With the constant rise in fuel prices, installing gas equipment on a car is becoming increasingly popular. No wonder. Having spent several thousand rubles on gas equipment, you can drive on fuel whose price is half that of gasoline. Typically, gas equipment is installed on gasoline cars. Their engines are more suitable for operation on natural or reduced gas. But there are also diesel cars with LPG. Can a diesel engine be converted to gas? Is it worth installing such equipment? Find answers to these questions in our article today.

Diesel features

As we said earlier, LPG is installed mainly on gasoline engines. If we consider gas diesel, only domestic MAZ and KamAZ trucks can serve as an example. Such equipment is not found on passenger cars. Why is it so rare to install gas on a diesel engine? The answer is simple, and it lies in the principle of fuel ignition.

As you know, gasoline engines ignite the mixture with the help of auxiliary devices. They are candles. When a fuel-air mixture is supplied to the chamber, they produce a spark, thanks to which the fuel ignites. Due to the fact that gasoline is ignited by third-party devices, such engines have a low compression ratio. Now it is about ten to twelve units. And if we look at the engines of Soviet trucks, then there are six. The only point is the octane number of gas, which is higher than that of gasoline. If for the latter it reaches 98, then for gas it is at least 102. But in order for the engine to operate normally on this mixture, the electronic control unit automatically adjusts the ignition angles and other parameters in real time.

As for diesel engines, there are no classic spark plugs. The mixture ignites due to a high degree of compression. The air is heated under pressure so much that the temperature in the chamber reaches 400 degrees Celsius. As a result, the mixture ignites and the piston makes a power stroke. Someone will say that a diesel engine has spark plugs. Yes, some engines have them. But these are completely different - glow plugs. They allow cold starts without difficulty by preheating the fuel. Such candles have a completely different structure and operating principle. By the way, the minimum compression ratio of a diesel engine is 20 units. If the indicator is less, the engine simply will not start. In modern car engines, the compression ratio can reach 30 units.

Thus, if the use of LPG on a gasoline engine does not cause operational difficulties (since the fuel is ignited by candles), then a diesel internal combustion engine is not able to “digest” such a mixture.

What does the equipment consist of?

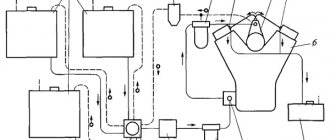

At its core, gas equipment for diesel engines is no different from the classic fourth-generation gas equipment set for gasoline engines. The following is installed in the car:

- cylinder for liquefied or natural gas;

- gearbox with integrated evaporator (methane heater);

- solenoid valve;

- filters;

- injection system with nozzles;

- electronic control unit connected to the gas equipment and vehicle sensors.

Depending on the manufacturer, an additional injector operation emulator may be installed along with electronic actuators for “original” diesel injectors. This allows gas equipment to take control of the fuel supply and control its quantity.

The main feature of LPG for a diesel engine is the operation of electronics, which regulates the proportion of fuel and gas. To do this, the gas equipment ECU takes over control of the diesel injectors.

Why is it difficult to convert a diesel engine to gas?

There are several factors that complicate the process of installing and operating gas equipment on such an internal combustion engine:

- Ignition temperature. If in a diesel engine the fuel spontaneously ignites at 400 degrees, then gas burns at 700 and above. And it doesn’t matter whether it’s methane or propane-butane.

- No candles. Whatever the compression ratio in a diesel engine, it will not be enough to heat the gas mixture to the auto-ignition temperature. Therefore, you cannot do without installing third-party spark plugs.

- Octane number. Diesel fuel has an OC of 50 units. Gas has at least 102. If such fuel gets into a diesel engine, it will go into overdrive (this is uncontrolled engine operation at high speeds). There are several ways to solve the problem. This is a correction of the compression ratio, or a decrease in the octane number of the gas mixture.

Complete rework

What is the essence of this method? The idea is simple - the diesel engine is completely converted to gas. Moreover, after such an intervention, it will no longer work on its “native” fuel - only on gas.

To prevent the unit from going haywire, its compression ratio is adjusted. It is about 12:1. This is the only way the engine can “digest” fuel with a high octane number. Next, a mixture ignition system is installed. There are no special mechanisms here. For arson, ordinary candles are used, as in gasoline engines.

What is the disadvantage of such a change? Due to the need to carry out a whole range of work, the cost of reinstallation can reach 200 or more thousand rubles. This is ten times more expensive than converting a gasoline car to gas. Therefore, the savings are very doubtful. Moreover, such a motor will have reduced power and torque.

Gas equipment for engine

A gas "spider" climbed into the engine compartment of a gasoline engine. A gas "spider" climbed into the engine compartment of a gasoline engine.

I myself drove cars with gas equipment for about 15 years, and installed it myself. But these were carburetor cars, where all settings could be made without special equipment. I was not involved in registration and never did pressure testing of cylinders. In those days there were simply no mechanisms for such verification. And now certification is mandatory, without it you won’t be able to fill the car, without it you won’t be given a diagnostic card. No wonder those years were called the dashing nineties... Nevertheless, I went and was happy. And this was in Moscow, although it happened to travel around the country.

