Any malfunctions in the operation of the car’s cylinder block require immediate intervention from the driver, since they directly affect the quality of the engine. One of the unpleasant situations that can arise during the operation of this engine unit is antifreeze getting into the cylinder block. Of course, in this case the engine will not stop working instantly, and the car will continue to move with virtually no major changes. Therefore, many drivers do not pay attention to signs of BC malfunction. But if you ignore the symptoms of a breakdown for a long time and continue to operate the car without fixing it, the consequences can be very serious.

Consequences of antifreeze getting into the cylinder block

It doesn’t matter what kind of liquid gets into the engine, it could be ordinary antifreeze or modern expensive antifreeze, the consequences will be identical. Further operation of the vehicle in the usual sense is not permitted. Coolant (hereinafter referred to as coolant) cannot harm the engine, even taking into account the aggressive and toxic components included in its composition. The problem is that ethylene glycol, which most coolants are made of, when mixed with engine oil, is converted into a solid, insoluble component, similar in action to abrasive materials. All rubbing parts quickly wear out and fail.

White emulsion on the plug: a clear sign of coolant in the oil

The second problem is a kind of scale or emulsion in the form of deposits on the walls of oil lines and numerous channels. The filters cannot cope with their task because they are simply clogged, the oil circulation is disrupted and, as a result, the pressure in the system increases.

The next problem is dilution of the engine oil, as a result of which the washing, lubricating, protective and other properties are lost. All this together invariably leads to overheating of the power unit and deformation of the cylinder block and its head. It doesn’t matter at all whether the engine is gasoline or diesel, the consequences will be similar.

Reasons for getting there

If you study the structure of a car engine, it becomes clear that the coolant circulates through the so-called jacket, removing excess heat. These channels do not normally communicate with the internal cavities, but at the junctions of different parts (especially where the cylinder head is connected to the block itself) there are weak spots and breaks. A special gasket is installed in this place, which becomes a connecting link and prevents antifreeze leakage. However, it often burns out as it wears out and the coolant leaks out or into the cylinders, sometimes in both directions.

Through such damage to the gasket, coolant enters the cylinders.

Often the problem occurs due to the fact that the cylinder head has defects along the plane that is pressed against the block. The slightest deviation creates microscopic cracks through which antifreeze is released under pressure. Well, the third reason is a crack in the channels on the block.

Antifreeze gets into the engine: signs

For any coolant, the signs of getting into the combustion chambers and into the crankcase with oil will be the same:

- white color of exhaust smoke (not to be confused with steam in winter);

- there is a specific sweetish smell of antifreeze in the exhaust gases;

- the level in the expansion tank is constantly decreasing (the sign is indirect, since it can also go away due to a banal leak through the pipes);

- when examining the oil level dipstick, you can see an uncharacteristic shade (dark or, conversely, white);

- spark plugs in cylinders with leaking damp from antifreeze;

- emulsion on the oil filler plug.

The most common factors by which you can understand that antifreeze has got into the oil

There are some signs of antifreeze getting into the lubricant. How to determine and detect antifreeze in oil:

- Reducing the amount of antifreeze, provided that it does not leak out of the car.

- The engine is shaking, the motor is running unevenly.

- Whitish traces of antifreeze on the dipstick.

- When you open the valve cover, you can see that it is white on the inside. There are also white spots inside the flask.

- Air bubbles are visually observed in the expansion tank at high engine speeds. There are grease leaks on the surface.

- Antifreeze is visible on the crankcase, spark plugs, under the head, in the pan.

- High concentration of exhaust carbon monoxide. The exhaust color is white, more like steam.

- The grease darkens quickly.

Remedies

In the vast majority of cases, the cause is the cylinder head gasket, and it will require replacing it and restoring the tightness of the cooling system. It is inexpensive, and replacement will not cost a fortune, especially for a Russian-made car. The most difficult thing is removing the head, because you need a special torque wrench to control the force when tightening the nuts. You also need to take into account the sequence in which the nuts on the studs are unscrewed and then tightened.

Changing the gasket is not enough and you have to grind the plane of contact of the cylinder head to the block; most likely, if the seal is damaged, the “head” will move. In this situation, you can no longer cope on your own; you need to attract experts. They will carry out troubleshooting, and if it turns out that the head is severely deformed, grinding will no longer help, and you will have to replace the cylinder head. If antifreeze gets into the engine due to cracks in the block, then there is only one option for eliminating the leak: replacing the block, and in most cases this means installing a new or contract engine.

