In the ignition system, the distributor plays the most important role. And it, in turn, has a slider that is responsible for the formation of sparks. Accordingly, the distributor slider plays a large role in ensuring high-quality operation of the power unit. For this reason, if a motorist suspects something is wrong with the operation of the engine, he should not waste time and check the serviceability of this element and determine its type of failure. At the same time, breakdowns of this part have their own characteristics. For example, a clear sign that there is a problem with the distributor slider on the car may be difficult starting of the engine or refusal to start at all. In some cases, such a problem may manifest itself in the form of adjustment of the motor during operation. In this case, when removing the drive, you may notice a yellow spark. This indicates a faulty element. As a rule, the distributor is in good working order if the spark is blue. Thus, the distributor slider stubbornly makes it clear that something is wrong with it. Almost always, the surest way to check the performance of this part is to test manipulations with the spark itself, the formation of which is actually its vocation.

Latest publications

Let's check the performance of the slider, the rotor element of the distributor.

These components remain suspect if spark is not observed on all plugs. First, we dismantle the slider to perform diagnostics. The part is located on the ignition system distributor. If the accessory is in working order, the car engine starts immediately. Activation problems arise when there is a damaged, punctured rotor. The breakdown occurs against the background of metallization of the existing channel. For prevention, this design must be checked periodically. Using a multimeter, check the resistance level. We connect the probes of the device on a questionable area of the slider. 1. First, remove the cover from the distributor (there are two latches here), disconnecting the wires. 2. Here we find the slider that needs to be checked. 3. We move the cap from the main wire of the coil, exposing the contacts. 4. Then we bring the copper contact near the armor wire to the rotor plate. 5. Start the ignition and crank the engine. When current discharges form, the rotor is considered broken. The component needs to be replaced. 6. Next we check the equipment - remove the slider. 7. Strip the end of the wire and wrap the plate around the removed slider. 8. We will also process the other side of the wire and fix it to ground. 9. Place the element on the plate with the tip of the coil. If there is no spark, it means that the noise suppression resistor is faulty (hold the rotor plates). Another slider should be placed. The solution is the same - replace the slider with a working one. Let's try to temporarily revive the element. The resistor is secured with a spring. To dismantle it, press it with a screwdriver from below. 1. Carefully remove the resistor. 2. Wrap it in foil and seal it on the sides. 3. Return the part to its position. Check the integrity of the slider by the nature of the spark and shade. The yellowish element is considered faulty, the blue fragment is considered capable. To purchase a resistor, follow the link https://pin-g.com.ua/

Buy only high-quality materials and then your equipment will serve you long and faithfully. Our products meet all quality requirements and will satisfy all your requirements.

Share information with friends on social networks

A device function called a slider

The slider is located in the ignition distributor. You can find it right under the lid. By design, runners are quite simple devices consisting of plates (central and spacer). Despite the fact that the models of distributor runners are different, they all have the same design.

One of the varieties of runner

These devices have an important function regarding sparking. We can say that the proper operation of the internal combustion engine directly depends on the slider.

You should know that the distributor rotor is a part of old cars equipped with a carburetor engine system. The slider is made of plastic and has a high-voltage contact inside. When the distributor operates and rotates, the contact of the slider is in direct contact with the contacts of the cover. Thus, the spark that is so necessary for the car is set.

In technical terms, the distributor rotor is needed to transmit high voltage current. The transmission goes from the ignition coil to the spark plugs through armored wires.

Fixing the slider on the distributor

The rotor is fixed directly to the distributor drive (shaft), and the rotation is set in such a way that for 1 revolution of the runner there are 2 revolutions of the crankshaft. It is in this way that the discharge is transmitted to the spark plugs in a strictly defined order.

On a distributor drive, the slider is fixed rigidly so that it does not jump off when the shaft rotates. When rotating, the side contact of the rotor contacts the CG (contact group) pressed into the distributor cap.

Interesting. The distributor cap is in the same position regularly. It does not move, but the sliding contact, “running” next to the electrodes of the cover, forms an alternating and short-term electric arc. This also explains the transmission of the discharge.

