The serviceability of the brake system and the condition of the brake pads directly affect the quality of the car's braking, so you should not drive a car with faulty brakes. This is the main rule that everyone should know. But in order to promptly change system elements, you need to know how to determine brake pad wear. These parts are subject to heavy loads during vehicle operation and need to be replaced on time, and not only after a complete failure of the braking system.

Brake pad manufacturers recommend replacement every 10-15 thousand kilometers, but the range may vary depending on certain factors. Therefore, it is so important to carry out a preventive inspection of system elements in order to identify possible malfunctions. More details about ways to check brake pad wear will be discussed in this article.

What happens if you don't change the brake pads for a long time?

What happens if you don't replace the brake pads on time? Severely worn pads can cause the pistons in the brake cylinders to become distorted and jam.

Interesting materials:

How to work with Voskoplav? How to work with the Burner? How to work with XML files? How to work with a tongue twister? How to work with layers in After Effects? How can a student work in Google Classroom? How to work in Bitly? How to work in the office and not get tired? How to work in telegram? How to calculate the percentage of work completed?

Why do they wear out?

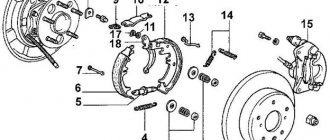

For the record, the brake pad design includes a frame and a lining made of friction material . When in contact with the disc, it gradually wears out, which is why this process is an area of increased attention. The rate of wear is influenced by various factors, from the chemical composition of the material and the quality of parts, and ending with operating conditions.

Causes of brake pad wear

Let's look at the main reasons for brake pad wear:

- car weight;

- quality of materials used in production;

- climatic conditions;

- driving type (if you drive quietly, the linings will last much longer);

- vehicle load;

- faulty brake cylinders.

Causes of squeaking brake pads

Important! Despite the resources specified by the manufacturer, improper use of the vehicle or exposure to the above factors can significantly affect the service life of the linings.

Wear of the front wheel pair brake pads

How to determine the degree of wear

If you have a special sensor, it is very easy to determine the degree of wear - when the friction lining is erased, a light on the dashboard lights up. This means that further use of the pads is undesirable, so they need to be replaced. But practice shows that such sensors do not always work correctly, and not all cars are equipped with them. In such cases, the driver can only rely on himself. There are two ways to determine the degree of brake lining wear: with wheel removal or without removal . Let's consider each of the methods separately.

How to check brake pad wear

With wheel removal

Periodically checking brake pads for wear is an important part of car maintenance. Below are step-by-step instructions for checking the condition of the linings while removing the wheel.

Checking the pads by removing the wheel

Table. Checking the condition of the brake pads.

| Steps, photo | Description of actions |

| Step one | Jack up your car on the side where the wheel will be removed. Before doing this, put the car on the parking brake. |

| Step two | Unscrew the mounting bolts and remove the wheel. You need to twist them counterclockwise. |

| Step three | Inspect the brake caliper and find a special hole in it through which the pads can be seen. |

| Step four | Using a caliper, measure the thickness of the brake pads (see photo). |

| Step five | If the thickness of the brake linings is less than the permissible standard, replace them. Then put the wheel in place. |

Note! People living in large cities have to change pads more often than people living in rural areas. The same can be said about other parts of the braking system.

Without removing the wheel

With alloy wheels, lining diagnostics are simplified. In this case, you won't even need to remove the wheels. Below are step-by-step instructions for this process.

Checking the brake pads without removing the wheel

Step 1: Prepare a caliper to measure the thickness of the pad. In our case, we use an electronic caliper - it is more accurate. You may also need a marker and a plastic straw to mark on. Although many motorists do without it.

Prepare the caliper for work

Some people use a straw to measure.

Step 2: Pull out the depth gauge (the inside of the caliper). It will be used to carry out further measurements.

Use a depth gauge

Step 3. Inspect the brake caliper - there is an inspection window in the caliper body through which you can measure the thickness of the pad.

Locate the inspection window in the brake caliper

Step 4. Insert the depth gauge into the viewing window until it stops, as shown in the photo.

Insert the caliper into the viewing window

Step 5: Gently press the caliper against the outside surface of the brake pad.

Press the caliper onto the block

Step 6: Pull out the caliper and look at the measurement results. If the thickness of the brake lining is less than 5 mm, then the elements need to be replaced.

Review your measurements

Important! The dimensions of the inspection hole do not always allow one to study the condition of the pad, which makes it impossible to take measurements without removing the wheel. In this case, the wheel must be removed.

