Pressure characteristics in an automobile fuel system are one of the most important parameters used during diagnostics. The behavior of the vehicle in various operating modes directly depends on this indicator. Using pressure data, the condition of various elements of the fuel system, for example, the pump, is studied.

What pressure should be in the VAZ 2110 fuel system?

On a VAZ 2110 with 1.6 liter engines, the pressure in the ramp is constant and amounts to 3.6-4.0 atm. Otherwise, the measurement technique is similar. Alternative ways:

- It is measured at the outlet fitting of the fuel pump module - this is the one with one tube. You will need a flexible gas-resistant hose with an internal diameter of about 8 mm and a pressure gauge (you need to remove the tube and put on a hose with a pressure gauge instead). The pressure should be 5-7 atm.

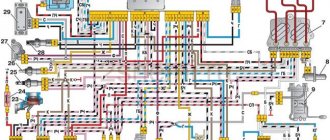

- Close the return line, as is done on an internal combustion engine with a drain ramp, but you must turn it off again at the fuel pump itself. We pull off the second hose (double) and insert a plug into the removed hose, made, for example, from an old fuel filter (saw off the nipple from it and plug it). A single hose must be put on the pump fitting, and now the measurement must be made at the fuel rail. According to the power system diagram, everything will be clear.

1 – fitting for checking the pressure in the power system; 2 – fuel rail; 3 – nozzles; 4 – fuel line; 5 – fuel tank; 6 – fuel pump module (in the fuel tank); 7 – fuel filter; 8 – tee.

What devices are used

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Several instruments can serve as devices for taking pressure readings.

- A special device purchased from an auto parts store. It comes complete with an adapter, drain hose and pressure gauge. Costs about 1.5 thousand rubles.

- Converted tire pressure gauge. The instrument scale and tube are subject to modification. As you know, the air pressure gauge shows a value of up to 20 atm, and the fuel measurement limit is around 5-7 atm. For this reason, reading errors may occur, and the device is modified to take this into account. Regarding the tube: you need to change it to a gas-resistant version.

Problems with the car's fuel system

are expressed by failures at high speeds, jerking of the car, or the car does not move when you need to accelerate sharply, and sometimes it simply stalls. Now knowing how to check the pressure in the fuel system of a car, we can diagnose the car ourselves. We can determine which component of the fuel system has failed (gasoline pump, fuel pressure regulator (FPR), injectors, filters, etc.), but first we need to understand how the fuel system works: The gas pump continuously pumps fuel while the engine is running. Excess gasoline is stupidly dumped through the RTD into the return line.

The pressure in the ramp changes (increases) not so much with the speed, but at the moment of accelerating (this is clearly visible in the video), because at this moment the vacuum (vacuum) in the receiver drops and the RTD adds pressure in the ramp.

If you turn off the engine, the pressure in the ramp will slowly begin to decrease exponentially. The rate of decline (from several minutes to several hours) depends on the quality of the check valve, which is located on the back of the fuel pump motor. When diagnosing, pressure measurements in the system are made in different ways:

- Measuring how much the needle jumps when the ignition is on

- Measured at XX

- Measurement with the tube dropped from the RTD

- Metering with pinched return

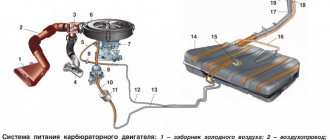

Checking the fuel pump of a carburetor car (mechanical)

Mechanical fuel pump - diagram

To check the operation of the fuel pump, you should:

- Remove the fuel hose from the carburetor inlet fitting.

- Immerse the hose in a specially prepared transparent bottle. By actively using the pumping lever manually, we notice how strong and dense the fuel is supplied. Air impurities should not be visually noticeable.

Delayed jet output is not a sign of a breakdown, especially if the car has been parked for a long time. As a rule, diaphragms eight and nine are the main cause of malfunction.

Be that as it may, you need to inspect both the strainer and the inlet/outlet valve.

Even if the gaskets are replaced, fuel may leak. In this case, the problem lies in the tightness of the fuel pump housing due to deformation during repairs.

