The gearbox is one of the most important units in the design of any mechanical vehicle, allowing interaction between the engine and the wheelbase, as a result of which movement occurs. When the transmission becomes unusable for one reason or another, further full operation of the car is no longer possible. Domestic cars are no exception.

Although the Russian automotive industry is successful in selling budget-class cars, it cannot be called successful. The assembly , which has no equal in the number of complaints against itself, frequent visits to service stations, rapid corrosion of body elements, a poor and unsightly interior - these eternal companions have not left the Lada from the moment its production began to this day.

The only advantage of the so-called “TAZ” among the people is the relatively low price, both for the machines themselves and for maintenance. But in fairness, it must be said that when it comes to the transmission, there are the fewest complaints from users. In particular, the VAZ 2107 gearbox is famous, oddly enough, for its durability and the relatively small number of service problems that arise.

At the same time, it would be unfair to say that repairing a VAZ 2107 gearbox is something out of the ordinary, and its operation occurs flawlessly.

Five-speed manual transmission

The seventh model Zhiguli has a five-speed gearbox with five forward speeds and one reverse.

It is made of duralumin and has similar covers on the front and back. The clutch cover is attached to the front of the box using studs. A steel cover is installed on the bottom of the device. There are sealing gaskets between the box body and each lid.

The front cover is connected to the clutch housing using a press fit. There is a hole in it for the input shaft to exit and install the cuff.

Inside the box, shafts with gears, synchronizers and gear shifting devices are installed in a certain order. There is an oil filler hole on the right, and a drain hole with a magnetic plug on the bottom.

At the bottom left of the cover comes the speedometer cable, which is driven by the secondary shaft using a gear.

The gear shift lever is on top. Consists of a gear selection device, rods and a locking mechanism. A handle is attached to the lever on top. This entire structure is attached to the lid using three studs.

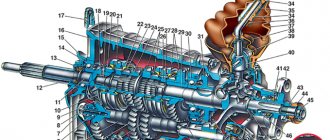

Type of gearbox:

- Clutch cover.

- Breather.

- Box body.

- Rear cover.

- Gear shift lever.

- Lever housing.

- Coupling flange.

- Screw.

- Speedometer drive.

- Tray cover.

- Hole for filling.

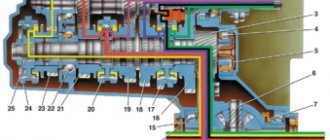

Exploded parts:

- Fork for engaging 3rd and 4th gears.

- Fork for engaging 1st and 2nd gears.

- Fork fastener.

- Engraving washer.

- Fork rod for engaging 1st and 2nd gears.

- Rusk.

- Fork rod for engaging 3rd and 4th gears.

- Gear shift lever.

- Fork rod for engaging 5th gear and reverse.

- Rusk.

- Rusk.

- 5th gear and reverse detent spring.

- Retainer cover with gasket.

- Retainer springs.

- Ball retainers.

- Fork for engaging 5th gear and reverse.

- Sleeve.

Moving parts of the gearbox:

- Intermediate shaft.

- Front intermediate shaft bearing.

- Rear main shaft bearing.

- Input shaft with 4th gear gear.

- Synchronizer clutch for 3rd and 4th gears.

- Synchronizer clutch hub.

- Synchronizer clutch for 1st and 2nd gears.

- Synchronizer clutch hub.

- Front secondary shaft bearing.

- Secondary shaft.

- Intermediate bearing of the secondary shaft.

- Rear secondary shaft bearing.

- 5th gear synchronizer clutch.

- Synchronizer clutch hub.

- Reverse gear.

- Gear with 5th gear synchronizer.

- Speedometer drive gear.

- Gear block for 5th gear and reverse gear.

- Gear block bearing.

- Reverse intermediate gear.

- Reverse idler gear axis.

- Rear intermediate shaft bearing.

- Gear with 1st gear synchronizer.

- Gear with 2nd gear synchronizer.

- Gear with 3rd gear synchronizer.

Gearbox VAZ 2101 - PURPOSE

The gearbox (gearbox) of the VAZ 2101 is one of the main components of the car. The purpose of the mechanism is to convert the torque coming from the engine crankshaft and transmit it to the transmission.

DEVICE

The “penny” was equipped with a gearbox of four forward gears and one rear gear. Switching between stages is carried out by moving the gear shift knob located in the cabin. At the time of production, this type of gearbox was considered one of the best, which was due to minimal losses. The main elements of the box are the crankcase, the shift mechanism and three shafts:

- primary;

- secondary;

- intermediate.

Details of the gearbox input shaft: 1 - retaining ring;

2 - spring washer; 3 - bearing; 4 - input shaft; 5 — synchronizer spring; 6 — synchronizer blocking ring; 7 - retaining ring; 8 - bearing There are a lot of components in the box, but the unit has relatively small dimensions. To make it possible to disconnect the box from the engine, the connection is made through the clutch. The primary shaft of the unit has splines, through which it engages with the drive (driven disk). The primary shaft is mounted inside the box using bearing units: the front one is mounted in the rear part of the crankshaft, and the rear one is located in the box housing.

Details of the secondary shaft of the gearbox: 1 - retaining ring; 2 - spring washer; 3 — synchronizer hub; 4 — synchronizer clutch; 5 - retaining ring; 6 — synchronizer blocking ring; 7 — synchronizer spring; 8 — washer; 9 — gear III gear; 10 - secondary shaft; 11 - 2nd gear gear; 12 — washer; 13 — synchronizer spring; 14 — blocking ring; 15 — retaining ring; 16 — synchronizer hub; 17 — synchronizer clutch; 18 — retaining ring; 19 — synchronizer blocking ring; 20 — synchronizer spring; 21 — washer; 22 — 1st gear gear; 23 — bushing of the 1st gear gear; 24 - bearing; 25 — reverse gears; 26 — spring washer; 27 — retaining ring; 28 — speedometer drive gear; 29 — rear bearing; 30 — oil seal; 31 — elastic coupling flange; 32 - nut; 33 - seal; 34 - centering ring; 35 — retaining ring

The reverse end of the input shaft is equipped with a sprocket, which is a single piece with the shaft and is engaged with the intermediate shaft (inlet shaft). To prevent lubricant from leaking out of the box body, the rear bearing element is sealed with a cuff. The end part of the secondary shaft fits into the primary shaft.

The secondary shaft is centered using three bearings, which simultaneously ensure its fastening. A needle type is used at the front; it is located at the end of the input shaft. The second ball-type bearing is intermediate and is located behind the 1st gear gear. The third bearing is also a ball bearing and is located in the box housing cover behind the secondary shaft. The industrial shaft is located below the two previous shafts. At the same level with it there is a unit that allows the car to move backwards.

