Sooner or later, any car enthusiast may be faced with the need to remove the intake manifold on a 16-valve VAZ-2112 engine. This may be needed to carry out incidental repair operations or other work.

The video will tell you how to remove the intake manifold, and also tell you about all the subtleties and nuances

Intake manifold removal process

General view of the intake manifold

Dismantling the intake manifold is carried out with the car cooled down for safety reasons. So, this operation can take about an hour and will require some knowledge of the car’s design, namely the injection system. So, let's consider the sequence of actions for dismantling the unit:

- We dismantle the throttle. To do this, it is not necessary to disconnect all the pipes and pipes; it is enough to disconnect the unit from the manifold and move it to the side. Of course, at the same time, it is still recommended to remove the throttle valve completely for cleaning.

Location of the throttle valve on a VAZ-2112 - photo of an editorial car

Removed the wires and coil

Unscrew the clamp and disconnect the vacuum brake booster tube

Using a Phillips screwdriver, unscrew the oil level indicator guide tube

Unscrew the ignition coils and receiver

Unscrew the bolts securing the manifold to the block head

Pull the collector towards you and dismantle it

It is worth noting that installation of the intake manifold is carried out in the reverse order and does not require any additions or changes.

Video

Main signs of pollution

While driving a car, various gases, traces of oil and dust particles enter the outer and inner walls of the throttle valve, which the air filter is not able to retain. This can cause deposits on the walls of the damper and lead to disruption of the normal functioning of this element of the intake system.

Typical signs of a clogged throttle body are:

- Difficulties in engine operation at idle, when it stalls or the speed fluctuates.

- Unstable starting of the internal combustion engine when it starts with difficulty.

- The appearance of car jerking at a speed of less than 20 km/h when pressing the accelerator pedal.

- Noticeable increase in fuel consumption.

The main causes of damper contamination include:

- Poor quality gasoline. This factor is considered the most common cause of contamination that requires cleaning the throttle valve. The reason for the low quality of fuel may be various impurities and additives added to increase the octane number of gasoline and ultimately precipitate. These contaminants enter the throttle and turn into carbon deposits, which interfere with the operation of the unit.

- Microparticles of motor oil that enter the assembly structure through the ventilation system, as well as dust particles that penetrate from the atmosphere into the air duct. These elements mix with each other and interfere with the normal movement of the valve, and ultimately disrupt the operation of the engine as a whole.

- A clogged fuel filter causes throttle contamination due to untimely replacement of this element. Once dirt elements from the filter element get onto the damper, it can no longer move as intended during the production of the car. Accordingly, when the damper is opened slightly, a small amount of air enters, which is why the fuel does not even ignite.

- Excessive air dust also often causes throttle contamination. Dust can enter the damper through a damaged air filter or faulty air duct, thereby interfering with its normal operation.

conclusions

Dismantling the intake manifold of a 16-valve VAZ-2112 is quite easy and simple. Of course, it’s worth understanding at least a little about the design of the main power unit, but if desired, any car enthusiast can remove this unit.

The 16-valve VAZ-2112 engine was at one time the most dynamic and responsive engine in the VAZ lineup, which made it both the most popular and difficult to repair and maintain. In this article we will tell you in detail about the design of this engine, its advantages and disadvantages.

What are swirl flaps used for?

As you know, it is not the fuel itself that burns in the cylinder, nor the air. The air-fuel mixture is burning. And the more homogeneous this mixture is, the better it burns, the higher the efficiency and economy of the engine. Accordingly, the question arises: what is the best way to mix this very fuel in the cylinder? Nozzles that supply fuel not with one large and thick stream, but even with a dozen small streams protrude from one side. And on the other side we have air supplied. And if this air is applied with force, and even at a tricky angle, you get a whirlwind. Which will mix everything perfectly and burn just as well.

But then the engineers faced a question: if they make the hole for the air supply narrow, then at low speeds the vortices will be excellent. But when the speed increases, too much air deficiency will form and too much energy will be spent on its supply. If you make the hole wide enough to operate at medium and high speeds, then there will be no swirl at low speeds, and the engine efficiency will again decrease.