Results

I will express my personal opinion. For the first seven years after graduating from university, he was involved in testing and fine-tuning diesel supercharged and naturally aspirated engines. I had in personal use a bunch of domestically produced carburetor cars, many of which (from UAZ-469 to Tavria) I installed gas equipment on. While working in a publishing house, I drove many cars of domestic and foreign production. And I concluded for myself that there is nothing better than a naturally aspirated gasoline engine with fuel injection and a timing chain drive instead of a belt. The most hassle-free option! And it makes sense to install diesel engines on fairly heavy SUVs, pickups, delivery vans, small trucks and further down the list, right up to long-haul tractors.

Petrol, diesel or gas - which engine is better?

Dual Fuel System

This is exactly the scheme used on some modifications of MAZ and KamAZ trucks. This is a combined fuel supply system. At the moment this is the cheapest, correct and easily implemented option. The cost of the alteration is about 70-85 thousand rubles. The peculiarity of the system is that there is no need to install spark plugs. Diesel fuel itself is used to ignite methane (or propane-butane). As for the main components of the system, these are the same gas reducer, hoses and lines, as well as fuel storage cylinders.

About automobile gas equipment

Gas-cylinder equipment must ensure safe storage, supply, as well as full operation of internal combustion engines using “blue” fuel. As we know, methane or propane-butane is used for cars. The first is in a compressed state, the second is in a liquefied state.

After switching the car to gas, the main type of fuel is used as usual. The factory power supply system does not change much during the installation of gas equipment; to a greater extent, it is only supplemented with special units for gas. As a result, the equipment is capable of operating on both types of fuel with separate or even simultaneous supply. The combustion of the gas-fuel mixture occurs according to the same physical laws as when working on the main fuel. You can learn more about the operation of the equipment by reading the article “GBO for a car.”

How it works?

The engine starts only on diesel fuel. After this, the gas reducer is used. It supplies the mixture to the combustion chamber through the intake valve. The gas goes along with the oxygen. Along with this, a small portion of diesel enters the chamber. When the piston almost reaches top dead center, the diesel fuel ignites. Its temperature is about 900 degrees, which is already enough for the spontaneous combustion of methane or propane. Thus, two types of fuel burn at once in the chamber. The efficiency of such a motor is unchanged, except that the portion of diesel is reduced by an order of magnitude.

What gas can be supplied to a diesel engine? You can install either a propane or methane system. But there are pitfalls here. As reviews note, gas installed on a diesel engine shows itself differently. If we talk about propane, its percentage in the mixture is relatively small - up to 50 percent. In the case of methane, up to 60 percent of the gas is used. Thus, the portion of diesel supplied to the chamber is reduced. This has a positive effect on savings. But it is impossible to completely limit the supply of diesel. Otherwise, such a mixture simply will not ignite without external sources.

Payment for HBO 10%

Increasing state subsidies for natural gas motor fuel.

New information has appeared (news statement dated June 16, 2020) that 60% of the costs of switching vehicles to LPG are now paid by the government.

Energy Minister Alexander Novak explained that compressed natural gas (methane) is an environmentally friendly and economical type of fuel. Therefore, the government’s task is to support the gas engine industry.

From 2022 to 2024, the government will actively finance this area. In total, the state plans to invest 50 billion rubles. To re-equip one car, it takes from 80 to 150 thousand rubles. Alexander Novak predicts that new increased subsidies will make this procedure more affordable. Doubling the size of subsidies will make the transition to CNG feasible for 10-12 thousand cars already in 2022.

Government subsidies for converting vehicles to gas now cover 60% of costs instead of 30%. This applies to both individuals and legal entities. These subsidies significantly reduce the cost of converting a car to LPG. Now is the best time for this!

Is it profitable?

Let's consider the feasibility of converting a diesel engine to gas. Since the operation of such an engine still requires a portion of the original fuel (in our case, diesel fuel), the savings are not so significant. If a gasoline engine runs entirely on gas, the cost of fuel costs is exactly halved. But in our case, the savings will be only 25 percent, or one and a half times. And this despite the fact that the price of installing the Dual Fuel system is at least 70 thousand rubles.

It is not difficult to calculate how long it will take for this system to pay for itself. Under favorable conditions, the payback of diesel gas equipment will occur in 70-100 thousand kilometers. And only after this mileage will you start saving. That is why gas is installed on a diesel engine only in rare cases, and only on domestic trucks. Such a system is practically never found on passenger cars.

Feasibility of installation

As we know, diesel units are already quite economical, is it worth paying 80,000 to install Dual Fuel? What's the benefit?

There is a benefit, but not as big as with the gasoline option.

Let’s say that our diesel consumption is 10 liters per 100 km, if we take average prices it is 35 rubles per liter, that is, 350 rubles per 100 km, without gas.

