The Daewoo Nexia car is equipped only with injection engines, and as you know, for the correct operation of the injector it is necessary to have many different sensors. Each sensor in a car is responsible for a specific function, and the failure of one of them seriously affects the operation of the engine and the entire car, and in some cases, a breakdown can completely stop the engine without the ability to start it.

This article describes in detail the injector sensors on the Daewoo Nexia, namely their purpose, signs of malfunction and locations.

Electronic control unit

The engine control unit, also known as the ECU, is responsible for the operation of all on-board systems of the vehicle, it controls all sensors. In this block, information from all sensors is collected, converted and supplied to the engine. Based on tasks from the ECU, the fuel mixture, ignition timing are adjusted, detonation is reduced, etc.

Signs of malfunction:

Signs of a faulty engine control unit include many breakdowns; as a rule, they are related and similar to sensor faults. Most often, the ECU fails due to wetness or mechanical damage. If the ECU is faulty, then the probability of starting the car is zero.

Fuel level

FLS for the fuel pump

There is a fuel level indicator on the instrument panel, which shows how much fuel is left in the gas tank. This information comes from the fuel level sensor, which is located under the gas tank closer to the front of the car. If the indicator shows incorrect information, the reason may be damaged wiring, poor contacts or a malfunction of the FLS (the author of the video is We Repair It Ourselves).

Speed sensor

To determine the speed of the car and calculate its mileage, the Daewoo Nexia uses a special speed sensor. It is located on the gearbox housing and is attached to it with a bolt. Through a connector connected to the sensor, readings from it are transmitted to the computer, and then to the car’s dashboard, for speed readings and calculation of the distance traveled.

Signs of malfunction:

- The speedometer on the car does not work;

- Car mileage is not counted;

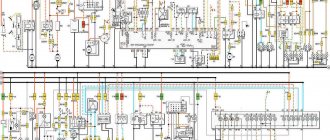

All injector sensors of the Daewoo Nexia

The Daewoo Nexia car is equipped only with injection engines, and as you know, for the correct operation of the injector it is necessary to have many different sensors. Each sensor in a car is responsible for a specific function, and the failure of one of them seriously affects the operation of the engine and the entire car, and in some cases, a breakdown can completely stop the engine without the ability to start it.

This article describes in detail the injector sensors on the Daewoo Nexia, namely their purpose, signs of malfunction and locations.

Crankshaft position sensor

This sensor is used to determine the top dead center of the piston based on the rotation of the crankshaft. The sensor works in tandem with a crankshaft pulley, which has setting marks for the operation of the DPKV. If this sensor breaks down, the car will not be able to start, as there will be no spark, which will make it impossible to ignite the fuel mixture in the combustion chamber.

Signs of malfunction:

- The engine is tripping;

- The engine does not start (no spark);

DPKV

DPKV for the engine

DPKV serves to determine the position and speed at which the crankshaft rotates, synchronizing the operation of the ECU with the operation of the pistons and the angular position of the crankshaft. The crankshaft sensor is primarily located on the crankshaft pulley, in front of a gear called the drive wheel. On F16D3 models it is located under the oil filter in the cylinder block.

On the drive disk, the gap between the teeth is the same, two teeth are missing. The missing teeth create synchronization. When the crankshaft rotates, the magnetic field of the DPKV changes, creating voltage pulses.

Knock sensor

Engine detonation is quite a big problem, which a knock sensor helps combat. Detonation in an internal combustion engine occurs due to poor fuel quality or incorrect ignition timing. This sensor detects all detonations occurring in the internal combustion engine and sends signals to the ECU, which in turn adjusts the SOP.

Signs of malfunction:

- Engine vibration during operation;

- Increased fuel consumption;

- The engine is tripping;

Daewoo Nexia sensors 8 valves location under the hood

Determines the position of the crankshaft and its rotation speed, and is also involved in determining misfires.

If the sensor fails, engine operation is impossible. Installation location: located at the crankshaft pulley opposite the reference (geared) disc. On the F16D3 engine, it is located in the cylinder block closer to the flywheel, under the oil filter.

Method for checking the sensor: disconnect the connector from the sensor, check the resistance with a multimeter by connecting it to pins 1 and 2 (numbers on the block) - the resistance should be 500-600 Ohms.

