The turbine on the VAZ 2107 is considered exotic among car enthusiasts. And the power advantages of turbo engines over their factory counterparts are driving the proliferation of passenger cars equipped with turbines. And not only among foreign cars...

In theory, their main goal is to achieve maximum horsepower. For fans of fast driving, this is the main argument for sure. Given the same displacement, a turbocharged engine is characterized by almost double power with standard fuel consumption. In modern conditions, small-displacement turbo engines are very relevant.

Turbocharging VAZ 2107

The conventional division of the turbine provides for 2 groups:

- With low pressure up to approximately 0.2-0.4 bar.

- With high pressure up to 1 bar and above.

Installing a high-pressure turbine requires significant modifications to the engine, and when installing a low-pressure unit, almost all factory elements of the system can be preserved.

Preparatory work

The installation operation requires certain preparatory measures.

It is worth thinking through every minor detail in advance. Technically, the installation is simple, but beginners may have some difficulties. The first step is to select a turbocharger. It must be suitable for a specific engine. The scheme of work performed depends on the type of supercharger, the size of the turbine, as well as its characteristics. It is necessary to find a compromise unit where the combination of power and heat dissipation is as optimal as possible. If a catalyst is installed, you should check whether it works or not. Excess exhaust gases will interfere with the operation of the turbocharger. The air filter is also checked. It must be airtight and solid. And it’s best to install a zero switch, say the reviews of the owners. The next step is to flush the crankcase ventilation system.

Setting up the turbine operation

A simple electric turbine on a VAZ can increase power, but only slightly. The use of mechanical turbochargers will be much more effective. The turbo engine is tuned using a wastegate. The pressure in the fuel system will be greater, the less it is released into the atmosphere. It is advisable to use special designs of boost controllers to adjust the pressure level.

View gallery

Using this simple device, you can set the required pressure directly from inside the car. With its help, the safety valve installed on the manifold does not relieve pressure. Therefore it is gradually growing.

It is imperative to “reflash” the electronic control unit, since the operating modes of the engine will change significantly. It is advisable to entrust this work to experienced specialists, otherwise improper operation of the engine will affect not only the power, but also the consumption of gasoline and oil. In addition, all engine components can wear out hundreds of times faster than with normal settings.

Installation of a turbine on a VAZ

How is a diesel engine turbine lubricated

? Typically, turbines are installed only on injection engines, but with some effort it is possible to install a turbocharger on a carburetor

.

Of course, the carburetor

does not meet all the fuel supply requirements for the turbine. There are two reasons for this: insufficient air flow for the interaction of the carburetor and turbine and the incompatibility of the operation of the turbocharger with the intercooler.

Turbine on a car

There are two options for installing a turbocharger on a carburetor.

- Place the air flow system in front of the turbocharger and pass the air-fuel mixture through the entire circuit.

- Install an air forcing system by placing the carburetor

after the supercharger.

Both options for installing a turbine on a carburetor

have their pros and cons. Moreover, when installing a system that pushes air, you need to take into account that the engine will only be effective in warm weather.

Unlike conventional mechanical tuning of parts, turbocharging on the VAZ 2106 changes the power unit quite radically. Please note that any intervention in the design and operation of the engine can shorten its service life. The turbine on a VAZ is installed complete with additional parts, without which its operation will simply be of poor quality. So, together with the turbine it is recommended to install a cooler that will cool the air.

Installing a turbine is quite a serious and difficult task; it is better to entrust it to professionals or at least follow the advice of specialists. Some parts may not fit and require adjustment, even if the manufacturer promises full compliance. For example, it is often necessary to adjust the air duct. Upon completion of the installation of the turbine on the VAZ 2106, it is necessary to configure the engine to operate in new conditions.

How is oil supplied to the turbine?

A complete turbocharging system cannot function without oil. So the driver who decides to install a turbine will have to solve this problem. When the turbine is installed, a special adapter is screwed to it (such adapters usually come complete with turbines). A heat dissipation shield is then installed on the intake manifold. Oil is supplied to the turbine through an adapter onto which a silicone tube is first placed. In addition, the turbine must be equipped with a cooler and an air tube through which air will flow into the manifold. Only in this way can an acceptable temperature of the oil supplied to the turbine be achieved. It should also be said here that sets of tubes and clamps for supplying oil to turbocharging systems can be found in spare parts stores.

This set costs from 1200 rubles. Despite the clearly inflated price, such a purchase will save the car owner a lot of time, since he will not have to bother with cutting and adjusting silicone tubes.

About the pipes

Pipes are needed not only for supplying oil. Exhaust gases from the turbine also need to be removed. To remove excess gas not used by the turbine, a massive silicone pipe on steel clamps is used. In some cases, a whole system of silicone pipes is used to remove the exhaust (their number is determined by the design of the turbine). Usually there are two of them, in some cases - four. Before installation, the pipes are carefully inspected for internal contamination. Any, even the smallest, speck that gets into the turbine can cause a breakdown. It is for this reason that each pipe is thoroughly wiped from the inside with a cloth soaked in kerosene.

When choosing clamps for pipes, you should remember: silicone is not a very durable material. And if, when installing the pipe, you tighten the steel clamp too much, it can simply cut the pipe. For this reason, experienced motorists recommend not using steel clamps at all, but instead using clamps made of special high-temperature plastic. It provides reliable fastening and does not cut the silicone.