On some cars, ignition systems have two working contacts on the slider. This is, in principle, a working classic Twin Spark ignition circuit from the Italian company Fiat. One of the contacts is implemented closer to the center, the other - as far as possible. In this way, the contacts correspond to the cover electrodes, packaged according to the same principle. And most importantly: this scheme ensures complete isolation of the CGs from each other.

Twin Spark ignition system

Twin Spark is considered one of the first systems used for effective afterburning of fuel in the combustion chamber of a car. The system has a simple design, but is very effective and economical.

Briefly about ignition coils

There are two types of coils - single-spark and double-spark. Regardless of the type, the principle of operation does not change and consists of electromagnetic induction of current, which is supplied to the spark plug in the form of a short pulse. This is enough to form a spark and ignite the mixture in the combustion chamber.

To understand what are the main signs of faulty ignition coils, you need to understand what they consist of. There is nothing complicated here. There is a primary and secondary winding. The secondary winds the core and is made of small-section wire, the primary is wound on top and has a thicker wire.

For both single- and double-spark coils, breakdowns are usually similar. Let's see what they are.

Source

Types of faults

As a rule, if the distributor slider is in order, then the car engine starts the first time, without any problems. But when difficulties are observed with the plant, this indicates a damaged or broken rotor (provided that the problem is not elsewhere).

Breakdown of the distributor slider

The most common malfunction of the distributor slider is its breakdown. It can be external or internal. Obviously, the external one is determined by noticeable signs - a black mark, the internal one must be checked by the presence of a spark (details below).

The breakdown occurs due to metallization of the channel. For preventive purposes, metallization should be checked regularly. This is done using a multimeter or other similar device. The channel is checked for moment of resistance. The probes of the device are connected to the place of the slider where there is doubt about breakdown.

You should know that the spark can escape either completely or partially through the formed channel.

Methods for checking the distributor slider

The first method of checking the slider is suitable for all device models.

The element is checked if there is a spark on the main armor wire. In other words, you need to check if there is voltage on the main wire of the coil. If not, then the cause of the problem must be looked for in the coil, wire, but not in the rotor.

Diagnostics of the slider operation

The first thing to do is remove the distributor cap:

- The cover is secured with 2 latches. They will need to be unfastened with a screwdriver or by hand.

- Then pull the lid up and towards you.

- Be sure to disconnect the wires (for safety reasons).

A slider comes into our field of vision. The check is carried out as follows:

- The rubber cap slides off the main armored wire of the ignition coil. Thus, the contact of the armored wire is exposed.

Attention. For safety, it is recommended to tape this same wire to a dry wooden stick, closer to the tip.

- Now you should bring the copper contact of the armor wire to the central plate of the rotor.

- Turn on the ignition and crank the engine.

If electric current discharges follow, that is, a spark strikes between the armor wire contact and the central plate, it means the rotor is broken. It will be necessary to replace or repair it (more about repairing a broken slider below).

Coil overheating

Regardless of the make of the car, be it a VAZ or a BMW, the symptoms are usually the same. A clear example of this is heating the coil. This happens most often due to melting of the winding inside. Consequently, the device loses its primary characteristics and is unstable.

This also affects the behavior of the motor. Usually all this is accompanied by dips in dynamics at speeds above 50 kilometers per hour.

But the cause of a malfunction is not always in the coil. There may well be a short circuit in the circuit, or the problem lies in the fuse box. In this case, you first need to check everything and only then replace the coil with a new one.

Distributor malfunctions and how to fix them yourself

For many car owners, the issue of reliable and quick engine starting is one of the priorities. And an important role in this is played by the ignition distributor-distributor or distributor. The impossibility of normal operation of the motor is largely due to problems with the breaker. In what cases is the distributor repaired and diagnosed and how to repair it yourself - read this article.

Purpose of the mechanism

Before we tell you how a faulty distributor should be checked to identify breakdowns, let’s look at the purpose of the device. The breaker is a unit designed to detect the moment of formation of high-voltage signals in the system. The distributor is installed on both carburetors and injectors, and this mechanism is used to distribute electric ignition among the engine cylinders. That is why many car owners are interested in the question of how to set the ignition and adjust the distributor, where to turn it - this is necessary for the normal operation of the power unit.

In its design, this mechanism differs from others in the presence of various elements in the structure, which tend to wear out over time. When the first signs of malfunctions in the operation of the distributor are identified, the device must be removed and repaired, since its condition largely determines the operation of the power unit and its characteristics.