Camshaft position sensor (CPRV, phase sensor)

The ECU, based on sensor signals, determines the position of the camshaft to synchronize the moment of opening the injectors with the intake stroke in order to achieve better filling of the cylinder and its timely purging.

Installation location: installed behind the camshaft housing, next to the timing belt cover under the crankcase ventilation pipe. On the F16D3 engine, it is located in the cylinder head (cylinder head) between the camshafts near the timing belt housing.

Method of checking the sensor: with a diagnostic scanner.

Throttle Position Sensor (TPS)

Monitors the throttle valve opening value, the readings affect the composition of the air-fuel mixture. When the damper is closed according to the sensor signal, the ECU switches the engine to idle mode. If the sensor malfunctions, the ECU goes into emergency mode and the Check Engine light comes on.

Installation location: on the throttle body.

Method for checking the sensor: it is necessary to measure the resistance between contacts B and C (marking on the wiring harness block). When opening smoothly, it should change smoothly from 1 to 7.5 kOhm (+-2 kOhm). More accurate diagnosis is only possible with a diagnostic scanner.

Knock sensor

Based on sensor signals, the ECU adjusts the ignition timing (IAF) as close as possible to the detonation zone, but without detonation, which is the most optimal for engine operation. If the sensor malfunctions, the ECU goes into emergency mode and the Check Engine light comes on. Detonation (characteristic ringing) may occur when the gas is pressed sharply. Detonation is extremely harmful to the engine and can lead to the destruction of its mechanisms.

Installation location: on the cylinder block, behind the starter.

Method for checking the sensor: remove the sensor and use a multimeter (ohmmeter) to measure the resistance between contacts 1 and 2 (numbers on the block). If you lightly tap the sensor, the resistance should change abruptly.

Absolute pressure sensor (MAP)

Using sensor signals, the ECU determines the amount of vacuum in the intake manifold, which indicates the engine load. Based on the readings of this sensor, the air-fuel mixture is adjusted. If the sensor malfunctions, the ECU goes into emergency mode, the Check Engine light comes on, and a sharp increase in fuel consumption is possible.

Installation location: on the right side of the engine compartment partition, next to the heater fan. A thin vacuum tube and wiring harness connect to the sensor. On the F16D3 engine, the sensor is located on the intake manifold.

Method of checking the sensor: with a diagnostic scanner.

Oxygen concentration sensor (DC, DCC, lambda probe)

It monitors the amount of oxygen content in the exhaust gases, and based on its signals, the ECU adjusts the quality of the air-fuel mixture to achieve stoichiometry and more efficient operation of the catalyst. The second sensor monitors the efficiency of the catalyst, and the mixture is also adjusted based on its signals. The sensor is equipped with heating, because located far from the collector, and begins to work at a temperature of about 300 degrees. If the sensor malfunctions, the ECU goes into emergency mode, the Check Engine light comes on, and a sharp increase in fuel consumption is possible.

Coolant temperature sensor

A coolant temperature sensor in a car is necessary not only to determine the temperature of the antifreeze, but also to adjust the fuel mixture and turn on the cooling fan. Inside the sensor there is a thermistor that changes its resistance as the temperature changes, so the sensor sends signals to the computer in Ohms, and the control unit converts them into readings and turns the fan on or off, or enriches and leans the mixture.

Signs of malfunction:

- The cooling fan does not turn on;

- Increased fuel consumption;

- The engine does not start well hot/cold;

Daewoo Nexia 2008. The smell of antifreeze in the cabin

Daewoo Nexia 2008. The smell of antifreeze in the cabin

Leak from expansion tank

As a rule, the cabin smells of coolant if it leaks from the expansion tank. In most cases, this malfunction is caused by long-term operation of the vehicle or a violation of the technical condition of the car.

But, no matter how surprising it may be, antifreeze leaks often occur on modern cars. The main reason for antifreeze leakage is wear of system components or manufacturing defects. Also, working fluid may leak if pipes or other components of the cooling system are incorrectly replaced.