Advantages and disadvantages

Electric turbine: characteristics, operating principle, pros and cons of operation, do-it-yourself installation tips and owner reviews

The turbine drive of the electric motor eliminates the main disadvantages of mechanical turbochargers.

- There is no lag, since the electric motor can provide a very high speed of rotation of the rotor.

- There is no turbo lag caused by a lack of exhaust gases, since in this case the lack of energy is compensated by the electric motor.

- The electric motor allows you to maintain boost during transient processes like anti-lag without the negative effects of the latter.

- This ensures a wide operating range and uniform torque.

- Some types of these mechanisms are capable of generating electricity, reducing the load on the generator and reducing fuel consumption.

- It is possible to recover lost energy, as Ferrari did in its Formula 1 engine.

- Electric turbines operate in more gentle conditions and at lower speeds (100 thousand instead of 200-300 thousand).

However, this technology has a number of disadvantages.

- Great complexity of the design, including an electric motor and controllers.

- This results in a high cost.

- In addition, the complexity of the design affects reliability.

- Due to the large number of structural elements (in addition to the turbine, this includes an electric motor, controllers, and battery), such turbochargers are much larger and heavier than conventional ones.

In addition, each type of electric turbine is characterized by specific features.

| Type | E.C. | EAT | EST | TEDC upstream | TEDC downstream |

| Advantages |

|

|

|

|

|

| Flaws |

|

|

|

|

|

In terms of durability, according to IHI, electric turbines will be equivalent to mechanical ones due to operation under the same conditions in a more gentle mode with greater design complexity.

Compressor kit TuningSport 0.5 bar VAZ 2101-2107, Niva without power steering /injector/

- We guarantee fast processing of your order during business hours (we work from 11-00 to 20-00, Saturday and Sunday are days off).

- We guarantee reliable packaging of your order (when sending it by Russian Post or transport company).

- We guarantee the fastest possible dispatch of your paid order (within 2-4 business days after receipt of payment).

- We guarantee a refund or exchange for another product (with recalculation) within 14 days from the date of receipt of the order (the product must be in good condition, without traces of installation, delivery costs are not reimbursed).

- We guarantee a free exchange of goods (transportation costs at our expense) if the purchased goods turn out to be defective.

Payment Methods

Delivery options

Pickup options

Turbocharging for a VAZ, who cares

Why does the turbine drive oil into the intercooler?

Turbocharging on a VAZ is certainly exotic. But the power advantages of turbo engines over “aspirated” ones themselves encourage the emergence of more and more cars that received a turbine. And not all of these cars are foreign cars...

Theory

Let's start with the theory. There is simply supercharging (mechanical supercharging, charger) and there is turbocharging. In both cases, the boost is created by a turbine installed between the air filter and the intake manifold. The difference is what exactly drives it.

In the first case, the engine itself turns the turbine. One of the advantages is the direct dependence of the turbine speed (the pressure created by the turbine) on the speed, i.e. no delayed reaction (turbo lag). The downside is that the engine spends part of its power spinning up the turbine.

Turbocharging is more complicated because consists of 2 turbines. One pumps more air into the engine and is driven by another turbine, which is installed immediately behind the “spider” (exhaust manifold). Thus, the chain looks like this: exhaust gases rotate one turbine, which is connected to a second turbine that forces air into the engine. The advantage of turbocharging is that it has greater efficiency because does not require engine power to rotate it. Minus turbo in the presence of the “turbo lag” effect. What does it look like? You sharply press the gas to the floor and wait for an instant response from the engine. And in order for a turbo engine to produce maximum power, it is necessary to sufficiently spin up the turbine, which “comes to life” only when the engine reaches 3000-3500 rpm.

Turbines can be conditionally divided into 2 groups: low pressure (up to approximately 0.2-0.6 bar) and high pressure (up to 1 bar and above). If a high-pressure turbine requires a fairly serious modification of the engine, then for a low-pressure turbine you can leave almost everything factory, but more on that later.

In fact, the main goal is to get the maximum possible number of horses. Well, at least for those who like to drive so precisely J With the same displacement, a turbocharged engine can have almost 2 times more power with approximately the same fuel consumption. So, small-displacement turbo engines have recently come into fashion. Fiat has been building small city hatchbacks with turbo engines and the dynamics of a sedan with a 3-3.5 liter engine for quite some time. A simple example of this is the Fiat Grande Punto with a 1.4 turbo engine with a power of 120 to 150 horses, and in some modifications up to 180. However, similar engines appeared in VW.

How can you boost a turbocharged engine?

The specificity of these engines is such that if some improvements give practically nothing on naturally aspirated engines, then on turbo the results obtained are simply amazing. A simple example is forward flow. Many people have the opinion that with it the engine “breathes” and spins easier, our forum is proof of this. But these are only subjective opinions. If in the case of a naturally aspirated engine the power is given more by the sound than the forward flow itself, then with a turbo, with the correct intake and exhaust you can achieve very good results.

The picture is the same with such a popular modification as chip tuning. If this procedure gives an aspirated engine no more than 10% of power, then a turbo will easily give up to 25%

Installation of turbocharging on a VAZ

Let's consider a more budget-friendly option, in terms of modifications, with a low-pressure turbine and a VAZ 21083 engine with distributed injection.

The cylinder block, crankshaft and connecting rods can be used as standard. Camshaft and valves too. The difference may be in the pistons and cylinder heads because... installing a turbine requires reducing the compression ratio. And this can be achieved either by enlarging the combustion chamber, or by using special pistons. Although you can leave the original pistons and limit yourself to just the head.

