In accordance with the requirements of OST 37.003 081-98, the spark plug has the following symbols (see Fig. 13).

Rice. 13. Option for the symbol of domestically produced candles

1. Thread on the body M 14×1.25 – “A”: M 18×1.5 (according to specifications) – “M”

2. Hexagon wrench size: 16.0 mm – “U”; 19.0 mm - “M”.

If the marking does not contain the letters “U” or “M”, the hexagon wrench size is 20.8 mm.

3. Conical bearing surface: “K”.

4 Length of the threaded part of the body for spark plugs with a conical seat: 7.8 mm – “M”: 17.5 mm – “D”: 25.0 mm – “C” If the marking does not contain the letters “M”. “D” or “C” before the heat rating designation, the length of the threaded part of the body is 11.2 mm.

5. Heat number: 8: 11: 14; 17; 20; 23 or 26.

6. Length of the threaded part of the body for spark plugs with a flat supporting surface: 19.0 mm - “D”. If the marking does not contain the letter -D", the length of the threaded part of the housing is 12.7 mm, with the exception of spark plugs with a hexagon wrench size of 19.0 mm. for which there is only one size - 9.5 mm.

7. Protrusion of the thermal cone of the insulator beyond the end of the housing: “B”.

8. Presence of a built-in resistor: “P”.

9. Bimetallic central electrode: “M> (with a copper core).

10. Serial number of development or modernization (except for basic designs): one or two digits at the end of the marking.

An example of a symbol for a spark plug with a thread on the body M 14×1.25, heat number 17, length of the threaded part of the body 19.0 mm, having a protrusion of the thermal cone of the insulator beyond the end of the body, with a built-in noise suppression resistor, with a bimetallic central electrode and having a basic design : A17DVRM

In addition to the type designation, each candle must indicate: date of manufacture (month or quarter, or the last two digits of the year of manufacture);

manufacturer's name or trademark; country of manufacture.

IRIDIUM CANDLE – IS IT WORTH OVERPAYING FOR “PRECIOUS METAL”

Despite the fact that the question of which spark plugs are better: platinum or iridium, everyone decides for himself, there are still no special differences between them.

In addition, many manufacturers combine the beneficial properties of these metals in their products. For example, spark plugs are produced that have a central electrode made of iridium, and a platinum solder on the side electrode. In practice, this allows you to maximize the resource and get a more stable spark.

This is especially important if the car is switched to gas. It is known that the gas-air mixture ignites much worse than gasoline, and it also requires a higher temperature

In such engines, the gap on iridium spark plugs, which is carefully calibrated at the factory, is especially important to keep intact.

Owners of powerful or sports cars also often wonder which spark plugs are better - iridium or platinum. There can be no clear answer here. For such cars, the best option would be a sample whose side electrode is made in the form of a cone, often with an additional notch inside. This increases spark stability to a certain extent and increases its temperature, which has a beneficial effect on engine performance. The video below clearly shows how iridium samples improved the performance of the simplest engine in a domestic car:

Another question that worries motorists quite a lot is the question of how to clean iridium spark plugs. In general, with a normally running engine, they clean themselves, and heavy carbon deposits do not accumulate on them. If such a problem does exist, you should look for the cause in the car itself, and not clean the spark plugs, especially modern ones - there is a high probability of ruining them. By and large, if there is one thing that distinguishes iridium spark plugs from conventional ones, it is their completely “problem-free” operation, and for the entire mileage allowed for their lifetime, they do not require any maintenance.

IS IT WORTH INSTALLING IRIDIUM PLUGS ON OLD CARS?

Is it worth installing iridium samples on old cars that have driven hundreds of thousands, or is it better to get by with a more budget option? This is a difficult question that cannot be answered unequivocally. The question here is, first of all, economic feasibility. On new injection models, expensive iridium options pay for themselves quite quickly. This happens not only due to improved technical characteristics of the engine, but also due to reduced maintenance costs, as well as a significant reduction in fuel consumption - and such spark plugs pay for themselves quite quickly.

An old carburetor car, regardless of whether it has iridium or regular spark plugs, will not “drive better”, and there will be no significant savings on gasoline. However, the operation of the ignition system will undoubtedly improve and become more stable, starting the engine in cold weather will be easier, and the engine will stop reacting violently to low-quality gasoline. Car maintenance is also important, especially one that runs on liquefied gas. Thus, installing modern spark plugs can significantly increase the comfort when operating a car, but it is unlikely that you will be able to save on the rest.

Top 10. APS AU17DVRM

Rating (2021): 4.33

- Characteristics

Average price: 203 rub.

- Country Russia

- Center electrode: nickel

- Center electrode diameter (mm): 3

- Number of side electrodes: 1

- Gap (mm): 0.7

- Heat number: 17

- Thread length/diameter (mm): 19/14

Before us is a Russian copy of German Bosch brand candles. And not a fake, but a licensed copy that has all the necessary certificates. In turn, Bosch is a good analogue of NGK and other top brands. The main difference from the original is the price. Modules are much cheaper, but much less attention is paid to copy protection. However, the price tag and low popularity of the brand do not particularly attract unscrupulous pirates. As for quality and reliability, these spark plugs cannot be called the best of their kind, but they strictly correspond to the declared characteristics, and some parameters, such as the recommended mileage, are even greatly underestimated.