In addition to setting the ignition, the distributor performs the following functions:

- interrupts the primary ignition circuit, which ensures the appearance of a high-voltage pulse;

- distributes the spark among the cylinder spark plugs in a certain sequence.

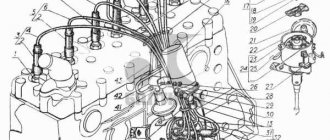

Breaker device design

Why does the VAZ-2107 twitch - let’s understand the operation of the “distributor”

Well, if the engine of your VAZ-2107 suddenly stalls and does not start, we will find the reason and eliminate it quickly. Everyone knows that this happens if the “spark” disappears or there is no gasoline supplied at all. It’s much worse when the car seems to be moving, but the nerves are fraying - uneven idling, jerking and twitching when driving. Finding the root of the problem can take a lot of time and take a lot of money out of your pocket. And more often than not, these searches ultimately lead to a distributor. This material will help you correctly replace it with a working one, select a suitable replacement, and understand the device and operation.

Before delving into the “electrics”, it must be said that the reason for the “jerking” of the VAZ-2107 and other “classic” VAZ models may be an unsuccessful combination of the clutch driven disc damper and the elastic coupling of the driveshaft. Spare parts are supplied with parts whose characteristics may differ greatly from the factory ones, therefore, if the “jerking” intensifies after replacing the clutch or “soft connection”, you need to look for the cause there. Try installing a unit from another manufacturer - its characteristics will be different, the resonance in the transmission will disappear and the “jerking” will stop.

Symptoms of a problem

Of course, repair of the distributor is carried out only after it has been diagnosed.

Listed below are the main symptoms of a distributor malfunction, in which it is necessary to disassemble and check the mechanism:

- the car began to jerk while driving;

- the engine basically won’t start;

- when the speed increases, detonation may be heard (knock of “fingers”);

- it takes longer to increase speed;

- Gasoline consumption has increased.

Of course, these symptoms may indicate other problems. Therefore, before repairing a disassembled unit, you need to know how to set, how to adjust and how to check the distributor.

To check it, you need to disassemble it and pay attention to the condition of the following components:

- slider;

- oxidized or burnt distributor cover contacts;

- failure of the Hall sensor (its bearing element could fail or become jammed);

- distributor capacitor;

- presence of cracks on the device body;

- stuffing box;

- Repair of the ignition distributor should also be carried out if engine fluid gets into its structure.

Distributor for car

avtoexperts.ru

One of the most important parts of a gasoline engine is the distributor, officially called the ignition distributor.

Thanks to the distributor, electrical impulses are supplied to each spark plug separately. As a result, a discharge and corresponding ignition of the fuel mixture are produced in each chamber of the piston. The nature of the work to date is not much different from the first prototypes.

The type of device, its dimensions, dimensions, and “fit” in the engine compartment may change, but the task of distributing discharges among the cylinders will not change. Keep in mind that there is much more than one cylinder in a car, which is why a distribution mechanism is required that evenly divides the charge among the “compartments.”

Remember the main thing, the functioning of some internal combustion engines of the gasoline or gas cycle is impossible without a distributor. In modern cars they try to get rid of them, due to their lack of reliability. They are replaced with individual coils (ignition modules), attached to the spark plug separately or in pairs. As we already understood, they are designed in modules containing from two to four coils. Having got rid of the distributor, the current began to be supplied directly from the ECU through transistor switches, which alternately transmitted 12 V to the coils. From the last impulses “went” to the candle. In this case, controllers control the coils. Thanks to various sensors, the ECU receives and analyzes information about the engine, and based on this it sends the necessary signal to the module. Modern models from manufacturers Mercedes, BMW, Skoda, Citroen, Peugeot, Honda, Subaru and others are equipped with such ignition modules.

The exception is diesel units; as is known, a spark is not required for ignition. Ignition occurs due to the compression of air and diesel. This principle of operation is not appropriate for “gasoline”, because if the latter is compressed, a banal explosion will occur.

