair work and costs.

To check the current status of the throttle position sensor you need to:

- Measure the voltage at the output of the slider, turning on the ignition and opening the idle contacts;

- If the test shows that the voltage is more than 0.7 volts, then the sensor has indeed failed;

- Open the damper completely. In normal condition, voltage readings should be no more than 4 volts;

- Measure the variable resistor for resistance;

- To do this, connect an ohmmeter or a multimeter in ohmmeter mode to the power supply and output;

- Slowly begin to turn the throttle;

- At the same time, monitor the readings on the device;

- If, as the damper opens, the resistance also changes slowly, then the unit is working properly.

If you find during the test that the sensor is faulty, you only need to replace it. It cannot be repaired.

The resistive layer along which the slider moves wears off over time due to friction. Because of this, the regulator begins to produce incorrect data, the characteristics of the supplied mixture change, and engine performance deteriorates.

Disabling the regulator

Common signs of TPS malfunction

If the sensor malfunctions, the ECU will incorrectly decipher the throttle position data or not receive it at all, which may cause the “CHECK ENGINE” light to come on.

Among the likely signs of failure or incorrect operation of the TPS, the following points can be noted:

- jerking, stalling at idle;

- turning off the engine when switching to neutral gear;

- jerks and dips when accelerating;

- “floating” speed in various operating modes of the power unit.

Replacement

In fact, changing this sensor is insanely easy. So don't rush to send your car to a service station. Everything can be done with your own hands, the quality will not suffer from this.

- To remove the throttle position sensor, you first need to find it.

- As we have already noted, the desired unit is located on the side of the throttle pipe on the throttle valve axis.

- Having found the element, pick up a shaped screwdriver.

- Using this simple tool, unscrew a couple of bolts that hold the device.

- Pay special attention to the gasket that is available under the old regulator. We do not recommend using it again; it is better to immediately buy a new one. Often the gasket is already included with the throttle sensor itself.

- After removing the old sensor, you can slightly clean the place where it is installed if there is dirt there.

- Next, a new sensor is installed along with a new foam gasket and the bolts are tightened.

- Try to tighten the fasteners as far as possible, otherwise the new throttle sensor will quickly lose its effectiveness. The work will have to be done again.

- There is no need to make any adjustments after replacement.

- The zero mark on the controller will determine that the throttle is completely closed.

Procedure for replacing the sensor

To get the job done, you only need a medium sized screwdriver. The sequence of actions is as follows:

- Disconnect the block with wires from the sensor.

- Unscrew the two mounting screws.

- Remove the sensor.

- Replace the foam pad.

- Install a new sensor.

- Connect the electrical block.

Thus, replacing the TPS yourself does not pose any problem, although there is one “but”. The sensor is tested by the vehicle's on-board computer. In the event of a malfunction, the “Check engine” is turned on. So, even after installing a new TPS, the alarm will not go off. You will have to disconnect the battery terminal for 15 minutes or reset the error in another available way.

What is TPS in a VAZ-2110 car?

The throttle position sensor is abbreviated as TPS among motorists. This part is used in several types of engines:

- Gasoline injection type.

- Single injection type.

- Diesel engines.

TPS is also known as a throttle valve potentiometer. This is due to the fact that the sensor is designed to function as a variable resistor. The sensor itself is installed in the engine compartment - the place of fixation is the throttle pipe. The mechanism of operation of the sensor is as follows: depending on the position and degree of opening of the throttle valve, the resistance also changes. That is, the level of the value of such resistance depends on the pressing of the gas pedal. If the pedal is not pressed, the throttle valve will be closed and the resistance will be minimal. The opposite is true when the damper is open. Accordingly, the voltage across the TPS, which is directly proportional to the resistance, will also change.

The control of such changes is carried out by the electronic control system; it is the one that receives all signals from the TPS and supplies fuel using the fuel system.

So, at the maximum voltage of the signal contact of the throttle position sensor, the fuel system of the VAZ-2110 car will supply the largest portion of fuel.

Thus, the more accurate the TPS indicators, the better the VAZ-2110 electronic system adjusts the engine to the correct operating mode.

Operating principle of TPS

Throttle position sensors are divided into two types: contact and non-contact. They are different in design, but the methods for testing them are the same. Their drive can be mechanical or electrical.

The first mechanical ones (film resistive or potentiometers) are a slider with contacts placed on it.

The throttle valve, through the drive and gear with the shaft, changing its position (angle of inclination) moves the slider along the resistor tracks. Based on the voltage from 0.7 to 4V (varies due to changes in the resistance of the resistor tracks), the ECU understands where the damper is located and adjusts the fuel supply.

Those. increasing the angular position of the damper increases the DC voltage value and vice versa.

When the driver just turns on the ignition, the ECU receives data from temperature sensors about the degree of engine warming up. Based on this, the throttle valve is set to the pre-start position at a certain angle.