VAZ 2101 gearbox diagram: 1 - gearbox pan; 2 — plug for the hole for controlling the amount of gearbox lubricant; 3 — gear of the 2nd stage PrV; 4 — gear of the 3rd stage PrV; 5 — PrV with a set of gears; 6 — bearing PrV (front); 7 - thrust bolt; 8 — washer; 9 — PrV gear (with constant clutch); 10 — synchronizer washer for the 4th stage of the PV; 11 - input shaft; 12 — crankcase front cover; 13 — oil seal; 14 — bearing PV (rear); 15 — clutch housing; 16 — housing 17 — breather of the crankcase ventilation system; 18 — PV gear (with constant clutch); 19 — explosive bearing (front); 20 — 4th stage synchronizer ring; 21 — synchronizer clutch of the 3rd and 4th stages; 22 — 3rd stage synchronizer ring; 23 — 3rd stage synchronizer spring; 24 — gear of the 3rd stage of the explosive; 25 — gear of the 2nd stage of the explosive; 26 — hub of the synchronizer coupling of the 1st and 2nd stages; 27 - secondary shaft; 28 — gear of the 1st stage of the explosive; 29 — bushing; 30—BB bearing (intermediate); 31 — gear ZH BB; 32 — lever rod; 33 - pillow; 34 — bushing; 35,36 — bushings (remote, shut-off); 37 — boot (external); 38 — boot (internal); 39 — lever support washer (spherical); 40 — gearshift lever; 41 — explosive seal (rear); 42 — cardan coupling flange; 43 — nut BB; 44 - seal; 45 - ring; 46 — BB bearing (rear); 47 — odometer gear; 48 — odometer drive; 49 — gearbox housing cover (rear); 50 — fork ZX; 51 — gear ZX (intermediate); 52 — gear ZH PrV; 53 — axis of the intermediate gear ZX; 54 — gear of the 1st stage PrV; 55 - magnet; 56 - plug

SPECIFICATIONS

In order for the car to move at different speeds, each gear in the VAZ 2101 gearbox has its own gear ratios, which decrease as the gear increases:

- first - 3.753;

- second - 2.303;

- third - 1.493;

- fourth - 1.0;

- rear - 3.867.

Such combinations of gear ratios provide high traction in the first stage and maximum speed in the fourth. To reduce noise during operation of the unit, all gearbox gears operating while the machine moves forward are made with oblique teeth. Reverse gears have straight teeth. To ensure ease of control and gear changes with minimal loads (shocks), the forward stages are equipped with synchronizer rings.

WHAT TRANSMISSION TO PUT ON A VAZ 2101

The VAZ 2101 can be equipped with several options for boxes. Their choice depends on the goals being pursued, i.e. what the car owner wants to achieve: greater traction, dynamics, or whether a universal car is needed. The main difference between gearboxes is the difference in gear ratios.

FROM ANOTHER VAZ MODEL

Rear-wheel drive Zhigulis at the dawn of their production, in particular, the VAZ 2101/02, were equipped with only one gearbox - 2101 (they did not have a reversing light switch). A similar gearbox was installed on 21011, 21013, 2103. In 1976, a new unit 2106 with different gear ratios appeared. They were also equipped with the VAZ 2121. In 1979, another gearbox was introduced - 2105 with its own gear ratios, which were intermediate between 2101 and 2106. The 2105 gearbox could be used on any classic Zhiguli model.

On the VAZ 2101 you can install a five-speed gearbox 21074

Which box to choose for the VAZ 2101? It is worth taking into account that the most universal is the 2105 gearbox. When developing gearboxes, compromise parameters were selected between reliability, efficiency and dynamics. Therefore, if you install a 2101 box on a VAZ 2106, the dynamics of the car will improve, but the service life of the rear axle gearbox will decrease. If, on the contrary, you set the gearbox from the “six” to a “penny”, then the acceleration will be slow. There is another option - to equip the VAZ 2101 with a five-speed gearbox 21074. As a result, fuel consumption will decrease slightly, and the load on the engine at high speeds will also decrease. However, a “penny” engine with such a gearbox will not pull well on climbs - you will have to switch to fourth gear.

Gear ratios at the gearbox

The seventh model of the Zhiguli received a good version of a five-speed gearbox. The designers of the Volzhsky Automobile Plant took a box from a VAZ 2105 as a prototype, replaced the gear ratio of the main gearbox pair from 4.3 to 4.1, then to 3.9 and obtained the following gear ratios.

| home | 1st gear | 2nd gear | 3rd gear | 4th gear | 5th gear | Reverse |

| 4,1/3,9 | 3,667 | 2,100 | 1,361 | 1,000 | 0,820 | 3,530 |

The gear ratio is the ratio of the number of teeth on the driven gear to the number of teeth on the drive gear.

Primary shaft

The input shaft transmits torque from the engine crankshaft through the clutch disc to the gearbox. The disc is located on the splines of the front part of the shaft. A constant mesh gear is rigidly mounted on the shaft.

For free rotation, it is placed in two bearings. One bearing is located at the end of the crankshaft, the other is in the front cover of the gearbox.

Secondary shaft

In a complex gearbox mechanism, the secondary shaft is the final stage in converting torque and transmitting it to the cardan. The gears of the first three speeds move freely on this shaft. At a certain gear, they engage with the intermediate shaft gears and provide the required torque.

The shaft is placed in bearings, there are three of them. One is pressed into the end of the input shaft, the other into the box body, and the third into the rear cover.

Intermediate shaft

The intermediate shaft transmits rotation from the primary shaft to the secondary shaft.

He plays the role of a satellite. The gears and shaft are made from a single piece. It is installed on three bearings. The gears for fifth and reverse speed are located on it.

Forks

In the process of switching speeds, forks are involved, which move gears along the shaft to a certain place.

The gear shift lever moves the forks.

Transmission device diagram

The gear shift pattern of a 5-speed gearbox itself is almost the same as a 4-speed gearbox, with the only difference being that another 5th speed has been added to it, which is activated by moving the lever all the way to the left and forward. A schematic representation of the main components of the structure looks like this:

The VAZ 2107 transmission is contained in housing No. 3, which is closed with covers. Shift lever No. 5 is located at the top.

Main details

The main systems and parts of the gearbox are located in building No. 3.

The transmission system consists of three shafts:

- primary with four gears;

- secondary No. 10 with gears;

- intermediate.

Since the schemes of these mechanisms are complex, we will dwell on them in more detail.

Primary shaft

The input shaft is one piece with gears rotating on bearing No. 3, which is located in the gearbox housing.

Secondary shaft

The secondary shaft is in some way an extension of the primary shaft. It contains gears of the 1st No. 23, 2nd No. 24 and 3rd No. 25 speeds, which move in predetermined positions, which mesh with the corresponding gears of the intermediate No. 1. The gears differ in diameter, as a result of which the amount of torque changes.

The secondary shaft rotates on bearings No. 9, No. 11 and No. 12. The first one - the roller one is placed in the primary one, the others - in the crankcase and the rear cover.

Intermediate shaft

The intermediate shaft is necessary to transmit the required torque to the secondary from the primary. Rotation occurs on ball bearings No. 2, No. 22 and No. 19. The gears and shaft are one unit. This block contains the gears of the 5th No. 18 and rear No. 20 gears. The rear one is placed on shaft No. 21 and connected to secondary splines.