Device

There are two dispenser options, contact and non-contact. The design of both is basically identical, with the exception of a couple of nuances. First, let's analyze the contact system. It is important to understand the configuration of only the main components:

1. The housing into which the shaft is inserted, also known as the device drive.

2. The drive, often called a rotor, is due to the existing gear, which is in engagement with the shaft (also known as an intermediate shaft that adjusts the speed) or directly with the camshaft. It all depends on the design and modification of the motor.

3. Coil with winding.

4. Breaker, with a group of terminals and a pair of couplings or a Hall sensor, depending on the specification.

5. The runner is a dielectric that is attached to the shaft and rotates with it. A discharge is transmitted to it, which, through a contact (bunny) on the lid, “goes” to the high-voltage wires.

6. In older cars (VAZ, Moskvich, Volga, some foreign cars), there is an octane corrector that allows you to adjust the shaft speed, depending on what octane number of gasoline is used.

In addition, in addition to the listed elements, there is also a voltage regulator. It protects the contacts from excess current, since part of this charge is absorbed by the capacitor.

Many people will probably want to know how this system works. So, at the moment when the driver turns the key, the circuit closes and the voltage is sent to the starter. That, in turn, thanks to the bendix (a kind of gear) engages with the flywheel crown, causing the rotation of the crankshaft to be transmitted to the distributor. Next, a short circuit occurs in the windings and a low-voltage current is formed, after which the terminals open, and a high-voltage current appears on the secondary circuit, flowing to the cover, through the contact, and then, accordingly, the voltage is transmitted to the “armor”. This type of operation and type of device are typical for models from VAZ, Moskvich, and some old foreign cars from BMW and Fiat.

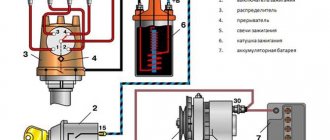

But, do not forget about more modern versions of the distributor, with a non-contact ignition system, paired with a pulse regulator, instead of a breaker. Not infrequently, owners of domestic cars VAZ 2110, 2107, Gazelles installed contactless distributors. There are three types in total, but only the Hall sensor has become widespread in the automotive industry.

It includes a magnet, semiconductor wafers with chips, as well as special gate systems that allow the magnetic field to pass through.

The Hall sensor completely replaces the breaker that was used in the first versions of the unit. The regulator must be paired with a device such as a commutator, that is, it performs the task of breaking the circuits in the coil.

In general, the principle of operation is completely similar. The rotating crankshaft acts on the distributor with the regulator, the latter generates pulses and transmits them to the switch. And the commutator already creates voltage in the coil itself. Next, the voltage is received by a distributor that directs it along the armor wires. Such devices are typical for models from Skoda, BMW (previous years), Toyota and others, and modern models from VAZ are also equipped with this type of ignition.

Distributor malfunctions

There are more than enough problem areas for such a part, given its complex work in the car system. Any part can fail. So:

• Problems with the lid. Malfunctions can be associated with damage to the cover, such as mechanical damage, for example, a crack or the formation of oxide on the contacts.

It is not uncommon for the “bunny” to break; the only solution for this is to buy a new cover.

Oxidized parts will have to be cleaned with an alcohol solution and dried. Often the problem is due to excess moisture in the area, so make sure there is no moisture there.

• The most common problem with distributors is the slider. The fuse-resistor may blow.

• Capacitor. If it is faulty, increased current is supplied to the spark plugs.

• Another malfunction that occurs rarely, more often after serious mechanical damage. It consists of a change in the plane of rotation of the shaft, its deflection or jamming. The only solution is to replace the entire part.

Repair

Before checking the cover or other structural elements, you need to prepare for repair work. Repairing the cover, replacing the distributor oil seal and other tasks to restore functionality are carried out after setting the marks. How to set marks - marks are applied to the device body, its cover, as well as the drives of auxiliary elements - this will allow you to maintain the required ignition timing without adjustment. Also, before removing the assembly, mark the position of the wires that go to the spark plugs, since if you mix them up during further installation, this may lead to damage to the mechanism.

As for the repair itself, it is performed like this:

- After dismantling the device, the cover is diagnosed. If you notice that it is broken, then it will have to be replaced with a functional one.

- Next, you need to check the distributor slider - it needs to be changed if the fuse has melted or rust and fumes have appeared on the element.

