The domestic SUV VAZ-2121, also known as the legendary Niva, has been tirelessly traveling around the expanses of our vast homeland and beyond its borders since 1977. Currently, this car not only has not lost its popularity, but on the contrary - the demand of car enthusiasts for this miracle of the automotive industry is only growing every year.

Why did the Niva become such a popular car? It's simple. The car's high seating position, all-wheel drive, ease of maintenance and relatively cheap prices for spare parts - that's the whole secret. Fishing, hunting, travel, expeditions and even sports racing - all this is the nature of the Niva.

Since 1994, serial production of the VAZ-21213 model under the name “Taiga” began.

This VAZ model is equipped with a 1.7-liter carburetor gasoline engine, a five-speed manual transmission, and a contactless ignition system. A Solex 21073 carburetor is installed on the Niva. In the modern world, when progress does not stand still, a carburetor under the hood of a car, and even an SUV, looks sad.

When buying a used car, most motorists prefer to choose an injection version rather than a carburetor. And today's youth look at the carburetor in surprise, completely not understanding what it is. But if a person has at least a little understanding of technology, then understanding the essence of the Solex 21073 carburetor will not be a problem.

It is enough to familiarize yourself with some information.

The best carburetor for the VAZ 2121 Niva

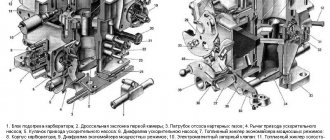

The carburetor on models 2121, 21213 and other cars has basically the same device. Functionally, it is located in the propulsion system, and with its help the fuel is mixed to the state of a combustible mixture. A carburetor, as a rule, consists of several main elements - a float chamber, a so-called jet (with a spray), a diffuser, and a throttle valve. It can have from one to four cameras on different cars, sequential or simultaneous opening of the throttle valves, horizontal, downward or upward movement of the working mixture.

Elements of the carburetor on Niva models

The carburetor circuit also includes: a drive lever from the accelerator pump, a diaphragm, an adjusting screw and an air duct from the starter, a shut-off valve (solenoid), an air damper, a needle valve, a fuel supply fitting, an economizer for power modes, a carburetor heating unit, fittings for crankcase ventilation, for supplying vacuum for the vacuum regulator in the ignition, and other elements.

Niva 2121 has the following sequence of passage of fuel elements through the carburetor chamber. First, fuel moves from the fuel tank to the float chamber in a controlled amount. The float rises or falls as the fuel moves.

Further, the fuel path lies through the nozzle into the atomizer, located in the narrow part of the diffuser, with simultaneous air entering the carburetor through the outer pipe. The throttle valves then deliver varying amounts of fuel into the engine cylinder through an intake manifold cast from aluminum alloys. The manifold is attached to the engine with studs through gaskets that have heat-resistant properties.

"Solex" and "Ozone"

The VAZ 2121 Niva model can be equipped with an “Ozone” carburetor with the serial designation 2107-110-7010-10 or 2107-110-7010-20. They differ from each other in that the first option has an old-style breaker and does not have a vacuum corrector. The second carburetor does not have a microswitch from the economizer, which affects the environmental friendliness of emissions and has some impact on fuel consumption.

The Niva 21213 is equipped with Solex type carburetors (model 21073-110-7010). They are considered quite “capricious”, which is primarily due to the negligence of the owners themselves. The incorrect operation of the device is primarily affected by low-quality fuel with a large amount of impurities, since in this model the fuel is taken through holes in the bottom of the float chambers (in other models these elements are raised above the bottom).

In addition, problems arise for those “nivovods” who do not promptly change the fuel or air filter, and also do not pay attention to proper cleaning of the carburetor from oil soot emissions through the ventilation system.

Adjustment of the VAZ carburetor is usually carried out in the float mechanism or in the starting and idle systems. These are very important operations that are best left to the experts.