Therefore, for optimal engine operation in all modes, the air supply was divided into 2 parts. In one part there are no dampers, and it is always freely blown, while the second part has the same damper that is completely closed at low revs and opens wider the higher the revs.

The figure shows a diagram of the operation of swirl flaps at low speeds. Air is supplied through only one channel. The second channel is completely closed.

As the engine speed increases and the engine requires more air, the second damper gradually opens slightly, controlling the strength of the air flow. A fully open throttle at high speeds is shown in the figure below:

The position of the swirl flaps is controlled by an integrated sensor and a corresponding drive that changes the angle of inclination of these flaps.

Schematic sketch of the VAZ-2112 engine

Detailed diagram of the VAZ-2112 engine.

1 – engine sump. 2 – front crankshaft oil seal. 3 – crankshaft. 4 – crankshaft pulley. 5 – oil pump. 6 – generator drive pulley. 7 – timing belt. 8 – front cover of the timing mechanism drive. 9 – coolant pump pulley (pump). 10 – tension roller. 11 – camshaft toothed pulley. 12 – rear cover of the timing mechanism drive. 13 – camshaft oil seal. 14 – exhaust camshaft. 15 – hydraulic pusher. 16 – valve spring. 17 – valve guide sleeve. 18 – exhaust valve. 19 – receiver. 20 – camshaft bearing cover. 21 – guide pipe. 22 – cylinder head cover. 23 – plastic cover. 24 – spark plug. 25 – intake camshaft. 26 – inlet valve. 27 – cylinder head. 28 – coupling. 29 – fuel rail. 30 – crankcase ventilation hose. 31 – nozzle. 32 – intake manifold. 33 – flywheel. 34 – crankshaft rear oil seal holder. 35 – rear crankshaft oil seal. 36 – cylinder block. 37 – oil dipstick. 38 – piston. 39 – connecting rod. 40 – connecting rod cover. 41 – crankshaft main bearing cover.

Comments

Repair manuals

Mikha

wrote on 07/26/2015 Guys! I’ll tell you right away that it’s better not to get involved in such a responsible task. My son-in-law said yesterday that it’s like two fingers on… asphalt. In short, we argued, it’s a pity that it was for a bottle of beer, but that’s not the point. So he ruined the whole life and that’s all. Of course, I won, but I had to help my son-in-law. In general, I unscrewed all the sensors and tubes, removed the power steering reservoir, and drained the fluid from it. I took out the intake manifold. By twisting the membrane (vacuum) to pull out the quadratic axis. I looked, everything seemed to be fine on the damper, and then mine said that it was the only one knocking and pointed to the end. I pulled out the axle with a hammer and nail, since the dampers were firmly on the axle. The son-in-law began to dig out the valves; one of his doors cracked, but the rest remained intact. Having freed the manifold from the flaps, I started cleaning it, but I didn’t find anything except 95, but what to do... I started cleaning the oil separator. Afterwards, he stacked it a little, inserted new bushings and flaps. And he began the reverse process, which is no less labor-intensive! There’s nothing complicated here, you just need to do it without pressure so that nothing cracks)

Engine device

16-valve 124 engine under the hood of a “two-wheeler”

- The engine is a sixteen-valve, in-line, four-stroke gasoline engine, consisting of four cylinders. The operating order of the cylinders is: 1-3-4-2 – starting from the crankshaft pulley. With a power supply system – distributed injection, controlled via a Bosch, “January” or GM controller.

- The engine is secured in the engine compartment using four elastic supports, of which the front and rear are rods that are fixed from the engine to the body, and the left and right are identical to the VAZ-2110(11).

- On the engine, on one side there are camshaft and crankshaft drives, a coolant pump (about checking the pump and choosing a pump - note), a generator, as well as a timing belt (about replacing it here), on the other side there are sensors: coolant temperature, pressure oil, starter, thermostat, front: ramp with injectors, intake manifold, oil dipstick, knock sensor, crankcase ventilation hose, phase sensor. On the reverse side: oil filter, crankshaft position sensor, exhaust manifold. Top: spark plugs, high-voltage wires. More details about all sensors are written here.

