How much does a GAZ 53 dump truck weigh?

In a GAZ car

-

unloaded weight

Interesting materials:

How to unsubscribe from spam mailings? How to unsubscribe from Facebook? How to unsubscribe from all subscriptions on Youtube? How to unsubscribe from all mail ru subscriptions? How to unsubscribe from all mailings? How to polish a refrigerator door? How to polish stainless steel at home? How to polish plastic to a shine? How to polish stainless steel dishes? How to send an email address on WhatsApp?

Design features of the GAZ 53 and ZMZ 53 engines

- The engine includes cylinder heads with a combustion chamber with increased turbulence, and the intake valve type is screw. This innovation had a positive effect on the compression and efficiency of the power unit.

- The combined lubrication system allows for the highest quality lubrication of rubbing surfaces, helps to increase the performance and service life of working units and parts.

- Due to the presence of an exhaust gas recirculation system in the internal combustion engine, several times less harmful substances are emitted into the surrounding space.

- The cooling system fluid circulates through special lines and channels, providing high-quality heat removal from the hot metal working elements of the internal combustion engine, regardless of the ambient temperature.

Short description

The ZMZ-511 engine and its modifications are used for installation on medium-duty trucks, such as GAZ-53, GAZ-66, GAZ-3307. ZMZ-511 is a modernized ZMZ-53a, 53-11. The ZMZ-511 uses an untuned single-tier intake manifold, which leads to flow pulsations that negatively affect mixture formation. Cylinder heads with highly turbulent combustion chambers and helical inlet ports are used. These heads provide a compression ratio of 7.6:1, versus 6.7:1 for older engines. The ZMZ-513 engine is a modification of the 511 designed for more difficult operating conditions (for military equipment, for transporting goods in rural areas and in other difficult conditions). The engine has a number of design differences, such as a specially shaped sump for the drive axle, shielded design of electrical components, etc. The power and torque characteristics are the same. The ZMZ-513 engine is distinguished by its heavy weight - 275 kg.

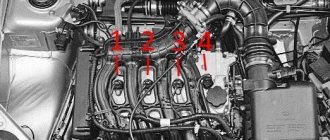

Operating procedure of the 8 cylinder GAZ 53 engine

Experienced auto mechanics who deal with repair and restoration work on these power units are familiar with the operating order of the cylinders. GAZ 53 engine cylinder switching diagram: 1-5-4-2-6-3-7-8. The material used to manufacture the block and both cylinder head heads is AL-4 aluminum alloy, which made it possible to significantly reduce the weight of the GAZ 53 engine.

Interesting: Judging by numerous reviews from experienced motorists, the design of the four-stroke Y-shaped 8-cylinder engine itself is very successful. However, all the advantages of this motor are greatly reduced due to numerous unfavorable factors:

- poor quality assembly of main components;

- use of lubricants with inappropriate properties and characteristics;

- failure to comply with technical inspection regulations and much more.

If you decide to repair the engine yourself, you must strictly follow the order in which the cylinders operate. The retail chain still offers spare parts produced for GAZ 53 and ZMZ 53 for major and current repairs.

Advice: It is recommended that instead of repairing, replace the old worn-out GAZ 53 engine with a modern diesel engine. Most often, motors designed for medium-tonnage trucks are used for these purposes.

The GAZ 53 engine continued to be produced until 1989. The latest versions of the engine have received the following changes:

- They were equipped with an improved camshaft configuration.

- The profile of the cams of the new shaft has received a modified curvature.

- A carburetor is installed, model K135M.

- Electrical equipment has been improved.

- The manufacturing materials for some parts have been changed.

- Many nodes began to be fixed in a different way.

Thanks to numerous improvements, the updated engine received a noticeable increase in power by more than 5 horsepower.

Making a motor

The origins of the GAZ-53 engine began in 1959. During this period, work began on calculating the unit that would replace the GAZ-51. The latter was very outdated at that time. In addition, the valves located at the bottom did not allow the engine to realize its potential; tuning and repair were complicated by design flaws. The cast iron from which the load-bearing elements were cast made the product clumsy and increased its weight. The prerequisites for an imminent design change are obvious and the work was urgent. The day before, the designers of the engine plant mastered the aluminum casting method, then this was considered a breakthrough and made it possible to apply the technology to a new product.

The first engine installed on the GAZ-53 car was a unit labeled “511”, this happened in 1961. Subsequently, more than one experimental engine model was installed on the car, but the units could not take root. Thus, a striking example of “engineering thought” is the GAZ-53F engine with pre-chamber ignition, other models: GAZ-53A (12). A number of modifications have been created that have not found mass application, but are popular among those who like to tune the GAZ 53 engine. In addition, there are engines whose use goes beyond the scope of GAZ products. For example, 53 is found on cars: UAZ and Gazelle. The year 1993 was the final stage for the engine, since the brand ceased to be produced. Nevertheless, the plant operates a workshop that produces spare parts for engines that have not ceased operation.

Engine GAZ-53:

Characteristics and applicability of ZMZ-511 engines

In 1959, serial production of gasoline 8-cylinder V-shaped engines ZMZ-13 began, which were installed on a number of GAZ vehicles. Already in 1964, deeply modernized ZMZ-53 engines (as well as ZMZ-66) began to be produced, especially widely used in GAZ-53 and GAZ-66 trucks. This series was produced until the early 90s, so 53 and 66 engines are still common.