The float mechanism on the Niva 2121 is adjusted in terms of the position of the floats relative to each other and relative to the walls of the float chamber. In addition, the mechanisms in the open and closed positions of the needle valve may need to be adjusted. In order not to disturb good adjustment, the car owner needs to carefully handle the carburetor cover when removing it, monitor the level of wear of the shut-off cone from the needle (its seat and tongue), as well as the axis of the mounting bracket.

We carry out the adjustment ourselves

Niva 21213 can be subject to adjustment of the starting system by the gap at the edges of the valves, if the carburetor is removed, or by the crankshaft speed directly on the car. In the first case, the gap at the location of the lower edge (in the direction of air movement) from the throttle valve is set to a width of 1.1 mm. It is adjusted with a screw that has a 0.7 cm hexagon on the head and a slot from the shank. This operation is carried out with the cam lever turned counterclockwise from the starting system control (all the way). In the same position, the gap at the lower edge of the air damper is set to 3 mm using a screw in the cover from the diaphragm mechanism in the starting system (you need to loosen the lock nut). At the same time, the rod from the diaphragm must be forcibly recessed completely into the adjusting screw. After adjustment, the screw is fixed with a locknut.

Adjusting the Niva starting system directly in the car saves time:

- You need to remove the air filter from the engine, pull the control lever away from the air damper, and start the engine.

- When the air damper is forcibly opened (by touching a flat screwdriver to a third of its full angle of rotation) using a screw (next to the lever on the axis from the throttle valve from the first chamber), the initial rotation speed is set to 2.08.mar.0 thousand rpm (on a warm engine).

- Remove the screwdriver, lower the air damper and, using the screw stop (next to the diaphragm), set the frequency to be 100 rpm lower than the original one (you need to select the appropriate position of the air damper).

- The screw can then be secured using a locknut.

If you have a gas analyzer, then the carburetor adjustment in the starting system part can be done based on the amount of CO (carbon monoxide) in the exhaust gases. If, with the choke control lever fully extended, the gas rate is 8%, then everything is in order. If there is less gas than this value, then the screw on the cover of the diaphragm mechanism is tightened; if there is more, it is unscrewed and repeated measurements are taken.

It is necessary to adjust the idle speed of the Niva 2121 so that there is less carbon monoxide in the exhaust gases and so that the engine runs stably. At service stations, such work is carried out with gas analyzers on the MV. In the garage, adjustments can be made using the tachometer.

For these purposes, on a warm engine, a plastic plug is pierced with a screwdriver, then the quality screw is rotated in different directions until the maximum idle speed is reached. Then, using the quantity screw (has a ribbed plastic handle), you need to set an increased speed (50-70 rpm more than at standard idle speed). Operations with screws must be repeated two more times. Then, on models 2121 or 21213, at idle speed, at speeds increased by 50-70 rpm, the quality screw is tightened, and the speed should drop to normal (i.e., decrease by 50-70 revolutions).

Carburetor repair for dips and jerks

Carburetor repair may be necessary if the engine idles unstable, and adjusting the quantity and quality screws does not always help. Often the reason lies in over-enrichment of the mixture, which may be a consequence of incorrect adjustment of the float system or malfunctions in the vacuum economizer system for power modes. In the latter case, a torn diaphragm may need to be replaced or the economizer valve through which fuel is leaking may need to be repaired.

Model 2121 may cause jerking, swaying or dips when moving. In this case, there may be several reasons for their occurrence, which may require carburetor repair to eliminate them. Dips that appear when the throttle valve is slowly opened are often associated with clogging of the idle jet. Here it is necessary to adjust the fuel level and check the level of clogging in the main fuel jets.

If the car gives a deep failure when trying to open the first or second throttle chambers, then in addition to clogged nozzles, the reason may be poor installation of small diffusers in the corresponding sockets.