Transmission lubricant is poured into the VAZ 2107 gearbox through hole No. 11, which is located on the left side of the case and is closed with a special plug. The lower part of the body is closed with a steel lid secured with nuts. The places where the cover and body connect are sealed with gaskets that prevent possible lubricant leakage. The bearings of all axes are sealed with special seals that prevent the lubricant from leaking out.

The volume of oil required to refill the VAZ 2107 gearbox is approximately 1.6 liters. Some drivers pour lubricating fluid through the place where the handle is inserted into the box. This method is much easier than the usual one, because the handle is located in an easily accessible place, which cannot be said about the oil filler neck.

Speed shifting occurs through forks driven by a lever. The key parts of the gearshift system are shown in the diagram.

Rules for disassembling and assembling the gearbox

If the user has never encountered the repair of such a complex unit, the procedure should be carefully prepared.

- Disassembly of the mechanism is carried out only after it has been completely cleaned of dirt.

- All the tools required for disassembly are pre-prepared - keys, squeezes, pliers, lock ring pullers. It is also advisable to have a separate container for storing small bolts, nuts, and washers.

- It is necessary to dismantle the mechanism parts by first treating the bolts with an anti-boiling agent.

- When disassembling, the units are folded in the dismantling sequence.

- Human memory is extremely unreliable - a photograph of a disassembled mechanism before its reassembly is the best reminder.

- All gaskets without exception must be replaced. Recycling of seals is strictly prohibited.

- No one has canceled the abundance of the cleaner. When washing the structure, you should not skimp on the cleaning material; the better you wash it, the more fun it will be.

- Assembly of the unit is carried out exclusively in the reverse order.

- If after installation there are excess parts left (which is not uncommon), the entire gearbox is completely rebuilt.

It is also necessary to maintain maximum cleanliness during work. Dust, metal shavings, or foreign objects can cause serious damage to the gears.

Types of gearboxes in a car

Let's look at the distinctive features of each type.

- A manual transmission, or, in other words, manual, is a classic type of gearbox. However, it has proven itself to be excellent among car owners who prefer maximum control over the car.

- Automatic transmission has also been known since relatively ancient times. The gears in this gearbox change automatically, but driver intervention is still required to change direction. The disadvantage of automatic transmission is higher fuel consumption and slow acceleration compared to manual transmission. Although in new automatic transmission models the acceleration is improved.

- The robotic gearbox is a manual gearbox with integrated automatic control. This variety combines the capabilities of an automatic (no need to monitor engine speed) and manual (for those who like fast acceleration).

The robotic (variable) gearbox has a significant drawback - the possibility of full use only on small cars. However, there are cases when a CVT was installed on crossovers such as the 2022 Honda CR-V with a 2.4-liter engine. The variable transmission design allows you to change the gear ratio thanks to continuously variable gear shifting or through electronic control. By changing the diameters of the pulleys, the speed of the car increases or decreases.

How much does a classic gearbox weigh?

A car's gearbox can be: Weighs together with the clutch, shift lever and clutch release fork 26.2 kg.

How much does a manual transmission weigh?

How much does a manual transmission weigh in kg? About 50.

How many gears are there on a VAZ 2101?

The VAZ 2101 4-speed manual transmission was introduced in 1970 and served as the ancestor of a series of classic manual transmissions that are still installed today. This transmission is essentially a reinforced version of the box from Fiat 124. The classic family also includes gearboxes: 2105, 2106 and 2107.

How much does the rear axle of the VAZ 2101 weigh?

52 kilograms – rear axle; 7 kilograms – radiator; 280 kilograms is the actual weight of the VAZ 2101 body.

How much does the gearbox on a VAZ 2106 weigh?

Body weight 300 kg. Curb weight of the VAZ-2106 is 1045 kg. Engine with equipment - 140 kg, gearbox - 26, Cardan - 10, ZM - 52, wheel assembly with tire - 15, radiator - 7 kg.

How much does it cost to scrap a VAZ 2106?

Scrap car prices table

| Automobile | Blockage | Price |

| VAZ (LADA) 2106 | 25 % | 7100 |

| VAZ (LADA) 2107 | 25 % | 7100 |

| VAZ (LADA) 2109 | 25 % | 6500 |

| Moskvich-412 | 25 % | 7100 |

How much does an automatic transmission weigh?

For information. A dry automatic transmission at 3.5 weighs 75 kg.

How many gears are there on a VAZ 2105?

The 4-speed manual VAZ 2105 was introduced in 1979 along with the second generation of the classic Zhiguli and its new engine. The manual transmission differed from its predecessors in other gear ratios. The classic family also includes gearboxes: 2101, 2106 and 2107.

How does VAZ 2101 stand for?

How to engage reverse gear on a VAZ 2101?

To engage reverse gear, push the lever down to compress its spring. In this case, the protrusion of the lever will drop below the petal of the locking bracket 63, and you can move the gear shift lever back until the reverse gear is fully engaged.

How much does the rear axle gearbox on a VAZ weigh?

Rear axle – 52 kg; Radiator – 7 kg; Body – 280 kg.

How much does the rear axle of a gazelle weigh?

How much does the rear axle weigh?

Good afternoon If you do the math, the mass of the rear axle will be from 800 to 1000 kg. The total weight of the tractor is 2595 kg, the engine weight is about 400 kg, the front axle weight is from 200 to 400 kg.

Technical characteristics of manual transmission

In the operating instructions, the technical characteristics of the box are indicated together with the characteristics of the transmission. This is given in tabular form:

| Clutch | Single-disk, dry with hydraulic drive and central diaphragm spring |

| Transmission | Mechanical, five-speed, three-way, three-shaft, with synchronizers on all forward gears |

| Gear ratios | |

| First | 3.667 |

| Second | 2.100 |

| Third | 1.361 |

| Fourth | 1.000 |

| Fifth | 0.820 |

| Reverse | 3.530 |

| Cardan transmission | Twin-shaft with intermediate support and elastic coupling |

| main gear | Hypoid |

| Final drive ratio | 3.9 or 4.1 |

| Differential | Conical, two-satellite |

Transmission malfunctions

The box on the seventh model Zhiguli is considered a reliable unit. If you maintain it regularly and treat it with care during operation, then repairs will not be needed for a long time. However, all components and parts are subject to wear. There are many reasons for this. In any case, if a malfunction is detected in the gearbox, it is necessary to carry out diagnostics and repairs.

Most malfunctions occur of the following types.

One of the gears does not engage

Without opening the box, we can assume that:

- the hinges and springs are worn out and need to be replaced, or better yet, a complete repair;

- on synchronizers, the rings have become unusable and need to be replaced;

- synchronizer spring burst, replace;

- The teeth on the transmission gears are worn, replace the gear.