- The cast-iron cylinder block has the same index “21083” with engines from the VAZ-2110 (11), however, they have different screws for the cylinder heads M10x1.25 in contrast to M12x1.25, as well as their smallest entry depth.

- Each engine has its own serial number.

Cylinders

This is what the cylinder block looks like with the engine removed.

The engine cylinders are bored directly into the block. The initial diameter is 82 mm and during repairs can be increased by 0.4 or 0.8 mm. The class of the cylinder is marked on the bottom plane of the block in Latin letters.

Crankshaft

This element practically does not fail.

The crankshaft is made of high-strength cast iron, and is equipped with five main journals, four connecting rod journals, and eight counterweights cast together with the shaft. The difference between this crankshaft and its analogues with the VAZ-2112 is due to its increased strength and wear resistance, so installation from younger models is completely excluded. The flywheel is secured to the back of the crankshaft using six self-locking bolts.

Causes of malfunctions

The gasket is placed between the exhaust manifold and the cylinder head. The stamped asbestos gasket is resistant to high temperatures, can be compressed (creating the necessary impermeability) and has increased strength. To enhance the latter quality, the exhaust manifold gaskets are additionally reinforced with steel.

IMPORTANT! The main task of the gasket is to prevent exhaust gases from penetrating under the hood, where they can cause ignition of parts/assemblies of the engine compartment. The gasket is recognized as the most vulnerable point of the exhaust manifold, which operates under extreme loads in both temperature and pressure

It is not surprising that gaskets have to be changed not only on cars with a significant mileage, but also on almost new cars

The gasket is recognized as the most vulnerable point of the exhaust manifold, which operates under extreme loads in both temperature and pressure. It is not surprising that gaskets have to be changed not only on cars with significant mileage, but also on almost new cars.

Gaskets need to be rotated for several reasons:

- poor factory quality;

- engine overheating due to intensive use;

- engine repair (a used gasket loses its properties when dismantled).

Modifications of the VAZ-2112 car

VAZ-21120 . Modification with a 16-valve injection engine with a volume of 1.5 liters and a power of 93 horsepower. 14-inch wheels were installed on the car. This modification has a problem with valves bending when the timing belt breaks. The problem can be solved by increasing the depth of the grooves in the piston bottoms.

VAZ-21121 . The car was equipped with a VAZ-21114 8-valve injection engine with a volume of 1.6 liters and a power of 81 horsepower.

VAZ-21122 . Budget modification with an 8-valve injection engine VAZ-2111. The car was produced without electric windows, the wheels were 13 inches in size, and the brakes were unventilated from a VAZ-2108 car.

VAZ-21123 Coupe . Three-door, five-seater hatchback. The only two doors for entering the car are 200 millimeters wider than those of the five-door hatchback, and they are mounted on new, durable hinges. The rear arches of the car have become wider. The engine was installed with a 16-valve injection engine with a volume of 1.6 liters and a power of 90 horsepower. The car was produced from 2002 to 2006 in small quantities, the reason for this was the high cost of the car.

VAZ-21124 . Modification with a 16-valve injection engine VAZ-21124 with a volume of 1.6 liters. Produced from 2004 to 2008. For this type of engine, the problem with valve bending was solved. To do this, the depth of the grooves in the piston heads was increased (up to 6.5 mm). In addition, the design of the cylinder block was changed to achieve a working volume of 1.6 liters, for which its height was increased by 2.3 mm, and the radius of the crankshaft was increased by 2.3 mm accordingly. There were also a number of other minor changes.

VAZ-21128 . The luxury version of the car, produced by Super-auto JSC, was equipped with a 16-valve VAZ-21128 engine with a volume of 1.8 liters and a power of 105 horsepower.

VAZ-2112-37 . A racing modification of the VAZ-2112, prepared for the “ring” in the Lada Cup qualifying group. The car was equipped with a 1.5-liter VAZ-2112 engine with a power of 100 horsepower. The racing car was equipped with a safety cage, an external aerodynamic kit and a front extension of the strut support cups.