- After these steps, the dust shield is dismantled - first, the voltage terminal is removed, after which the two bolts securing the Hall sensor support plate are unscrewed, and the plate itself is also removed after these steps. Having done this, remove the retaining ring from the plate pin, unscrew the bolts securing the vacuum corrector, and remove the component itself. Then the support plastic is pulled out and its bushing is diagnosed - there should be no signs of damage on it.

- Next, remove the spring ring that secures the coupling pin. If you see that the condition of the ring is sad, it needs to be changed, because otherwise it will be of no use. Next, you need to knock out the pin from the coupling - it can only be replaced if the pins have worn out.

- Many car owners are interested in the question of how to check the capacitor. This element can also fail, so check the capacitor first. You will need to prepare a multimeter. Diagnostics is carried out by a tester.

- A centrifugal control device with a roller is removed from the structure. The distributor is replaced if there are gaps, signs of wear and other damage (the author of the video is Roman Romanov).

How to remove and replace a part

The sequence of steps when following the instructions is as follows:

- The car is being prepared for work (you can learn how to do this from other articles and sources).

- The negative wire is disconnected from the battery.

- Now you can remove the distributor cap, first loosening its side latches.

- After removing the lid, it is recommended to start checking the coal.

Note. The ember undergoes a thorough inspection. First of all, you need to check how mobile he is, visually assess his condition.

- Next, you need to wash the surface of the distributor cap with a degreaser, and clean the contacts with sandpaper and fine abrasive.

Attention. No cracks or burns in the body are allowed. If absolutely necessary, the cover can be replaced.

The queue reaches the runner:

- It's better to check it first. To do this, first clean the surface with a degreaser, then with sandpaper.

- The diagnostics continues: we integrate ohmmeter probes with the contacts of the slider. The resistance is measured, which should be within 5-6 kOhm.

If the indications give reason to replace the slider, this should be done.

- It is necessary to unscrew the slider retaining screws that secure the part with the ROZ* plate.

- The runner is removed.

- At the same time, when the runner is removed, it becomes possible to check the ROZ weights. In this case, it will be necessary to diagnose their mobility.

ROZ – ignition timing regulator

Installation of a new part is carried out as follows:

- The new slider is placed on the ROZ plate.

Attention. When installing a new part, you should focus on the figured cutout. The rectangular protrusion of the slider should fit into this very cutout.

- All armor wires should be cleaned of dirt using rags and degreaser.

- The connection of VSKV wires is carried out according to the markings indicated on the cover.

VAZ 2105 - checking the cover and runner of the ignition distributor

09 September 2013

Periodically, during the operation of the VAZ 2105 car, it is necessary to perform a scheduled check of the technical condition of the cover and ignition distributor slider and, if necessary, replace them. To carry out repair work, prepare a standard set of tools, a multimeter. Then do the following sequence of actions:

- First of all, you need to de-energize the car; to do this, disconnect the minus terminal from the battery.

- Next, unclip the two spring clips of the cover and remove it.

- We wash the outer and inner surfaces of the lid with clean kerosene.

- Using a small flat-head screwdriver, check the movement of the center ember; it should move without jamming, otherwise the cover will need to be replaced. The cover must also be replaced in case of damage or severe burnout of the side contacts.

- Next, we check the ignition distributor slider. First of all, it must be washed and the contact surface cleaned from oxidation using fine-grained sandpaper. If cracks or burns are found, replace it with a new one.

- Now we need to check the resistance of the distributor slider resistor. To do this, connect the ohmmeter probes to the contacts; the resistance should be in the range of 5.0-6.0 kOhm. If it is more or less, then we replace it.

- Lubricate the axles of the ignition timing regulator weights.

- To do this, use a flat-head screwdriver to unscrew the two screws securing the slider cover to the base, and then remove it.

- We push the sliders apart with a screwdriver, if necessary, wash all the elements with clean kerosene, and then do an inspection. If defects, deformations, chips or severe signs of wear are detected, we replace it. Lubricate the mechanism with grease.

- Next, install the slider cover back onto the ignition timing mechanism plate, so that the rectangular protrusion on the slider fits into the figured protrusion on the plate.

- Connect the high-voltage wires to the distributor cover, after wiping them with a rag.

A breakdown of the slider is one of the reasons for the inability to start the engine

There is probably a ton of literature written about the reasons why a car won’t start In fact, there are all sorts of reasons, sometimes even the most exotic ones. So, one such reason will be discussed in this article. Namely, a breakdown of the distributor rotor in the distributor (in other words, the slider).