When the Niva 21213 gives slight twitches at low and medium speeds and accelerates sluggishly, it may be due to poor fuel dosage on the shut-off valve side due to its wear. In this case, repairs are needed in terms of replacing the shut-off valve with a shut-off needle made of metal with a valve that has this needle made of a different material.

Preparing to modernize the engine power system

In order to install two carburetors, it is recommended to initially drain the antifreeze through the fuel heater. After this, it is necessary to dismantle part of the fuel system. To remove the intake manifold, you need to unscrew the five bolts that secure it.

Connecting the carburetor to the manifold is not done on the car. This type of work is carried out in good lighting. Having connected the carburetors one by one to the intake manifolds of the Oka, you need to open both chambers and check the condition of the joint. It is strictly forbidden to allow the edges of the collector to protrude above the joint. The air-fuel mixture will swirl at the junction at high speed and the engine will starve.

To eliminate protruding edges, use a metal cutter inserted into a screwdriver or drill. The transition between parts should be as smooth as possible. For better results, you can use sandpaper or special sanding pastes.

During a visual inspection, it is possible to detect sagging and casting defects in both the carburetor and the manifold. A car owner who independently installed and tuned the fuel system knows about the need for modifications, but a newbie may be surprised by the protruding pins inside the manifold. This creates strong resistance to air flow, which significantly reduces the effect of installing two carburetors.

Why is the carburetor replaced on a Niva?

- If we remember all the shortcomings of the classic device, it has increased fuel consumption, which is not entirely justified for a passenger car. Many people buy a Niva exclusively for city driving and only occasionally go off-road. In such conditions, consumption must be reduced. Repair in this case is impossible.

- The second reason is suitable for those for whom the dynamic characteristics are too low. To do this, they install systems of a more advanced design, two carburetors, or perform tuning. This option is quite rare, so let’s consider the first one to reduce fuel consumption. Only replacing the carburetor will help here.

Modification results

The main concern that car owners have when tuning is the appearance of excessive fuel consumption. The engine, working with two carburetors, consumes fuel within normal limits, since the increase in power occurs mainly due to a more optimal ratio of fuel to air in each cylinder.

The increase in gasoline consumption occurs only due to a more aggressive driving style, which is observed after an increase in torque and power. Car owners provide maximum fuel supply to the cylinders when starting at traffic lights, since dynamic characteristics, as a result of this modernization, increase by 10-15%.

The reliability of this system is at a high level. Although the presence of additional components increases the risk of breakdown, if installation and adjustment operations are performed correctly, carburetors will not require owner intervention for a long time.

Installing a second carburetor cannot be considered an easy tuning. The car owner should realistically assess his strength before starting modernization. If you take a risk, the result will not take long to arrive. The significant improvement in low-end thrust thanks to the high torque and increased top speed are well worth the effort of installing two carburetors.

Disadvantages of the VAZ 21213 power unit

- Water pump;

- Engine, manual transmission and transfer case oil seals;

- Generator;

- Starter;

- manual transmission;

- Valve cover gasket;

- Cooling system pipe connections;

- Radiator;

- Thermostat;

- Expansion tank;

- Vacuum brake booster.

The water pump (pump) is characterized by frequent failures on new cars after 2,000 km.

Due to poor quality, oil seals require more frequent replacement than required according to the operating manual.

The generator has a high probability of failure. As a rule, it burns out even on new cars that have not reached 4,000-10,000 km.

The starter has a low service life without repair.

On a gearbox, one of the common defects is the fifth gear slipping out. In addition, the gears are not fully engaged.

The valve cover gasket loses its properties over time and allows oil to leak out.

The connections of the cooling system pipes in the places where the clamps are installed are not reliable and lose their tightness very early, which is fraught with loss of antifreeze.

The radiator is leaking. The problem occurs due to the appearance of cracks in the radiator pipe package, accompanied by loss of coolant. This defect has become widespread.

