The desire of the owners of the domestically produced VAZ-2109 car to replace factory rims with elements with a different diameter is extremely clear.

Modern lightweight designs can improve the car's handling characteristics and fuel consumption, but, as a rule, the reason for such replacement is a simple desire to improve the appearance.

Such an operation is not difficult to perform.

True, depending on the chosen replacement options, this is either carried out without problems, or such a procedure requires intervention in the design of the car.

What wheels were installed on different bodies and configurations?

The VAZ-2109 car is a 5-door version of the VAZ-2108. Over the entire period of production, from 1987 to 2004, the car underwent 7 modifications, including options for export. Their disk parameters also changed, although the bolt pattern always remained the same. These differences were expressed in the choice of rim width, in the size of the offset and in three options for the diameter of the circle.

But in the factory, only wheels with a diameter of 13 inches were usually installed. Wheels R14 and R15 were considered only acceptable for installation. Here are the two main brands of rims that cars were equipped with on the factory assembly line:

- 5Jx13 ET35;

- 5Jx13 ET40.

The first numbers of the marking indicate the width of the rim, 13 is the overall diameter, ET35-40 is the offset in mm. The standard factory disk design was a stamped steel product. Losing to its cast light-alloy competitors in a number of indicators, steel stamping has always been and remains durable, inexpensive and reliable.

How the rim models of cars produced in Tolyatti during the Soviet period changed over time

The Volzhsky Automobile Plant, which is the largest domestic automaker, has produced a sufficient number of passenger vehicle models over the years. And until now, the manufacturer has not given up its position, offering consumers new types of products that constantly occupy leading positions in sales rankings. Since the moment when the first car (VAZ-2101) rolled off the assembly line in 1970, dozens of brands and modifications of budget cars have seen the light of day.

To equip vehicles, wheels with different characteristics were used (the table clearly demonstrates the differences in the wheels of VAZ cars of different models).

Table. Comparison of disk models that were installed on VAZ cars

| Model | Description of disks | Photo |

| VAZ - 2101 | Disks from FIAT-124 (4.5″ wide and 3.7 cm offset) were installed, which had 8 oval-shaped holes for ventilation. In addition, the cars were equipped with wheels with the same parameters, but with 16 round holes. Protective and decorative functions were performed by chrome caps. In the nineties, the width of standard wheels was increased by 1/2 inch per penny. | |

| VAZ-2103 (2102, 2106) | This model was equipped with wheels 5″ wide and 2.9 cm offset. The appearance remained unchanged (16 round holes for ventilation). Decorative caps on the third and second models were installed the same as on the VAZ-2101, while accessories with a black trim were used on the “six”. In 1995, the diameter of the central hole increased to 6.05 cm | |

| Niva | The cars of this brand were equipped with 16″ wheels. 5 bolts were used to secure them. The discs had 12 round holes and an offset of 5.8 cm. | |

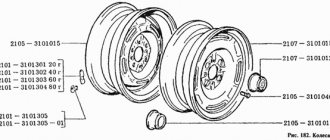

| VAZ - 2105 (2107) | The wheels of these models began to look more original: the central cap was no longer installed, there were 4 or 5 ventilation holes, they received rectangular outlines. | |

| Samara | The first cars with front-wheel drive were equipped with wheels with a 4 cm offset and a new design. They were not designed to accept hubcaps (there were no tabs), and the mounting bolts did not close. Subsequently, the width of the disc was increased to 5″, and the ventilation holes were reduced in size. |

Now it’s clear how to distinguish VAZ car wheels (standard) by external characteristics.

Almost all passenger cars produced in Tolyatti during Soviet times were equipped with 13″ wheels. Many modern cars coming off the AvtoVAZ assembly line are equipped with such stamped wheels.

Standard disk sizes

The main technical characteristics of the rims of any car, including the VAZ-2109, are expressed by the following parameters:

- Diameter. This refers to the size of the rim in inches, excluding the tire.

- Rim width is the size of the tire seat in inches.

- The size of the central hole for the hub.

- Bolt pattern is a parameter indicating the number of holes and the diameter of the circle connecting their central points.

