03.03.2022 4,958 Cooling system

Author: Victor

Antifreeze circulation in the engine is the main requirement for the cooling system (CO). Due to the fact that the liquid passes through all components of the CO, stable operation of the motor is ensured and it is prevented from overheating. We will describe below what elements the cooling system consists of and how consumables circulate.

[Hide]

Video “Design and principle of operation of the cooling system”

This video shows how antifreeze circulates in the cooling system.

One of the special liquids that is designed to ensure the correct operation of car mechanisms is antifreeze.

If you do not properly treat the quality and level of antifreeze in the tank, this can lead to quite serious malfunctions, both individual parts and complete machine components.

The principle of operation of antifreeze. The engine cooling process involves circulating coolant through a specific circuit of hoses and tubes. In a situation where the engine has not yet warmed up to the required temperature, the antifreeze pump will only circulate in a small circle, which includes the cylinder block, cylinder head and stove. If the antifreeze is already heated to a temperature of 90-100 degrees Celsius, the thermostat opens, and the coolant goes through the same circle, but with the radiator captured.

As the antifreeze warms up, its volume increases to 5%, which is returned back to the tank. Once the antifreeze cools, it is sent back to the engine. This operating principle makes it possible to prevent the occurrence of air and steam plugs.

If the antifreeze level has decreased, then there may not be enough of it to cool the engine. As a result, situations arise when air-steam plugs appear in the system, which necessarily disrupt the functioning of the system.

The result of such a situation is excessive heating of the head, its destruction, the occurrence of various types of defects in the oil supply channels, an increase in fuel consumption and a decrease in machine power.

With an increased amount of antifreeze in the tank, the pressure throughout the system will increase. The consequence of this may be a leak in the radiator, tank cap or hoses.

Dependence of antifreeze volume. The level of engine cooling fluid depends on several parameters, which include:

- Ensuring the integrity of the gasket itself, cylinder head, radiator, tank, tubes and hoses;

- Correct operation of the radiator and tank valves;

- Proper operation of the fuel ignition system;

- Correctly selected brand of antifreeze.

Correctly fixed hoses using clamps of the required size;

If there are defects in either the cylinder head or the gaskets, the cooling liquid will penetrate either the cylinders or the oil. A sign of this will be thick white smoke in the first case, and bubbles in the oil in the second.

If the gasket is broken, then both of these signs will be present at the same time. In addition, the car owner will pay attention to an increase in fuel consumption, as well as a decrease in engine power.

If there is damage to the valves of the tank or radiator, the boiling point of the antifreeze will be reduced, which will certainly lead to the appearance of plugs. A mixture that is too rich, on the contrary, will lead to the need to use increased force to press the gas pedal.

Checking the antifreeze level. To correctly check the antifreeze level, you need to perform the steps in this order:

- Remove the reservoir cap with the engine cold;

- Inspect the lower edge of the outlet to which the expansion tank hose is attached. The fluid level must correspond to this;

- When inspecting the expansion tank itself, the location of the antifreeze level should be exactly between the minimum and maximum.

Bottom line. Checking the coolant in the car's tank should be carried out as often as possible, at least twice a week. Timely addition of antifreeze ensures proper engine cooling.

Hello everyone, my dear readers! Even a high school student today knows that a modern car is equipped with several key systems. Some are responsible for power, another for lubrication, and the third for cooling from overheating. I propose to dwell in more detail on what kind of coolant circulation scheme is provided - the understanding of the importance of cooling in general will depend on this.

Hydraulic pump problems

One of the reasons for overheating of the car’s power unit may be a malfunction of the cooling system pump. Most often the problem is that the hydraulic pump drive belt has broken or its tension is too weak. In this case, the pump will stop pumping antifreeze, or will not do it fully. Checking this is quite simple, you just need to bring in the engine and observe the behavior of the drive belt. If it works with slippage, the tension should be increased or the belt should be completely replaced with a new one. Most often this solves the problem.

Situations arise when the problem lies in the pump itself: wear of the impeller, bearing, and sometimes even a crack in the shaft. Among other things, the joints connecting the pipes to the pump may not be sealed, and the pressure created by the pump will cause a coolant leak. Diagnosing a leak is quite simple; you need to place sheets of white paper on the floor under the engine for several hours. If even small spots of blue or greenish color are visible on it, this indicates wear on the pump gaskets.