In the late 1980s, based on the ZMZ-53, power units of the 500 series were developed, among which the ZMZ-511, 513 and 523 “survived” (and are successfully produced) to this day. Motors ZMZ-511 (modernization of the ZMZ-53A, ZMZ-53-11) were and are installed in GAZ-53 and GAZ-3307 trucks, ZMZ-513 (modernization of ZMZ-66-06) - on GAZ-66 trucks, and ZMZ-523 - on GAZ-3307, 3308 and PAZ buses.

The most popular engines today are the ZMZ-511 engines, which are presented in dozens of modifications, but they all have fundamentally the same design and characteristics.

ZMZ-511 is a gasoline carburetor 8-cylinder V-shaped engine with a displacement of 4.254 liters and a power of 125 hp. (at 3500 rpm). Compression ratio - 7.6. According to modern classification, the motor has an environmental class of “Euro-0”. The ZMZ-513 unit has similar characteristics, but it has a reinforced design for operation in more difficult conditions. The weight of the 511th engine is 262 kg, the 513th engine is 275 kg.

ZMZ-511 engines are installed on cars of the GAZ-3307 family, but they have gained some popularity among home-made people. The motor has good boost potential, so it is often modified and installed on trucks, Volga cars and others, as well as on boats and other vehicles.

Maintenance of GAZ 53 and ZAZ 53 engines

The duration of operation of these motors depends on compliance with the rules of care for working mechanisms and systems. The list of maintenance work for power units includes the following items:

- Checking the fastening of the working cylinders.

- Cleaning valves from carbon deposits and other harmful deposits.

- Adjusting the gaps between valves and rocker arms of the gas distribution mechanism.

- Checking the engine oil level using the dipstick.

- Periodically change the oil and oil filter in the engine lubrication system.

- Daily monitoring of coolant level. If the radiator is filled with water, its level should not reach 40 mm to the edge of the neck; when using non-freezing liquid in the cooling system, this size is 70 - 80 mm.

- Regular cleaning and flushing of power system components (carburetor, fine filter, float mechanism, etc.).

Modification of the Gas 53 engine

Since the GAZ-53 power plant is unpretentious, with an increased resource, craftsmen often use the engine for tuning. Additionally, the work is stimulated by the availability of the price of the device and spare parts. For this reason, owners prefer to install the engine on other cars, such as Gazelle and UAZ.

It seems that the engine is not suitable for such cars in terms of weight and dimensions. But, thanks to the use of aluminum, the motor actually weighs relatively little (230-270 kg). This factor does not negatively affect the chassis; the engine fits in the space under the hood and is compatible with these cars. To adapt to changing conditions, some elements in the design of products are changed: fastenings, cooling, etc.

Improved GAZ-53:

A popular modification is the installation of an injector on the power unit. The procedure requires knowledge and skills, since it is difficult to adjust the engine to the changed parameters. A standard carburetor is not able to make the consumed mixture of improved consistency, so an injector is relevant in this case. By the way, attempts to install the product on the engine were also made by the plant. Thus, in the eighties, modifications of the “504.10” and “5232.10” engines received fuel injection as standard. The injection engine was distinguished by increased power, efficiency, and an increased range of settings. However, these engines did not make it into serial production and most users know nothing about the modifications.

Features of the GAZ 53 engine ignition system

The following indicators depend on the quality of operation of the ignition system elements:

- Spark power.

- Timeliness of its education.

- Complete combustion of the air-fuel mixture.

With stable operation of the power unit, an electrical voltage appears on the electrodes, which is necessary for successful spark formation. If the spark is weak or absent altogether, the power performance of the internal combustion engine decreases and fuel consumption increases. The power of the spark depends on the distance between the electrodes (gaps) and the voltage.

The main reasons leading to malfunctions in the ignition system of the GAZ 53 engine:

- A spark does not form when the coil and commutator overheat. In this case, the engine does not start until the temperature drops so that a spark appears.

- Breakdown and sparking of high-voltage wires.

- Burning contacts of the moving slider on the distributor.

- Burnout of the distributor cap at the spring locations.

- Failure of spark plugs.

In order to prevent engine overheating, it is recommended to adjust the ignition process. To do this, the gaps between the electrodes of the system are adjusted using a special device called a “car strobe”. Using this device, experienced craftsmen adjust and control the ignition timing.

When ignition is early, the following malfunctions occur:

- failure of the cylinder head gasket (breakdown);

- burning out of pistons;

- valves

If sparking is delayed:

- gasoline consumption increases;

- the engine overheats.

What engine modifications are there?

There are several varieties of the GAZ 53 engine. There are not so many of them. This is explained by the fact that during the release of the power unit they did not particularly strive to create a variety of designs. The familiar ZMZ 53 was always taken as a basis.

The following modifications are distinguished:

- ZMZ 6606. Differs in piston stroke, which reaches 92 mm. The diameter is 80 mm. This design allows you to achieve a power of 120 horsepower. The engine displacement is the same as the standard model.

- ZMZ 511. The piston stroke and diameter are the same as the first version of the modification. The engine capacity is 4.25 liters, which allows it to achieve a power of 125 horsepower.

- ZMZ 523. The designers increased the engine capacity, reaching a value of 4.68 liters. Maximum power is 130 horses. The piston stroke diameter is 88 mm, the element stroke has not changed.

There are other modifications, but they are not widely used. Among the power units, it is worth highlighting ZMZ 5233, 5234 and 513. They are extremely rare on GAZ models.