The thermostat does not provide thermal conditions for the coolant in the engine cooling system. The manifestation of this problem is no exception. The cause of the defect is a failure of the valve mechanism inside the thermostat. To check that the thermostat is working properly, after starting the engine, simply place your palm on the lower (outlet) hose, through which hot antifreeze circulates into the radiator for cooling. If the thermostat is working properly, after some time the hose should become hot; if the hose remains cold, the thermostat must be replaced.

The expansion tank cracks and antifreeze leaks out. The appearance of cracks occurs due to the failure of the steam-air valve in the tank plug due to increased pressure.

Vacuum brake booster (VUT). Manifested by a stiff brake pedal. The speed may fluctuate when the brake pedal is pressed, as well as hissing. The problem is solved by replacing failed rubber products and replacing clamps in connections.

- Vibration at speed 80-90 km;

- Unreliable timing tensioner design;

- Ignition module;

- The fuel pump is noisy;

- Low torque;

- Long stroke of the gear lever;

- When the timing chain breaks, the valves bend;

- Vibration of the gear lever;

- Poor dynamics on the highway due to insufficient power.

PS. Dear Nivovody! I look forward to your comments, questions and feedback on the problems that have arisen, weaknesses and shortcomings during the operation, maintenance and repair of the VAZ 21213 engine.

Niva engines have excellent technical characteristics and have proven themselves to be quite reliable power units. At the same time, it should be understood that, like all other VAZ power units, they are not without drawbacks.

The disadvantages of this motor include:

- increased noise;

- tendency to vibration;

- increased oil consumption.

Such problems often appear after a mileage of 100,000 kilometers. Car owners need to closely monitor the condition of the cooling system.

Often, problems with the pump and thermostat lead to overheating of the power unit. The result of such overheating can be the appearance of cracks in the cylinder head, which in turn leads to coolant entering the oil. The VAZ 21213 engine in this case requires complex and expensive repairs.

Checking and adjusting the idle speed of an engine with a 21073 Solex carburetor

Conditions for checking and adjusting idle speed

— The car engine is warmed up to an operating temperature of 80-90º

— The carburetor air damper is completely open (“the choke” is recessed all the way)

— The throttle valves of the first and second chambers are completely closed

— The air filter housing with the filter element is not dismantled

Checking the idle speed of an engine with a 21073 Solex carburetor

The idle speed of an engine with a Solex carburetor 21073-1107010 should be in the range of 750-800 rpm (for a Niva car). Checked using a standard or connected external tachometer. At idle, the engine should run smoothly without interruption. When you sharply press the gas pedal, the engine speed at idle increases without “dips”, and when you release the gas, they decrease without stalling the engine.

If the picture does not correspond to the required one, we adjust the idle speed.

The most basic adjustment of the idle speed of a car engine with a 21073-1107010 Solex carburetor comes down to rotating the screw for adjusting the “amount” of the fuel mixture. Clockwise - the speed increases, counter - decreases. The “quantity” screw with its tip moves the throttle lever of the first chamber and it slightly opens or, conversely, closes the throttle valve. This regulates the amount of fuel mixture entering the engine cylinders (See “The principle of operation of the Solex carburetor idle system”).

or use the standard one in the instrument panel

Use the “quantity” screw to set the minimum stable idle speed

At the same time, the tip of the screw lightly presses the throttle lever and opens it slightly. There should be no vacuum in the tube from the vacuum advance regulator.

Using the “quality” screw we increase them to the maximum possible value

Using a slotted screwdriver with a thin blade, we rotate the “quality” screw in different directions, achieving the maximum speed of the crankshaft (we use the tachometer as a guide).

When the screw is tightened, the amount of fuel emulsion entering the fuel mixture decreases and it becomes lean; when unscrewed, the fuel mixture, on the contrary, becomes richer.

Initial position of the “quality” screw: 1-1.5 turns from the fully tightened state.

Using the “quality” screw, set the idle speed within 750-800 rpm

Screw it clockwise using a slotted screwdriver.