Knocks out gear when driving

It happens that when you turn on a gear, it does not turn off randomly. Possible reasons:

- the lever hinge is jammed, inspect and clean;

- the clutch is faulty, it may not engage completely, adjust it, if the disc is worn, replace it;

- The shift lever is broken, replace it with a new one;

- Forks, shift gears are bent, replace with new ones.

Crunching and grinding in the box while driving

This problem appears for the following reasons:

- the bearings are worn out, they should be replaced, and at the same time check the seals;

- the teeth of the gears are worn out, in this case it is better to make a major repair;

- There is not enough or no lubricating fluid in the gearbox, find the leak and fix it, add oil.

Grease leaking from box

The gearbox is designed so that lubricant cannot leak out spontaneously. But if an oil stain has formed under the car, an inspection should be made and the leak eliminated.

The reason may be:

- wear of oil seals and sealing gaskets due to natural aging of rubber must be replaced with new ones;

- the fastenings of the covers on the box have become loose, tighten all the nuts and bolts completely;

- mechanical damage to the body or lids of the box; if the steel lid is damaged, it can be welded. If the crankcase is damaged, it is better to replace it, since it is cast from an aluminum alloy.

Work on dismantling the five-speed gearbox VAZ 2107

Installing the car on a lift (you can use an overpass or a pit) is preceded by disconnecting the battery and removing the radio panel:

- Remove and disassemble the gearbox rod.

- Remove the cover from the gap where the lever attaches and remove the foam filling.

- Remove the exhaust pipe from the exhaust system.

- Move the starter, disconnect the speedometer wire.

- Unscrew the bolts holding the cardan and remove it.

- The clutch cylinder is removed using the same method.

- After this, the gearbox is removed from the car. To do this, it is best to invite assistants who will support the mechanism while you unscrew the mounting bolts. At this stage, it is also advisable to drain the transmission oil.

After all these steps have been completed, we repair the VAZ 2107 gearbox.

How much do VAZ cars weigh if they are sold for scrap?

Vehicles from the Volzhsky Automobile Plant were popular in the post-Soviet countries. These cars served their owners for many years; many still have their vehicles. That is why questions about the weight of VAZ cars when selling them for scrap do not surprise anyone. Almost all VAZ models are currently outdated and must be disposed of.

Features of recycling

Before you sell your car for scrap, you should familiarize yourself with the recycling procedure.

Let's start with the fact that the average weight of one VAZ car is one ton. More detailed values will be posted below. If the owner of the vehicle wants to recycle it completely, then at the collection point they will deduct 30% from him for garbage and other unnecessary non-metallic parts.

You can consider in detail using an example how much a VAZ 2105 weighs for scrap metal. The exact weight of this car is 955 kg. Taking into account debris and excess non-metallic parts, the vehicle will weigh 660 kg.

It should be remembered that the price of scrap metal in large and small cities varies greatly. Therefore, it is important to be interested in the cost of scrap, and not just how much a particular vehicle weighs. It is worth asking relatives, acquaintances or friends about the approximate price of one kg of scrap in the region of residence. This will reduce the risk of falling for scammers.

Also, before deciding to scrap a car, you need to think about its transportation. If the car is a pile of metal, then it must be delivered to the location by tow truck. If the car has wheels and a tow, then the cost of a tow truck is significantly reduced.

In order to find out how much a Zhiguli costs for scrap metal, you need to ask how much a VAZ 2109 weighs for scrap metal or how much a VAZ 21099 weighs for scrap metal. It is important to find out all the features of the venue, conditions, rules and follow them so as not to get into an unpleasant situation.

Self-analysis of VAZ

Some people who find out how much a VAZ 2101 body weighs for scrap metal decide to disassemble it themselves. You can remove all the expensive parts, sort them, recycle them and receive revenue. Only in this case will self-disposal be beneficial.

A little more about VAZ

To better understand the topic, it is important to consider a couple more examples.

How much does a VAZ 2107 weigh for scrap metal? Its mass ranges from 1030 to 1060 kg. If you subtract 30%, it turns out that the owner of the vehicle will only be paid 721-751 kg of scrap metal.

How much does a VAZ 2106 weigh for scrap metal? The mass of its body is about 300 kg. Motor – 140 kg. Mosta – 52 kg.

You should not dispose of a vehicle yourself without certain skills. It is better to take it to a specialized point where disposal will be quick and safe.

Which bearings are better for a VAZ 2107 box?

Transmissions of classic models from AvtoVAZ are distinguished by good reliability, ease of maintenance and relative, compared to foreign models, ease of repair. However, given the advanced age of even the youngest models, many may have problems not only with the body, electrical and other parts, but also with the operation of the gearbox. Its system contains a large number of parts, the operation of which as a whole is critical for the system. These components include the bearing of the input shaft of the VAZ 2107 gearbox. This small part is responsible for the operation of the gearbox shaft itself, which ensures unimpeded transmission of torque and changes in gear ratios.

Similar functions are performed by other bearings in the box - the secondary shaft and the intermediate shaft. These parts are made of especially strong metal cases in the shape of a circle, with a large number of moving parts in the form of metal hinges, which allow the shafts to freely carry out their direct functions.

At the same time, the reliability of these parts is quite high; they fail only at very high mileage or when critically high loads are applied to the gearbox. Also, such parts undergo simple diagnostics. There are many different components on the market in the form of spare parts for VAZ cars.

Attention! Foreign brand companies that supposedly produce products specifically for the classic VAZ 2107 model often hide cheap Chinese products, which, even if they fit into the seats, will not be able to fully ensure trouble-free long-term operation of the box.

Gearbox device for VAZ 2107

In general, the five-speed transmission has the same functions as its predecessors: it varies the direction and magnitude of torque from the engine. The differences are that the five-speed has 6 speeds, including 1 reverse speed.

Inside the gearbox housing there are:

- two types of shafts with different numbers of gears - primary and secondary;

- levers responsible for changing gears.

If any malfunctions are detected, it is recommended to remove the box based on the manufacturer's instructions.

Signs and causes of box malfunctions

The gearbox on the VAZ 2107 is considered a fairly reliable unit, however, during long-term use, some of its elements may fail for one reason or another. If the first disturbances in the operation of the gearbox appear, in order to avoid more serious breakdowns, it is necessary to diagnose and fix the problem as quickly as possible.

The list of main breakdowns of the VAZ 2107 manual transmission, the causes of their occurrence and methods of elimination are varied. It is important to pay attention to the following signs, as well as choose the right repair methods:

- The gears are engaged randomly or not at all (wear of the moving parts of the gearbox (spring, hinges), wear of the locking rings on the synchronizers, wear of the synchronizer spring, wear of the teeth on the gears). The problem is eliminated by replacing faulty parts, or by carrying out a major overhaul of the box;

The gear is knocked out when switched on, the engine is subjected to heavy loads (the clutch is not fully engaged, the hinge on the shift lever is jammed, the shift lever is faulty, the forks in the gearbox are deformed). The problem is eliminated as follows: adjusting the clutch mechanisms, cleaning the hinge joints, replacing the lever or replacing a whole set of forks;

VAZ 2107 box repair

Taking into account all the design and operational features of the VAZ 2107 gearbox, carrying out repair work independently is only possible if you have extensive experience in servicing and repairing such units. If the box on a VAZ 2107 needs repair, the main stages of repair work are:

- preparation (availability of the necessary tools, pit or overpass);

- installing the car on a pit/overpass, draining the oil from the gearbox, etc.);

- dismantling the box;

- disassembly and troubleshooting;

- trouble-shooting;

- assembly and installation of the box in place.