The exhaust is also different - there is now a turbine between the exhaust manifold and the exhaust pipe. The resonator and muffler can be used as standard ones, although a direct-flow exhaust can be installed to obtain more power.

The injection needs a larger receiver and a non-standard control program. The lubrication system will also require minor changes.

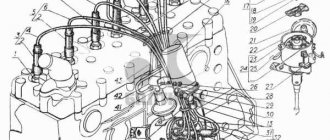

Low pressure turbine - at your discretion and capabilities. In the case of a VAZ, the turbocharger is mounted above the right wheel drive between the exhaust manifold and the exhaust pipe. The compressor is supplied with 2 air pipes. The first is connected to the air filter, and the second to the receiver.

Thus, the most expensive and scarce part is the turbine itself.

Remember also that in addition to the engine, you will also need to modify the brake system and, quite possibly, the transmission.

Where to begin?

Not every car is suitable for tuning. It is important to pay attention to the condition of the car. It is better to disassemble the car to the ground. The main problem is corrosion. You need to understand that the metal on AvtoVAZ cars is quite thin, and high loads are contraindicated for it. If you apply a serious load, the rusty metal will literally tear.

You should start by replacing the metal in the engine compartment with a more powerful one. When all body faults have been repaired, you can continue tuning further. If the car was purchased specifically for tuning, then the first thing you need to do is get it moving in stock condition. Next, they change the electrical wiring, bring the engine into good condition, or change it to a sixteen-valve one. The brake system and transmission are also inspected.

This is the first point from which the instructions for turbocharging begin. When the iron has returned to an ideal, close to factory condition, you can continue further. Moreover, we already know enough about turbocharging equipment.

Features of turbocharging

The most important thing to understand is that although turbocharged engines are similar to naturally aspirated internal combustion engines, they are built on the basis of completely different principles. This is due to the specific features of combustion of a mixture of fuel and air under conditions of excess pressure and loads. The more air, the more fuel needed. Accordingly, the car's dynamics will be more acceptable.

In practice, on the one hand, the planned increase in capacity is 20-30 percent, while the volume of work and the injection of funds are significant. Therefore, it turns out that it is best to raise the result to an average level so that the costs pay for themselves and meet the desired requirements.

Gas turbine

Among the features of the turbine, one can highlight its rotation speed. It can reach 200 thousand rpm, and the pressure can reach up to 2 bar. This turbine can increase engine power by up to 50 percent. Turbine bearings rotate at enormous speeds and require lubrication. The system is connected to the lubrication system of the internal combustion engine. The turbine needs a certain time to gain the required speed. Therefore, it will start working only after three thousand revolutions. If you try to press the accelerator pedal sharply at low crankshaft speeds, the exhaust gas pressure will be too low for the unit to operate. You can feel the failures. This phenomenon is called nothing less than “turbo lag”.

How to Install a Turbine on a VAZ 2107 Carburetor

Turbine for VAZ 2107

According to tuning specialists, the turbine on the VAZ 2107 is not a business that appreciates, from the category of those about which they say “the production work is not needed.”

The idea of a turbine in itself is not bad, and with its implementation you can significantly increase engine power (for example, a 2-liter engine up to 700 hp) and torque on almost any model. It is only on VAZ vehicles that this is problematic.

The features of a classic carburetor engine are such that installing a turbine is quite difficult, troublesome and expensive. When installing a turbine on VAZ models, it is necessary to have an intercooler (to cool the air heated by the turbine), which still does not give the expected effect. Then. The turbine on the VAZ 2107, like other classics, is unsafe for installation, unlike the compressor. There is a great danger that the exhaust manifold cannot withstand the high pressure created by the turbine. What does this mean? no need to explain. Having decided to install a turbine on your forward-thinking (or overlooked) VAZ 2107, sooner or later, you will have to change (or change) the engine to an injector.

All this will take hundreds of hours and tens of thousands of money. The question is in the name of what? It's clear that you are a greedy tuner and decided to get something like this:

(1.7 liter engine from Niva, turbine, 5-speed manual transmission, front brake discs with perforation, rear discs, rims.R15, Goodyear Tire F1 tires 195x50, body kit, rear lighting neon lining, JOM leather sports seats, salon equipment)

https://youtube.com/watch?v=5yyMEMSvleI

VAZ 2107 turbo carburetor!!!!

VAZ 2107 volume 1.6 l carburetor. turbine from skyline!! completely fucked up.

DESIGN REVIEW VAZ 2101 1.6 turbo carburetor 2014 / turbo carburetor review

Hi all! In this video I will talk about the design of the turbo engine in our design. Enjoy watching.

And if you want, like any driver, to improve engine performance even at traffic lights, and not accelerate by 20 seconds and at least 8-10, take an interest in the “Kit-kit” (0.5 bar compressor, increases power to 45-50%). Drive pump installation kits have been developed for all domestically produced models. They are characterized by their small size, low noise level in operation and high reliability.

Structurally, the supercharger consists of two parts: a centrifugal compressor and a high-speed multiplier.

Drive is via a poly-V belt from the engine crankshaft pulley. The compressor is not serviced during operation

When installing on foreign cars, you can orient the direction of the cochlea head relative to the position of the air duct.