Video: Consequences of antifreeze getting into the engine

The ingress of antifreeze is not an exceptional case and occurs everywhere; even a novice motorist can determine the malfunction. The solution to the problem can be different and differ in both complexity and cost of repair. You should not delay diagnostics if any symptoms appear; this is fraught with more serious consequences, including replacing the engine.

Any problem with the cylinder block, be it mechanical damage or improper operation of the unit, needs to be addressed immediately, otherwise it can lead to more serious malfunctions. One of the unpleasant situations that a driver may encounter is the ingress of coolant (antifreeze or antifreeze) into the cylinder block. In the article, we will look at why this can happen, what are the symptoms of such a problem, and how to eliminate it.

Why does antifreeze get into the lubricant?

If antifreeze or its traces are found, you need to understand the path through which it gets into the lubricant and fix the problem.

Some possible reasons:

- The cylinder head gasket is worn, punctured, or deformed. There is no barrier for antifreeze to leak into the lubricant. This will clearly be observed on the spark plugs. They will be covered in whitish streaks of antifreeze.

- Poor installation of the cylinder head gasket. The head bolts are not tightened sufficiently or, conversely, they are overtightened.

- Lack of tightness of the heat exchanger.

- Head deformation due to harsh operating conditions, overheating.

- Poor quality antifreeze. Could freeze at low sub-zero temperatures. After thawing, such liquid leads to deformation of the block head. And also the use of low-quality fluid leads to the fact that the cylinder liners rust and collapse.

- The fluid pump is clogged or incorrectly installed.

Symptoms of antifreeze getting into the cylinder block

There are several signs of engine operation by which you can determine that coolant is getting into the cylinder block:

White smoke, similar to thick steam, comes out of the exhaust pipe of a car when the engine is running. The smell of this smoke clearly smells like burnt antifreeze;

- The coolant level in the reservoir is constantly decreasing. It is worth noting that antifreeze can also leave the tank for other reasons, so it is worth considering this symptom in conjunction with the others;

- When checking the oil on the dipstick, you can see the formation of a white emulsion. Or, on the contrary, the oil becomes much darker. At the same time, an emulsion is formed at the oil filler neck;

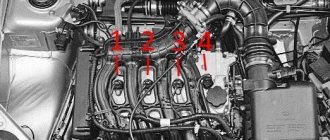

- Spark plugs may have a characteristic wet residue or carbon deposit. It is better to check all the spark plugs, since the problem may only be expressed in one or a few of them. Also, when antifreeze gets into the cylinder block, the spark plugs will have an antifreeze aroma.

How to tell if coolant has entered the engine

Extensive practice allows us to identify the main signs of antifreeze penetration into the cylinder block. These include the following phenomena:

- In the expansion tank, the coolant level gradually decreases. It must be remembered that this is an ambiguous indicator that the antifreeze goes into the cylinder block.

- The exhaust becomes thick and light. This almost always happens in winter, so you need to pay attention to the smell. If you feel the presence of coolant in it, then you should think about it.

- The color of the oil changes. A light emulsion or a very black substance may appear on the dipstick.

- When you unscrew the spark plug, you smell antifreeze.

- An emulsion is observed under the engine oil filler neck.

What you should know

. These symptoms usually accompany problems caused by antifreeze getting into the engine cylinders. It must be remembered that these symptoms, although accurate, are far from unambiguous. For example, exhaust gases may turn white due to oil combustion. In any case, if you notice the symptoms described above, you need to pay attention to the cooling system. It is important to understand that coolant is a mixture of ethylene glycol (or propylene glycol) with distilled water. The entry of this composition into the lubrication system and its mixing with engine oil significantly worsens the properties of the lubricant. Operating an engine with such oil will lead to rapid wear of its components and the need for major repairs.

Other signs of coolant in the engine

. Antifreeze ingress into the engine can also be diagnosed by the appearance of extraneous noise, usually in the form of a characteristic knocking sound that has not been observed before. The crankshaft and camshaft liners begin to knock. Why is this happening? If oil mixed with antifreeze begins to circulate through the channels of the lubrication system, the first to suffer are the loaded plain bearings, which are more often called liners. Scores appear on the surface of these parts, causing knocking. After disassembling engines with such damage, you can see that the friction layer on the liners is literally erased, and the metal surface is covered with scratches and burrs. The smooth and shiny surface of a sliding bearing of the usual gray color becomes brown, covered with spots and damage.