- socket wrench at “10” and “19”;

- Phillips-blade screwdriver;

- tweezers and two screwdrivers with a thin flat blade;

The general procedure is as follows:

- install the car on a viewing hole or on an overpass;

- by disconnecting the wire from the negative terminal on the battery, drain the gearbox lubricating fluid (gear oil);

- Having removed the radio panel and pressing the lever, insert a flat-head screwdriver into the hole in the locking sleeve of the box to bring it out;

- Having removed the rod from the lever, use tweezers to remove the elastic rubber insert of the damper from the lever;

REPAIR

The VAZ 2107 has -speed gearbox, which, despite the comparative simplicity of its design, can become unusable for reasons classic for manual transmissions:

- wear and tear due to natural reasons: high mileage, irregular operation and depletion of the service life of components, weather conditions not meeting the desired ones, and as a result - a decrease in service life, etc.;

- non-compliance of the working fluid with standards suitable for normal operation of the transmission;

- non-original spare parts included in the box;

- damage to the gearbox housing due to mechanical impact;

When it comes to the gearbox, even if it is a Zhiguli, the best option would be to entrust diagnostics and maintenance to specialists at a service station. Fortunately, repairing it will not cost too much, except in rare cases that require a complete replacement of the entire mechanism, when it would be more advisable to purchase the same new car.

Gearbox seals and their replacement

Oil seals in any mechanism where they exist act as gaskets. In this case, they are designed to seal the holes from which the primary and secondary shafts come out. Previously, oil seals were cast from rubber.

Currently made from modern composite materials, more resistant to temperature changes and aggressive environments.

Input shaft oil seal

The oil seal, which is installed on the input shaft, has the following dimensions:

- • outer diameter – 47 mm;

- • internal diameter – 28 mm;

- • width – 8 mm;

- • weight – 20 grams.

It is installed in the shaft output hole in the clutch housing and serves to prevent lubricant from flowing through the shaft.

There is no difficulty in replacing the oil seal, but the gearbox will have to be removed.

The order of work to change the oil seal is as follows:

- Remove the clutch cover from the gearbox.

- Remove the release bearing and clutch fork.

- Remove the used oil seal by picking it up with a screwdriver or knife.

- Clean the place where the oil seal was located and wipe it dry.

- Install the new oil seal in its original place.

- Replace all the parts that were removed from the box in reverse order.

Secondary shaft oil seal

The oil seal, which is installed on the secondary shaft, is larger and has dimensions:

- outer diameter – 56 mm;

- internal diameter – 32 mm;

- width – 10 mm;

- weight – 10 grams.

It is installed at the output of the secondary shaft at the rear of the box.

The order of work to change the oil seal is as follows.

- Unscrew the nut securing the flange, having previously secured it.

- Remove the centering metal ring from the shaft.

- Remove the flange and washer using a puller.

- Pull out the old oil seal using a tool.

- Clean and wash the seal area.

- Install a new oil seal.

Replacing gears and synchronizers

The work of replacing gears and synchronizers is one of the most difficult when repairing a gearbox. There is a standard repair kit containing all the necessary parts to help cope with the task. It is advisable to prepare a special tool.

Gears and synchronizers on the primary and secondary shafts are changed in almost the same way.

The process goes like this:

- remove the shaft from the box;

- clamp the shaft in a vice, wrapping it in something soft;

- Remove the retaining ring from the shaft using a special tool or a screwdriver:

- press the bearings off the shaft;

- remove the shaft from the vice, place it vertically, resting the first gear on two supports;

- carefully press the gear off the shaft;

- Carry out similar operations with the remaining gears and synchronizers.

Removing and replacing the fifth gear gear occurs differently.

Transmission oil for gearboxes

To select gear oil for the Lada gearbox, you need to take into account the region where the car will be operated.

Two types of oils are offered. The first - with a temperature range from +35 to -26, this is SAE 80W85 and the second - with a temperature range from +45 to -40, this is SAE 75W90.

The best oil is synthetic, but semi-synthetic and mineral oils will not harm the Seven’s transmission. The amount of oil in the VAZ 2107 gearbox is about 1.6 liters. The oil change time is carried out according to the instructions in the technical instructions supplied with the car.

Manual transmission oil level

The oil level in the box is checked as follows:

- drive the car onto an overpass or pit;

- clean the filler plug;

- unscrew the plug;

- measure through the hole with a probe or other object resembling a probe. The oil should be level with the end of the filler hole; top up if necessary.

Oil change

It is better to change the oil on an overpass or pit with a warm engine, so the oil will drain faster. Prepare the tool in advance, a container for working out at least two liters, oil for changing.

The order is as follows:

- clean the fill and drain plugs from dirt;

- Place the prepared container for used oil under the drain hole;

- open the drain hole and wait until the oil completely drains into the container;

- clean the plug of old oil and close the drain hole;

- pour 1.5 liters of new oil into the box through the filler hole (it’s better to fill it with a supercharger);

- let it sit for ten minutes, then check the level and top up if necessary.

OIL IN GEARBOX VAZ 2101

The oil in the “penny” gearbox, like in any other vehicle unit, needs to be replaced periodically. But before you perform this procedure, you need to know when and how to replace it and what lubricant to use.

WHAT OIL TO PUT INTO THE VAZ 2101 GEARBOX

Today there is a wide selection of transmission oils for cars. The difference between them lies in the additives used, or, more precisely, in their classes. There are the following classes of markings: from GL 1 to GL 5. For the VAZ 2101 gearbox, the best option is considered to be GL 5 class oil with a viscosity grade of 85W90 or 80W90. This lubricant is intended for hypoid gears and provides good lubrication of rubbing elements even under high loads. In addition, GL 5 oil can be used not only for the gearbox, but also for the rear axle. Of the manufacturers, preference should be given to those who are suitable in terms of price.

The VAZ 2101 gearbox must be filled with GL5 class gear oil with a viscosity of 85W90 or 80W90

CHECKING THE OIL LEVEL

For the gearbox to function properly, the oil level in the crankcase must always be optimal. It needs to be checked periodically. If the grease level in the box is normal, it should be level with the bottom edge of the filling hole. The oil volume in the VAZ 2101 gearbox crankcase is 1.35 liters.

HOW OFTEN TO CHANGE THE OIL IN THE TRANSMISSION OF A VAZ 2101

Although transmission oil is rarely changed, you still need to know when this procedure is necessary. As a rule, on a “classic” it is done every 40–60 thousand km. mileage or 3 years from the date of filling.