Advantages and disadvantages

- Compliance with the stated parameters

- Licensed copy of a popular brand

- Not copy protected

Interchangeability of spark plugs

Table 1. Summary table of interchangeability of hot spark plugs.

| RUSSIA | A11 A11-1 A11-3 | A11P | А14В А14В-2 | A14VM | A14VR | A14D | A14DV | A14DVR | A14DVRM |

| AUTOLITE | 425 | 414 | 275 | 275 | — | 405 | 55 | 4265 | 65 |

| BERU | 14-9A | 14R-9A | 14-8B | 14-8BU | 14R-7B | 14-8C | 14-8D | 14R-8D | 14R-8DU |

| BOSCH | W9A | WR9A | W8B | W8BC | WR8B | W8C | W8D | WR8D | WR8DC |

| BRISK | N19 | NR19 | N17Y | N17YC | NR17Y | L17 | L17Y | LR17Y | LR17YC |

| CHAMPION | L86 | RL86 | L92Y | L92YC | — | N5 | N11Y | NR11Y | RN11YC |

| EYQUEM | 406 | — | 550S | C32S | — | — | 600LS | — | RC52LS |

| MAGNETI MARELLI | FL4N | FL4NR | FL5NR | F5NC | FL5NPR | FL5L | FL5LP | FL5LPR | F5LCR |

| NGK | B4H | BR4H | BP5H | BP5HS | BPR5H | B5EB | BP5E | BPR5E | BPR5ES |

| NIPPON DENSO | W14F | W14FR | W16FP | W16FP-U | W14FPR | W17E | W16EX | W16EXR | W16EXR-U |

Table 2. Summary table of interchangeability of medium candles.

| RUSSIA | A17B | A17D | A17DV A17DV-1 A17DV-10 | A17DVM | A17DVR | A17DVRM | AU17DVRM |

| AUTOLITE | 273 | 404 | 64 | 64 | 64 | 64 | 3924 |

| BERU | 14-7B | 14-7C | 14-7D | 14-7DU | 14R-7D | 14R-7DU | 14FR-7DU |

| BOSCH | W7B | W7C | W7D | W7DC | WR7D | WR7DC | FR7DCU |

| BRISK | N15Y | L15 | L15Y | L15YC | LR15Y | LR15YC | DR15YC |

| CHAMPION | L87Y | N4 | N9Y | N9YC | RN9Y | RN9YC | RC9YC |

| EYQUEM | 600S | — | 707LS | C52LS | — | RC52LS | RFC52LS |

| MAGNETI MARELLI | FL6NP | FL6L | FL7LP | F7LC | FL7LPR | F7LPR | 7LPR |

| NGK | BP6H | B6EM | BP6E | BP6ES | BPR6E | BPR6ES | BCPR6ES |

| NIPPON DENSO | W20FP | W20EA | W20EP | W20EP-U | W20EXR | W20EPR-U | Q20PR-U |

Table 3. Summary table of the interchangeability of cold candles.

| RUSSIA | A20D A20D-1 | A23-2 | A23B | A23DM | A23DVM |

| AUTOLITE | 4054 | 4092 | 273 | 403 | 52 |

| BERU | 14-6C | 14-5A | 14-5B | 14-5CU | 14-5DU |

| BOSCH | W6C | W5A | W5B | W5CC | W5DC |

| BRISK | L14 | N12 | N12Y | L82C | L12YC |

| CHAMPION | N3 | L82 | L82Y | N3C | N6YC |

| EYQUEM | — | — | 755 | 75LB | C82LS |

| MAGNETI MARELLI | FL7L | FL8N | FL8NP | CW8L | F8LC |

| NGK | B7E | B8H | BP8H | B8ES | BP8ES |

| NIPPON DENSO | W22ES | W24FS | W24FP | W24ES-U | W24EP-U |

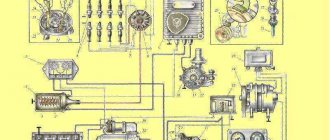

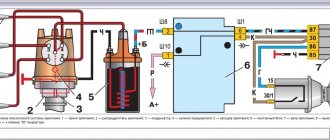

Gas-53 diagram - car diagrams. gas ignition circuit 53

Which spark plugs for VAZ are better to choose?

There are a large number of different modifications of the part, which complicates life for motorists. The problem is that each motor is designed for a specific type of spark plug. If you supply the wrong part, a number of negative consequences can arise.

- Misfire of the mixture due to the gap between the electrodes of the element being too wide.

- Interruptions in the operation of the internal combustion engine caused by too low spark power.

- Instant failure of the device due to too much electrode protrusion.

Also, depending on the inconsistencies present, other malfunctions may “pop up” that reduce the comfort of using the car.

What to look for when choosing. AvtoVAZ plant specialists recommend selecting spark plugs according to a number of parameters

Specialists from the AvtoVAZ plant recommend selecting spark plugs according to a number of parameters.

- Heat number. The parameter characterizes the rate of heat removal from the working part of the candle. At the same time, the electrode transfers excess heat to the spark plug skirt in a timely manner, which ensures stable operation of the part. If energy is removed too quickly, scale forms on the working part of the part, which prevents normal spark breakdown. If the withdrawal is too slow, the thin electrode overheats. The process provokes the formation of glow ignition. This prevents the engine from operating normally due to detonation of the mixture or its early ignition. Under normal thermal conditions, a spark adequately breaks through the spark plugs and does not form excessive carbon deposits.

- Spark gap. Some users know that for the engine to operate correctly, the spark gap on the spark plugs must be maintained. The working gap on VAZ spark plugs is strictly set by the manufacturer of the power plant and is necessary due to the fact that the formed electric arc has a certain strength. As the distance increases, the spark loses stability, which can lead to misfires. In the opposite case, easier starting of the engine is ensured, but when the gas is released, the electric arc current may not be enough. This is justified by the fact that each ignition coil has a certain transformation ratio, usually equal to 2000 units. This means that during the start-up of the internal combustion engine, the elements produce up to 14 kW, and during normal operation it is already 24. Consequently, failure to comply with this parameter can lead to serious disruptions in the operation of the motor.