Why do engine parts get damaged?

. To understand why mixing antifreeze with motor oil causes scuffing on the liners, it is enough to examine the surface of the damaged parts under a microscope. At high magnification, you can see white balls, the size of which is 20–35 microns. They tightly cover the surface of the affected plain bearings. That is, having abrasive properties, these solid particles erase the friction layer and form scuffs. Chemical analysis makes it possible to determine that such particles contain phosphorus, calcium, sulfur and other elements. These inclusions are formed from motor oil additives as a result of heating and interaction with antifreeze. Additives quickly dissolve in water, which is part of coolants, and the high temperature in the engine significantly accelerates the occurrence of chemical processes. Water quickly evaporates from the surface of the liners, and the remaining hard grains of sand cause accelerated wear of the parts.

Why does coolant seep into the cylinder block?

There are 3 main malfunctions that lead to antifreeze getting into the cylinder block:

Gasket burnout or rupture. Antifreeze in a car engine moves in a vicious circle when it is running. The isolated channels through which it flows have breaks at the junctions of parts, including at the junction of the cylinder head with the cylinder block itself. To eliminate the possibility of antifreeze leaking into the cylinder block, a special gasket is installed. If it burns out or ruptures, then coolant can get into the block itself;

Why does antifreeze get into the cylinders?

- As you know, coolants circulate in the engine through special insulated channels. Those, although isolated, have breaks at the junctions of different parts of the engine. More precisely, such breaks are concentrated at the junction of the cylinder head with the block itself. A gasket is installed here, which prevents coolant leakage, both inward and outward. When this gasket burns out, then the antifreeze gets into the cylinder or flows out. And in severe cases it goes both ways.

What to do if antifreeze gets into the cylinder block

Three main problems that can lead to such a malfunction were discussed above. Depending on what problem is occurring, the method for troubleshooting will differ. To diagnose the exact cause, you will need to disassemble the engine.

The simplest situation is a damaged cylinder head gasket. If the gasket has cracks, burnouts or other defects, it will need to be replaced with a new one. The cylinder head gasket cannot be repaired.

Important: When working with cylinder head components, you must follow the engine manufacturer's recommendations as much as possible. This applies to both the selection of replacement components and the repair work itself. In particular, you need to take into account the recommendations on the strength and procedure for tightening the cylinder head with a torque wrench.

If it is not the gasket that is damaged, but the cylinder head itself, you need to determine the degree of its suitability for repair. In some cases, the cylinder head can be restored by grinding. But if there are serious cracks on it, or as a result of grinding it is necessary to remove a layer greater than the permissible one, the part will need to be replaced.

The case of a crack in the cylinder block itself is the most difficult. In such a situation, you can try to repair the defect by welding, or replace the block.

What to do

The method for eliminating an antifreeze leak depends on the cause of its occurrence. The simplest situation is a burnout or rupture of the gasket. It cannot be repaired, so the gasket should be replaced.

If a deformation of the cylinder head occurs, most often you cannot do without the help of a specialist, since performing this action incorrectly will lead to failure of the part. A deformed cylinder head will require grinding on a special machine. But if the defects are serious, it is necessary to remove more than the permissible layer. In this case, the part will have to be replaced.

The discovery of a large crack in the cylinder block requires its immediate replacement. Small cracks in cast iron or silumin blocks can be repaired by welding - electric or “cold”.

Replacing the BC gasket with your own hands

Replacing the cylinder block gasket is a simple manipulation, and any car owner can easily cope with this task on his own. The main condition for obtaining the desired result without additional breakdowns is to follow the car manufacturer’s recommendations regarding the strength and procedure for tightening the cylinder head with a torque wrench. The sequence of actions when replacing the gasket is as follows.

- The car is de-energized by removing the negative terminals of the battery. If necessary, drain the antifreeze and reduce the pressure in the supply.

- First, the attachments are disconnected from the cylinder block. If you have no experience working with parts, it is advisable to sketch or otherwise record the sequence of dismantling the elements. Craftsmen advise arming yourself with a marker and applying the appropriate marks to each dismantled part.

- The screws securing the cylinder head begin to unscrew from the center, making half a turn each time.

- Disconnect the cylinder head and remove the old gasket.

- Clean the cylinder head and wash it with gasoline.