You can check the functionality of the pump itself by holding the upper radiator hose with your fingers for a few seconds while the unit is running. A working pump will create strong pressure and after releasing the hose, you will feel as if the liquid is quickly running along the line. It is also worth remembering that increased noise of the internal combustion engine and play in the pump pulley indicate bearing wear. Usually its wear is associated with fluid seeping through the seal, which washes the lubricant from the bearing.

Water pump design for engine cooling system

The coolant pump, unlike the thermostat, can be partially replaced, but often car owners prefer to completely change the mechanism.

It is recommended to replace the pump every 90,000 km, or after every second replacement of the timing belt (gas distribution mechanism).

- First of all, it is necessary to disconnect the vehicle's mass from the battery, and the piston of the first cylinder must be at top dead center. Dismantle the belt tension roller and remove the camshaft pulley.

- Next, you should drain the coolant from the bottom plug in the radiator.

- After unscrewing the pump's mounting bolts, it must be disconnected from the cylinder block.

- By visually assessing the removed mechanism, it is important to determine its wear. If the impeller, oil seal and drive gear are damaged, it is better to replace the pump completely.

- The new mechanism must be installed with a new gasket, since the old one may have even minor damage, which will subsequently lead to a coolant leak. The pump is installed so that the number indicated on the body faces up.

- Further assembly is carried out in the reverse order of disassembly. It is better to fill in new coolant, but you can also use the existing one if its resource has not yet been exhausted.

What happens on a cold engine

While the internal combustion engine is operating, it produces significant amounts of heat. As a result, many different parts are exposed to high temperatures. To remove excess heat, a scheme for the movement of antifreeze in different circles was provided: the so-called “large” and “small”. Each of them is closed, but differs in the list of equipment and parts that are involved in it.

We talk in more detail about how the cooling system works in a separate article. So, we start the engine, and antifreeze immediately begins to circulate. This is ensured by the operation of the water pump, which, in turn, operates thanks to the drive belt. At the beginning, our engine is still cold, so fluid circulates between it and the water pump. This is called a small circle, and this happens until the engine warms up to a certain temperature level.

After this, the thermostat automatically closes the small circle, but opens movement in the large circle. The pump again pumps antifreeze into the power unit. As soon as its temperature rises to the operating level, it reaches the radiator through the pipes. With its help, excess heat is released into the environment, and the engine again operates at an acceptable temperature.

Thermostat wear

Most often, problems in the system are associated with the valve that switches the circulation circles, also known as the thermostat. If a part jams in one position or the valve does not close the channels of the circulation circles tightly, warming up the engine may take much longer or, conversely, the unit will begin to overheat severely without sufficient cooling.

Thermostat operating principle

As a rule, thermostat failure is associated with a violation of its integrity. The basis of the valve is thermal wax, which, when heated, expands and compresses the membrane, opening a large circulation circle. If the wax leaks out of the part for any reason, the valve will stop functioning and the antifreeze will not be able to fully cool. Wear may also be caused by untimely replacement of the coolant or its poor quality. Corrosion of the thermostat spring causes the part to jam in the open or, less commonly, closed position. In both cases, the engine will not be able to operate in the normal temperature range - the liquid will either be constantly cooled, even when it is not necessary, or, conversely, will be hot all the time.

Thermostat spring is corroded

Determining wear is quite simple and can be done in two ways. The easiest way to check is with a non-removable method. To do this, immediately after starting the engine, touch the radiator inlet pipe. If it becomes warm almost immediately after starting the engine, this indicates that the thermostat is stuck in the open position. Conversely, when the hose remains cold even if the temperature indicator is at its peak, this indicates an inability of the thermostat to open.

You can more accurately verify that the reason for the incorrect operation of the cooling system lies precisely in the malfunction of the thermostat by dismantling it. The removed valve is placed in a container of water and heated. When the water temperature reaches 90 o C, a working valve must work - the thermostat rod will move. If this does not happen, you can confidently consider the part to be faulty.

A failed thermostat cannot be repaired and must be replaced. Its cost for most cars rarely exceeds 1000 rubles. It is quite possible to replace the valve yourself, without visiting a car service center.

Using a “large” circle

The cooled antifreeze is re-entered into the engine by pumping it through the water pump. However, a situation may arise in which this is not enough for normal cooling. Fans will come to the rescue, and their activation will be ensured by a special sensor. It’s called the “fan switch” and is located under the radiator. When its contacts close, these devices turn on, providing additional forced cooling.