- Departure of the working part of the electrodes. The parameter is critical for adequate operation of the power plant. The spark plugs on the VAZ 8-valve injector, as well as for carburetor models, have electrodes strongly pushed forward. This is due to the fact that the structural parts are located in the corner of the combustion chamber, where there is no adequate ventilation. The overhang of the working part allows for better ignition of the mixture and stabilizes engine operation. If the spark plugs are mounted in a multi-valve engine, where the inserts are located in the center of the valve head, it is recommended to install spark plugs with a deep-set core - this will prevent damage to the electrodes by the piston bottom and an abundance of carbon deposits on the structural elements.

- Number of electrodes. Initially, manufacturers position this parameter as a definite plus. When one electrode “burns out,” the spark plug switches to another, which significantly increases its service life. However, not everything is as simple as it seems at first glance. If the mixture is sprayed unevenly in the cylinder (poor ventilation of the combustion chamber), and at this moment the spark jumps to the shadowed part (the place where the exhaust remains), misfire may occur, which will lead to unstable operation of the power plant. Additionally, this fact increases the wear of the catalyst and engine oil, which is critical for VAZ cars.

- Manufacturer. The manufacturer of the product is also an important parameter. Users recommend buying from trusted brands that have been on the market for a long time. The cost of such candles will be significant, but with proper selection and operation they will work for a long time and without significant complaints.

By adhering to the specified parameters, a car enthusiast can buy a fairly high-quality product, while saving on the frequency of car servicing and repairs.