The outer diameter at the compressor inlet is 74 mm, at the outlet. 62 mm with a coil diameter of 195 mm. The high-speed multiplier is assembled on rolling bearings of a special high-speed series. Replacement is carried out every fifty thousand kilometers of the car. Torque is transmitted by a PJ series polypropylene belt. Replace every fifty thousand.

The supercharger is almost silent during operation. Oil and coolant are not supplied. When installing a supercharger, there is no need to make any changes to the engine design, with the exception of pressure parameters above 0.5 bar.

Pay attention to how to determine the wear of the cross on a VAZ 2106 and VAZ 2107

labavto.com

Every vehicle owner sooner or later thinks about tuning his “iron horse”. Who doesn’t want their car to be the fastest and most maneuverable? In principle, speed is what we will talk about in this article. We invite you to find out what the compressor on the VAZ 2107 carburetor is, what parts it consists of and what functions it performs.

Installation of a turbine on a VAZ 2107

Installing a turbine allows you to double the power of the VAZ 2107 engine without increasing fuel consumption.

Reasons for installing a turbine on a VAZ 2107

Installing a turbine on a VAZ 2107 will allow:

- reduce vehicle acceleration time;

- reduce fuel consumption of injection engines;

- increase engine power.

Turbine operating principle

To increase engine power, you need to make the supply of the fuel-air mixture to the combustion chambers more intense. The turbine crashes into the exhaust system, is driven by a stream of exhaust gases and, using the energy of these gases, increases the pressure in the power unit. As a result, the rate of mixture entering the cylinders increases.

Under normal conditions, the VAZ 2107 engine has a gasoline combustion rate of about 25%. After installing a turbocharger, this figure increases noticeably and the engine efficiency increases.

Choosing a turbine for VAZ 2107

There are two types of turbines:

- low-performance (boost pressure 0.2–0.4 bar);

- high-performance (boost pressure 1 bar and above).

Installing a second type turbine will require a major engine upgrade. Installation of a low-performance device will ensure compliance with all parameters regulated by the automaker.

Before turbocharging the VAZ 2107 engine you will need:

- Intercooler installation. When using a turbine, the air heats up to 700 o C. Without additional cooling, not only can the compressor burn out, but the engine itself can be damaged.

- Conversion of a carburetor fuel supply system to an injection system. A weak intake manifold on carburetor engines will not withstand the pressure of the turbine and may rupture. On units with a carburetor, you can install a compressor instead of full turbocharging.

In general, the advantages of the VAZ 2107 turbocharged engine are very doubtful. Therefore, before installing a turbine on a discontinued car with modest technical characteristics, you should carefully evaluate the feasibility of the decision being made. It is much easier to install a compressor on a VAZ 2107. In this case:

- there will be no excess pressure in the system that could destroy the manifold, car suspension, etc.;

- no need to install an intercooler;

- no need to convert the carburetor system to an injection system;

- the cost of re-equipment will be reduced - the complete compressor costs about 35 thousand rubles, which is much lower than the cost of the turbine;

- Engine power will increase by 50%.

I had to watch with my own eyes how a VAZ 2107 with a turbocharged engine rushes. It is difficult to overtake it on the highway, but the car cannot maintain speed for a long time, in my opinion, although I have not driven it myself.

About the choice of turbocharging systems

Currently, car enthusiasts do not need to design turbines themselves, since a wide range of ready-made systems are available on the aftermarket. But with such abundance, the question will inevitably arise: which system to choose? To answer this question, the driver must decide how much he is going to modify the engine, i.e. how deep the modernization will be. Having decided on the degree of intervention in the engine, you can move on to turbines, which come in two types:

- reduced power turbines. These devices rarely generate pressure above 0.6 bar. Most often it varies from 0.3 to 0.5 bar. Installing a low-power turbine does not involve serious intervention in the engine design. But they also provide an insignificant increase in productivity - 15–18%.

- powerful turbocharging systems. Such a system is capable of creating a pressure of 1.2 bar or more. To install it in the engine, the driver will have to seriously upgrade the engine. In this case, the engine parameters may change, and not necessarily for the better (this especially applies to the CO level in the exhaust gas). However, engine power can increase by a third.

What is meant by modernization

Before it comes to installing the turbine, the driver will have to carry out a number of preparatory procedures:

- cooler installation. This is a device for cooling air. Since the turbocharging system runs on hot exhaust gas, it gradually heats up. Its temperature can reach 800°C. If the turbine is not cooled in a timely manner, it will simply burn out. In addition, the engine may also be damaged. So you can’t do without an additional cooling system;

- The carburetor “six” will have to be converted into an injection engine. The intake manifolds of the old carburetor “sixes” were never particularly durable. After installing the turbine, the pressure in such a manifold increases approximately five times, after which it ruptures.

All of the above points indicate that installing a turbine on an old carburetor six is, to put it mildly, a questionable decision. It would be much more advisable for the owner of such a car to install a turbocharger on it.

This solution has several advantages:

- the driver will no longer worry about the problem of high pressure in the intake manifold;

- there is no need to install additional cooling systems;

- there will be no need to redo the fuel supply system;

- installing a compressor costs half as much as installing a full-fledged turbine;

- Motor power will increase by 30%.