- Overhang is the distance between the hub mounting surface and an imaginary plane passing vertically through the middle circumference of the disk.

For the VAZ-2109, two parameters were always the same:

- The central hole is 58.5 mm.

- Bolt pattern - 4x98.

The wheels are manufactured in three versions: R13, R14 and R15. Other factory parameters, taking into account the corresponding tires, are shown in the table.

| Disc diameter, inches | Rim width, inches | Departure amount, | Tire parameters, mm |

| in mm | |||

| 13 | 5 | 35-38 | 165/70 155/75 |

| 5.5 | 35-38 | 185/65 175/70 | |

| 14 | 4 | 45 | 135/80 |

| 5.5 | 35-43 | 175/65 165/65 | |

| 6 | 35-40 | 185/60 175/65 | |

| 15 | 6 | 30 | 185/55 |

| 6.5 | 30 | 195/55 195/50 | |

| 6.5 | 35 | 205/50 195/50 | |

| 7 | 35 | 205/50 195/50 |

Tires for VAZ 2107

The safety of the car driver and his passengers depends even more on the characteristics and condition of the car’s tires. Their choice must be approached very carefully, and in no case should you skimp.

Types of tires by seasonal use

According to seasonal use, tires are divided into:

- winter;

- summer;

- all-season.

The first ones are made of soft rubber and have a special tread. At the same time, each manufacturer tries to increase the tread area, because the larger it is, the better the tire will perform on winter roads.

The larger the tread area, the better the tire performs on slippery roads.

Summer tires are rougher, and their tread pattern is designed more for better grip on wet surfaces and drainage of water from the plane of contact between the tire and the road.

Summer tire tread is designed for wet grip

All-season tires are a generalized version of the first two types. If the “all-season” tire is really of high quality, then in winter it copes with its duties normally, but in the summer it is significantly inferior to summer tires in terms of the quality of grip on wet surfaces.

High-quality all-season tires do a good job in winter

VAZ 2107 tire parameters

Like wheels, car tires have their own parameters. These include:

- profile width (the width of the tire itself, measured in millimeters);

- height (expressed as a percentage of the profile height to the width, measured as a percentage);

- landing diameter (determines the inner diameter of the tire, measured in inches);

- load capacity (indicates the maximum load per tire, measured in kgf);

- permissible speed value (indicates the estimated maximum permissible speed, measured in km/h).

VAZ 2107 leaves the assembly line of the plant shod with thirteen-inch radial tires with a profile width of 175 or 165 mm and a height of 70%. Standard tires are designed for 190 km/h and a load on one wheel not exceeding 470 kgf.

Tires, like wheels, have their own parameters

It is impossible not to mention the tire pressure, because the vehicle’s cross-country ability, its driving performance, and fuel consumption depend on it. The manufacturer of the VAZ 2107 recommends observing the following pressure indicators.

Table: recommended tire pressure for VAZ 2107

| Load | Tire parameters | Recommended pressure, bar | |

| front tires | rear tires | ||

| In the cabin there is a driver and up to 3 passengers | Width - 175 mm Height - 70% Fitting diameter - 13 inches | 1,7 | 2,0 |

| Width - 165 mm Height - 70% Fitting diameter - 13 inches | 1,6 | 1,9 | |

| 4–5 people in the cabin and cargo in the trunk | Width - 175 mm Height - 70% Fitting diameter - 13 inches | 1,9 | 2,2 |

| Width - 165 mm Height - 70% Fitting diameter - 13 inches | 1,8 | 2,1 | |

The choice between beauty and functionality of wheels should be based on how you use the car. If it is intended for city car rides, or participates in exhibitions of tuned cars, festive motorcades, then alloy wheels and low-profile tires are an ideal option. If the car is used daily in our off-road conditions for work, then it is better to install “stamping” on it with standard tires.

Parameters of standard nuts

Fastening the cast disk to the hub involves the use of special bolts or nuts. It should be noted that nuts from stamped disks are unacceptable here. Firstly, because in cast specimens the conical or spherical part of the fastener is more pronounced than in stamped ones.