Table of applicability of the main types of spark plugs for domestic equipment

Table of applicability of the main types of spark plugs for domestic equipment

| AUTOMOTIVE ENGINEERING | CANDLE | GAP |

| MOTORCYCLES | ||

| Sunrise | A23B | 0,7 |

| Owl | A17B | 0,7 |

| IZH-Planet | A23B | 0,7 |

| IZH-Jupiter | A23B | 0,7 |

| MMVZ-3.111 | A23B | 0,7 |

| MMVZ-3.112 | A23B | 0,7 |

| Minsk | A17B | 0,7 |

| MT-10 | A17B | 0,7 |

| Java | A17B | 0,7 |

| Dnieper | A14B | 0,5 |

| Ural | A14B | 0,5 |

| MOTOR SCOOTERS and MOPEDS | ||

| Veterok, Tulitsa, Tourist | A17B | 0,7 |

| Riga, Carpathians, Verkhovyna | A17B | 0,7 |

| TRACTOR STARTING MOTORS | ||

| PD-10 | A11 | 0,85 |

| P-46 | M8-1 | 0,7 |

| BOAT MOTORS | ||

| Moscow 30D | A17DV | 0,7 |

| Moscow Z0D | A17DV-10 | 0,7 |

| Moscow 25 | A17B | 0,7 |

| SNOWMOBILES | ||

| Buran | A17DV | 0,7 |

| MOTORCYCLES | ||

| Chainsaws | AM17V | 0,5 |

| Small mechanization equipment | ||

| (motor plows, motor cultivators, etc.) | AM17V | 0,5 |

| STATIONARY ENGINES | ||

| AB8 electric unit engine | CH305A | 0,6 |

| Compressors, turbo-isolating and | ||

| cleaning machines, asphalt distributors | ||

| (door ZMZ-404.10) | A11 | 0,85 |

| Stationary electric welding units, | ||

| mobile power stations | ||

| (door ZMZ-403.10) | A11 | 0,85 |

| Stationary units with increased | ||

| quality requirements | ||

| regulation and radio interference level | ||

| (door ZMZ-322.10) | A11 | 0,85 |

| Stationary engines SD-12,-16,-60 | CH310 | 0,4 |

| GAS MOTOR COMPRESSORS | ||

| 10GKN | CH424 | 0,3 |

| GM-8 | CH424 | 0,3 |

| DR | CH441 | 0,3 |

| MK-8 | CH436 | 0,3 |

| VAZ CARS | ||

| 2101,-02,-03,-04,-05,-06,-07,-21 | A17DV | 0,5 |

| (year of manufacture before 06.88) | A17DV-10 | 0,5; 0,7 |

| 2104,-05,-06,-07 | A17DVR | 0,5 |

| 1111.2104, -06 (BSZ) | A17DVR | 0,7 |

| 2108,-09,-099,-10,-213 (BES) | A17DVRM | 0,7 |

| 2108,-09,-099.-10 (ECM) | A17DVRM | 1 |

| VAZ RPD-311 | A26DV-1 | 0,6 |

| VOLGA | ||

| GAZ-21 | A11 | 0,85 |

| GAZ-24 (engine ZMZ-24D) and modifications | A17B | 0,7 |

| GAZ-3102 (engine ZMZ-4022.10) | A14D | 0,7 |

| GAZ-31021,-022,-024,-029 (engine ZMZ-4021.10) | A14VR | 0,8 |

| GAZ-31021,-023,-029, (engine ZMZ-402.10) | A14VR | 0,8 |

| GAZ-31029 ((engine ZMZ-4062.10) | A14DVR | 0,7 |

| GAZ-3302 ((engine ZMZ-4061.10) | A14DVR | 0,7 |

| GAZ-3302 (engine ZMZ-4025.10, ZMZ-4026.10) | А14В-2 | 0,8 |

| ZAZ | ||

| 966, 968 and their modifications | A23-2 | 0,75 |

| MOSKVICH | ||

| 407, 408, 410, 412, 2140 | A20D | 0,7 |

| 2141 | A17DV-10 | 0,7 |

| UAZ | ||

| 31512 (door UMZ-4178) | A11 | 0,85 |

| 31512 (door ZMZ-4021.10) | A17B | 0,7 |

| 31514 | A11 | 0,85 |

| 31516 | A11 | 0,85 |

| 31519 | A11 | 0,85 |

| 3160 | A17B | 0,7 |

| 31601 | A17B | 0,7 |

| TRUCKS | ||

| GAS | ||

| 41, 52, 53, 66, 71, 73 | A11 | 0,85 |

| 307, 3402, 3403, 4905 and their modifications | A11 | 0,85 |

| ZIL | ||

| 130, 131, 152, 157, 431, 433 | A11 | 0,85 |

| 441, 495, 496, 508 | A11 | 0,85 |

| UAZ | ||

| 396, 452, 2206, 3303. 3741 | A11 | 0,85 |

| CARS WITH SCREENED IGNITION SYSTEM | ||

| ZIL | ||

| 130, 375 and their modifications | CH302A | 0,6 |

| 130, 375 and their modifications | SN302B | 0,6 |

| 131, 135LM and their modifications | CH307V | 0,5 |

| UAZ | ||

| 452, 469 and their modifications | SN302B | 0,6 |

| URAL | ||

| Ural-375 and modifications | CH307V | 0,5 |

| BUSES | ||

| LAZ | ||

| 495, 499 and their modifications | A11 | 0,85 |

| LIAZ | ||

| 677 and their modifications | A11 | 0,85 |

| GROOVE | ||

| 3203, 3742 and their modifications | A11 | 0,85 |

| BUSES | ||

| KaVZ | ||

| 685 and modifications | A11 | 0,85 |

| RAF | ||

| 22038-02, 2203-01 | А14В-2 | 0,8 |

Transcripts

Let's look at the decoding of Bosch spark plug designations using the example of WR7DCR

First character

— thread designation.

W - M14x1.25 thread with a flat sealing seat and a wrench size of 21 mm (designation SW21); F - M14x1.25 thread with a flat sealing seat and SW16; M - M18 thread with a flat seal seat and SW25; H - M14x1.25 thread with conical seal seat and SW16; D - M18x1.5 thread with a conical seal seat and SW21. The second symbol

R - indicates that the spark plug has resistance to suppress radio interference.

The third character

7 is the heat number.

The fourth character

is the thread length designation.

A - length of the threaded part is 12.7 mm, normal spark position; B - thread length 12.7 mm, spark position extended; C - thread length 19 mm, normal spark position; D - thread length 19 mm, spark position extended; DT - thread length 19 mm, extended spark position and three ground electrodes; L - thread length 19 mm, spark position far advanced. The fifth symbol

is the material of the middle electrode.

C - alloy of nickel and copper; S—silver middle electrode; P—platinum middle electrode; O - standard spark plug with a reinforced middle electrode. The sixth symbol

is the resistance to burning. R = 1 kOhm.

Using our candles as an example - A17DVRM: “A” is the dimension of the threaded part, in this case M14x1.25 “17” is the heat rating “D” is the length of the threaded part, in this case 19mm, (without the letter D - 12.7mm.) “B” - protruding thermal cone of the insulator “R” - the presence of a resistor (resistance), it is necessary so as not to create electrical interference with radio equipment and injection control systems. “M” - the central electrode is made of copper

Spark plug gap:

A large gap has a good effect on fuel ignition, since a lot of fuel and air mixture gets between the contacts, the probability of ignition of which is very high. Unfortunately, with a large gap, the probability of spark loss is much greater. At high speeds, this manifests itself as misfire in certain cylinders (the engine troits). Often the fuel explodes already in the exhaust system and popping noises are heard. This happens due to the fact that the energy of the coil is not enough to break through a large gap with such a high speed (frequency) of the spark plug. h. s - in order to increase the spark, it is necessary to have wires and spark plugs with resistance, but its burning time becomes shorter, so we increase the spark plug gap and the spark burning time becomes longer. It's worth it.

With a small gap, the spark will be very powerful, but very short. Due to limited access to the fuel-air mixture, this can become a problem and the spark plugs will simply start to flood. This again manifests itself in the fact that the engine begins to stall. At high speeds, it is very likely that an arc will ignite on the spark plug. Due to the short interval and high revolutions, the spark simply does not have time to break and a constant flow of plasma is formed between the contacts. This is dangerous, as it can even lead to the combustion of the ignition coil - in essence, a short circuit occurs for a long time in the output (ignition coil contacts). The engine also does not operate stably at high speeds and may even stall (jam).

Diagnostics of engine operation based on the condition of spark plugs

Photo

No. 1

shows a spark plug removed from an engine whose performance can be considered excellent.

The skirt of the central electrode is light brown in color, soot and deposits are minimal. Complete absence of oil traces. The owner of this engine can only be envied, and there is something to be desired: economical fuel consumption and the absence of the need to add oil from replacement to replacement. Photo No. 2

is a typical example of a spark plug from an engine with high fuel consumption.

The central electrode is covered with velvety black soot. There are several reasons for this: a rich air-fuel mixture (incorrect adjustment of the carburetor, ignition timing or malfunction of the injection system), clogged air filter. Photo No. 3

is, on the contrary, an example of an excessively lean air-fuel mixture.

The color of the electrode is from light gray to white. There is cause for concern here. Driving with a too lean mixture and under increased loads can cause significant overheating of both the spark plug itself and the combustion chamber, and overheating of the combustion chamber is a direct path to burnout of the exhaust valves. No. 4

- the skirt of the central electrode of the spark plug has a characteristic reddish tint.

This color can be compared to the color of red brick. Redness is caused by running the engine on low-quality fuel containing an excessive amount of additives that contain metal. Long-term use of such fuel will cause metal deposits to form a conductive coating on the insulation surface, through which it will be easier for current to pass than between the electrodes of the spark plug, and the spark plug will stop working. In photo No. 5

, the candle has pronounced traces of oil, especially in the threaded part.

An engine with such spark plugs after a long period of parking tends to “triple” for some time after starting, and as it warms up, the operation stabilizes. The reason for this is the unsatisfactory condition of the oil seals. There is increased oil consumption. In the first minutes of engine operation, at the moment of warming up, there is a characteristic white and blue exhaust. No. 6

- the spark plug is turned out of the idle cylinder.