Turbo kit for VAZ 16v up to 250 hp

A set of parts for installing turbocharging on VAZ 2110 - 2112 cars. Designed for cars with a 16 valve engine. The installation allows you to increase the car's power to 250 horsepower. The declared power is achieved by installing a TD05H-16g turbocharger. Boost pressure 1 bar. The kit consists of the following parts:

| Turbocharger Mitsubishi TD05H – 16G style | 1 | PC. |

| Turbo manifold 16 cl. Subaru flange, budget | 1 | PC. |

| Hairpin M10 | 3 | PC. |

| Bolt M10 x 30 x 1.25 | 2 | PC. |

| Nut M10x1.25 | 8 | PC. |

| Downpipe VAZ, TD04L, budget | 1 | PC. |

| Banjo bolt M10×1.5 | 1 | kit |

| Oil supply hose Clubturbo (length 50 cm) 10-14 mm | 1 | PC. |

| Oil intake bolt from the VAZ cylinder head for supply to the turbocharger | 1 | PC. |

| Copper washer 10 mm | 2 | PC. |

| Copper washer 14 mm | 6 | PC. |

| Banjo bolt M14×1.5 | 2 | kit |

| Antifreeze supply hose Clubturbo 14 mm | 2 | PC. |

| Universal turbine oil drain kit | 1 | PC. |

| Piping VAZ 2110 - 2112, kit with silicone | 1 | PC. |

| Silicone pipe, 28 mm | 1 | PC. |

| Clamp 25/40 | 2 | PC. |

| Blow off Forge | 1 | PC. |

| Front intercooler (700x180x65), inlet 51 mm | 1 | PC. |

| Receiver Clubturbo Trapezium 16v | 1 | PC. |

| Air temperature sensor | 1 | PC. |

| DBP Motorola 6250 (1.5 bar) | 1 | PC. |

| Wiring harness for the transition of mass air flow sensor - DBP + DTV | 1 | PC. |

| Fuel injectors Bosch 430 cc (Set of 4 pieces) | 1 | kit |

| Submersible fuel pump 255 l/h CreditParts GSS342, silver | 1 | PC. |

| Turbo pistons VAZ 2112 F 82.0 mm (set of 4 pieces) | 1 | kit |

| Piston rings 82.0 mm VAZ (1.5/2.0/3.947), set for 4 cylinders | 1 | kit |

| Gasket set for VAZ 2112 engine | 1 | PC. |

| Cylinder head gasket VAZ 2112 | 1 | PC. |

| Oil pan gasket VAZ 2108 | 1 | PC. |

| Hairpin M6*22 | 2 | PC. |

| M6 nut with skirt | 2 | PC. |

| Silicone vacuum hose, 4mm (blue) | 2 | m |

PRICE 67,500 RUR

Turbocharger for KamAZ: types, manufacturers, prices

Currently, on various modifications of KamAZ you can find engines of four environmental classes - from Euro 0 (only on older models) to Euro 3.

Euro 0 class consists of two engines:

– KamAZ 740.10; – KamAZ 7403.

On sale you can find turbochargers only for various modifications of the KamAZ 7403 engine - these are the well-proven TKR7N-1. But the Euro 0 class is gradually being replaced, so the time is very close when such turbochargers simply will not exist.

Euro 1 class includes two popular engines:

– KamAZ 740.11; – KamAZ 740.13.

A large number of turbochargers are available for these engines, including various modifications of TKR7 and K27, as well as foreign units from CZ Strakonice (Czech Republic) and Schwitzer (Germany).

Euro 2 class is one of the most common; four engines correspond to this class:

– KamAZ 740.31-240; – KamAZ 740.30-260; – KamAZ 740.50-360; – KamAZ 740.51-320.

These engines are equipped with the turbochargers already mentioned above in Euro 2 modifications.

The Euro 3 class is by far the highest class of KamAZ engines and includes five units:

– KamAZ 740.60-360; – KamAZ 740.61-320; – KamAZ 740.62-280; – KamAZ 740.63-400; – KamAZ 740.37-400.

There are not too many Euro 3 class turbochargers yet; they are represented by the K27-TI and Schwitzer S2B models.

Also, a number of KamAZ models are now equipped with engines from the American company Cummins - they have their own models of turbochargers, which differ in design and characteristics from the turbochargers of KamAZ engines.

If we talk about manufacturers of turbochargers for KamAZ engines, then today there are not too many of them.

OJSC "KAMAZ"

for KamAZ engines TKR7 turbochargers of various modifications (from Euro 0 to Euro 2). These units are available at an affordable price.

NPO "Turbotechnika"

Domestic enterprise (city of Protvino, Moscow region), specializing in the production of turbochargers. Manufactures the most popular TKR-7 units of various modifications.

"TURBO ENGINEERING"

The domestic manufacturer of turbochargers offers popular K-27TI units of modifications from Euro 1 to Euro 3.

OJSC "Borisov Plant of Aggregates" (BZA).

A Belarusian enterprise that, among other things, offers turbochargers similar to TKR7.

CZ Strakonice.

A Czech plant from the city of Strakonice, offering popular turbochargers in our country - analogues of K-27 units. Despite their high quality, they are somewhat more expensive than domestic turbochargers.

Borg Warner Turbosystems.

A German concern offering high-quality turbochargers under the Schwitzer brand.

It should be noted that all turbochargers for KamAZ engines are paired. That is, each unit is presented in one of two modifications - right or left. This must be taken into account when purchasing, since installing a turbocharger on a “foreign” series is simply impossible.