Let's summarize:

The causes of fuel pump problems, both electrical and mechanical, are varied, and the need to find/fix a breakdown may take you by surprise along the way. By following the above recommendations, you will be able to independently carry out the entire necessary set of measures to diagnose this device. And you should start with the power supply (if it is an electric fuel pump) and the operation of the diaphragm when checking a mechanical fuel pump. Very often, the unstable operation of a fuel pump is not due to its breakdown, but to related parts - a filter, check valve or injectors.

To provide information more conveniently, we will divide the article into two large parts:

How to measure the pressure in the fuel system with your own hands

to find out the pressure in the fuel rail . For example, buy a device to check fuel pressure. A kit with a fuel pressure gauge, adapter and drain will cost you 1200-1300 rubles. Pay RUB 300 to the service station and take measurements there. You can also measure the pressure in the fuel system with an air pressure gauge , which is used to measure tire pressure. I will dwell on this point in more detail. Since the site is dedicated to cars of the tenth family, then further figures and some nuances will relate specifically to the VAZ 2110. Otherwise, the procedure is similar to any other car.

How to determine the status of the fuel pressure regulator (FPR)?

There are two ways to determine if an RTD is faulty:

- If the pressure with the engine not running with the fuel pump turned on is below 2.8 atm. To turn on the fuel pump directly without starting the engine, then on the diagnostic block we close the closest contacts to the gear shift lever.

- Turn off the fuel pump. The pressure in the ramp should drop by about 0.7 atm and remain at this level. If the pressure in the fuel system does not hold and immediately drops to zero, then the RTD or the pump check valve is faulty (located on the back side of the fuel pump motor; it is not advisable to change the pump because of it). Do not rule out cracks in the fuel line or poor condition of the injectors (gasoline flows in)

Determination of RTD performance

An RTD is a sensor that, if faulty, affects pressure readings in the entire system. To determine the performance of an RTD, 2 main methods are used.

- Close the nearby contacts on the diagnostic block near the gearshift lever if the pressure with the engine stopped is below 2.8 atm. A short circuit will allow the fuel pump to bypass the engine.

- Stop the fuel pump. Measure the pressure, which under normal conditions should drop to 0.7 atm and remain at this level, without varying. On the contrary, if the indicator instantly drops to 0, either the sensor is faulty or there is a problem in the pump return system. Fuel leaks, poor condition of injection elements, etc. are also possible.

How to determine the condition of the fuel pump?

In order to determine a fuel pump malfunction, you need to check the fuel pump “at the wall” (zero supply pressure or “at the plug”). In simple terms, this is the pressure that the fuel pump develops.

It is by this parameter that the service life of the fuel pump can be determined. As the pump wears out, this parameter gradually decreases. When the pressure is “into the wall”:

- about 3 atm - the car stalls

- 4 atm - the pump will still serve

- 5-7 atm – the state of the new pump (the Czech gas pump produces 7 atm)

Checking the fuel pump “for a plug” is quite simple; you need to pinch the return line with pliers (for 2-3 seconds) with the car running and watch the pressure gauge readings. Another way to check the fuel pump: smoothly raise the engine speed to 3000 rpm. If the pressure gradually drops, then this is a sign of a “dead” pump.

How to check the condition of the fuel system without a pressure gauge?

Unscrew the fuel supply line and apply power to the fuel pump. If everything is in order, then about 1.5 liters should flow in a minute. By the way, if the pressure in the fuel rail is only 1 atm and the sound of the pump is uneven. The reason is there is no gasoline in the tank! Now, if you stalled far from the city, then diagnosing the car yourself in the field is not a problem for you! Intense acceleration of the car without dips and jerks is the first sign of a serviceable fuel system of the car! If after such a diagnosis the problems remain, then pay attention to other points (compression in the cylinders, ignition module, etc.).

Different measuring methods

In addition to measuring against the wall, there are many other ways to measure yourself. One of the options for checking the fuel supercharger is the “plug” diagnosis. In this case, the return line is clamped for two seconds, the engine starts, and the pressure reading is taken.

Another testing option. The speed of the power plant increases to three thousand revolutions per minute. At the same time, you need to monitor the instrument readings. If the pressure drops to 0, this is a sign of a “dead” pump.