The central electrode and its skirt are covered with a dense layer of oil mixed with drops of unburned fuel and small particles from the destruction that occurred in this cylinder. The reason for this is the destruction of one of the valves or the breakage of the partitions between the piston rings with metal particles getting between the valve and its seat. In this case, the engine “troubles” incessantly, a significant loss of power is noticeable, fuel consumption increases by one and a half, two times. There is only one way out - repair. No. 7

- complete destruction of the central electrode with its ceramic skirt.

The cause of this destruction could be one of the following factors: prolonged operation of the engine with detonation, the use of low octane fuel, very early ignition, and simply a defective spark plug. The engine operating symptoms are the same as in the previous case. The only thing we can hope for is that the particles of the central electrode managed to slip into the exhaust system without getting stuck under the exhaust valve, otherwise repairing the cylinder head cannot be avoided. #8

is the last one in this review. The spark plug electrode is overgrown with ash deposits; the color does not play a decisive role, it only indicates the operation of the fuel system. The reason for this build-up is oil combustion due to depletion or obstruction of the oil scraper piston rings. The engine has increased oil consumption, when over-gasping there is strong blue smoke from the exhaust pipe, the exhaust smell is similar to that of a motorcycle.

Applied technologies and their features

In the production of Akom batteries, modern calcium technology is used, designated as follows: Ca-Ca, or Calcium-Calcium. Its essence is that calcium, not antimony, is added to lead during the manufacture of electrodes. The latter is not used at all in the production of Akom. This makes the products safer for humans and the environment, and the batteries more reliable. This technology increases the strength and durability of the product, reduces fluid consumption, and increases resistance to deep discharge.

Expanded Metal Technology Ca/Ca

Also, in the manufacture of gratings, instead of casting, rolling technology is used. This protects the plates from wear, oxidation and corrosion, and increases current characteristics.

The starting power of Akom batteries is higher than that of classic batteries, and they are also easier to start at sub-zero temperatures. The equipment is resistant to self-discharge and overcharging.

All Akom battery models are maintenance-free. The operating level of the electrolyte remains unchanged when used correctly for three years. It does not boil over (if the voltage does not exceed 16 V), there is no need to remove the lid and add water.

Top 7. Finwhale FS21

Rating (2021): 4.57

High-quality copy protection Candles that are maximally protected from counterfeiting. They have several distinctive quality marks, which reduces the number of fakes to a minimum.

- Characteristics

Average price: 213 rub.

- Country: Germany

- Center electrode: nickel

- Center electrode diameter (mm): 3

- Number of side electrodes: 2

- Gap (mm): 0.7

- Heat number: 21

- Thread length/diameter (mm): 19/14

The modern market is full of low-quality fakes. If you take an unknown Chinese brand, of course no one will copy it, but if you turn to the top brands, an incredible number of copies of very illegal quality immediately pop up. This spark plug has the best level of copy protection. Original packaging in addition to the serial number, which is easy to check. Equipped with codes and a complex hologram, which is very expensive to copy. There are no complaints about the quality either. This is an excellent analogue of NGK with a nickel central electrode. And two side modules significantly increase the life of the candle.

Advantages and disadvantages

- High level of security against counterfeiting

- Recommended for French cars

- An infrequent guest on retail store shelves

Domestic or foreign, how to choose?

Different types of protective equipment from one manufacturer

Candles from foreign manufacturers do not have specific labeling requirements. Russian products must contain symbols indicating the following information:

- name of the manufacturer or company logo;

- date of manufacture;

- designation “made in Russia” or RUS;

- markings that comply with state standards.

Foreign candles are marked according to a similar principle to domestic devices. However, their designation is deciphered differently. Products of different brands, for example “BRISK” and “NGK” with the same parameters have different designations. The lack of generally accepted labeling standards significantly complicates the selection of an analogue

To choose the right SZ, you should use the table of interchangeability of spark plugs or pay attention to the packaging of the spark plug, it contains information indicating for which types of engines the SZ is suitable

Table. Selection of the main types of protective equipment from different brands based on compatibility.

If it is impossible to find an analogue for candles, then a dash is placed in the table.

Features of production technology

Frequency of replacement of spark plugs. spark plug tester. spark plug gap

One of the stages of manufacturing Bosch products Bosch engineers invented the world's first spark plug. Since then, BOSCH spark plugs have been installed by leading automakers when producing cars. This is due to the high quality of Bosch products, the compliance of their designs with generally accepted requirements. Depending on the design of the candle, the materials used in its manufacture, as well as the area of application of the SZ, various requirements are imposed on the manufactured products.

Bosch SZs are manufactured not only in Germany; their production is established in Brazil, Russia, China and other countries. At the same time, the same requirements are imposed on the quality of products, regardless of the country of origin. The same level of quality of products is ensured by the centralized preparation of contracts for the supply of raw materials. In addition, specialists from Germany work in other countries and carry out quality control of products.

The range of BOSCH spark plugs includes products for all types of transport; there are practically no car models on which it is impossible to install Bosch spark plugs. The ignition sections of this brand have proven themselves to be excellent for motor-boat transport, block heat and power plants and low-power engines, as well as in motorsports.

You can select BOSCH spark plugs by the markings on the product; you can also use the online catalog https://www.bosch-automotive-catalog.com/ru/ to select spark plugs.

According to the manufacturer's catalog, BOSCH spark plugs are used in various fields:

- cars with gas engines;

- two-wheelers;

- low-power engines;

- industrial equipment.

Please note that there are a lot of counterfeit products on the market, so the Bosch catalogs indicate how much SZ should be in the package, what marking is accepted by the manufacturer

How to check spark on a spark plug

If you experience unstable engine operation, it begins to “triple”, it is quite possible that it is time to change the spark plugs, or the PVN, or the ignition module needs to be replaced. So, first, let's check the spark plugs of the VAZ 2114, most often the reason is in them.