For example, the conical part of a bolt or nut has an angle of 60 degrees. This is done in order to increase the area of their contact with a material softer than steel. Secondly, the stamp is thinner than the casting, and when replacing the disk, the length of the bolt simply will not be enough.

It is better to immediately use the fasteners that correspond to the light-alloy wheel used, otherwise deformation of the holes, crumbling and scratches are possible.

By saving on the necessary nuts or bolts, you can irreversibly damage a more expensive element.

The softness of the metal also means regularly checking the tightness of the fasteners, especially at first and with new discs, when the material has not yet become compacted from work loads. Otherwise, under the influence of cyclic shock and vibration, the nuts may spontaneously unscrew.

Nuts must have conical or spherical washers. It is necessary to ensure that the profile of the washers exactly fits the corresponding recess in the hole of the disk being installed. Some disc models are designed to use cylindrical fasteners with flat washers.

Calculation, index, code, marking

Few people understand codes and markings. So, for example, the designation with the Latin letter R means radial, and the number that is stamped after R means the diameter of the disk. You can calculate the parameters of wheels and tires with your own hands, or rather with your own head.

Anyone who wants to learn how to drift with front-wheel drive in the summer, do not forget to prepare the car: wide tires forward, narrow tires back.

Calculation of rubber profile height

To calculate the height of the rubber profile, you need to multiply 175 mm by 0.7 (this is 70% divided by 100). The profile height is 122.5 mm.

You can decipher a car’s VIN code yourself, or you can use online services.

Calculation of diameter (conversion from inches to cm or mm)

Calculation of the total wheel diameter (disc + tires)

The car's passport indicates what size wheels can be installed on this model. These are: R13, R14.

If you install 15-inch wheels on this car and tires that are not low profile, then on bumps during shock absorption the rubber treads will touch the wheel arch liners or the wings themselves.

If you still decide to install R15 wheels, then you need to choose the following tires:

- 185/55 R15;

- 190/50 R15 (this option needs to be checked to see if the width is suitable or not).

Classification of disks by manufacturing method:

What drives can be installed

When planning to replace old steel wheels with alloy wheels, you should choose either original products or products from well-known manufacturers who care about the quality and safety of their products.

Alloy wheels combine the following useful properties: they are lightweight, practical to use, endowed with sufficient strength and have an attractive appearance, which is aimed at transforming the entire appearance of the car.

The most common among alloy wheels are aluminum products. This is due to the fact that they are resistant to corrosion, meet strength requirements and, in comparison with other alloy wheels, remain relatively inexpensive.

Titanium alloy is the most expensive option. It also meets all the technical specifications, but at the same time has a more attractive appearance. In third place is the option using a magnesium alloy.

The latest models from AvtoVAZ use wheels with a 4x100 mounting pattern. When installing them on a 4x98 hub, you should use studs with an eccentric to compensate for the difference of 2 mm. To install disks with other mounting patterns, you will have to use the appropriate adapters (spacers).

You must understand that installing wheels larger than 15 inches is impossible without interfering with the car’s design.

Freelance options

VAZ-2107 cars are equipped with stamping, which has certain advantages and disadvantages. Stamped discs serve for a long time and reliably, bend and do not burst upon impact, and can be easily repaired even at home. Such models are easy to use, affordable, and do not attract the attention of intruders. However, the relatively large weight increases fuel consumption, makes acceleration and braking difficult, and creates inconvenience during installation and dismantling.

Innovative light alloy models are divided into 3 categories based on their manufacturing method:

- cast;

- forged;

- prefabricated

Cast ones are made from alloys based on aluminum or magnesium, which allows them to reduce their weight by a third compared to standard versions. The fragility and inelasticity of the material upon impact leads to chips or even bursting of the wheel.

Forged products are distinguished by increased strength and lower density due to hot stamping technology. Deformation requires a lot of force, but the inflexibility of the material forces the suspension to take on the full force of impacts when driving on a bad road.

Prefabricated ones consist of 2-3 segments fastened with bolts. You need to pay special attention to the fastening material. Steel bolts rust quickly, titanium bolts do not corrode. Components can be manufactured using different methods and from different materials. This technological solution makes it possible to reduce weight, increase the interchangeability of parts and the maintainability of products.