For example, on the Lada Priora and Kalina, where there are two TPS (in cars with an electronic throttle pipe module), at this moment the output signal voltage should be:

- The first output is in the range of 0.39-0.52V.

- The second is 2.78-2.91V.

For each car brand, these indicators may differ, but if we consider the above models, then the following happens:

- If after turning on the ignition within 15 s. nothing happens (the gas pedal is not depressed, the engine does not start), the ECU turns off the electric throttle drive, and the throttle drops to 7%.

- 30 seconds after the ignition is turned on and the driver is inactive, the ECU closes the damper completely and then returns it to the pre-start position.

In this case, the signal output voltage is equal to:

- In the first case, 0.5-0.6V.

- In the second - 2.7-2.8V.

If there is a break in the throttle sensor circuit, the ECU turns off the throttle drive and stores an error code in the memory.

Also, on cars with two TPS, as is the case with Lada Priora and Kalina, their total signal output voltage should not exceed 3.2-3.4V.

The operating principle of non-contact (magnetoresistive TPS) is based on the magnetic-resistive effect - they rarely fail, due to the absence of contacts rubbing against each other. For this reason, they are more reliable and last longer, although they are more expensive than contact ones.

Common causes of malfunction are short circuits in electrical circuits, broken wiring.

Communication of the throttle valve with other automotive systems of the VAZ-2110

The throttle valve of a VAZ-2110 car is a component of the engine intake system and is directly connected to a large number of other vehicle systems. These include the following systems:

- directional stability;

- anti-blocking;

- anti-slip;

- anti-slip;

- cruise control.

In addition, there are those systems that are controlled by the electronics of the gearbox. After all, it is this throttle valve that regulates the flow of air into the car system and is responsible for the quality composition of the fuel-air mixture.

TPS design

The throttle position sensor can be of two types:

- film;

- magnetic or contactless.

In its design, it resembles an air valve - in the open position the pressure corresponds to atmospheric pressure, in the closed position it drops to a vacuum state. The TPS includes DC and AC resistors (each resistance is 8 ohms). The process of opening and closing the damper is monitored by the controller, with subsequent adjustment of the fuel supply.

If at least one symptom of a malfunction occurs in the functioning system of this sensor, then fuel may be supplied to the engine either in excess or in deficiency. Such malfunctions in engine operation are reflected in the engine of the VAZ-2110 car and on its gearbox.

Characteristic symptoms of a malfunctioning TPS condition

Thanks to the correct functioning of the throttle position sensor, the fuel system of the VAZ-2110 car engine works with a smoothing effect. That is, the vehicle moves smoothly, and the gas pedal responds well to pressure. Therefore, a malfunction of the TPS can be noticed almost immediately by the following signs:

- Poor engine starting.

- Noticeable increase in fuel consumption.

- The car's movements are intermittent.

- The idle speed of the engine is noticeable when running.

- The Check e light comes on on the dashboard

- The car accelerates poorly due to delays in acceleration.

- Popping sounds are heard in the intake manifold.

Of course, these signs of a faulty sensor may not all be observed at once. But even if you notice only one of the above symptoms, it is worth carrying out computer diagnostics of the vehicle at a service center.

Why is it better to buy a contactless TPS

The factory equipment of the VAZ 2110 provides for the installation of a conventional film-resistive throttle position sensor. The main reason for this preference is the low price of the sensor. Non-contact TPS models are considered a more expensive, but also reliable alternative. In the latter case, the operation of the sensor is based on the magnetoresistive effect, which reduces wear of parts and significantly extends the service life of the TPS.

Contactless TPS is expensive, but reliable

TPS problems and their diagnosis

As you know, eternal parts for cars have not yet been invented. And the breakdown of the TPS can be foreseen; for this you need to inquire about the possible reasons for the failure of this part. Here are the main ones:

- Abrasion of the sprayed base layer, which serves to move the slider (the result is incorrect TPS readings).

- Failure of the movable type core (the result is deterioration of the contacts between the slider and the resistive layer).

How can you figure out problems with this sensor yourself? To do this, you can independently diagnose the operation of your diagnostics:

- Listen to the VAZ-2110 engine idling:

- the breakdown is obvious if you notice that its speed is in a “floating” state;

- Quickly release the gas pedal:

- a malfunction is present if the engine stops after this action.

- Pick up speed:

- There is a problem with the TPS if the car starts to move jerkily, which indicates an incorrect supply of fuel to the system.

Checking the operation of the throttle position sensor

To check the TPS yourself, it is not necessary to call an auto electrician for consultation. To do this you need a multimeter or voltmeter. Next, experts offer step-by-step instructions for checking the sensor.

The first step is to turn the key in the ignition switch, take the voltage readings between the sensor slider contact and the minus. In normal condition, the indicator will be up to 0.7 V.