- We remove the PVN tips from the spark plugs

- Unscrew all 4 spark plugs (you will need a 21 key)

- We put the tip on the spark plug and lean it against the metal (possibly against the body of the engine block)

We start turning the starter and look at the spark plug, if there is a spark, then the spark plug is working. We do the same actions with other candles.

Author Auto mechanic

- Fuelfree fuel saver: scam or truth? (+ real reviews) — 04/26/2020

- Infiniti QX50 (infinity qx50) 2018-2019: review, prices and reviews - 04/26/2020

- Tire markings and full explanation of their designations - 02/04/2020

- Rating of the best crossovers up to 2,000,000 in 2022 - 02/01/2020

- How to pass the traffic police exam the first time: tricks and tips from the inspector - 01/16/2020

View other articles

Top 9. HOLA S15

Rating (2021): 4.39

Spark plugs for cars with high mileage The manufacturer recommends installing these spark plugs on cars of previous generations, manufactured before 2010.

- Characteristics

Average price: 128 rub.

- Country: Holland

- Center electrode: nickel

- Center electrode diameter (mm): 3

- Number of side electrodes: 3

- Gap (mm): 0.8

- Heat number: 15

- Thread length/diameter (mm): 19/14

The NGK brand primarily specializes in spark plugs for modern cars. At the same time, he very delicately avoids old cars, which also need replacing spark plugs and are still plying the roads. This product is designed specifically for these workhorses. The list of recommended cars includes VAZ from a penny to 99 and European brands of previous years. This is a nickel spark plug, but it has three side electrodes, which ensures stable operation on engines with a lot of wear. There are no modern bells and whistles here, but they are not needed. HOLA S15 are exactly the spark plugs that were on your “swallow” when it first came off the assembly line.

Advantages and disadvantages

- Spark plugs for cars of previous generations

- Attractive price

- Many side electrodes

- Rarely found in stores

Spark plug interchangeability table.

Note. * non-standard designation of a spark plug with two “ground” electrodes. n.d. - no data. The completeness and spark gaps of analogue spark plugs may differ.

Now let's look at the table in more detail.

A17DV.

Country of origin: Russia.

On which cars it is used: VAZ 2101-2107 and their modifications until 1988.

Analogues:

- BOSCH (Germany) – W7D;

- NIPPON (Japan) – DENCO W20EP-U;

- NGK (Japan) – BP6ES;

- AC DELCO (USA) – 42XLS;

- BRISK (Czech Republic) – L15YC;

- BERU (Germany) – 14-7DU;

- CHAMPION (USA) – N9Y;

- EYQUEN (France, Italy) – 750LS.

A17DVM.

Country of origin: Russia.

On which cars it is used: VAZ 2101-2107 and their modifications until 1988.

Analogues:

- BOSCH (Germany) – W7DC;

- NIPPON (Japan) – W20EP-U;

- AC DELCO (USA) - C42XLC;

- BRISK (Czech Republic) – L15YC;

- CHAMPION (USA) – N9YC;

- NGK (Japan) – BP6ES;

- BERU (Germany) – 14-7DU;

- EYQUEM (France, Italy) – C62LS.

A17DVRM.

Country of origin: Russia.

On which cars it is used: VAZ 2104-2111 and all their modifications.

Analogues:

- BERU (Germany) – 14R-7DU;

- BOSCH (Germany) – WR7DC;

- NIPPON (Japan) – W20EPR;

- AC DELCO (USA) – CR42XLC;

- BRISK (Czech Republic) – LR15YC;

- NGK (Japan) – BPR6ES;

- CHAMPION (USA) – RN9YC.

A10.

Country of origin: Russia.

On what vehicles is it used: ZIL-157KD and its modifications.

Analogues:

- BOSCH (Germany) – W9AC;

- AC DELCO (USA) – 46F;

- BRISK (Czech Republic) – N19;

- NGK (Japan) – B4H;

- BERU (Germany) – 14-10A;

- AUTO LITE (USA) – 416;

- CHAMPION (USA) – L90.

A20D.

Country of origin: Russia.

On what vehicles is it used: AZLK, IZH.

Analogues:

- BOSCH (Germany) – W6CC;

- MARELLI (Italy) – 7LPR;

- BRISK (Czech Republic) – L14;

- NGK (Japan) – B7ES;

- BERU (Germany) – 14-6CU;

- AUTO LITE (USA) – 4054;

- CHAMPION (USA) – N3C.

A14B and A14B-2.

Country of origin: Russia.

On which vehicles is it used:

- GAZ-24;

- buses: RAF, ErAZ;

- motorcycles: “Dnepr” and “Ural”.

Analogues:

- BOSCH (Germany) – W8BC;

- AC DELCO (USA) – 43FS;

- BRISK (Czech Republic) – N17YC;

- NGK (Japan) – BP5HS;

- BERU (Germany) – 14-8B;

- CHAMPION (USA) – L92YC;

- AUTO LITE (USA) – 275;

- MARELLI (Italy) – F7NC;

- NIPPON (Japan) – W14FP;

- EYQUEN (France, Italy) – 550S.

A14D.

Country of origin: Russia.

On what cars is it used: GAZ-3102.

Analogues:

- BOSCH (Germany) - W8CC;

- BRISK (Czech Republic) – L17C;

- NGK (Japan) – B5ES;

- BERU (Germany) – 14-8C;

- CHAMPION (USA) – N5C;

- AC DELCO (USA) – 43XL;

- MARELLI (Italy) – CW6L;

- NIPPON (Japan) – W17ES;

- AUTO LITE (USA) – 394;

- EYQUEN (France, Italy) – 600L.

A11 and A11-3.

Country of origin: Russia.

On which cars it is used: GAZ, ZIL, UAZ.