Pros of installing a turbocharger

If you purchased a turbine for a carburetor engine of proper quality and no violations were made during the installation process, you can expect an improvement in the following engine performance indicators:

- Acceleration improves, dynamic characteristics increase

- Increased traction

- Reduced fuel consumption (due to faster acceleration)

- Overcoming climbs and obstacles will become more comfortable

- An increase in air density in the cylinders leads to complete combustion of gasoline, making exhaust gases less hazardous to the environment

As an example of changes in engine power characteristics, you can use the data obtained after testing a 1.5-liter carburetor engine of a VAZ 2183 car.

| Standard indicators | Turbocharged | |

| Power, kW/hp at rpm | 51.5/70 at 5600 | 78/106 at 5600 |

| Maximum torque, N.m at rpm | 107 at 3500 | 144 at 4000 |

| Maximum speed, km/h | 155 | 190 |

| Acceleration from standstill to 100 km/h, s | 13,8 | 10,6 |

| Fuel consumption, l/100 km | 5,5 | 7,7 |

Final result

During the research, the turbine installed on the VAZ 2107 engine injector showed the following results: provided that the clutch and tires are of high quality, the acceleration time to 100 km/h is reduced by 5 seconds (compared to the base engine). The same principle applies to elasticity: acceleration time in 4th gear from 60 to 100 km/h is also reduced by 5 seconds.

Practical implementation

The idea itself is simple. However, it is difficult to implement it on the VAZ 2107. Representatives of companies that will undertake the production of turbochargers are counted on the fingers of one hand. But turbine kits for installation on a conventional injector began to appear on the market. The kit includes all the pipes, a new block cover, the turbine itself and the intercooler.

The difficulties of installation and further adaptation to the injector are as follows:

- The exhaust gas temperature level that the turbine must withstand is theoretically between 900˚C and 950˚C.

- The working speed of the rotor injector with the impeller is numerically represented not only in tens, but in hundreds of thousands of revolutions per minute.

- The functional resources of the volume of engine compartments of passenger cars are limited, and therefore require the manufacturer to place the unit within a specific framework.

Based on the above, a turbocharger must have high heat resistance, be compact, well-balanced, and at the same time inexpensive.

Which turbine to choose

The most common equipment for installation on the VAZ 2106 is a turbo kit. It is designed specifically for 16-valve engines of VAZ cars. Turbines are sold along with everything necessary. Installation of the kit does not require modifications to the engine. Power increases to 130-140 horsepower. Moreover, this complex can be subjected to tuning in the future.

Some car enthusiasts prefer turbines and Mitsubishi. Productive and reliable compressors GT25R, GT28R, GT28RS are chosen from the Garrett series. They allow you to develop power up to 250 horsepower.

The VAZ 2106 turbo is designed for high-speed driving on city roads and is not at all similar to the usual Soviet “six”. Do not forget that any car equipped with additional equipment requires attention and care, monitoring the operation of systems and periodic technical inspection.

The pleasure of installing a turbine on a VAZ 2106 will cost half the price of the car itself. It is worth thinking several times whether this device and all additional equipment are really necessary when operating the machine. Usually a turbine

installed by avid fans of street racing in VAZs.

We recommend watching:

- The principle of operation of a turbo engine

- Air blower for cars

- How to properly operate a diesel engine with a turbine

- Installing a turbo on a VAZ

- The principle of operation of an automobile turbine

- Means for decarbonizing internal combustion engines

Is the installation justified?

Tuning a VAZ 2107 carburetor in the form of installing a turbine requires a balanced decision. Do not forget that the VAZ 2107 is an outdated passenger car in all respects. For an adequate owner, modification of the engine with a gas turbine supercharger is purely theoretical. In practice, this is a series of problems unworthy of attention.

The seventh model of Zhiguli does not itself provide for the use of a turbine as such. The manufacturer did not provide for the possibility of introducing such a unit at the design stage. For stubborn amateurs who have installed a turbine on an injection-type engine, there is no problem with the injector itself.

From a technical point of view, such an installation on the VAZ 2107 is acceptable. However, it is impossible to escape without consequences:

- A passenger car is not designed to withstand the loads that a suddenly stronger engine will impose on it.

- In addition to the suspension, other components may be damaged.

- The exhaust manifold, for example, may simply not withstand the gas pressure that the turbine will supply to it.

Installing a turbine on a VAZ requires a special base. Amateur replacement carries certain risks. For example, the exhaust manifold may not withstand the high pressure created by the turbine. People are adults - the consequences are clear to everyone. Such engine modernization can be done by professional service center workers.

Turbocharging on diesel engines

Manufacturers of diesel engines immediately adopted turbocharging for good reason. The operating characteristics of a diesel engine are ideal for a turbocharger. Diesel has a high compression ratio and, as a result, a low combustion temperature. Relatively low. Therefore, its exhaust gases are much colder than those of a gasoline engine.

The first to use a turbine on a diesel engine was in the production car MV 300 SD, followed by Volkswagen Turbodiesel. The Volkswagen turbodiesel revolutionized the engine industry because it raised the power of a diesel engine to the level of a gasoline engine, and fuel consumption was reduced by several percent.

Therefore, if you plan to install turbocharging yourself, it would be more logical to use a diesel engine for this, rather than a gasoline one. Efficiency will be higher, fuel consumption will be lower and the service life will not suffer as much as when installing supercharging on a gasoline engine due to the difference in temperature conditions. Select the boost correctly, do not exceed the permissible pressure, and good luck to everyone!

Having become the owner of a car, every driver strives to improve it in some way, hence the desire to make a turbocharger with his own hands. Someone makes adjustments to the external exterior of the car, someone updates the interior, and someone makes more serious tuning, adding power to the engine.