Subtleties of repair

- Deformations, signs of wear or other damage on the pads are a signal to replace them: the components cannot be restored.

- Dirt or old grease on the linings can be removed using a wire brush and white spirit.

- Defects on the working cylinder can be eliminated by grinding or lapping, but worn seals and pistons will have to be replaced.

- Deformed tension springs must also be replaced.

- Restoring a Honda, Ford or Suzuki brake drum involves boring it and grinding it with fine-grained abrasive stones.

If diagnostics have confirmed a change in the geometry of the drum, for example its oval shape, or too many signs of wear are found on the surface, the unit cannot be repaired. The procedure for replacing it is quite complex and multi-stage, requiring careful actions without the use of brute force.

Particularly difficult is removing the old drum, during which you can accidentally break the thread. Sometimes the internal diameter of the mechanism exceeds the permissible value - it is not possible to put it back on without forcibly removing the excess protrusion on the edge using a grinder or a file.

Replacing a failed unit or its parts is half the battle: after that, the system must be properly assembled, adjusted and tested using special equipment. If the experts’ verdict is positive, you can safely hit the road, remembering to protect the brakes from excessive overheating and increased loads. The quieter you go, the further you'll get!

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Uneven wear on a car's pads sometimes occurs on cars with both drum and disc brakes. As a rule, the reasons for this phenomenon are typical - improper operation of the guides, the piston is not fully retracted, damage to the protective rubber seal, rust on the caliper bracket and some others. Usually, eliminating the causes of uneven brake pad wear does not take much effort. Most often, a lot of time and attention is spent on diagnosis and directly searching for the cause. Therefore, we will consider a number of cases, both general and specific, where it is worth looking for the cause of uneven wear of brake pads.

Brake disc wear

Brake disc wear is more stable and predictable. Most often, there are enough discs for two sets of pads. A reduction in disc thickness of approximately 2 mm means 100% wear. Over time, wear causes a chamfer to form on the edge of the brake disc.

The design of many wheel rims allows you to stick your hand between the spokes and feel the wear of the brake disc by touch. The main thing is not to do this while the brake disc is still hot, immediately after a trip with intense braking. This technique will be useful for those who plan to purchase a used car. Based on disc wear, one can draw conclusions about the actual mileage of the car or the conditions in which it had to drive. But it is best to remove the wheel and carefully inspect the brake mechanism, including the inside of the disc. It happens that it is there that grooves and a wavy surface are formed due to corrosion.

Car brake system repair

To be confident in your car, you need to regularly check the condition of all its brake parts. Uneven pad wear is common. This is due to the design features of the car. The car is always heavier at the front, because there is a heavy power unit there. Accordingly, wear occurs faster on the front axle. Also, unevenness is often observed on the sides. Due to a broken brake cylinder, one of the pads may get stuck, and therefore the performance will be uneven. That is why it is recommended to regularly monitor the condition of the entire brake system and it is not at all necessary to contact the services of a service center every time. Discs and pads can be seen even without removing the wheels if the casting has large holes.

When to change brake discs and pads

Replacing brake pads on a car can be done in a number of cases:

When their natural wear occurs, the linings wear down to a critical thickness. If a reduction in disc thickness of less than 10% is considered dangerous, then the linings can wear up to 50%. You need to remember about the unevenness, and not wait for the moment when they rub bare metal on the discs or rear brake drums.

Damage to parts after careless driving on a sandy road. Large particles that enter will certainly cause serious damage in the form of deep scratches. This is a dangerous condition, so you need to change the pads and grind the discs.

Replacing discs and pads

Replacing brakes is, in principle, the same on all cars, but there are differences between different types of structures. There are two options: with brake discs on both axles and discs only at the front, and drums installed at the rear. Repair of the brake system in this case is carried out according to the following plan:

- First you need to loosen the wheel bolts with a wheel wrench because it will be inconvenient for the canopy to do this job.

- Then you need to raise the car to the safest possible height so that repair work can be carried out. If you have one jack, it is convenient to do this one wheel at a time.

- Next, the wheel is removed and access to the brake mechanism is opened. At the front there are discs and brake calipers. To remove the discs, you must first move the caliper to the side by unscrewing it from the mounting on the reverse side.

- The disc is attached to the front wheel hub with 4 or more stud screws, depending on the design of a particular car.

- It is possible that the disc will have to be knocked off the hub groove because it has not been removed for a long time and has become welded with corrosion. To tap, use a wooden tip. They do the same with drums, because they are made of cast iron or aluminum - fairly soft metals. The planting site is first treated with WD-40 to dissolve the rust.