HOW TO DRAIN THE OIL

To drain the oil from a VAZ 2101 gearbox, you will need a hex wrench and a container of suitable volume, for example, a cut-off plastic bottle. Using a hexagon, unscrew the drain plug, which is located in the lower cover of the crankcase, and drain the oil.

To drain the oil from a VAZ 2101 gearbox, unscrew the drain plug in the bottom cover of the box using a hexagon.

The drain plug is wiped clean of dirt and screwed back into place. In addition, you need to pay attention to the drained oil and, if there is metal dust in it, you will need to repair the box as soon as possible.

HOW TO FILL OIL

To fill the gearbox with lubricant, you need to unscrew the filler plug with a 17mm wrench and clean it of dirt. The oil is poured in the required volume using a special syringe. Many people do not measure the required volume of lubricant, but simply fill it in until it begins to flow back out. After filling, immediately screw the plug into place. Instead of a syringe, you can use homemade devices if you have the desire and time to make them.

Oil is poured into the gearbox using a special syringe through the oil filler hole.

VIDEO: CHANGING THE OIL IN THE TRANSMISSION ON A CLASSIC

Transmission repair: when to do it

Repair of the VAZ 2107 gearbox may be required in the following cases:

- Excessive noise is produced when the box operates. This noise is caused by increased wear of bearings, gears and synchronizers.

- It becomes difficult to change the transmission. The reasons for this consequence are hidden in the wear of the lever, the lack of lubricant inside the box, and the deformation of the gearbox lever. Also, the cause of this phenomenon may be jamming of the blocking cracks or damage to the coupling splines.

- Spontaneous transmission shutdown. The reasons for this consequence are wear of the ball holes on the rods, jamming of the clamps, blocking rings and the synchronizer itself.

- Oil leakage occurs. Repair of the VAZ 2107 gearbox must be carried out when oil leaks are detected on it. The causes of leakage can be either serious damage or simple wear of oil seals and seals.

In any case, disassembling the gearbox will be required if one of the above symptoms occurs, which will allow us to identify the exact cause of the malfunction and eliminate it. If even the slightest malfunction of the gearbox is detected, it is necessary to begin repairing it, which will prevent unforeseen consequences in the form of complete failure of the gearbox.

Features of repairing a gearbox on a VAZ 2107

The design of the gearbox is no more complicated than the design of the engine itself, but in order to carry out repairs correctly, a certain sequence must be followed. We will find out in more detail in what sequence the disassembly and assembly of the gearbox is carried out.

- Initially, the gearbox should be removed from the vehicle. We will not consider how to remove the gearbox, since there is appropriate material for this. One has only to note that first you need to drain the oil from the gearbox. We will begin repair work immediately.

- The box is dirty and oily, so it is recommended that you take your time with the repair and clean the outer surface of the product.

- Using a screwdriver, you need to pry off the cover of the fork, which is used to disengage the clutch. The fork is moved to the side. To remove the plug, you need to rotate it 90 degrees and remove it from the hole.

- The gearbox disassembly scheme is common for both 4 and 5 mortars. You need to unscrew the clutch housing mounting nuts, then unscrew and remove the spring washers. These washers are located directly behind the nuts.

- When the fasteners are removed, you can continue to disassemble the gearbox. To do this, you need to pull the crankcase, disconnecting it from the main device.

- There is a sealing element behind the crankcase that also needs to be removed. If the gasket is worn, it should be replaced. There is a spring washer on the shaft, which also needs to be removed.

- Using a “10” wrench, you need to unscrew the 10 nuts securing the crankcase cover. After unscrewing all the nuts, remove the spring washers located behind these nuts. The cover also needs to be removed.

- Behind the cover there is a seal, which should also be removed by prying it off with a screwdriver.

- The photo below shows the nuts that need to be unscrewed. These nuts secure the rear engine mount to the gearbox housing. Behind the nuts there are washers that must be removed, as well as a cushion complete with a cross member.

- Do-it-yourself disassembly of the gearbox continues with unscrewing the speedometer drive nut. After unscrewing this nut, it is necessary to dismantle this drive.

- The VAZ 2107 transmission is a mechanism with a set of gears and forks through which the vehicle moves. Having turned the gearbox over to the other side, you need to remove the reverse light switch.

- The bolt securing the fork, which is responsible for switching third and fourth gears, is unscrewed.

- You need to turn on the first transmission using the gearshift lever on the VAZ 2107.

- At the same time as first gear is engaged, fourth gear must also be engaged. Using a screwdriver, move the synchronizer clutch to the side to connect it to the gear.

- You may ask, why is it necessary to engage 2nd gears at the same time? This is done in order to block the rollers from turning.

- The retaining ring is dismantled by prying it with a special puller on the secondary shaft.

- Using chisels and a hammer, bend the locking plate securing the flange nut.

- The nut must be loosened by 2-3 turns, which will allow the coupling centering ring to be removed. After moving the ring, you need to screw the nut.

- Using a special kind of puller, you need to dismantle the coupling ring.

- After removing the ring, it is necessary to dismantle the centering ring seal.

- Now you can use a wrench to unscrew the nut.

- There is a retaining ring behind the nut that also needs to be removed.

- Using another puller, it is necessary to dismantle the flange.

- The gearshift lever must be set to the neutral position, and then the sealing collar must be pulled up.

- Behind the cuff there are nuts that need to be unscrewed. After unscrewing them, the lever or rocker is dismantled.

- Behind the scenes there is a seal that must be removed.

- The gearbox on the VAZ 2107 is further disassembled by unscrewing the two nuts securing the exhaust pipe.

- There is a bolt behind the bracket that should also be removed.

- To remove the back cover of the box, you need to unscrew the 5 outer nuts.

- Another nut secures the cover from the inside, so after unscrewing the 5 outer nuts, you should proceed to the last one - the inner one.

- It is necessary to disconnect the back cover and the box housing, which requires moving the back cover. The fastening nut is unscrewed, and then the washer is removed.

- After unscrewing all the nuts, it is necessary to remove the rear cover from the crankcase, rocking it. The crankcase cover will come off on its own.

- After removing the cover, it is necessary to remove the inner ring from the secondary shaft. Behind the ring is the speedometer drive gear, which must also be removed.

- The cover of the clamps is found, after which the two bolts securing it are unscrewed. After removing the bolts, you must remove the cover.

- There is a gasket under the cover that needs to be removed.

- The spring clips are removed.

- The gearbox must be turned over, thereby removing the retaining balls.

- You need to find the drive gear retainer ball and remove it. The oil deflector washer also needs to be removed.

- You should continue further if two gears are engaged at the same time. With two gears engaged, it is necessary to unscrew the bolt securing the 5th gear gears. As you guessed, this procedure is performed for the VAZ 2107 5 mortar gearbox.

- The fastening of the 5th gear shift fork, as well as the reverse gear, is unscrewed. After unscrewing, you must remove the plug.