Analogues:

- BOSCH (Germany) – W9AC;

- BRISK (Czech Republic) – N19;

- NGK (Japan) – B4H;

- BERU (Germany) – 14-10A;

- CHAMPION (USA) – L86C;

- AUTO LITE (USA) – 416;

- MARELLI (Italy) – CW4N;

- AC DELCO (USA) – 45F, 420Z;

- EYQUEN (France, Italy) – 406.

A14DV.

Country of origin: Russia.

On what cars is it used: GAZ-14, GAZ-3102 and its modifications.

Analogues:

- BOSCH (Germany) – W8DC;

- AC DELCO (USA) – 43XLS;

- BRISK (Czech Republic) – L17C;

- NGK (Japan) – BP5ES;

- BERU (Germany) – 14-8DU;

- CHAMPION (USA) – N11YC;

- MARELLI (Italy) – CW6LP;

- AUTO LITE (USA) – 55;

- EYQUEN (France, Italy) – 600LS.

Applicability of spark plug NGK BPR6ES-11

Suitable for cars and engines

NGK BPR6ES-11 on Mitsubishi

Installed on Mitsubishi cars

Colt CJ1A 1.3i 4G13 after 6.2000 Colt C12A 1.5 G15B with catalyst 8.1984- C52A 1.5i 4G15 83 hp Lancer C61A) 1.3 12V (4G13) to 4.1991 (C12A) 1.5 (G15B) with catalyst 8.1984- Lancer 4WD C77A 1.8i 4G37 Sigma (F16A) Sigma Wagon (F07W) 3.0i SOHC 12V (6G72) Galant E15A 2.0 4G6 3) with catalyst E33A Eclipse D21A 1.8i 4G37 (D32A) 2.0i Turbo 4G63T L200 4WD K33T 2.6 G54B L300 (P04V/W, P14V, P24V/W) 2.4i 4G64 Pajero (L042G) 2.6 +kat (L047G) 2.6 4G 54 with Space Wagon N34W catalyst 2.4i 4G64 produced before May 1992 right-hand drive Mitsubishi Eterna Sava (E32A) 1.8 4G37 Lancer Mirage Wagon 4WD C37W 1.8i 4G37

Rear

For clarity, we recommend watching a video about replacing the rear brake pads on a VAZ 2110. This will make it easier to complete the task and have a visual representation of each stage of repairing the brake system.

It will be good if you once installed disc elements on your rear brakes. The beauty of them is that the process of replacing the rear pads will be similar to the front ones.

The situation is completely different for those who use factory drum braking systems. The work will have to be done delicately, but completely achievable on your own.

To get started, arm yourself with a set of tools, which includes:

- Balloon wrench;

- Jack;

- Pliers;

- Screwdriver;

- Hammer;

- Sharp chisel;

- Open-end, socket and ring wrench sizes 12, 13 and 17 - 3 sizes of each type of wrench.

Now we proceed directly to replacing the rear brake pads.

- Place chocks under the front wheels and remove the rear wheel.

- Unscrew the guides using a 12mm wrench.

- Guides are required for fixing to the axle shafts of the drums.

- It may be quite difficult to remove the drum from its place. This is where you will need a hammer and a wooden stand. Tap the inside of the drum. It is strongly not recommended to hit the drum directly with a metal hammer, as the mechanism may be damaged.

- If the drum cannot be removed even after hammering, treat the contact areas with the hub with WD40 or other penetrating lubricants.

- Then, arm yourself with pliers and remove the springs from the bottom and top of the pads.

- Remove the guide spring located in front.

- This will allow you to completely remove the block.

- When the bar is removed, you can begin to remove the spring from the rear pad.

- Well, now remove both parts of the block. When removing the back one, remember the hook. It comes from the handbrake cable.

- After removing the old block, put a new one in its place. Assembly is carried out in reverse order.

- But there is one caveat - the bushing must be removed from the drive arm, which will greatly facilitate the reassembly process. The upper part of the pads is inserted into the grooves located on the cylinder rod.

- Be prepared for the fact that certain difficulties may arise when installing a new element. The reason is the large output that remains as a result of the operation of old brake elements.

- Take two pry bars and squeeze the two blocks together to bring them as close as possible. At this point the replacement can be considered completed.

- At the last stage, mandatory bleeding of the brake system is carried out. Without it, not a single intervention in the design of car brakes can be done.

Top 4. Torch QH5RIU-13

Rating (2021): 4.69

The best Chinese analogue A candle from a little-known brand, which showed excellent test results and strict compliance with the labeling.

- Characteristics

Average price: 520 rub.

- Country: China

- Center electrode: iridium

- Center electrode diameter (mm): 1

- Number of side electrodes: 1

- Gap (mm): 1.1

- Heat number: 5

- Thread length/diameter (mm): 24/14

This is a Chinese brand that has become increasingly popular in recent years. In terms of popularity, it is unlikely to be able to compete with NGK, but today it is easy to find tests and reviews from real owners online. Including on the well-known portals Drom and Drive2. As practice has shown, the Chinese version, although not the best analogue of the Japanese, is quite worthy. There is an iridium solder, and the declared resource is 80 thousand mileage. Not a bad result, however, the product costs a lot of money. Tests also showed that the spark plug performs well and has all the advantages inherent in iridium models. Perhaps we will soon see a new big name in this market.

Advantages and disadvantages

- Complies with markings

- Fully fulfills the declared resource

- Little information about the brand and product

- Not copy protected at all

The main criteria by which selection is carried out

Products from various brands

Modern motors are manufactured with certain design features that provide them with certain technical characteristics. For normal operation of the power unit, it is necessary to install an SZ, with certain parameters corresponding to the type of car engine

When choosing an analogue of SZ, you should pay attention to their main parameters:

- Screw-in dimensions:

- length of the threaded part;

- thread pitch;

- thread diameter;

- turnkey hexagon dimensions.