However, do not rush to close this page, read it. After all, the reason is, in fact, exotic, although it seems banal in appearance.

So here are the symptoms. The car drives as if nothing had happened. It tears up, etc. And suddenly, at medium speed... failure. Then the engine no longer responds to pressing the gas pedal. More precisely, it reacts, but somehow strangely: when pressed to the maximum, it reduces the speed, or even stalls. But at minimum speed (at idle), it seems to work. For a while. But then it still stops.

Well, experts will immediately say: the mixture is too rich. Fuel supply is faulty. In fact, we unscrew the spark plugs, look - and sure enough: black as coal. Well, everything is clear. We install new ones. And, naturally... the car started up as if nothing had happened. He moves on. Until the next sudden stop. We are trying to start the engine - it is useless. Well... we sit and think. We look around and become aware of existence... the sun, the sky, the birds. We are trying to start... It started up again (although, perhaps, it would have been better not to start up at all - then it would have been clearer what was what). And he goes. But - again, only for a short time - 500 meters. Or several kilometers.

Well, definitely – the power supply system. Well, we somehow get to the garage (or service station) and adjust the power system. Everything is fine. The car is like new. And the candles no longer clog. True, for only 2..3 days (or weeks). Then the situation repeats itself.

Or maybe the candles are bad (for, in fact, the cheapest of those candles that are on sale were used; however, they were candles from a well-known manufacturer)? But no, let’s not be like Internet trolls and start scolding what we shouldn’t – just because we haven’t really understood the situation yet.

So maybe the ignition is wrong? Perhaps, but why do the spark plugs get clogged again? With a CORRECT power supply system? Maybe the service repaired it incorrectly? No, everything is correct. We check it, this system, after visiting a car service: no, the servicemen were great, they did everything right.

Okay, let's check the ignition system. We remove the wire from the spark plug, install a calibrated spark gap and close it to the housing. We are trying to start the engine. Well, the spark, although a little weak, is still blue (not red), good enough for this car. And before, when everything was fine, it was the same. Instead of a spark gap, a spark plug was then used, closed with its body to the “Ground” of the car - the same result. Moreover, when checking one by one, it turns out that the spark is normal on all four spark plugs. Well, then it's not the ignition?

Still... maybe the valve stem seals? They can also cause such a situation (unfortunately, not all service providers are aware of this). Okay, let's change them too. In the sense, we change the caps, not the servicemen (let other people change the latter). We adjust the chain tension along the way. And again - complete idyll. True, again - not for long. After another couple of weeks we are convinced that everything remains the same. Either the engine won’t start at all, or it will start, but as soon as you drive a couple (tens) of kilometers, it stalls, often completely.

For reliability, we change the ignition coil, the switch - no, nothing has changed. Everything, they say, the car began to crumble.

It’s clear that “they make bad cars these days.” Now it’s time to go to the Internet and troll there properly, listen to what people like you say. We can agree like this (like a gentleman’s agreement): if we don’t start an inexpensive car (for example, a Chinese one, and even more so a domestic one, and what’s more, the age of which is 7, or even 10-plus years), then we scold the manufacturer cars, as well as our “old barn” and pretend that we are beginning to envy the owners of more expensive and prestigious cars. And if it’s expensive and prestigious, then we try our hand at harassing an authorized car service center and; Yes, by the way, let’s not forget to at least somehow weave the current financial crisis into the thread of our trolling - this is generally an indispensable sign of good manners today - a sign that a person heard on TV about what is in the Russian language, it turns out, such a word - "economy". Oh, I almost forgot: at least a couple more words need to be said about sanctions against Russia. In general, almost anything can be attributed to them.

And then by chance, let’s say, out of nothing to do, the distributor cover was opened. We see the distributor rotor ( runner ): everything is fine; runner - like a runner . Just in case, we check its electrical resistance - and it is normal, as indicated in the book. For reliability, we carry out measurements several times.

Or maybe what happened to the distributor? Although - what could be wrong with it, because the spark on ALL the candles is very decent. But, nevertheless, we remove the slider . And only here, having accidentally seen what is going on below him, do we understand EVERYTHING. And there - a little melted. Which is obviously caused by overheating of the resistor located in the slider . Overheating, in turn, is caused by poor contact in the circuit.