The pressure on the ramp is measured as follows:

- fum tape is wound around the pipe;

- the device hose is reinforced with a clamp (if homemade);

- a rag is placed on nearby parts to prevent fuel from spilling (especially carefully you need to close the generating device in order to avoid a fire hazard in the engine space);

- there is a cap on the fuel rail that needs to be unscrewed;

- access to the hole with the nipple is opened - the latter is unscrewed with a cap from the car wheel;

- To prevent gasoline from splashing too much, it is necessary to release the pressure in the vehicle in advance;

- the end of the meter hose is threaded into the ramp hole and is also secured with a clamp;

- The rag is removed, the engine starts, and readings are taken.

On a vehicle without return.

- It is necessary to measure the pressure at the outlet of the fuel pump module (located on the fuel tank). For measurements, a hose with a diameter of eight millimeters is suitable, which must be resistant to gasoline. An ordinary pressure gauge is suitable as a meter.

- The original hose is removed from the pressure gauge and an 8 mm one is inserted. Pressure readings are taken, which should be within 5-7 atm.

Measurements are made in different ways:

- with the ignition on, watch how much the scale needle jumps;

- measurements are carried out with the RTD (fuel sensor) hose removed;

- separate idle pressure test;

- check with a pinched return hose.

Causes of malfunction

The main causes of malfunctions of the VAZ 2110 fuel pump are the low quality of the fuel being filled, low fuel supply pressure, the regular presence of a small amount of gasoline (less than 5 liters) in the fuel tank and improper operation when starting the engine - before starting the engine, you must wait after turning on the ignition 2-4 seconds to pump fuel into the engine power system.

It is also possible that the fuel pump as a part will naturally fail, depending on the mileage of 150 - 200 thousand km. or for a period of 4-5 years, but again this malfunction depends on the operating conditions of the car itself. Usually the factory fuel pump is replaced with a BOSCH one.

There are secondary malfunctions of the VAZ 2110 fuel pump failure - failure of the relay, blown power fuse, they are located in the fuse mounting block either under the hood or in the lower left part of the dashboard, front console, depending on the engine modification, and contamination of the fine filter mesh fuel cleaning (located directly on the fuel pump).

These faults can be fixed relatively quickly and without large financial investments. Fuel pump repairs are performed quite rarely, and the cost of repairs relative to the cost of the pump is insignificant.

How to buy a quality device?

The price for a VAZ 2110 fuel pump in market conditions will be 2 times lower than in a specialized store. The equipment is in durable and sealed packaging. Inside the package is purified gasoline. If you smell gasoline, then the seal of the packaging is broken and there is a possibility of corrosion forming inside the gasoline pump. Submerged equipment is lubricated and cooled by fuel. When using low-quality additives and gasoline, internal electrical mechanisms are corroded. If additional substances are not used in the operation of the device (dry), then the brushes wear off and it overheats. The service life of the equipment is longer. Some car owners are planning to replace the VAZ 2110 Bosch fuel pump, the characteristics and pressure of which are not normal only due to long-term use. Its pressure can be 6-7 atmospheres. It was amazing to hear from an experienced driver his method for testing the fuel pump. To do this, he took a jar of water, turned it on on the battery, and by the flow of liquid he realized that the power of the gas pump had decreased.

Troubleshooting

The main symptoms of a malfunction of the VAZ 2110 fuel pump are engine interruptions in various operating modes, lack of pressure in the fuel system, loss of acceleration dynamics, increased fuel consumption, or complete failure when trying to start the engine.

The first step is to check the functionality of the pump. When you turn on the ignition, you should hear a slight whirring sound from the pump under the rear seat for a few seconds.

If the engine is running, it is necessary to check the fuel supply pressure using a pressure gauge; the fuel supply pressure to the injector should be 3.5 - 4 atmospheres. If the sound of the fuel pump is not heard, if you have an electrical tester, you can check whether power is being supplied to the pump.

To do this, you need to remove the back seat of the VAZ 2110, the decorative cover, and the terminal from the fuel pump housing, turn on the key to crank the starter, if the tester does not receive power, you need to check the relay, fuse or wiring trace for a break! If there is power, the fuel pump needs to be replaced.

The serviceability of the relay can be checked by replacing it with a working one from the fuse box, for example the high beam headlight relay. When replacing a new relay, you need to pay attention to the manufacturer and the recommendations of a spare parts specialist in the store; it is better not to save on the cost of the relay.