One of the costly but effective methods of modernization includes equipping a car with turbocharging. It significantly increases engine power, which is why many take this step. Owners of old domestic cars especially often resort to such conversions.

Installation

It must be remembered that equipping an engine with a turbocharging system is a rather lengthy process. Although kit manufacturers say that you can do without upgrading the engine, this is not entirely true. Where to begin? Of course, with the purchase of the necessary spare parts and preparation of the engine. It is necessary to replace the pistons, rings, cylinder head gasket, fuel regulator, throttle, as well as pipes and other parts. All these mechanisms must be as reliable as possible.

You also need to remember that building a powerful car can vary significantly depending on the turbine model. The instructions will be quite average. For example, in order to build a turbo VAZ-2106, you first need to replace the engine.

It is necessary to install a 16-valve injection unit. The first step is to prepare the engine. The engine is disassembled, the cylinders, crankshaft, connecting rods, and oil pump are checked. If necessary, grind the block. Pistons should be purchased after the cylinders have been prepared.

Next, the attachments are assembled. At this stage, the injectors are installed and the fuel pump is changed. Then a receiver and exhaust manifold are installed and a turbine is used. All steel elements are also installed. And finally, the last stage is setup. The maximum power, torque and other characteristics of the motor will depend on how professionally and correctly the adjustment is performed. If all the operations for preparing and assembling the system can be done with your own hands, then for setup it is better to turn to professionals (especially if the VAZ is a turbo on gas). By the way, there is now a lot of controversy about whether it is possible to install an LPG on a “turbo”. Experts say that the octane number of such a mixture is more than 102. Therefore, gas will not harm the operation of such a power unit.

What does turbocharging do for a car?

Since the VAZ 2106 car is not equipped with an industrial turbo system, like many modern foreign cars, all work to increase the car’s power will have to be done independently in a garage or by hiring a specialist. But it should be taken into account that installing a turbine is quite a difficult task, and if you have no experience, you should seek help from experts.

The mechanism of operation of turbocharging is to pump treated and compressed air into the combustion chamber, which leads to mixing gasoline with air and increasing the power of the power unit. The turbine is usually located between the exhaust pipe and the intake manifold. The processed and released gases coming out of the combustion chambers rotate a special turbine

connected to the compressor. The last unit forces air into the cylinders. The quality of turbine operation directly depends on the amount of used gasoline.

Turbo kit for the "six"

Turbine installation

on the VAZ 2106 has its advantages:

- the turbocharger is fairly lightweight;

- the turbine can be adjusted for any car engine, for any carburetor

; - turbo can be installed on a motor that has undergone tuning;

- installation of the unit does not interfere with further modernization of the car;

- The turbine is suitable for an engine of any size.

There are 2 types of turbines. A low-pressure unit is a cheaper option, and its installation does not require major changes to the design of the car, which saves money. A high-pressure turbine involves tuning the main components of the machine and is expensive. To install this unit, you will have to redo the exhaust system, injection system and perform engine chip tuning. The car becomes sporty, sharp, agile and dynamic.

Review of the compressor for the carburetor "seven"

Below we will review the compressor for the VAZ 2107 with a carburetor. Let’s take the PK-05d compressor as an example, since this device is the most popular among owners of “Sevens”. The excess air pressure indicator is 0.5 bar at an engine speed of 6,200. It is immediately worth noting that the installation of this device does not imply serious intervention in the engine structure. Namely, the owner of a VAZ 2107 with a carburetor will not need to redo the piston group.

VAZ 2107 car

You can install a compressor for a VAZ 2107 carburetor on your own, without the help of specialists. Of course, if you have an idea of how it should be done. As for the advantages, recently many improvements have been made to the operation of these devices, which allows them to operate almost silently. If we talk about sizes, the “pk-05d” model is relatively small in size, but there are also more bulky designs on the automotive market.

By design, the compressor consists of two parts: the centrifugal device itself, as well as a high-speed multiplier. During operation, this device is not serviced, and the drive itself is carried out by a poly-V-belt from the engine crankshaft. As for the appearance, we will not consider it, since it, like the dimensions of the compressor, depends solely on the manufacturer.

In such mechanisms, the high-speed multiplier is assembled on special bearings. They should be replaced at least every 50 thousand kilometers. The torque itself is transmitted using special belts, which need to be changed at the same intervals as the bearings.

Compressor for VAZ 2107 carburetor

For the compressor to function, it does not need to be supplied with antifreeze or engine oil. For installation, you should not change the design of the motor either. The only thing that needs to be done is to replace the shafts of the generator, crank pulley, and also the water pump for installing the serpentine belt. As a rule, for the VAZ 2107 in such cases, craftsmen use a belt from a Chevrolet Niva. After installing a standard compressor, the vehicle's power rating will increase by 50%.

How to install a turbine on an engine yourself

The principle of operation of the turbine is that flows of exhaust gases from the exhaust manifold enter its housing; the gases, in turn, begin to intensively spin the impeller, which is attached closely to the compressor wheel. In this case, the compressor is already beginning to suck in an increased additional amount of air through the air filter, which is necessary to enrich the fuel mixture and subsequently feed it into the combustion chamber. Thus, a much larger amount of working mixture is formed in the cylinders, which helps to increase engine power and increase its potential.