After a while, the antifreeze temperature drops and the fans turn off. A figure around 90 degrees is considered conditionally acceptable for most internal combustion engines, although some thermostats are designed to maintain 87 degrees. The efficient operation of the entire cooling system as a whole is achieved by using the above-described scheme. When the engine is not warmed up, heat removal is not required. But in further work it will be necessary to include additional equipment in the cooling process.

The effectiveness of this scheme

It’s not for nothing that manufacturers have set a certain temperature regime. It is with this that thermal clearances are optimal. All this manifests itself in the behavior of the engine. Its power increases, while dynamics and throttle response increase. At the same time, fuel consumption returns to normal. The task of the cooling system is not only to lower the temperature, but also to warm it up as quickly as possible - and this is necessary for it to reach its performance level. This situation is most relevant in cold weather. That is why there is a division into a large circle and a small one.

Dear subscribers! Poor circulation of coolant will definitely make itself felt; in some cases, flushing the system can help. These could be various leaks and wet spots, a drop in the level of antifreeze in the tank, overheating of the engine with loss of its dynamics, etc. I recommend inspecting your car more often not only from the outside, but also under the body and in the engine compartment. We'll come back to the topic of cooling, bye!

liquid during, this will lead to increased.

Cooling system requirements:

• automatic maintenance of optimal thermal conditions in the engine, independent of operating mode and external conditions; • quick warming up of the engine to operating temperature; • long-term heat retention after stopping the engine; • low energy costs associated with driving the cooling system units.

The combustion of a combustible mixture is accompanied by the release of a significant amount of heat. If the engine is not cooled or cooled insufficiently, its parts can heat up to a high temperature, and this reduces their strength and filling of the cylinders, worsens the operating conditions of the lubrication system due to a decrease in the viscosity of overheated oil, accelerates the response of oil additives and increases the amount of deposits and soot on parts .

"Most automobile engines have closed-type liquid cooling systems".

Types of coolant

The cheapest liquid is water, especially if it is soft. It has good heat capacity and low viscosity, which allows it to seep through small holes. However, it is highly corrosive and freezes at relatively high temperatures, so it is replaced with antifreeze.

In Soviet times, there was an institute that was engaged in the development of coolants. The totality of all liquids that fight freezing and icing is called antifreeze (translated as “anti-freeze”). These include an aqueous solution of ethylene glycol, less commonly propylene glycol, which is non-toxic, but much more expensive.

Antifreeze not only freezes at lower temperatures, but also expands less when it freezes. For example, water expands by 9%, and a 40% aqueous solution of ethylene glycol expands by only 1.5%. The freezing process also occurs in different ways. When water freezes, it turns into a solid monolith, and the ethylene glycol solution crystallizes without harming the mechanisms.

Additives that are included in antifreeze are aimed at fighting corrosion, lubricating rubbing parts, and fighting foam. It is also important that they also have an increased boiling point, which has a beneficial effect on the engine.

With all the advantages, ethylene glycol antifreezes also have disadvantages. The main one is high toxicity. For a person weighing 70 kg, 140 milliliters is enough to cause death. Not only the liquid itself is poisonous, but also its vapor. Even a small leak in a heating radiator can lead to serious consequences. For timely detection of malfunctions, such antifreezes have fluorescent properties.

Another disadvantage is the large expansion coefficient. For new cars this is not a problem, they already have an expansion tank for this case, but for old ones without modification it will be difficult. When hot, the antifreeze will be released, and when it cools, the level will drop significantly. There is another difficulty, which is much more difficult to cope with.

Antifreeze transfers heat worse, by about 15 - 20%. In hot weather, it simply cannot do its job, and the motor may overheat.

The shelf life of ethylene glycol is limited to 2 - 3 years; at elevated temperatures, the shelf life is greatly reduced, and when the temperature exceeds 105 degrees, additives that lubricate engine parts are quickly destroyed. To improve quality, silicate antifreezes began to be used. In the USA and Japan, phosphate antifreezes are used, but for Europe they are unsuitable due to increased water hardness.

Liquid cooling system

The liquid cooling system is more inertial; the engine warms up slowly, but also cools down slowly. In addition, the large heat capacity of the coolant ensures intense and uniform heat removal and lower temperature of parts.