- Install a new gasket. To ensure precise installation, there are special bushings on the center of the block. The hole for the oil passage should be between the 3rd and 4th cylinders.

- Screw all parts in reverse order.

- Return hanging elements to their place

IMPORTANT! The fastening bolts must be cleaned before unscrewing. This will prevent the key from falling off and protect the bolt splines from damage.

Repairing a cylinder crack

The most common way to seal a BC crack is welding. The work requires certain skills and abilities, since a violation of the technology will lead to divergence of the seam, and the problem will return. The welding sequence and technology is as follows:

- The ends of the crack on the block are drilled at an angle of 90 degrees. This procedure is necessary to prevent further expansion of the crack.

- The cylinder block is heated to 650 degrees. Then a cast-iron-copper filler wire is applied to the crack and a continuous weld is made using flux.

- The part is gradually cooled in a heating cabinet. Sudden cooling of the cylinder block after welding is unacceptable: this will lead to rupture of the seam and complete failure of the part.

The seam on the part can be made without heating, using electric welding and copper electrodes in a tin wrapper. In this case, the resulting seam requires additional reinforcement with epoxy resin. The surface is degreased with acetone or a special compound, then a layer of epoxy paste is applied to the seam with a spatula. After this, the BC is dried for 24 hours at room temperature. After drying, the seam is sanded.

Minor cracks can be repaired without welding by applying fiberglass and epoxy resin. The surface of the crack is degreased, then several layers of fiberglass are applied one by one, each coated with epoxy paste.

What is the danger of antifreeze getting into the cylinder block?

If coolant penetrates into the cylinder block, stop operating the engine immediately. This is due to the fact that antifreeze contains ethylene glycol, which, when it gets into the oil present in the cylinder block, leads to the formation of insoluble solid components. They can cause serious damage to engine components.

It is also worth noting that the emulsion formed as a result of the interaction of antifreeze with oil reduces the patency of the channels. That is, the overall performance properties of the motor deteriorate. The engine is not cooled and lubricated properly, which also leads to serious problems, including deformation of the cylinder block and complete failure of the engine.

Consequences of driving with a broken gasket

It is prohibited to operate a vehicle where antifreeze gets into the oil. What is the reason? The liquid itself, despite its toxicity, does not harm the engine. But the danger is posed by ethylene glycol, which is contained in the coolant. If it mixes with oil, the result is abrasive particles. Because of this, there is a risk of scoring.

What happens when antifreeze gets into the cylinder block? Then it interacts with the oil, and deposits are formed in the form of an emulsion. This leads to a decrease in the diameter of the channels. Lubricant and antifreeze are not able to circulate normally. As a result, the engine runs with insufficient oil pressure and overheats. The oil filter also becomes significantly dirty.

The oil itself, diluted with coolant, loses its lubricating and protective properties. This reduces the resource of the internal combustion engine and threatens high repair costs.

How does the problem manifest itself?

You can determine that coolant has entered the cylinder block based on several signs. The main ones are considered to be the following:

Typically, the smoke coming from the exhaust pipe when antifreeze leaks into the cylinder block may not have any odor at first. Only later can it acquire the distinct aroma of burnt antifreeze. In addition, if coolant enters the cylinder block, the color of the oil may darken. In this case, it is quite possible that a coating in the form of a white emulsion will form on the oil filler neck.

What conclusions can be drawn?

So, antifreeze ingress is a fairly common problem and relatively easy to diagnose. A leak can be indicated, firstly, by a constant decrease in the liquid level in the expansion tank, and secondly, by thick white smoke with a characteristic odor from the exhaust pipe. In addition, the color of the oil on the dipstick and on the filler cap changes. Well, if the spark plugs are also wet and smell of antifreeze, then this is a sure sign of antifreeze in the cylinders.

The difficulty and cost of solving the problem depends on the reason why the coolant got into the oil. In any case, you cannot delay diagnostics and repair, since even untimely replacement of an affordable gasket can lead to subsequent serious expenses for engine repairs.

Basic methods for repairing a cracked engine block. Crack detection, repair by welding, riveting or applying an epoxy layer.

What malfunctions are indicated by the emulsion on the oil dipstick and oil filler cap? Ways to independently determine the causes of this problem.

Why does the engine overheat? What should the driver expect and what damage may occur if the engine overheats. What to do if the internal combustion engine overheats.

Types of sealants for car engines: anaerobic, silicone, belt sealants. Operating principle, differences, scope of application. How to choose the best sealant.