VAZ-2112-90 Tarzan . All-wheel drive modification with a VAZ-2112 body on a frame chassis with transmission and suspension parts from a VAZ-21213 Niva. It was also equipped with a 1.7 or 1.8 liter engine from the Niva.

Receivers 16V

This section contains sports intake receivers for VAZ cars, which are equipped with 16-valve engines. The sixteen-valve engine is the most common engine for tuning VAZ cars as it has greater potential for modifications. Accordingly, our online store of tuning spare parts offers you the maximum selection of receivers for 16-valve cars from various manufacturers.

Sports and tuning 16v receivers in this section differ in the production method (welded, cast). Cast aluminum receivers allow you to obtain a more optimal shape for better filling of the cylinders, so they can safely be classified as “sport”. Such receivers include the LADASPORT cast receiver. But the price of such a sports receiver is quite high due to the complex manufacturing technology.

Receivers for tuning VAZ are made of steel, their design and shape also allows you to get good cylinder filling rates (StingerSport channel on YouTube) The price of steel tuning receivers is much lower than the prices of aluminum ones, and besides, steel receivers are made for different types of throttle valves: for throttle VAZ with a maximum bore diameter of 56 mm, and for a GAZ throttle with a bore diameter of 60 mm

Electrical diagram of VAZ-2112

Designations: 1 – Headlight, 2 – Klaxon, 3 – Main radiator fan, 4 – Starter, 5 – Battery, 6 – Generator 2112, 7 – Gearbox limit switch (reverse), 8 – Actuator in the front passenger door, 9 – Power window enable relay, 10 – Starter relay, 11 – Heater fan, 12 – Electric heater partition drive, 13 – Main pump, 14 – Washer reservoir sensor, 15 – Driver’s door actuator, 16 – Front passenger window selector, 17 – Unlock button fifth door, 18 – Heater fan resistance unit, 19 – Main wiper motor, 20 – Driver’s window lift selector, 21 – Front passenger’s window lift motor, 22 – Central locking, 23 – Exterior light switch, 24 – Brake fluid leakage sensor, 25 – Pump additional, 26 – Driver's window lift motor, 27 – PTF on indicator, 28 – PTF switch, 29 – Dashboard, 30 – Heated glass on indicator, 31 – Heated glass switch, 32 – Steering column selector switch, 33 – PTF relay, 34 – Ignition switch, 35 – Main fuse block, 36 – Illumination of heater controls, 37 – Hazard warning button, 38 – Heater control controller, 39 – Glove compartment lighting, 40 – Glove compartment lid end cap, 41 – Cigarette lighter, 42 – BSK – display unit, 43 – Ashtray illumination, 44 – 12V socket, 45 – Instrument lighting switch, 46 – Actuator in the right rear door, 47 – Right rear passenger window selector, 48 – Clock, 49 – Right rear passenger window motor, 50 – Brake limit switch (closed – pedal is pressed), 51 – Left rear passenger window motor, 52 – Left rear passenger window selector, 53 – Actuator in the left rear door, 54 – Turn signal, 55 – Handbrake limit switch (closed – handbrake on), 56 – Rear wiper motor , 57 – Navigator's lamp, 58 – Interior lamp, 59 – Temperature sensor in the heater, 60 – Limit switch for the open front door, 61 – Limit switch for the open rear door, 62 – Trunk light, 63 – Rear optics (on the body), 64 – Rear optics (on the fifth door), 65 – License plate illumination.

The letters indicate the terminals to which it is connected: A – Front speaker on the right, B – Radio, C – Injector harness, D – ESD diagnostic connector, D – Front left speaker, E – Diagnostic connector for the heater controller, G – Rear right speaker, W – Rear left speaker, I – BC connector, K – glass heater thread, L – fifth door actuator, M – Additional brake light.

Wiring diagram VAZ-2112 injector 16 valves - full view

Reasons for the appearance of oil in the air filter and its housing

Air filter that has absorbed oil

If we take the normal condition of the car, then the air filter must be dry throughout its entire service life. But the presence of oil indicates that there are problems in the mechanical part of the engine. Therefore, we will not consider problems in the electronic control unit, since this part has nothing to do with it in this case . So, let's look at the reasons for this effect:

- Compression.