The heat removed from the engines is used to heat the intake manifold and improve mixture formation, as well as to heat the cabin or interior of the car in cold weather.

Cooling system devices:

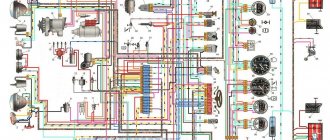

radiator 3, fan 1, liquid pump 8, cylinder block cooling jacket, cylinder head cooling jacket, thermostat 10, pipes 6, 17, hoses 9, expansion tank, fluid temperature monitoring devices 13, drain valves 18, 19.

Cooling system operation

Liquid circulation in the cooling system is carried out in two circles: small and large .

in a small circle when the engine is started cold, ensuring its rapid warm-up in the following sequence: liquid pump - distribution pipes - cylinder block cooling jacket - cylinder head cooling jacket - upper thermostat pipe (valve closed) - bypass hose, receiving cavity of the liquid pump.

Water pump repair technology

Signs and causes of malfunctions

Engine overcooling is accompanied by an increase in mechanical losses due to an increase in oil viscosity, a deterioration in the processes of mixture formation and combustion, resulting in increased fuel consumption. Condensation of water vapor in the crankcase cavity of a cold engine and on the cylinder walls leads to corrosion. The content of hydrocarbons from unburned fuel and highly toxic aldehyde compounds increases in the exhaust gases. Forced removal of heat from engine parts is carried out using liquid or air, and therefore a distinction is made between liquid and air cooled engines.

The radiator is the heat exchanger of the cooling system, where the fluid coming from the engine transfers heat to the air flow.

installation of an expansion tank,

modification of the radiator cap

The filler plug in closed liquid cooling systems has two safety valves with sealing rubber gaskets and springs. The steam valve is adjusted to excess pressure (0.145-0.160 MPa), the air valve opens when the pressure in the system drops against atmospheric pressure by no more than 0.01 MPa.

During normal operation of the valves, the cooling system can only briefly communicate with the environment or the cavity of the expansion tank.

Blinds are installed in front of the radiator; they help regulate the amount of air passing through the radiator core. Blinds are made in the form of a set of vertical or horizontal plates - sashes made of galvanized iron, which are united by a common frame and equipped with a hinge device that ensures their simultaneous or group rotation around its axis. The blinds are attached to the radiator frame or to its outer lining. The shutters are controlled manually or using a device with a thermostat.

The liquid pump will create forced circulation of liquid in the cooling system. Single-stage centrifugal-type liquid pumps are used. The pump drive is usually driven by a crankshaft pulley via a V-belt drive.

The liquid pump consists of a housing, a drive shaft with an impeller, a hub for attaching the drive pulley, a self-clamping sealing collar, two brass clips, a rubber collar, a sealing washer and a spring ring. The pump shaft rotates on two ball bearings.

centrifugal pumps , designed for pressure and 0.04 -0.1 MPa, are compact and provide sufficient fluid supply with relatively large gaps between the impeller and the housing walls.

cooling system malfunction

It is worth mentioning that the engine is forced to cool, which means it maintains excess pressure (up to 100 kPa), as a result of which the boiling point of the coolant rises to 120°C

.

small circle of circulation

large circle of circulation

An electrically heated thermostat is also found on powerful engines. Full opening of such a thermostat occurs under heavy load on the internal combustion engine. The fan is an important part of the radiator. It increases the cooling intensity and can operate on different drives such as mechanical, electric or hydraulic. Most often, cars are equipped with an electric drive. The elements of the control system have their own purpose and allow you to use the entire system at full capacity. The temperature sensor displays the necessary information on the screen, converting it into a signal. The electronic control unit receives signals from the sensor, converts them into execution signals and transmits a coded signal to the same devices. The execution devices perform the tasks assigned to them, having received a certain signal. Among them are: heater, relay, fan control unit, another relay for the engine.

The engine cooling system consists of the following main parts:

- radiator

- expansion tank

- coolant pump

- fan

- thermostat

- supply lines

The engine cooling system allows the engine to quickly warm up and protects it from overheating, maintaining an optimal temperature. The radiator is connected by a tube to the expansion tank. The radiator neck is closed by a plug equipped with a safety valve that dumps excess heated fluid from the radiator into the expansion tank, as well as an inlet valve that allows the fluid to return to the radiator if the engine temperature drops.