We check the operation of the engine (see above).

If necessary, repeat the adjustment.

Notes and additions

If the idle speed of an engine with a Solex 21073 carburetor cannot be adjusted, or after adjustment the engine still runs intermittently and stalls, you should pay attention to the following points:

— Correct installation and serviceability of the carburetor solenoid valve

— “Sucking” excess air into the carburetor (ring on the EMC, gasket under the carburetor, etc.)

— Contamination of the idle system (see “Cleaning the idle system of the Solex carburetor”)

— Correct setting of the ignition timing (see “Setting the ignition timing on a Niva carburetor engine”)

— Engine serviceability (valve clearance)

— Serviceability of the ignition system (spark plugs, armored wires, distributor cover, slider, resistor)

You can adjust the idle speed of a car engine by ear, but this requires some experience in car repair and maintenance.

TWOKARBURATORS VK -More information on the topic in our VKontakte group

Which Carburetor is Better to Put on Niva

Which carburetor is best to install on the field?

21213

More than fifty years later, the Russian auto industry continues to firmly hold its favorite position in the automotive market. The VAZ family has a very reasonable price and is quite standard in service.

There was great demand for the Russian VAZ-21213 jeep and its analogues. This type of VAZ car has achieved great success in world motorsport, setting unattainable records. Working with wag-com; battery management; decent taxi fleet; THE USSR; Photo; how to sheathe a roof profile; what tires to put on the field in winter; Daewoo Winstorm max. Chevrolet Front Hub. This car model is very intensively exported to European countries and beyond.

Motorists who do not have much experience in servicing this type of car often encounter various problems associated with the operation and repair of Niva. One of these common problems is carburetor repair and replacement.

Many drivers do not know which model is better

choose how they differ and how to manage them when choosing one or the other.

Often the carburetors on different Niva models are very similar and located in the same way. They are located in the drive system and create the desired fuel mixture of fuel, combining fuel with air, and supply it to the engine. The carburetors ordered are also identical. Key elements include:

- Float chamber (jet).

- Diffuser.

- throttle

Depending on the car model, the carburetor can have from 1 to 4 chambers; the flaps can be opened alternately or immediately; The movement of the flammable consistency can be horizontal, downward or upward.

Inexperienced motorists can use a carburetor diagram, which will list all the parts and describe their positions and functions. It will be much easier to find and change a specific part.

Niva 21213 replaced the previous VAZ-2121 and became more sophisticated and refined. The updated model has:

- 1.7-liter engine, the founder of which was the engine from the Russian “six”;

- five-speed gearbox;

Solex carburetor- contactless ignition using a microcontroller.

To always be confident in your car, you need to thoroughly know all its “inner money”, understand its features and understand its details. Later in this article we will look at the design of the Niva 21213 carburetor in order to have an idea of this part and learn the intricacies of its operation.

53 No worse, maybe even better 73 per car 21 213 1.7 l

Carburetors on a world map near you! Purchase of nails.

Does he want something NIVA?! (About choosing a carburetor)

In this video, Nil Poroshin talks about which carburetor

NIVA

5 doors !

Carburetor in field 21213 what I put

Initially, when the VAZ 21213 was designed and manufactured by the manufacturer, it had a carburetor

Ozone brand.

In 1994, the manufacturer decided to update the Niva. In addition to the engine and other parts, it was replaced carburetor . Car owners still argue about which division is better Niva owners have varying opinions, and each type of carburetor does have many pros and cons. which model of the unit is better

.

A little history

A new carburetor was needed when the front-wheel drive VAZ project was being developed. The transverse arrangement of the engine did not make it possible to install the old OZONE carburetor, which was used for the “classic”. But the development of the French company Solex, after a little “finishing with a file,” went off without a hitch.