- By holding the rod of the 5th gear, as well as the reverse transmission, you need to remove the rod from the crankcase and the shift fork.

- The gear block of the 5th gear and reverse gear is dismantled manually.

- The gear bushing is removed in the same way from the secondary shaft.

- Once the bushing is removed, you will need to remove the gear, ring gear, locking ring and synchronizer clutch for the five-speed transmission.

- The 5th gear synchronizer clutch hub is removed.

- The reverse control gear is also removed.

- From the inside, the intermediate shaft bearing is pressed out. To do this, you will need to take a hammer and a punch, and apply light blows.

- Next, the bushing is removed from the secondary shaft. It is also necessary to remove the outer ring from the rear bearing.

- Using a puller, you need to unclench the locking ring and remove it.

- Two gears are engaged at the same time - first and fourth. The bearing securing bolt is unscrewed.

- Place a screwdriver between the outer side of the ring and the shaft gear, thus removing the bearing ring together with the balls.

- The rear inner ring is pressed out.

- The intermediate shaft is removed.

- The locking block of the transmission rod 3 and 4 is removed.

- Crackers vary in size, so remember their location.

- The shift rod 3 and 4 of the transmission is removed.

- The 3rd and 4th gear shift fork is removed.

- The bolt securing the fork 1 and 2 of the transmission is unscrewed.

- The transmission rod 1 and 2 is removed.

- The locking block 1 and 2 of the transmission is removed.

- The fork for selecting these gears is removed.

- The complete input shaft is removed.

- The needle bearing is removed.

- It is necessary to unfold the locking plate until it disengages from the groove.

- The reverse gear axis is removed.

- The intermediate ring is removed.

- The key is removed from the groove of the secondary shaft.

- The intermediate bearing is removed.

- The secondary shaft is recessed into the inside of the crankcase, thereby removing it.

- Using a hammer, it is necessary to press out the secondary shaft bearing.

- The sealing gland is removed.

- The bearing from the 5th gear can be removed with a screwdriver, using it as a lever.

We extract copper from the generator of the VAZ 2107.

Copper and aluminum and ferrous metal in the generator. We extract copper from the generator.

A table of the amount of copper in electric motors is suitable. ... It contains a large number of different materials, namely copper, aluminum and ferrous metal. Therefore, many users have a question about how much of this different metal is contained in electric motors, namely in the Soviet-made VAZ 2107 generator. Device parts containing copper.

Total weight 4.2 kilograms including aluminum, copper and ferrous metal. Let's try to break it down into its components.

Remove the voltage regulator relay with brushes.

Let's look closer - in a plastic case 1702.3702.-01 14 volts 5 amperes. Such a voltage regulator is easy to change on a dismantled generator; it is done very simply, without difficulty.

Inside you can see a thick copper wire, exactly what we were striving for today.

Unscrew the nuts and remove the four long bolts.

Remove the generator pulley and impeller.

We knock out the bearing and remove the aluminum generator cover.

The starter stator has some copper or copper windings.

We remove another bearing and in front of us is an internal rotor with a shaft and metal. Let's look further.

We bite off the copper wire from the connection points in the housing with simple wire cutters and the stator winding, but still with ferrous metal that needs to be removed.

But we see that there is also a copper wire on the rotor, but it sits far inside under the protection of the metal.

The rotor was removed. Let's start extracting copper from the rotor.

We extract from the autogenerator i.e. from the cover there is an iodine bridge, it will go into another category of valuable radio components.

These are diodes from the generator of a ZIL truck and as you can see inside, the yellow metal is gold, but white is also found and it’s probably palladium, we don’t know for sure.

Looking closer we see that the internal parts are gold plated. Most likely, the diode bridge of the Zhiguli 2101 also contains precious metals, including palladium.

But this needs to be checked, because they were produced in Soviet times, and then the diode production technology was completely different than it is now. So, let's take note of this and put radio components in the basket, if you have one, of course.

We look even closer and see that it is gold in color, copper has a completely different color and shade.

To knock out the rotor protection of the copper wire, you need to put in a lot of effort, but then we just knock out the copper coil of the rotor winding with a hammer.

The weight of the rotor copper wire is 251 grams of almost pure copper. If you burn it, there will be much more dirt.

Well, the weight of copper from the stator of the autogenerator was 358 grams.

Ferrous metal weighs almost 3 kg. with all stator and rotor parts + bearings.

Aluminum from two covers and a diode bridge holder turned out to be 884 grams. But it will be like auto duralumin and the prices for it in the purchase of scrap metal are different everywhere, you need to monitor where is the best place to sell it?

The total amount of copper obtained from the rotor and stator of the VAZ 2107 generator was 663 grams

-copper 663 grams

-aluminum 884 grams

- Ferrous metal 4 kg.

How much copper is there in a VAZ 2107 auto generator and how many different and valuable metals are there. Answer.

generator VAZ 2101. Content of ferrous, non-ferrous and precious metals in the generator VAZ 2101. Name of metal. Weight gr. % by weight. Copper. only 663 grams. Aluminum only 884 grams. Ferrous metal about 3 kilograms. Gold-plated diodes for radio components.

Now consider for yourself whether the VAZ 2107 generator needs to be disassembled into different metals and what is the benefit of it.

How much copper is there on average in autogenerators of the VAZ family and how much different and valuable metal is there. Answer.

generators of the VAZ family Content of ferrous, non-ferrous and precious metals in the VAZ generator Name of the metal. Weight gr. % by weight. Copper. only 900 grams on average. Aluminum 900 grams is also on average. Ferrous metal 2.4 kilograms + - kilogram. Gold-plated diodes for radio components.

Splines and forks

There is a reverse gear between the wall of the VAZ-2107 gearbox housing and the fifth gear. Since it produces a reverse movement, the part is not connected directly, but through an intermediate gear. It is installed on the axis of the rear wall of the transmission housing. The gear fork fits into the groove of the gear. When it moves, the intermediate element engages with the reverse gear. The secondary shaft has synchronization clutch hubs. They are motionless. A speed synchronization clutch is put on the gear ring of the hub.

As for the shift fork, it fits into the annular groove of the synchronization clutch. The latter moves along with the movement of the rod. The clutch begins to act on the synchronizer blocking ring and, as a result, moves it. Thanks to the friction force, the rotation speed of the hub and gear is equalized. The teeth mesh with the gear timing ring. Torque begins to flow to the secondary shaft through the hub and clutch from the gear.

Gearbox VAZ 2107 design description, device

The VAZ 2107 gearbox is designed to change the magnitude and direction of the torque transmitted from the engine to the drive wheels of the car. VAZ 2107 cars have a gearbox with five forward gears and one reverse gear. The gearbox of the VAZ 2107 consists of a steel front cover (installed in the clutch housing) and a cast aluminum alloy housing and rear cover. The connections between the gearbox housing and the rear cover and the clutch housing are sealed with gaskets. In front of the gearbox there is a clutch housing mounted on seven studs, which is attached to the gearbox with nuts and spring washers. At the rear, the gearbox is mounted on two studs to the power unit support. Front cover

VAZ 2107 gearbox is pressed into the clutch housing.