Since the coolant tends to erode, the car owner may not notice a slight leak of the mixture. In this case, a malfunction of the car’s cooling system will be indicated by a foreign smell in the cabin. Visually, it is easier for the vehicle owner to detect a significant leak.

In this case, the liquid leaves noticeable stains on the system components. If antifreeze or antifreeze quickly leaves the expansion tank, this can be determined by the readings of the corresponding analyzers or when characteristic leaks appear.

When the fluid leaves the system to a small extent, you can feel a sweetish smell in the vehicle interior. In this case, it is necessary to promptly begin diagnosing the vehicle’s cooling system.

The heater or radiator is leaking

Often the reason is that the stove or its radiator is leaking. Since it has a complex design, it is recommended to replace it with a new one rather than make repairs.

Leakage can also occur due to loose connections between the pipes.

If it is not possible to change the heater radiator, then you can continue driving as is, but you should check the fluid level in the cooling system more often.

Diagnostics

First of all, it is necessary to conduct a visual diagnosis of the cooling system. During diagnostics, it is necessary to carefully check all conductors of the system for mechanical damage or leaks. If damaged conductors were found during the inspection, it is necessary to restore the tightness of the cooling system by replacing them.

Also, one of the most common malfunctions of the cooling system is coolant leakage into the engine crankcase. This malfunction can lead to quite serious consequences and significantly disrupt the function of the engine.

This malfunction can be identified by visually inspecting the oil tank cap. If coolant enters the crankcase, a white emulsion appears on the cover. If coolant leaks out, you may notice a formation under the car.

If the inside of the car smells like antifreeze, then coolant leaks directly into the interior. The smell of antifreeze in the cabin indicates a leak in the heater core.

If the radiator leaks, some of the coolant leaks directly into the passenger compartment and the driver of the vehicle may notice a characteristic sweet smell. Also, coolant can get under the gas distribution mechanism drive.

In this case, it is quite difficult to visually determine the leak, but by diagnosing the space under the timing belt, you can notice characteristic traces of moisture. As a rule, the cause of moisture formation under the timing belt is a faulty pump.

As you know, the combination of maintaining temperature conditions plays an important role in the proper and long-term functioning of the engine. If the cooling system malfunctions, the engine is subject to overheating and premature wear of the components.

During vehicle operation, the cooling system operates in difficult conditions. System components are constantly exposed to high pressure and temperature changes.

In this regard, the elements of the cooling system are subject to increased wear and require timely diagnostics and regular maintenance.

The smell of antifreeze in the cabin indicates a malfunction of the connecting hoses of the systems and the need for diagnostics. With prolonged use of the vehicle, the rubber components of the system wear out and often become unusable. If diagnostics have shown the maximum permissible wear of the system conductors, they must be replaced.

To secure the cooling system hoses, it is best to use special metal clamps, which are characterized by a long service life, reliability and do not allow leakage of the working mixture. In addition, it is necessary to pay attention to the condition of the radiator and, if necessary, restore its tightness or replace it.

If there is a coolant leak, the car engine is subject to increased wear. In this regard, if you do not pay attention to the condition of the cooling system in a timely manner, you can end up with a large number of engine repair costs.

Timely diagnostics and regular maintenance of the cooling part will allow you to remain confident in the reliability of the engine and increase the service life of its elements.

Danger to the body

You also need to remember that antifreeze is harmful to the body and toxic, and therefore, with a high concentration of vapors in the cabin, you can lose consciousness and create an emergency situation on the road. To prevent this from happening, it is recommended to eliminate all antifreeze leaks and stop using such a car unless absolutely necessary.

Source: https://zinref.ru/avtomobili/Daewoo/001_Daewoo_nexia_s_2008_goda_za_rulom/099.htm

Air flow sensor

The mass air flow sensor is necessary to account for the air entering the engine. These parameters are necessary for the correct composition of the fuel-air mixture before it enters the combustion chamber. Inside the sensor there is a special sensitive element that counts the air passed through it and transmits the readings to the computer.