The design of Solex carburetors made it possible to install them on engines of different types and power, slightly changing some parameters. So, the most common was the Solex model 21083, which was installed on a 1.5 liter engine. VAZ 2108, 2109. For “classics” with a 1.45-1.6 liter engine. modification 21053 was developed, structurally similar to Solex 21073, designed for the VAZ 21213 Niva with a powerful 1.7 liter engine. And even for Moskvich with a 1.5 liter engine. Solex 21041 was installed, and for 1.8 liters. – modification 21041-10, suitable for both Volga and UAZ.

Elements of the carburetor on Niva models

The carburetor circuit also includes: a drive lever from the accelerator pump, a diaphragm, an adjusting screw and an air duct from the starter, a shut-off valve (solenoid), an air damper, a needle valve, a fuel supply fitting, an economizer for power modes, a carburetor heating unit, fittings for crankcase ventilation, for supplying vacuum for the vacuum regulator in the ignition, and other elements.

Niva 2121 has the following sequence of passage of fuel elements through the carburetor chamber. First, fuel moves from the fuel tank to the float chamber in a controlled amount. The float rises or falls as the fuel moves.

Further, the fuel path lies through the nozzle into the atomizer, located in the narrow part of the diffuser, with simultaneous air entering the carburetor through the outer pipe. The throttle valves then deliver varying amounts of fuel into the engine cylinder through an intake manifold cast from aluminum alloys. The manifold is attached to the engine with studs through gaskets that have heat-resistant properties.

Features of servicing DAAZ-21073 devices

All possible disruptions in the operation of the device directly depend on the quality and frequency of service. Despite the design differences between the VAZ DAAZ-21073 and the DAAZ-4178 carburetor on the UAZ, their maintenance is not much different. The technically required work includes:

- external cleaning;

- washing the float chamber strainer;

- cleaning the float chamber;

- cleaning jets;

- adjustment of the float device;

- adjustment of the starting device;

- stabilization of the XX system.

Washing the external and internal parts of the carburetor unit is carried out using kerosene, white spirit or preparations in aerosol cans. The aerosol composition is injected into the chambers and jets while the engine is running. The cleaned apparatus is blown with compressed air.

VESKO-TRANS.RU

AutoNews / Reviews / Tests

Which Carburetor to Put on a VAZ 2121

Which carburetor

better

put it on Levels 2121

Niva 2121 , or VAZ-2121 is considered a small-class SUV, which has a supporting body and permanent all-wheel drive. The first model of this car had an engine with the same markings. VAZ-2121. I entered his package and the Daaz 2107-20 or “seven by twenty” carburetor If this doesn't work, is it best to use a Niva 2121 carburetor from modern models?

Features of the Niva 2121 carburetor

If we are talking about the carburetor, you should know that this part is called that because its main functional purpose. carburetor or mixing. Indeed, in the carburetor, fuel is mixed with water. I changed the thermostats and what thermostat to use if I turn off the thermostat. In addition, the flow of the acquired consistency in the engine cylinders is regulated.

The mechanism of the carburetor depends on the design of the carburetor device itself. Which power steering is best to put on gas 69? (Page 1. So, the Niva 2121 carburetor installed on the “native” one consists of:

- float chamber (with the level of fuel liquid

, this device depends on the best functioning of the idle system and the transition systems of all chambers); - nozzle (the main metering part through which fuel liquid and air enter the carburetor in metered quantities, also called nozzles or plugs);

- diffusers (they are constrictions in the carburetor tubes of both chambers; they are necessary to increase the speed of air passage into the mixing chambers);

- throttle (a mechanical regulator of the cross-section of a channel designed to quantitatively configure the fuel liquid

or gas passing through this channel).

The carburetor feed mechanism on the Niva 2121 has the following diagram:

- From the fuel tank, fuel liquid enters the float chamber in a rational quantity.

- The float chamber lowers under the weight of the fuel water.

- As the water moves, the float chamber rises.