The input shaft oil seal is installed in the cavity of the gearbox cover. There is a hole in the end wall of the gearbox cover to drain oil flowing from the gearbox housing in case of damage or wear of the oil seal. The gearbox housing

contains: primary and secondary shafts with gears and synchronizers, an intermediate shaft and gear shift drive parts.

There is a filler hole in the left side wall of the gearbox housing, closed with a plug with a conical thread. From below, the gearbox housing is closed with a cover stamped from steel and secured to ten studs with nuts. The lid has a drain hole, closed with a plug with a conical thread and a permanent magnet. The cavity of the gearbox housing communicates with the atmosphere through a hole on top in the front wall of the crankcase and a breather mounted on the clutch housing. There is a hole in the rear wall of the crankcase to allow oil to pass into the cavity of the rear cover. The volume of oil poured into the gearbox on VAZ 2107 cars is 1.6 liters. The gear shift drive

is mechanical.

The gear shift drive consists of a gear shift lever, a gear selection mechanism, three rods with forks, clamps and a locking device. A handle is attached to the top of the lever on a thread. The shift lever shaft is connected to its lower part through elastic damper bushings, which absorb vibration and provide smooth gear shifting. The gear shift lever housing assembly with the gear selection mechanism and the ball joint housing is secured on top of the rear cover studs with three nuts. The spherical part of the gear shift lever is movably installed in the ball joint housing. The lower part of the lever fits into the groove of one of the rods. The gear shift lever, turning in the ball joint, acts on the rod, moving it and the fork fixedly fixed to the rod. The shift fork rod for the 1st and 2nd gears and the shift fork rod for the 3rd and 4th gears are movably installed in the holes in the front and rear walls of the crankcase. The fork rod for selecting V gear and reverse gear is installed in a hole made in the boss of the rear wall of the crankcase. The rods are held in the neutral or on positions by spring-loaded ball retainers, for which there are three slots in each rod. The clamps with springs are located in bushings pressed into the holes of the gearbox housing and closed with a common cover. To prevent the simultaneous engagement of several gears (moving the rods), the drive has a locking device consisting of three locks located in the holes of the rod of the 3rd and 4th gears and the rear wall of the crankcase. The rear cover

of the VAZ 2107 gearbox is installed on six studs and secured with nuts and spring washers.

The speedometer drive is mounted on the left side of the rear transmission cover, the driven gear of which meshes with the drive helical gear mounted on the splines of the rear journal of the secondary shaft. The input shaft

of the gearbox is manufactured integrally with a constant mesh helical gear.

The spur ring of the 4th gear synchronizer is pressed onto the rear belt of the shaft and then welded. On the crown of the 4th gear there is a spring-loaded synchronizer blocking ring secured with a locking ring. The teeth of the inner ring of the synchronization ring engage with the teeth of the 4th gear synchronizer. The front part of the shaft has splines on which the clutch driven disc is located. The shaft rotates in two ball bearings; the front one is located at the end of the crankshaft, and the rear one is located in the front wall of the gearbox housing. An adjusting ring in the groove of the rear bearing outer race prevents axial movement of the shaft. The secondary shaft, located on the same axis as the primary shaft, rotates in three bearings. The front roller bearing is located in the bore of the end of the input shaft, the intermediate ball bearing is located in the rear wall of the crankcase. The rear roller bearing is installed in the socket of the rear cover of the gearbox and is sealed from the outside with an oil seal. A flange of an elastic coupling (propeller shaft) is attached to the rear splined end of the secondary shaft. Transmission gears with synchronizers are movably mounted on the secondary shaft. They are made in the form of a single block, consisting of a helical transmission gear and a synchronizer ring gear, with blocking rings attached to them. The gears of the gears are in constant mesh with the corresponding gears of the intermediate shaft and the gear block of the 5th gear and reverse gear. The intermediate shaft

of the gearbox is made in the form of a block of four gears and rotates in bearings installed in the front and rear walls of the VAZ 2107 gearbox housing. The intermediate shaft drive gear is in constant mesh with the input shaft gear.

The block of gears of the 5th gear and reverse gear is bolted to the rear end of the intermediate shaft. The other end of the block rests on the bearing in the wall of the rear cover of the gearbox housing. A reverse gear is installed on the splines of the secondary shaft

between the rear wall of the crankcase and the 5th gear.

The reverse gears are connected through an intermediate gear mounted on the axle, with the possibility of axial movement. The axle is secured with a nut on the rear wall of the crankcase. The annular groove of the gear includes a gear shift fork, when moved, the intermediate gear meshes with the reverse gears. The synchronization clutch hubs are fixedly mounted on the secondary shaft. The protrusions on the inner surface of the hubs of the synchronization clutches of the 1st - 2nd and 3rd - 4th gears fit into three grooves on the shaft, and the hub of the 5th gear clutch is put on the splined part of the shaft. A gear synchronization clutch is placed on the outer gear rim of the hub with its inner gear rim, forming an engagement with the clutch. The gearshift forks

fit into the ring grooves on the outside of the synchronization clutches. When the rod moves, the fork displaces the coupling. The clutch, acting on the synchronizer blocking ring, moves it. Under the influence of friction forces arising between the clutch and the synchronization locking ring, the rotation speed of the gear and hub is equalized. The teeth on the gear synchronization clutch mesh with the teeth on the gear timing ring. The moment is transmitted from the gear through the clutch and hub to the secondary shaft.

Front cover

It is installed in the clutch housing. Inside there is an oil seal for the input shaft. On the end wall there is a hole for draining transmission oil, which can flow out of the crankcase if the oil seal is worn. In addition, the box housing contains:

- Primary and secondary shaft.

- Gears, synchronizers.

- Intermediate shaft with shift drive elements.

There is a filler hole in the left wall of the new VAZ-2107 gearbox. It is closed with a metal plug with a conical thread. At the bottom, the box housing is closed with a stamped steel cover. The crankcase is secured with ten nuts. There is a breather in its cavity. There is a passage for oil in the rear wall of the crankcase. it enters the cavity of the lid

Sources

- https://7vaz.ru/remont/kpp-na-vaz-2107.html

- https://rus-avtomir.ru/remont/kpp-vaz-2107

- https://prometey96.ru/tyuning/korobka-vaz-2107.html

- https://kalina-2.ru/remont-vaz/razborka-sborka-kpp-vaz-2107-5-stupka

- https://iga-motor.ru/avtomobili/kak-raspolovinit-korobku.html

- https://GrandFart.ru/tormoza/korobka-pyatistupka.html

- https://AvtoSotka.ru/korobka-peredach/sborka-kpp-vaz-2107.html

- https://CoptersWorld.ru/pro-dvigatel/transmissiya-vaz-2107.html

[collapse]