But the spark was normal. Where does it come from if there is poor contact in the slider ? And its resistance (tens of kilo-ohms, usually) is normal. This is such a paradox. But after replacing the runner, the car began to start and drive as if nothing had happened. Despite the fact that components were used (high-voltage wires, spark plugs, distributor) belonging, let’s say, to a relatively low price category.

Still, what is the reason for such oddities? It was like this. I had to remember. Once I happened to drive through heavy rain and downpour. The windshield wipers did little to save us - water flooded the windows so much that it seemed as if we were driving under water. However, the road was empty, as almost all the cars were standing, waiting for this downpour to end. And I’ve already developed the habit (on all-wheel drive) of not looking for workarounds and waiting, but just taking and going where I want (well, of course, not into a pole, not into a wall, etc. - of course). Therefore, it was decided to move on, and at high speed. So, after a while... the car stalled. Then, after standing for about 10 minutes, as if nothing had happened, she started up and drove on (well, apparently, she rested, gained strength, and drove off). And only after about six months did what was mentioned above begin.

So, in the process of moving through the downpour, water apparently got into the distributor . And - it cooled the heated slider and, among other things, its resistor (at the same time hitting the high-voltage wires). The latter, being made of hard material, was probably a little cracked. Its resistance increased and the engine stalled. Then, after a short stop, the resistor cooled down a little, temperature deformations occurred in it, and... the resistance was restored to normal.

Subsequently, as the resistor wore out internally, changes occurred in it after six months that began to lead to an increase in its resistance more and more often. Moreover, while the engine speed (and the speed of rotation of the runner ) are small, the effect of centrifugal forces on the resistor elements was not too great - the resistance of the runner did not increase! But as soon as the speed was increased, apparently, the contact elements inside the resistor diverged from each other, increasing the resistance of the resistor. The current through it became small, insufficient to ignite the mixture in the engine cylinders. Moreover, the resistance apparently had a variable value, i.e. The candles sometimes lit the mixture well, sometimes poorly, sometimes they didn’t try to do it at all. As a result, the fuel did not burn completely - hence the carbon deposits on the spark plugs (it is clear that the power system has nothing to do with it at all, although the symptoms seem to clearly indicate a malfunction of the power system). The increased resistance is the cause of strong heating of the resistor, its subsequent failure, as well as melting of the lower surface of the slider .

But then the engine stalled and the slider stopped rotating. Under the influence of elastic forces, the contact elements in the resistor began to press better against each other. The decrease in temperature also played a role (after all, the engine was not running). As a result, at low speeds it transferred voltage to the spark plugs quite normally and gave a good spark! But as soon as the engine starts to pick up speed, the resistance of the slider immediately increases - and the spark plugs begin to lack voltage. At first, this effect appeared only at high speeds, but as the resistor wore out, it became noticeable even at idle. It was then that starting the engine ceased to be possible in principle. Whereas when starting the engine (at the speed LOWER than at idle), the resistance of the resistor was still within the normal range and a good spark was observed. But as soon as the engine tried to start and go to idle, immediately, as if automatically, the voltage to the spark plugs stopped flowing. That’s why the engine then even stopped “grabbing”.

This is such a paradox. It is clear that the slider is a small thing. It seems that they replaced it - and that’s it. But, in this case, it was difficult to suspect the ignition system of a malfunction - at first. Although, if you check the car at the appropriate stand - at the moment of starting the engine, then, quite possibly, this malfunction would be revealed: the voltage on the spark plugs during engine operation would not correspond to the norm. True, for such identification one would have to check the engine on a stand (in running condition) for 15-20 minutes. For for a short time the engine worked perfectly, interruptions occurred after the resistor in the slider warmed up.

What's the conclusion? Even if known methods for diagnosing a car (in particular, an engine) give some (say, positive) result, you still cannot be completely sure that there really is no malfunction. Well, until the car has been rebuilt “piece by piece,” of course. By the way, a similar paradox is sometimes observed in the front suspension of a car, contributing to the wheel alignment angles. When, it seems, the suspension is working properly, but as a result of “mysterious” play in it, the car “for some reason” does not want to drive correctly.