- the fuel liquid

passes through the float chamber, it enters the nozzle. - From the injector, fuel is supplied to the nozzle (it is located in a narrow area of the diffuser).

- Air enters the carburetor through the outer pipe.

- Through the intake manifold, a certain amount of fuel water is supplied by throttle bodies directly into the engine.

If the old carburetor on a Niva 2121 fails, experts recommend replacing it with a more modern model.

Which carbohydrate is best for Niva 2121?

Experienced auto mechanics offer a choice of two modern models of the Niva 2121 carburetor:

What does NIVA want?! (About choosing a carburetor)

In this video, Nigel Poroshin knows what kind of carburetor

best for a 5-door Niva!

53 No worse, maybe even better 73 on a car 21 213 1.7 liters

Carburetors on the world map. close to you! Purchase of nails.

According to experts, these carburetor models are actually similar. But there are differences:

- Ozone is not equipped with a vacuum concealer.

- Solex works without an economizer.

What is the significance of each designated carburetor device? Let's look at their multifunctional features:

- the vacuum concealer is designed to rotate the table inside the toggle switch, which leads to a change in the ignition timing;

- Economizer. This is a heat exchanger that must preheat the water supplied to the boiler.

Diagram of the idle system and transition systems of the carburetor 21073 Solex |

Scheme CXX 21073 Solex

Elements of the CXX circuit

1. First chamber of the carburetor.2. Second chamber of the carburetor.3. Carburetor air damper.4. Air channels of the idle system and the transition system of the second chamber.5. Air channel plugs.6. Anti-drainage hole.7. Air jet for carburetor idle system 21073 Solex.8. Fuel jet for idle system.9. Rubber seal for carburetor solenoid valve.10. Carburetor solenoid valve (EMV).11. Solenoid valve needle.12. Emulsion channel CXX and transition system of the first chamber.13. Air intake hole in CXX.14. Adjusting screw for the composition (“quality”) of the fuel mixture.15. Rubber O-ring on screw "quality".16. Hole for the exit of fuel emulsion from the emulsion channel of the CXX system.17. A recess in the carburetor body for the outlet of the emulsion channel CXX.18. Slot hole for the exit of the fuel emulsion of the transition system of the first carburetor chamber.19. Emulsion channel of the transition system of the first carburetor chamber.20. Throttle valve of the first chamber of the carburetor.21. Fuel channel CXX and transition system of the first chamber.22. Emulsion tubes GDS.23. Fuel channel pipe СХХ.24. Rubber sealing ring of the fuel channel tube СХХ.25. Air intake hole into the air channel of the transition system of the second chamber of the Solex carburetor 21073.26. Air channel of the transition system of the second carburetor chamber.27. Emulsion channel of the transition system of the second carburetor chamber.28. Air jet of the transition system of the second chamber.29. Fuel intake pipe of the transition system of the second chamber.30. Fuel nozzle of the transition system of the second chamber.31. Float chamber.32. The outlet of the fuel emulsion from the transition system of the second carburetor chamber.33. Throttle valve of the second chamber of the carburetor.

Details about the design of the idle system of the carburetor 21073 Solex: “Idle system of the carburetor 21073 Solex, device”.

Notes and additions

— The Solex 21073 carburetor, unlike the Solex 2108, 21081, 21083, has an enlarged outlet located in another recess in the lower part of its body.

— The transition system of the Solex 21073 carburetor is structurally combined with the idle system. The transition system of the second carburetor chamber is autonomous.

— The carburetor solenoid valve is an element of the EPHH system.

More diagrams of the Niva carburetor Solex 21073

Source

When does a carburetor need repair?

This moment cannot be missed in principle. If the carburetor on a Niva does not work correctly, then even at idle the engine will not be able to operate correctly.

However, using quantity and quality screws is unlikely to get rid of the problem. In most cases it lies much deeper. It is very likely that the float systems have stopped working properly.

Also, the reason may be in the vacuum economizer for engine power modes.