Changing brake pads is no more difficult than the previously described procedure. You don't need to unscrew the caliper to do this. It is enough to remove the guide from its installation location without losing the spring. Then remove the old pads. At the same time, it is worth checking the condition of the brake cylinders and their boots. Often they tear and various contaminants get under the rubber, which leads to damage to the surface of the working cylinder. You can wash off the dirt with the same WD-40, but then be sure to lubricate and develop it, because they are most likely stuck. To do this, press the piston into the cylinder and, by gently pressing the brake pedal and holding it, push it back out. A jammed cylinder is easily recognized. The wheel on one side slows down later than the other and there is uneven wear on the linings.

Replacing the rear brake pads is also easy, even if there are drums there. The design of the brake mechanism looks different. The pads are secured in the center with cotter pins and are spring-loaded, since they are in a floating state and independently level their position. There is also a manual braking mechanism and other parts. It is important to assemble everything exactly as it was installed. Don't forget to check the functionality of the rear brake cylinders. This can and should be done with the pads installed. Place a pry bar against the metal boot and press down on the pads. Then press the brake pedal, it should move in evenly on both sides. It should not be wet under the cylinder, the anthers should be intact.

How to properly break in new brakes

After replacing a worn disc or brake pads, they need to be run in. This is an important procedure because new parts are not centered and the wheels will brake unevenly. Any brake replacement after repairs have been performed needs to be inspected.

A reliable braking system is the key to safety when driving a car, so the break-in stage should be taken with full responsibility. As investigations into various accidents show, in some cases the car skids precisely after replacing the brake pads.

Running in involves the grinding process. Pads and discs, like clothing, must fit perfectly to each other to ensure effective braking across the entire surface, and not just one edge. Loose pads can also cause skidding. If your car has had a comprehensive brake replacement with the installation of new pads or discs, be sure to wipe them down. Incorrect or lack of running-in will certainly lead to the following troubles:

- When braking, you will feel a vibration in the steering wheel. It will be pulled from side to side because the wheels will brake separately.

- Some time after repairing your brakes, you will notice uneven wear on the pads. This is also a very dangerous condition that leads to problems. It is not difficult to determine this fact. The discs will definitely show signs of uneven fit of the linings.

- New pads and discs, while they are grinding in, have low braking efficiency. Therefore, immediately after installing these parts, you should not go for a technical inspection. Measurements on the bench will definitely show insufficient braking.

The running-in procedure involves a cyclic increase in speed to 60-65 km/h and a slow decrease to 10 km/h. Over the next 300 km you need to adhere to this mode and avoid sudden braking.

Tips and tricks

To prevent premature brake pad wear, you need to follow a few simple rules.

How to extend the life of brake pads

- Do not press the brake pedal unless necessary . Many motorists accelerate on short sections of the road, knowing that after 20-30 meters they will have to slow down. This significantly reduces the life of brake discs and pads.

- Choose quality spare parts. You don’t have to spend a lot of money on the original, but you shouldn’t skimp on the braking system either. Experts recommend buying discs and pads from the same manufacturer.

- Carry out regular checks of the condition of the pads and other system elements . You don’t have to do this yourself - you can ask service station employees for help.

- When choosing pads, give preference to parts with a wear indicator. They cost a little more than regular brake pads, but having an indicator will greatly facilitate the maintenance process.

When you installed new pads

The brake system is an important component of the car. It is responsible for the safety of the driver and passengers, so maintenance and care must be correct. By following all of the above recommendations, you will not only learn how to determine brake pad wear, but also ensure reliable operation of the entire system.

Characteristic signs

Experts identify several main signs by which the degree of wear can be determined. Let's consider each of them separately.

Signs of Brake Pad Wear

The appearance of knocking or other sounds

When the life of the lining ends, it begins to wear unevenly, which is why various cracks or chips may appear on the surface of the friction layer. Worn brake pads make pounding and noise when they come into contact with the disc.

Knocking noise when braking

Increased braking distance

Experienced drivers may notice that when the pads are used for a long time, the braking distance may increase, and the brake pedal must be pressed harder to stop the car.

Increased braking distance

Replacement dates and signs

Based on the model of the brake mechanism and the friction material of the bars, manufacturers indicate how many thousands of kilometers the pads can last. Manufacturers also recommend when it is necessary to change the strips, focusing on the remaining minimum permissible friction layer.

All this is described in the instructions for the car, but there are average standards, the value of which ranges from 20 to 30 thousand km, for the front slats in disc brakes. And for drum and disc type rear brake pads, this mileage interval in km must be multiplied by two.