What is the purpose of demining the power unit and why? The main advantages of this solution are installing additional mass yourself.

Purpose of the cylinder block in the design of the internal combustion engine. Varieties, materials and manufacturing methods. Advantages and disadvantages of blocks made of cast iron and aluminum.

Such a nuisance as antifreeze getting into the oil is a common occurrence. It can happen in a car of any brand and does not depend on the type of fuel used. The methods and reasons are different. The human factor and technical problems could have played a role here.

Reasons for antifreeze getting into the cylinder block

Various reasons can lead to coolant getting into the cylinder block. But the most common among them are considered to be the following:

- Burnout or complete rupture of the gasket;

- The presence of defects in the cylinder head;

- Formation of damage in the cylinder block.

Since the antifreeze in the engine moves in a closed circuit, there may be breaks at the junctions of parts. In order to prevent antifreeze leakage, special gaskets must be installed at the joints. So, when these gaskets burn out or tear, then the coolant begins to leak into the block itself. The same thing can happen if the block head does not fit tightly through the gasket to the block itself. Accordingly, antifreeze will flow through the cracks that form into the cylinder block.

Antifreeze leakage: why is it dangerous?

If there is an antifreeze leak, engine operation must be stopped immediately. This is due, first of all, to the fact that the coolant contains the substance ethylene glycol, which, when it gets into the automobile oil that is located in the cylinder block, contributes to the formation of insoluble solid components. and they can already lead to serious damage to the engine.

In addition, the emulsion that is formed by the interaction of oil and antifreeze significantly reduces the permeability of the channels. As a result, the overall performance of the power unit is significantly reduced. In this case, the engine is poorly lubricated and practically not cooled, which means serious problems arise, including deformations on the cylinder block or its complete failure.

This video will tell you what to do if coolant is leaking into the cylinder block:

Causes of antifreeze in oil

There are a number of typical faults that cause a mixture of engine oil and coolant in the internal combustion engine. Among them:

- Burnout of the cylinder head gasket . According to statistics, this reason is, firstly, the most common, and secondly, the easiest to eliminate. Burnout of the gasket can be caused by various factors, in particular: overheating of the engine, which causes the head to “drive”, incorrectly selected tightening torque of the fixing bolts, natural aging of the material from which the gasket is made. The described breakdown can be repaired by the car owner himself if he has the appropriate tools. As for financial costs, you will only have to spend money on a new gasket.

- Violation of cylinder head geometry . Another popular name is “moved its head.” Most often, this malfunction occurs as a result of significant overheating of the engine, and is more typical for engines that are small in both power and size (for example, city runabouts).

- Failure of the heat exchanger (oil cooler) and/or its gasket.

- Damage to the cylinder block . Occasionally (usually as a result of damage or defects) there are microcracks on the block liners, which leads to mixing of oil and antifreeze. Here we can also note such a phenomenon as corrosion of cylinder liners.

- Incorrect connection of the cooling system line to the throttle valve. This is a fairly rare reason, but it occasionally occurs on used cars, whose previous owners or craftsmen incorrectly connected the mentioned cooling system pipes. In this case, the antifreeze goes directly into the engine oil, and from there into the exhaust system (manifold and beyond).

For clarity, the reasons listed above and brief information on methods for eliminating them are summarized in a table.

| Cause | Troubleshooting methods |

| Cylinder head gasket burnout | Replacing the broken gasket with a new one. It is important to observe both the tightening torque value and the sequence of tightening the bolts. |

| Violation of cylinder head geometry | Crimping, milling, grinding of the head. Performed in specialized workshops. Checking its tightness. |

| Failure of the heat exchanger and/or its gasket | Replacing the gasket, repairing or replacing the heat exchanger. |

| Damage to the cylinder block | Repairing the unit in a car service center or replacing it with a new one. |

| Corrosion of sleeves | Boring or replacing sleeves with new ones. |

| Incorrect cooling system connection | Revision of the connection diagram. The problem is often relevant for cars purchased secondhand. |

It is interesting that many novice car enthusiasts confuse slightly frozen oil during frosts and the antifreeze emulsion itself. It is important to understand that when the machine is idle for a long time in the winter with significant frosts, the oil thickens and may take on a yellowish tint. Therefore, it is necessary to perform additional diagnostics with a warm engine in order to find out what the car owner is dealing with - frozen oil or emulsion.