Signs of malfunction:

- Increased fuel consumption;

- Idle speed fluctuates;

- The engine stalls spontaneously;

Symptoms and causes of IAC malfunction

Signs of a malfunctioning idle speed sensor appear as follows:

- during a cold start, the crankshaft speed does not increase, which is why the engine runs unstable and tends to stall;

- there is a drop in the number of idle revolutions after a significant increase in the load on the generator - turning on headlights, electric heaters, and so on;

- the engine periodically stalls when any gear of the manual transmission is switched off (the symptom manifests itself while driving);

- The speed “floats” - it spontaneously increases and decreases.

Important point! There is a misconception that a regulator failure is necessarily accompanied by the inclusion of the Check Engine indicator on the dashboard. Since the element is an actuator, the light warning option is not provided in all cars.

If the car shows signs of IAC malfunction in the form of floating engine speed at idle, advanced diagnostics may be needed. A spontaneous change in the crankshaft rotation speed occurs for many reasons - failure of a sensor, air leaks, gas distribution malfunctions, and so on. It is better to start troubleshooting by checking the regulator.

IAC failure occurs for three main reasons:

- Open or poor contact in the power supply circuit. Simply put, there are problems with the wiring.

- Breakdown of the stepper motor due to natural wear and tear. In this case, only replacing the idle speed sensor will help.

- Contamination of the rod and cone with oil deposits.

There is a fourth reason - problems with the electronic control unit.

The problem is quite rare and is accompanied by additional symptoms - increased gas mileage, unstable operation in all modes, difficult starting, and the like. Oil deposits reach the rod thanks to secondary gases sent by the crankcase ventilation system for re-combustion. The more worn out the engine, the more deposits accumulate on the working cone. As a result, moving the rod becomes difficult; in advanced cases, the mechanism simply jams.

Idle speed control

To regulate idle speed, the Nexia engine has a special sensor-valve that regulates idle speed by opening or closing a small air channel through which air passes during engine operation at idle.

Signs of malfunction:

- The speed is XX;

- The engine stalls at idle;

Removal and installation

Before performing any actions with the DBP if a malfunction is suspected, the sensor must be removed from the engine. First, the battery terminals are disconnected. Then, by squeezing the mounting block, the wire cable is removed from the sensor itself.

Next, the DBP fastening nut is unscrewed and the low pressure pipe is disconnected.

Installation of a repaired or new unit occurs in the reverse order.

Throttle position sensor

The throttle sensor is used to determine the opening angle of the valve inside the throttle. There is a special resistor inside the sensor that changes its resistance when the damper opens. The sensor transmits readings in Ohms to the ECU, which converts them into throttle channel opening percentages.

Signs of malfunction:

- Loss of car dynamics;

- Stalls when you press the gas pedal;

- The revolutions jump from 500 to 2500 rpm at idle;

Nexia's idle speed - the causes of the problem

In the case of the electronic control system of the Daewoo Nexia injection engine, the most vulnerable area is the sensors.

The main one is the idle speed sensor. It is located near the throttle control sensor. This sensor is checked using a special device - a multimeter. The optimal level of resistance between the contacts should vary from 40 to 80 ohms. If excellent readings are obtained, the sensor must be replaced; it is responsible for idle speed. Not less often, the mass air flow sensor (MAF) fails. Its functionality is checked with the ignition on, but the engine should not be started. A multimeter measures the voltage level between the yellow and green wires. The optimal value is from 0.9 to 1.2 V. The malfunction of the sensor is also determined by the condition of the spark plugs: the part is replaced if there is black carbon on the surface of the spark plugs.

“Floating” speed in the Nexia (Daewoo Nexia) may occur as a result of malfunctions in the EGR system. This sensor is located in the intake manifold and is responsible for the release of exhaust gases. To maintain its normal performance, the sensor must be cleaned regularly.

You may encounter other reasons for this problem. These often include:

- Malfunctions in the operation of the electronic control unit of the car, in other words, the system has “gone bad” and requires diagnostics and re-flashing;

- Broken throttle sensor;

- Incorrect temperature sensor readings;

- Damage to the crankcase ventilation valve.

Oxygen sensor

The sensor is used to detect unburned fuel in the exhaust gases. It is installed directly in the exhaust manifold to collect information about exhaust gases. The received information is transmitted to the ECU to adjust the fuel mixture.

Signs of malfunction:

- Loss of power;

- Increased fuel consumption;