The protrusions of the plug in the “closed” position should be adjacent to the tank. The fluid level is checked at the expansion tank. If the fluid level drops below the “LOW” mark, it is necessary to add enough fluid so that the level rises to about.

The coolant pump, installed at the front of the engine housing, is driven by a timing belt.

Rice. Components of the cooling system in the car (radiator, expansion tank, fan): 1 - radiator, 2 - radiator cap, 3,4,5 - fastening elements, 6 - fan casing, 7 - fan impeller, 8 - fan motor, 9 - expansion tank, 10 - tube connecting the radiator to the expansion tank

Rice. Components of the cooling system (fluid supply line): 1 - thermostat cover, 2 - cover gasket, 3 - thermostat, 4 - radiator inlet hose, 5 - radiator outlet hose, 6 - engine inlet hose, 7 - engine inlet pipe, 8 - gasket, 9 - inlet hose of the radiator of the heating device, 10 - outlet inlet hose of the radiator of the heating device.

Radiator and fan problems

Insufficient engine cooling may be due to problems with the radiator and fan. First of all, it is worth remembering that a radiator that is too clogged with dust and insects is unable to be fully cooled either by the oncoming air flow or by the fan. Often cleaning it solves the cooling problem.

The design of a “classic” engine cooling radiator. In many modern engines, coolant is not poured through the radiator neck, but into the expansion tank.

And yet, more serious situations are also possible - radiator cracks, which can occur both during an accident and as a result of corrosion. In most cases, the radiator can be restored. Brass and copper are repaired using soldering, and aluminum with special sealants.

Before soldering, the damaged areas are thoroughly cleaned with emery cloth until a metallic shine appears. Afterwards, the crack is treated with soldering flux and a uniform layer of solder is applied using a powerful soldering iron (see video).

It is not possible to solder an aluminum radiator, however, special sealants are offered for repairing them, or you can use regular “cold welding”. Before starting to seal cracks, it is important to thoroughly clean the defective areas. The adhesive mass is well kneaded until smooth and applied to the problem area. It is worth remembering that the car can only be used the next day after repair - epoxy glue takes quite a long time to dry.

As for the cooling fan, its failure may be due to a break in the electrical wiring or a disruption of the drive from the crankshaft if the rotation is transmitted from the power unit.

In the first case, it is worth visually assessing the condition of the wires going to the fan motor; if a break is detected, you need to reconnect the damaged contacts. If the condition of the wires is normal, but the fan still does not work, the motor itself or the sensor responsible for its timely activation may have broken down. In this case, it is better to contact a car service center, where they will determine the reason why the fan does not turn on. If there are problems with the sensor, the airflow may either continuously or not turn on at all.

In cars where the fan begins to rotate when transmitting torque from the engine, the breakdown is most often associated with a broken drive belt. Replacing it is quite simple: you need to loosen the pulley tension and install a new belt.

Read more about the design and repair of a cooling fan here.

CO components

The operation circuits of cooling mechanisms include many elements. Each of the parts performs its own functions; accordingly, for the ideal operation of all systems, the elements must be in good condition, and they must not be affected by external negative factors. There are times when coolant is not circulating and this is a sign that one of the components is not working properly.

- Radiator. Its task is to reduce the temperature of the refrigerant under a constant flow of cold air. Heat output is increased, thereby increasing efficiency and cooling capabilities, allowing you to get more work done in less time.

- An oil radiator can be installed along with the main one. It is designed to cool the lubricant.

- Another type of device of the same type is a radiator designed to cool exhaust gases. It is necessary to reduce the combustion temperature of the fuel mixture.

- The job of the heat exchanger is to heat the air. The operation of this device will be more efficient if it is installed at the point where the coolant exits the engine.

- The expansion tank helps compensate for the changing volume of coolant as a result of its expansion.

- The circulation and movement of coolant is provided by a centrifugal thrust pump. Such a pump is often called a pump. The operating system may vary depending on the type of device. In particular, there are pumps on a belt, and there are pumps on gears. Some powerful engines require the installation of an additional pump of the same type.

- Thermostat. The purpose of this device is to set the level and amount of refrigerant. All refrigerant is controlled, thereby maintaining the most acceptable temperature conditions. You can find the thermostat in the middle between the radiator and the cooling jacket in the pipe.