The second step is to turn the plastic sector and open the damper, and then take measurements again. In the normal state of the sensor, the device will show a result of 4 V.

The third step is to turn on the ignition completely (as a result of this the connector will stretch out), measure the resistance between the slider and any terminal. When rotating the sector, you must monitor the measuring device:

- when the multimeter or voltmeter needle moves smoothly, the sensor is working;

- when the needle on the meter shows sudden changes, the DPPZ is faulty.

Once the sensor is faulty, it can be adjusted or replaced. The VAZ-2110 car repair service center will tell you how to do the right thing.

The days of carburetor engines for VAZ cars are irrevocably gone; the manufacturer is trying to introduce more and more electronics into engine control systems. On the one hand, this greatly simplifies maintenance and operation. On the other hand, this does not eliminate the need for timely maintenance and especially diagnostics. This fully applies to a rather simple, but extremely important unit - the throttle valve of the VAZ 2110. Its timely diagnosis and care do not take much time, but can save a lot of nerves and money.

How to check the functionality of the sensor

If you observe one or more symptoms from the above list, then you can check the serviceability of the sensor without complex diagnostics in the following way:

- turn on the ignition and take the tester, switching it to voltmeter mode;

- Install one of the tester probes to the slider terminal, the other to ground;

- with the throttle valve fully closed, the readings should not exceed 0.7 volts (this is the starting point in the sensor measurements);

- by turning the plastic sector by hand, it is necessary to open the damper and take readings again - the volts should increase to at least 4 V;

- after this, you need to turn off the ignition and connect the probe, fixed to ground, to one of the two remaining sensor terminals;

- Now you need to switch the tester to ohmmeter mode and determine the resistance value in different ranges, smoothly rotating the sector with your hand - in any position the resistance should be approximately the same, without jumps.

The engine stalls at idle - the TPS is faulty

Sensor replacement:

- Remove the negative terminal from the battery or use the ground disconnect button;

- Press the plastic latch on the throttle position sensor and disconnect the wires from it;

- Remove the sensor by unscrewing the 2 mounting screws;

- Installing a new sensor is done in the reverse order.

How it works and why you need a VAZ 2110 throttle valve

The injectors are responsible for the dosage of fuel in the fuel injection system, and the throttle valve controls the air supply.

An internal combustion engine requires a precisely balanced mixture of oxygen and fuel to operate correctly. The injectors are responsible for the dosage of fuel in the fuel injection system, and the air supply is controlled by the throttle valve. It is a fairly simple throttle assembly with a valve that can rotate on its axis. It is installed between the air filter and the intake manifold. The valve is controlled by pressing the accelerator pedal - the more the pedal is pressed, the more the damper is open and can supply more air to the combustion chamber.

It would seem that it couldn’t be simpler, however, in injection engines, each parameter is monitored and controlled by an electronic control unit, the ECU. In order for the control unit to know how much fuel needs to be supplied to the combustion chamber, it needs electrical impulses. These signals are sent to the computer by several sensors that monitor the operation of the throttle valve, more precisely, its angle of rotation, the amount of air passed through and its technical condition. This entire assembly is called the VAZ 2110 throttle assembly, and the sensors are the VAZ 2110 throttle position sensor, the mass air flow sensor. The second of them is installed immediately behind the air filter along the path. In addition, the design of the VAZ throttle unit provides an electromechanical device responsible for adjusting the idle speed, the idle speed regulator.

Device

1 - Shaft;

2 - Housing; 3 - Connector; 4 - Contacts; 5 - Resistor; 6 - Ring; 7 — Spring stopper; 8 - Spring; 9 - Cover; This component of the system is a fairly simple electrical resistor, which changes the resistance when the axis is rotated.

The sensor is located on the damper shaft and, when it opens, performs the function of turning together with the damper. Due to the fact that the design is quite primitive and unreliable, the sensor often fails, resulting in certain problems with the formation of the fuel mixture. So, in most cases, the problem is the rubbing of the tracks, but the possibility of other problems with the condition of the resistor cannot be ruled out.

Idle speed regulator VAZ 2110, device and principle of operation

If in a carburetor engine the idle speed system was responsible for the operation of the engine at idle, then in an injection engine it was the regulator. It consists of:

- housings;

- stepper electric motor;

- lead screw;

- cone valve;

- electrical terminals.

Video repair of idle speed and main faults

The device is installed behind the throttle valve along the air flow, and the cone valve closes the bypass air channel. Using an actuator, a stepper motor, the valve can change the amount of air supplied to the manifold, thereby changing the amount of idle speed when the throttle is fully closed. The regulator is controlled by an electronic motor control system.

Changing the cross-section of the bypass air channel is necessary in order to keep the idle speed within different limits when the damper is closed, for example, to warm up the engine after starting, the idle speed should be slightly higher than when the engine is warm, and the ECU can also determine the connection of additional equipment for which Higher idle speeds are also required.