If you try to drive off with the above-mentioned problems in the carburetor, the car will begin to twitch and sway. It is not surprising, because the fuel mixture that enters directly into the combustion chamber is prepared incorrectly.

In most cases it is over-enriched. During diagnostics, it is imperative to assess the level of nozzle clogging.

Nail Poroshin will tell you which carburetor is best suited for the Niva:

Name: Mikhail Reg.: 05.25.2006 Threads / Messages: 4 / 696 From: Samara Age: 32 Car: 2123

Reg.: 01/09/2008 Threads / Messages: 4 / 3014 From: Tolyatti Age: 44 Car: 2131 2001.

Reg.: 08/21/2007 Threads / Messages: 1 / 82 From: Novosibirsk Age: 40 Car: Niva 21219 1993

Hi all! Then a carb 2140-1107010-20 turned up for free. Who can say anything about this combination: VAZ 2121, 1.6 l + 2140-1107010-20? I’m asking not out of idle interest, but because of the possible sudden death of my 2107-1107010-20 :-((

Added after 6 minutes 11 seconds:

PS: on my first Muscovite I had the same one - there (1500 cc) it proved itself to be the best (reliable, simple, with reliable EPHH, modest in appetite).

Reg.: 03/03/2006 Messages: 1200 From: Ukraine. Kharkov Age: 42 Car: VAZ 2123 2008 in Geely Emgrand EC 7 2014

Reg.: 08/21/2007 Threads / Messages: 1 / 82 From: Novosibirsk Age: 40 Car: Niva 21219 1993

Carburetors on models 2121, 21213 and other cars, in general, have almost the same design. Functionally, it is located in the propulsion system, helping to mix the fuel until it becomes a combustible mixture.

Carburetor components:

- float chamber;

- jet (with spray);

- diffuser;

- throttle valve.

The carburetor can have from one to four chambers for different cars, simultaneous or sequential opening of the throttle valves. The movement of the working mixture is downward, upward or horizontal.

The carburetor circuit includes:

- diaphragm;

- drive lever from the accelerator pump;

- adjusting screw;

- needle valve;

- fuel supply fitting;

- economizer for power modes;

- block for heating the carburetor;

- air channel from the starting device;

- shut-off valve (solenoid);

- air damper;

- fittings for crankcase ventilation.

Niva 2121 has a certain sequence of passage of fuel elements through the carburetor chamber. First of all, fuel in a regulated amount passes from the fuel tank to the float chamber. In this case, the float lowers or rises as the fuel moves.

Then its path will lie through the nozzle into the atomizer, which is located in the narrow part of the diffuser, and at the same time air enters the carburetor through the outer pipe. The throttle valves then deliver some fuel into the engine cylinder through an intake manifold cast from aluminum alloys. The manifold is attached to the engine with studs through gaskets that have heat-resistant properties.

Preparing to modernize the engine power system

In order to install two carburetors, it is recommended to initially drain the antifreeze through the fuel heater. After this, it is necessary to dismantle part of the fuel system. To remove the intake manifold, you need to unscrew the five bolts that secure it.

Connecting the carburetor to the manifold is not done on the car. This type of work is carried out in good lighting. Having connected the carburetors one by one to the intake manifolds of the Oka, you need to open both chambers and check the condition of the joint. It is strictly forbidden to allow the edges of the collector to protrude above the joint. The air-fuel mixture will swirl at the junction at high speed and the engine will starve.

To eliminate protruding edges, use a metal cutter inserted into a screwdriver or drill. The transition between parts should be as smooth as possible. For better results, you can use sandpaper or special sanding pastes.

During a visual inspection, it is possible to detect sagging and casting defects in both the carburetor and the manifold. A car owner who independently installed and tuned the fuel system knows about the need for modifications, but a newbie may be surprised by the protruding pins inside the manifold. This creates strong resistance to air flow, which significantly reduces the effect of installing two carburetors.