Our gas cost is 16 rubles (we take propane), it will replace about 50% of liquid fuel. That is, it turns out (16 X 5 = 80 rubles) and (35 X 5 = 175 rubles) = 255 rubles, the difference is 95 rubles from 100 km, from 1000 - 950 rubles.

Of course, if you move around a lot, then of course it makes sense! However, for a private passenger car with a mileage of 1000 - 1500 km per month, the payback of the equipment will occur in 60 - 70 months, here, in my opinion, you need to think very hard.

Now we are watching the video version.

I’ll end here, I think my article was useful to you, sincerely your AUTOBLOGGER.

(

15 votes, average: 4.40 out of 5)

Similar news

Gas for cars: pros and cons. Let's look at propane and methane + video

Removes moisture (water) from the gas tank. With your own hands

Which gasoline burns faster, longer and better? 92 – 95 – 98 or 100.

Add a comment Cancel reply

Comments

TOP articles for the month

The holidays are coming, which means most of our country will be drinking alcohol. Easy: -…

I have many different articles and videos on various gearboxes, for example here...

The vehicle battery voltage, as well as its capacity, are the most important indicators of this automotive unit,...

Let's sum it up

So, we found out whether it is possible to install gas on a diesel engine. Due to a different operating principle, installing an LPG on such a motor requires major modifications. Moreover, as a result, this unit will still require, albeit a small, portion of diesel. There are savings from using such equipment. But it is so insignificant that no one bothers with the question “is it worth installing gas on a diesel engine?” High payback periods and installation complexity are the main factors that prevent the use of gas-cylinder equipment on a diesel engine.

Advantages and disadvantages

When converting a car to gas, significant benefits arise:

- Savings on fuel consumption. Propane-butane consumption is 18-20% higher, but its cost is almost 2 times lower than gasoline. The savings are felt when the car is actively used, if the mileage is more than 15,000 km per year.

- The parallel use of gasoline and gas is especially valuable for drivers who travel long distances. This results in a double power reserve. The risk of refueling a car at a gas station that supplies poor quality fuel is reduced. On the highway they usually switch to gasoline, in populated areas - to gas fuel.

- A gas turbo engine runs quietly and smoothly because the octane number of the gas is higher. As a result, possible vibrations are reduced. In Europe, great importance is attached to reducing noise pollution on city streets.

- On gas, ignition in an internal combustion engine is more efficient. The gas mixture burns out more slowly and more evenly. The load on the piston group is less. Less detonation. Reduced wear of parts. The answer to the question whether it is possible to install gas equipment on a turbocharged engine without causing damage to the car is positive.

- The gas mixes evenly with air and does not smoke. The engine oil becomes cleaner and the viscosity level remains longer. The oil film protects the cylinder walls. The total time between overhauls of the engine increases.

- When the turbo operates on gas, tar does not accumulate, and there is less soot on the spark plugs. The service life is up to 40% longer due to the hydrogen content in gas fuel.

A gas car is more environmentally friendly. Gas fuel is less toxic. Its use means a reduction in emissions into the atmosphere. No harmful impurities are added to the propane-butane product. In terms of environmental friendliness, gas fuel is inferior to electric vehicles and hydrogen engines.

There are also inconveniences when switching a turbocharged car to gas fuel:

- The combustion rate of gas is lower than that of gasoline, so a drop in car power of up to 15% will not help you. In practice it is not noticeable. Only an experienced driver can notice the difference during strong acceleration. Modern gas equipment reduces this difference in the power characteristics of turbocharged engines to zero.

- The fact of re-equipment leads to the need for service. If you do everything correctly from the beginning, refuel with high-quality gas, the costs will be minimal. The only action is to replace the filter every 15,000 km. mileage

- The weight of the car increases, the capacity of the trunk decreases if a gas tank is installed there. The cylindrical one takes a lot, and because of the toroidal one you have to drive without a spare wheel.

- Underground parking lots do not always allow cars with gas equipment to be parked on their premises. Propane-butane lingers in the room. It is not advisable to park a car with propane-butane fuel in a garage where the inspection hole is open.

- HBO must be registered. A document for HBO and a car repair shop license are required. Self-installation of gas equipment is excluded.

The disadvantages include the expense of purchasing and installing gas equipment. Consider the issue of refueling with gas fuel. Not all areas have problems with this.

It is up to the car owner to decide whether to convert a car with a turbo engine to LPG or not. The benefits are obvious, and they are associated with significant savings on fuel, extension of the service life of the internal combustion engine and environmental friendliness. To reduce the negative aspects, you need to choose good equipment and perform proper setup at a car service center that you can trust with your car.

Read further:

Is it possible to put gas on a turbocharged engine?

Installing LPG on a diesel engine: what does it look like in practice?

The engine stalls on gas: what is the reason and what to do?

HBO for Polo sedan: how to do it correctly?

Everything you need to know about installing gas equipment on the Lada Largus