The weight of the machine also plays a big role in the wear rate. The above figures are relevant for small passenger cars weighing up to 1300 kg. If we consider large sedans weighing about 1600 kg, then the wear of the bars will occur one and a half times faster. For cars with a curb weight of 1800 kg or more, the pads will need to be replaced after they have covered a distance half as much as a small passenger car can travel.

If the car was bought used, there is often no way to find out when the pads were last changed and what their mileage was. Some signs will help you understand that it’s time to replace them:

- The pad wear warning light on the instrument panel came on. Some brake pads have an electronic or mechanical indicator that signals when the friction material has worn down to the minimum limit and it is time to replace them.

- There was a sound when the car stopped. This sound occurs at a certain percentage of wear of the friction material, when it is worn down to metal.

- When stopping suddenly, a sound is heard and a beating is felt in the area of the wheels. The reason for this is uneven wear of the pads or cracks and chips that may occur on the disc or friction layer. In this case, even the indicator, if present, may not work. Uneven wear of the friction layer is dangerous because after a certain number of kilometers you will have to change not only the strips, but also the wheel disk or drum.

About what not to do

Not every car owner regularly checks their brake system. This leads to a variety of consequences, including accidents on the road. This is still good if you crash into a tree in your yard, but what if the brakes fail on the highway? Of course, experienced motorists will use engine braking, but not everyone will have time to figure out what’s going on.

So, never allow the brake pad linings to wear down to metal. This will damage the brake disc and ultimately cause the system to fail. Check the condition of the brakes regularly. It’s not difficult to do this yourself. You shouldn’t crawl under the car every 5 thousand km, but when the time comes, don’t be lazy.

Proper Pad and Disc Inspection Process

Before checking, review the table of permissible dimensions of brake parts. When the data matches, start making replacements. The process is divided into the following stages:

- We place the vehicle on a jack and remove the front wheel.

- We clean the disk from settled dust.

- Using a caliper we determine the thickness of the disc. The permissible wear parameter is 10.8 mm.

- In the inspection window we determine the thickness of both pads; you can take a caliper.

- Use a screwdriver to see how the pads move. When they move tightly, it means they have compressed the disc. If the wear is uneven, a new cylinder and caliper must be installed.

- To get to the rear ones, remove the wheel and drum.

- We measure their thickness and the size of the drum surface. The diameter should not exceed 201.5 mm.

Brake pads

Parts need to be replaced if:

- linings in oil;

- products thinner than 1.5 mm;

- the linings are not tightly connected to the base;

- Discs need to be replaced if there are scratches or deformation.

Signs of Drum Brake Problems

Since the main role in braking is assigned to the front wheels, problems with this unit may not be noticed immediately, except when vigorously decelerating or reversing. The pedal becomes soft, does not work immediately, and sometimes only after repeated presses, the braking distance lengthens, and the roll-up decreases. A grinding noise that is uncharacteristic for a car can be caused by skewed pads touching the drum. If, when trying to stop, jerks appear or the pedal vibrates, you should sound the alarm.

The average service life of drum brakes under favorable conditions reaches 60 thousand km. For comparison: disc analogues have to be replaced after 25 thousand km.

Factors affecting pad wear

Let's look at the factors that influence how often your brake pads will need to be replaced. There are few of them, but they directly affect indicators such as how long it will take for this to happen, and how many kilometers the car will travel before the corresponding indicator on the instrument panel works. Here are some of them:

- Travel mode. When the car moves in the city, it is often necessary to stop at short intervals, which contributes to rapid wear of the bars.

- Driving style. A non-aggressive driving style puts less stress on the brake mechanism and increases the interval after which the pads will need to be changed.

- The nature of the machine loading. When the trunk is constantly loaded, the load on the front brake trims is reduced, and accordingly, they will need to be changed less often.

Causes of Brake Wear

According to modern rules for monitoring the technical condition of vehicles, disc brake pads must be changed once every 10,000 kilometers. But this figure cannot be a single standard for everyone, since the wear of consumables greatly depends on driving style.

If you brake smoothly and not often (the mileage is mainly on the highway), then you can change the pads after 20,000 kilometers. On the contrary, if you brake frequently and sharply (aggressive driving style in the city), then the pads may wear off after 5,000 kilometers.

An important factor is the quality characteristics of the pads themselves. Some manufacturers openly save on raw materials. The same manufacturer may have several models of pads - more expensive and cheaper, softer and harder.

Everyone is different, so it is important to check your brake wear from time to time.