- Adjustment of valves.

- Crankcase ventilation.

- Additives.

- Catalyst.

Once the causes have been considered, you can move directly to methods for solving problems, in the order in which they might occur.

Solution methods

The main reason where the problems lie is the valve stem seals. It is through them that the oil enters the pipe, which squeezes the lubricant onto the filter. First of all, it is necessary to replace this particular element. Of course, there are quite a lot of reasons besides valve seals, so it is necessary to dwell on each separately.

Air filter in oil compared to new and clean

Compression drop

A loss of compression may cause traces of oil to be visible on the air filter element. The problem can be corrected quite easily - a small tube with a diameter of 1 mm extends from the brood pipe near the crankcase. It often gets clogged, which causes a drop in compression. Next you need to clean it and put it in place. If you put your finger to the tube and feel that it is being sucked in, then you need to adjust the valves.

The process of measuring engine compression

Adjustment of valves

A fairly common cause, along with valve stem seals, is incorrect valve clearance. A characteristic sign is the appearance of bluish smoke from the exhaust system. To eliminate the malfunction, a simple adjustment of the valve clearances is necessary. This is quite simple and not difficult to do.

Valve clearance adjustment process

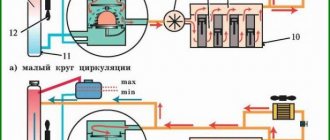

Crankcase ventilation

One of the reasons for the appearance of oil in the car air filter is the oil level is higher than normal or its poor quality . So, at an increased level, the crankshaft creates foam, which enters the rest of the system through the ventilation pipes, especially the air filter element.

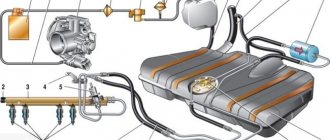

VAZ-21124 engine control circuit

Connection diagram of the VAZ-21124 engine control system with distributed fuel injection to Euro-2 emission standards (controller M7.9.7): 1 - ignition coils; 2 — nozzles; 3 - controller; 4 - main relay; 5 - fuse connected to the main relay; 6 — cooling system electric fan relay; 7 - fuse connected to the cooling system electric fan relay; 8 - electric fuel pump relay; 9 - fuse connected to the electric fuel pump relay; 10 — mass flow and air temperature sensor; 11 — throttle position sensor; 12 — coolant temperature sensor; 13 — solenoid valve for purge of the adsorber; 14 — oxygen sensor; 15 — knock sensor; 16 — crankshaft position sensor; 17 — idle speed regulator; 18 — immobilizer control unit; 19 — immobilizer status indicator; 20 - phase sensor; 21 — vehicle speed sensor; 22 — electric fuel pump module with fuel level sensor; 23 — oil pressure warning lamp sensor; 24 — coolant temperature indicator sensor; A - block connected to the wiring harness of the ABS cabin group; B — diagnostic block; B - block connected to the air conditioner wiring harness; G - to the “+” terminal of the battery; D — to the side door wiring harness block; E - block connected to the instrument panel wiring harness; G1, G2 - grounding points; I - the order of conditional numbering of plugs in the block of the immobilizer control unit; II - the order of conditional numbering of contacts in the diagnostic block.

Connection diagram of the VAZ-21124 engine control system with distributed fuel injection under Euro-3 toxicity standards (controller M7.9.7): 1 - ignition coils; 2 — nozzles; 3 - controller; 4 - main relay; 5 - fuse connected to the main relay; 6 — cooling system electric fan relay; 7 - fuse connected to the cooling system electric fan relay; 8 - electric fuel pump relay; 9 - fuse connected to the electric fuel pump relay; 10 — mass flow and air temperature sensor; 11 — rough road sensor; 12 — throttle position sensor; 13 — coolant temperature sensor; 14 — idle speed regulator; 15 — control oxygen sensor; 16 — diagnostic oxygen sensor; 17 — solenoid valve for purge of the adsorber; 18 — knock sensor; 19 — crankshaft position sensor; 20 — immobilizer control unit; 21 — immobilizer status indicator; 22 - phase sensor; 23 — vehicle speed sensor; 24 — electric fuel pump module with fuel level sensor; 25 — oil pressure warning lamp sensor; 26 — coolant temperature indicator sensor; A - block connected to the wiring harness of the ABS cabin group; B — diagnostic block; B - block connected to the air conditioner wiring harness; G - to the “+” terminal of the battery; D — to the side door wiring harness block; E - block connected to the instrument panel wiring harness; G1, G2 - grounding points; I - the order of conditional numbering of plugs in the block of the immobilizer control unit; II - the order of conditional numbering of contacts in the diagnostic block.