Checking the serviceability of the fuel pump on the injector

When, when you turn the ignition key, you hear a slight buzzing, a slight hum, this is how the fuel pump works, pumping gasoline creates pressure in the system. If, when you try to start, there are no such signs of the fuel pump working, then you can assume a malfunction of the electrics, the pump itself or its individual parts. Therefore, let’s look at how you can check the operation of a gas pump using a step-by-step logical chain. Starting from whether power is supplied to the fuel pump and ending with whether the fuel pump pumps at all, and if so, what pressure is created in the fuel rail.

Step 1: Checking the fuse

Checking the fuel pump fuse involves inspecting the integrity of the conductive plate and, if broken, replacing it. But if there is no new fuse, then wind one strand of copper wire around the fuse contacts. If it burns out again, it means the problem may be in the wiring.

Stage 2: Checking the relay

To check the fuel pump relay, remove it from the socket and connect a 12 volt light bulb according to the diagram. If the light bulb works, the relay itself is also working properly. An alternative is to use a multimeter in ohmmeter mode to measure the resistance of the relay coil winding. One probe is connected to terminal 85, and the other to 86. The device will show a break if the relay has failed.

Make sure that the terminals are not oxidized - this will negatively affect the power supply to the fuel pump engine!

Replacement

Replacing a fuel pump with a new one requires careful selection of the manufacturer; each pump has its own performance. The absolute leader in this area is BOSCH.

To replace or remove for repair the VAZ 2110 fuel pump we will need: a 17mm wrench, depending on the modification, a 10mm socket, pliers, a flat screwdriver. We remove the rear seat, it is advisable to unscrew the gas tank cap to relieve excess pressure in the system. Disconnect the plastic pump power terminal.

Depending on the modification, we remove the fuel supply and return hoses, or, by pressing the spring clip and pulling the hose, disconnect it from the fuel pump housing. In the second option, use a 17mm wrench to unscrew both fittings and disconnect the tubes.

In both cases, it is necessary to disconnect carefully, since the system is under pressure and when disconnected, the pressure will be released from the injector and a small amount of fuel will leak. If the performance of the old fuel pump is small, there will be no pressure in the system.

Unscrew the 8 nuts from the studs using a 10mm socket and remove the retaining ring with the seal. Carefully pull out the VAZ 2110 fuel pump housing at a slight angle so as not to damage the fuel level sensor; repairing it is unlikely. Using a screwdriver and pliers, remove the lower part of the fuel pump housing and remove the connectors and hoses from the pump. We dismantle the pump.

Assembly is carried out in reverse order. By the way, the original BOSCH fuel pump comes with a mesh. The new fuel pump has high performance, so after replacing it, when you turn on the ignition several times, there will be extraneous sounds when the system is pumped.

Electric fuel pump for VAZ 2107

Increasingly, owners of “classics”, including the VAZ 2107, are installing modern devices on their cars. So, the mechanical fuel pump is replaced with an electric one. The main goal of introducing an electric fuel pump is to get rid of the problems that arise with standard pumps. However, you need to understand that if on injection “sevens” such a mechanism is installed directly in the gas tank, then on carburetor cars it is placed under the hood.

Which one can be installed

As an electric fuel pump, you can install any device designed to work on fuel-injected cars on the “classic”. Based on reviews from Zhiguli car owners, Chinese-made pumps, as well as Magneti Marelli and Bosch, are often used. It is important to know that the product must provide low pressure . A standard mechanical pump produces about 0.05 atm. If the indicator is higher, then the needle valve in the carburetor will simply let fuel through, which will lead to it leaking out.

Installation of an electric fuel pump

To install an electric fuel supply pump on a carburetor “seven”, you will need a certain list of materials:

We carry out the work in the following sequence:

Bosch fuel pump performance - from 3 to 3.8 bar

The manufacturer Bosch produces its own fuel pump for each type of fuel system. Why, after the original fuel pump fails, do people install a Bosch fuel pump from a VAZ 2110? How does the pressure and performance of the fuel pump compare with the original one? If you put it with high pressure, will the flow rate increase?