We seem to have figured out the principle of operation, now we need to understand where to install the turbine, where its place is on the car engine. If the engine has an original turbocharger, you must try to understand the cause of its malfunction

It is important to remember that the installation of turbines in no case accepts any sealants on the oil pipelines, since at high temperatures they can liquefy, after which pieces can get inside and destroy it. If you decide to install the turbine yourself, you should remember these rules and during installation, ensure that no foreign liquids and all sorts of small particles of dust and sand get into the oil. Installing turbines on an engine, as a rule, begins with replacing the air and oil filters, as well as the oil, and flushing the oil line hole

It is necessary to completely clean the oil lines, and replace damaged pipes with new ones.

Installing turbines on an engine, as a rule, begins with replacing the air and oil filters, as well as the oil, and flushing the oil line hole. It is necessary to completely clean the oil lines, and replace damaged pipes with new ones.

The next step is to remove the breather from the engine, followed by cleaning it. Rotate the turbine rotor to determine its rotation force, then flush the supply lines and remove the oil. Before placing the turbine at the place of further service, you need to lubricate all the friction joints of the turbine using a syringe; for this, it has a special oiler (hole) for supplying oil. For this procedure, engine oil is usually used from the engine on which the turbines are installed. Think through everything down to the smallest detail, down to the position of the oil line, and only after that can you install the turbine on the car. The oil line must be positioned strictly vertically, without any sharp bends.

Before you buy and install a turbine on a carburetor, you should understand some general rules and recommendations. Well, first of all, the engine on which you want to install a turbine must be gasoline and run on high-octane fuel, since a mechanical supercharger will produce a pressure of about 3 atmospheres, therefore the compression ratio in the cylinders will increase significantly. For those wishing to install a sports turbine, I would like to inform you that such models will significantly increase fuel consumption, therefore the installation of turbines of this type is the prerogative exclusively of racers who plan to take part in competitions.

If you correctly install a good quality turbine on a carburetor, you can achieve a significant increase in thrust, as well as increase engine dynamics and improve acceleration. In normal day-to-day use of a turbocharged vehicle, fuel savings may occur as acceleration times will be reduced and the handling of obstacles and inclines will now follow a completely different principle. Installing turbines on carburetor engines may also require replacing the spark plugs. However, after installing the turbine, adjusting the jets and sealing the carburetor, combustion of the mixture will improve significantly. To find out the optimal ratio of motor and compressor when choosing a turbine, you need to take into account the engine size of the car. So, before installing a turbine on a carburetor, make simple calculations or simply seek advice from specialists, they will definitely tell you which turbine is best to install on your car.

Turbine check

Before installing the turbocharger, it is recommended to change the oil, as well as the air and oil filters. The turbine is checked in the following order:

- the oil drain and supply parts of the compressor are inspected for the presence of foreign impurities;

- the catalyst is checked (excess exhaust gases will negatively affect the operation of the compressor);

- all air supply channels are inspected for dirt and blockages;

- The rotor rotation speed is checked.

Familiarization with the turbine design will help when checking its performance.

In other words, checking a turbocharger comes down to:

- control of the quality and quantity of gases released from the collector;

- checking the quality of fresh air supply to the compressor;

- checking the output of hot gases from the turbine;

- checking the compressed air output from the compressor.

Self-installation of a turbocharger

Despite the complexity of repairing a turbocharger, there are operations that the owner, with the proper technical skills, can perform independently. We are talking about dismantling and installing the unit. In this case, you should follow some rules to avoid trouble.

- Before installing a repaired turbocharger, thoroughly rinse the oil supply pipe, since the health of the unit directly depends on the oil supply to it. In addition, after repairs, remaining dirt can get inside the unit and initially damage it. In general, when working with a turbine, maximum cleanliness and accuracy should be observed. Before installing the TC on the engine, about 20 g of oil should be poured into the receiving hole, after which it is necessary to rotate the shaft several times to distribute it evenly. You definitely need to change the oil, oil and air filters.

- It is prohibited to use sealants when installing pipes through the gasket. Only new, good quality gaskets should be used. After assembly, you need to start the engine and let it idle for 10-15 minutes. In this case, you need to make sure that there are no oil or coolant leaks through the connections. The turbine running-in period is 1000 kilometers. In this case, you should not exceed the speed above 100 km/h, and also avoid sudden changes in driving modes.

For the injection "seven"

What are the advantages of a supercharger for a VAZ 2107 with an injector? When compared with turbocharging systems, an injector compressor has many advantages. In particular, we are talking about the following advantages:

- compressor for VAZ 2107 injector does not allow the engine to overheat during its operation;

- the vehicle compressor increases its activity simultaneously with an increase in engine speed;

- The operation of this device does not require external intervention.

Compressor for 2107 injector

It should be noted that the last point is especially relevant for domestic vehicles equipped with an injector. This is due to the relatively complex design of the motor. Actually, like any other device, a compressor can have its drawbacks. In particular, we are talking about reducing the efficiency of the motor. This is due to the increased power consumption that is generated during the operation of the motor.

Another important disadvantage is the large size of the supercharger. As a rule, such devices are very bulky, which causes certain difficulties with its installation. Also, some car owners of the VAZ 2107 injector may not appreciate the loud sound that the supercharger makes during operation. In addition, it should be added that for normal installation of the device, in most cases it is necessary to purchase a special drive. Actually, if you do not have the skills to install superchargers, then you may have certain problems, unlike installing a compressor on a carburetor.