When to change: self-diagnosis

The fuel system of an injection engine has a fairly extensive architecture and faults can only be identified after an accurate diagnosis of each of the system elements. For example, a drop in engine power may be the result of either a malfunction of the injectors, insufficient performance of the fuel pump or a clogged fuel filter.

In addition, jerks and dips, unstable idle and difficult starting, increased consumption, can occur when the injector is simply clogged.

You can check the injectors themselves directly on the engine without removing them. To do this, just start the engine and remove the wires from the connector one by one. If the stability of the engine changes at the same time, the engine starts to oscillate, then the injector is in order. If, when removing the wires from the connector, the stability of the motor does not change, the injector needs to be cleaned or replaced.

VAZ-2112 harness diagrams

Instrument panel harness diagram

1, 2, 3, 4 – instrument panel harness pads to the front harness; 5 — block of the instrument panel harness to the side door harness; 6, 7, 8 — instrument panel harness pads to the rear harness; 9 – rear window heating switch; 10 – light signaling switch; 11 – windshield wiper switch; 12 – block of the instrument panel harness to the radio; 13 – mounting block; 14 — instrument cluster; 15 – heater control controller; 16 – heater motor switch; 17 — block of the instrument panel harness to the ignition system harness; 18, 19 — blocks of the instrument panel harness to the air supply box harness; 20 — ignition switch; 21 – fog lamp relay; 22 – sound signal relay; 23 — power window relay; 24 — starter relay; 25 – seat heating relay; 26 – external lighting switch; 27 – fog lamp switch; 28 – cigarette lighter; 29 – lampshade lighting of the glove box; 30 – glove box lighting switch; 31 – switch for rear fog lights; 32 – right steering column switch; 33 – socket for connecting a portable lamp; 34 — instrument lighting switch; 35 – brake signal switch; 36 – sound signal switch; 37 – alarm switch; 38 – air distribution drive gearmotor; 39 – VAZ-2112 illuminator; 40 — instrument panel harness block to the front harness; 41 – trunk lock drive switch; 42 – rear fog light relay.

A – grounding point of the instrument panel harness.

Tuning

Simple firmware or chip tuning for 124 engines not the technical characteristics . To significantly increase power, it is necessary to modify the engine.

- The simplest and most common tuning of the 21124 engine is the installation of sports camshafts, a direct-flow resonator, an increased throttle - in this way you can increase the power to 120 hp. Installing a lighter piston engine can add some power to this. This, at the same time, will reduce the fuel consumption of the VAZ 21124.

- About 150 hp can be ensured by modification of the cylinder head and installation of camshafts with increased valve opening phases.

- Installing a compressor has approximately the same effect; it is installed on eight-valve and sixteen-valve engines.

- Stable engine operation at any speed is ensured by installing four chokes, one for each cylinder. According to popular experience, the most suitable option is to install an injection system from ToyotaLevin. To do this, a set is assembled from the chokes themselves, an adapter manifold, a zero-resistance filter, injectors, an absolute pressure sensor and a fuel pressure regulator. Due to the fact that the speed exceeds the limit, it is necessary to install lightweight piston and wide-phase camshafts. With this modification, engine power can reach 200 hp. But such modernization sharply reduces the service life of the engine, is fraught with frequent breakdowns and the need to carry out serious repairs of the VAZ 124, due to the fact that the engine easily and often spins up to 9,000 rpm.