Consumption does not increase due to the performance of the fuel pump, since on cars the return line is activated and excess fuel is returned to the tank, there is also a fuel pressure regulator, from the name it is clear, I think what function it performs.

Consequently, there was a 2.8 bar pump, they installed a Bosch VAZ 2110 fuel pump with 3.8 bar and it will only get better. Fuel consumption may increase if the fuel pump does not create sufficient pressure in the rail and the injectors begin to pour gasoline, which does not burn, rather than spray.

Injection pump pressure on a Mercedes

This is a high pressure pump installed on diesel cars and some gasoline cars.

This is how pressure is measured.

The normal value should vary within 3 volts. If it is less, you need to raise the speed of the power plant and keep it within 2000 rpm. Adjust the pressure bolt in this mode by rotating clockwise. At the same time, you need to look at the device to stop rotation as soon as the pressure reaches the standard value of 3 volts.

If the pressure does not want to return to place, you can draw conclusions about a fuel leak or a malfunction of the fuel system elements, including the pump.

Video: how to measure the pressure of injection pump 4g94

Source

Characteristics of the Bosch fuel pump 0580453453

Especially for my readers, I got confused and measured the fuel pump that is on my display case. In fact, the characteristics of Bosch gasoline pumps differ in the length and very rarely in the diameter of the body. Why? The diameter of the body can be adjusted using a gasket made of petrol-resistant rubber.

Most often, the characteristics of fuel pumps (not only Bosch, but also from other manufacturers) may differ in length, pressure, location of terminal chips and that’s it :). The fuel pump mesh does not differ in seating, but it may differ in shape. The chip for the terminal can be remade or supplied from the same VAZ. The length of the fuel pump is important, since its operation depends on this when the fuel level in the tank is low, and if it is in the module, then you need a match to install it.

Fuel pump length:

- Bosch fuel pump 0580453453 - 105 mm

- Bosch fuel pump 0580453449 - 65 mm

- Bosch fuel pump 0580453465 - 90 mm

Instructions for diagnosing pressure and repairing a fuel pump

- If the fuel supply is insufficient, this can lead to a decrease in engine power. This is also manifested by the fact that during active acceleration, characteristic jerks may appear. The same applies to driving at higher speeds. So, we remove the rear seat, which is located on the right side of the car. There we find a special metal plate that will need to be unscrewed.

- Now turn on the ignition. You should hear the characteristic sounds of a pump that pumps fuel. If this sound is heard very faintly, you can remove another seat to hear it clearly. But it also happens that there is no sound in this case. As a result, we will need to check the relay, as well as the fuses that control the operation of the fuel pump.

- The next step will be to loosen the fastening clamp, followed by disconnecting the fuel hose from the suction pipe of the fuel pump. The indicated hose is located slightly lower than the current fuel mark in the tank. And, so that gasoline does not start leaking, you need to close its hole with any suitable object that is at hand. Most often, we are talking about a bolt of the appropriate diameter.

Check the fuel hose for damage- Now we disconnect the fuel hose, and then lower it, simply pointing it down, finding the most convenient position. Next, you can tightly close the hole in the hose with your finger, and use the manual fuel pumping lever to pump the liquid several times. You should feel a characteristic force, which is provoked by the presence of resistance from a tense spring that is compressed. We are talking about a spring related to the diaphragm on the lever. If such an effect is not observed, then it is necessary to slightly turn the engine crankshaft, using a special fastening bolt that holds the pulley, to the desired mark.

- With each finger press, you should feel that the pressure in the hose is increasing, and the fuel pump begins to make a characteristic sound, more like a “squelching” sound. But, if there is no pressure, then this may indicate an insufficient level of tightness of the suction-type valve, or damage to the diaphragm.

- Close the suction pipe tightly with your finger and repeat the pumping cycle again.

In this situation, the absence of a vacuum effect in the pipe will indicate that the diaphragm or discharge valve has been damaged.

And, if there is no vacuum or discharge pressure, then in addition to the indicated possible breakdowns, it may turn out that a foreign object is stuck in the fuel pump filter.

Don't forget to wash the filter

To eliminate it, it will be enough to rinse the filter with regular gasoline, and then blow it with compressed air or a compressor.

If the filter is excessively deformed or cannot be cleaned to the required level, it must be replaced with a new one.