We recommend: Technical characteristics of Idemitsu 5W-40 engine oil

Products with overall and connecting dimensions that do not correspond to the engine type cannot be mounted on the power unit. The use of devices with a threaded part that is too long or short, in most cases ends in a major overhaul of the car engine.

- The thermal part of the analogue should be as close as possible to the characteristics of the original. We are talking about the heat number, which reflects the ability of candle products to heat up at different thermal loads of the engine. Please note, when selecting SZ for compatibility, that domestic products are marked indicating the heat number, while foreign ones are divided into cold (having a large heat number) and hot (having a small heat number).

- The distance between the spark plug contacts must correspond to the size specified in the machine manual. An increased spark plug gap will lead to a decrease in spark power, and a reduced gap will lead to breakdowns in the ignition system.

- Number of spark plug electrodes. Many motorists are of the opinion: the more spark plug contacts, the stronger the sparking. This is an erroneous statement; the spark occurs between two contacts. In multi-contact devices, the operating principle is as follows: if one electrode burns, sparking will occur on the second. Such modernization of the SZ design makes it possible to increase their operational period, but does not affect the spark power.

- The material from which the spark plug contacts are made. It is possible to buy iridium, platinum or classic candles. The operational period of the product, the rate of formation and the power of the spark depend on the material of their contacts.

We recommend watching a video about how the SZ marking is deciphered:

Candle parameters

Overall and connecting dimensions are the pitch and diameter of the thread on the contact part, which is screwed into the cylinder, the size of the hexagon and the length of the threaded part.

These dimensions correspond to each individual type of engine, since the seat on the cylinders has its own design size. The drip number is an indicator of the level of thermal property that shows how the plug heats up depending on the various thermal loads of the engine. If it has a small drop number, then it is called hot. Its thermal cone heats up to 900º C. They are used on low-power engines with a low compression ratio. Cold spark plugs are those in which ignition occurs under high thermal loads; accordingly, they are used for highly accelerated engines.

The size of the spark gap. This value is usually indicated in the vehicle operating rules and has limits from 0.5 to 2 mm. The gap can be structurally adjustable.

Rear

For clarity, we recommend watching a video about replacing the rear brake pads on a VAZ 2110. This will make it easier to complete the task and have a visual representation of each stage of repairing the brake system.

It will be good if you once installed disc elements on your rear brakes. The beauty of them is that the process of replacing the rear pads will be similar to the front ones.

In some cases, depending on the design of the rear brakes, it may be necessary to completely remove the rotor and caliper. All other activities are carried out in exactly the same way as in the case of the front pads.

The situation is completely different for those who use factory drum braking systems. The work will have to be done delicately, but completely achievable on your own.

To get started, arm yourself with a set of tools, which includes:

- Balloon wrench;

- Jack;

- Pliers;

- Screwdriver;

- Hammer;

- Sharp chisel;

- Open-end, socket and ring wrench sizes 12, 13 and 17 - 3 sizes of each type of wrench.

Now we proceed directly to replacing the rear brake pads.

- Place chocks under the front wheels and remove the rear wheel.

- Unscrew the guides using a 12mm wrench.

- Guides are required for fixing to the axle shafts of the drums.

- It may be quite difficult to remove the drum from its place. This is where you will need a hammer and a wooden stand. Tap the inside of the drum. It is strongly not recommended to hit the drum directly with a metal hammer, as the mechanism may be damaged.

- If the drum cannot be removed even after hammering, treat the contact areas with the hub with WD40 or other penetrating lubricants.

- Then, arm yourself with pliers and remove the springs from the bottom and top of the pads.

- Remove the guide spring located in front.

- This will allow you to completely remove the block.

- When the bar is removed, you can begin to remove the spring from the rear pad.

- Well, now remove both parts of the block. When removing the back one, remember the hook. It comes from the handbrake cable.

- After removing the old block, put a new one in its place. Assembly is carried out in reverse order.

- But there is one caveat - the bushing must be removed from the drive arm, which will greatly facilitate the reassembly process. The upper part of the pads is inserted into the grooves located on the cylinder rod.

- Be prepared for the fact that certain difficulties may arise when installing a new element. The reason is the large output that remains as a result of the operation of old brake elements.

- Take two pry bars and squeeze the two blocks together to bring them as close as possible. At this point the replacement can be considered completed.

- At the last stage, mandatory bleeding of the brake system is carried out. Without it, not a single intervention in the design of car brakes can be done.

As you can see, replacing the pads is not difficult if you act consistently. The best option is to install disc brakes everywhere. They are easier to work with, they are more efficient in their tasks, plus replacement is carried out without any problems, unlike drums.

NGK Iridium Spark Plugs

Iridium ngk spark plugs are considered the best solution, as they have excellent quality. Iridium is a noble metal and the hardest. This metal melts at a temperature of 2450 degrees. If you compare an iridium spark plug with a regular spark plug, it will last you twice as long.

NGK iridium spark plugs have a platinum plate on the middle electrode. It provides high spark plug power even in difficult conditions. These spark plugs have a thin middle electrode and less voltage is required during ignition.

Innovative technologies have developed such a system that electrical charges occur in the annular gap between the middle electrode and the insulator. Thanks to this, soot particles that collect in this area are removed. The self-cleaning effect of such candles extends their lifespan.

Characteristics

Let's start with the main characteristics. The length of the thread of the AU17DVRM spark plug is 1.9 cm; a 16 mm hexagon is used to unscrew and screw the devices into the engine. One of the main characteristics is the gap, which in this case is 1 mm. If we talk about stability, then these SZ cannot boast of it, especially if we compare this brand with the Bosch and NGK brands. If you believe the manufacturer, then SZ AU17DVRM are produced using modern technologies and innovations, which makes it possible to achieve a high quality product.