Frequency of the procedure

Despite its amazing maintainability, the ZMZ-402 was not very successful in its technical characteristics. The lower location of the camshaft, the presence of long pushrods, and the not very high quality of the parts, all this increases the vibration load on the gas distribution mechanism, and therefore reduces the time interval between adjustments. If the motor is used carefully, without operating under maximum load and without sudden starts, then adjustments must be made every 15 thousand kilometers. If the driver likes quick starts, driving at low speeds and high gears, and is also forced to carry heavy loads or drive through the mountains, then the mileage is reduced to 10 thousand kilometers. If you use gasoline that does not match the cylinder head (cylinder head), then regardless of the ignition settings, the valves must be adjusted after 5–6 thousand kilometers . This will reduce the likelihood of valve burnout and loss of compression.

This is interesting: Do-it-yourself adjustment of ZIL 130 valves

The size of thermal gaps

In the official ZMZ-402 maintenance manual, the thermal clearances of the intake and exhaust valves are defined as 0.40 mm. However, this adjustment is only suitable for Gazelles that constantly carry heavy loads. It is known from experience that reducing the thermal gap to 0.25–0.3 on the intake and exhaust valves allows increasing the throttle response and torque of the engine, as well as reducing fuel consumption. However, this only applies to quiet driving. If you like to drive fast, take off abruptly, or often drive in the mountains, then the clearances must be increased to 0.30–0.35, and in especially severe cases to 0.40.

It is also necessary to increase the gaps to 0.40 if the cylinder head is for 92nd gasoline, and you drive 76th (80th). And vice versa, if the head is for AI-76 (AI-80), and you fill in AI-92. If the cylinder head is for 92 gasoline, and you drive on liquefied natural gas (LNG), then the clearance should be 0.35 for the intake valves and 0.40–0.45 for the exhaust valves. You cannot use gas from a cylinder head for 76-octane gasoline; the pistons and valves will quickly burn out.

Hello everyone. Tortured by the crackling of valves. I tried to adjust according to the book, but the marks on the damper (crankshaft pulley) did not coincide with the first cylinder. What to do, what to do? Given; ICE-402 Mileage: 170,000 km. There is no wear on the rocker arms (from a Gazelle with a mileage of 23,000 km.) The rods are free of scuffs and signs of friction. Yes, and explain to the clueless. The book says: “...after adjusting the 1st cylinder (intake, exhaust), adjust through one to the 4th cylinder. Then rotate the elbow 360 degrees.” Is it possible to put it in the same place under the first cylinder? Sorry for the stupid questions, but I always had a 405 engine. Thanks everyone and beer from me

Adjusting valves GAZ 402

The ZMZ-402 engine has been produced since 1985; it first appeared on the transitional GAZ 24M models. It is also widely used

on Gazelles. The eight-valve engine has a lower camshaft and an overhead valve arrangement; its gas distribution mechanism contains the following parts:

- camshaft, it rotates in five supports of the cylinder block;

- camshaft, transmits movement from the crankshaft to the camshaft;

- 8 pushers, driven by camshaft cams;

- 8 aluminum rods;

- the rocker axis, on which the rocker arms themselves are located (8 pcs.) with adjusting screws;

- exhaust and intake valves located in the cylinder head.

When the camshaft rotates, the valves in the cylinder head rise and fall. Just like all other modern engines, the ZMZ-402 operates on a four-stroke circuit:

- first, an intake occurs into the internal combustion engine, the air-fuel mixture fills the cylinder;

- then the mixture is compressed in the cylinder, and it is ignited by a spark from the spark plug;

- working progress occurs;

- The last step in the process is the release of exhaust gases.

When compression occurs, both valves are closed and sealed - the valves are adjusted in this position. In order for the combustion chamber to be sealed at the moment of compression, there must be a thermal gap between the valve stem and the rocker arm - if there is none, when the metal expands on a hot engine, the valve will not fit tightly to the seat (seat), the engine may lose power, and in some cases In some cases, it will not start at all.

The valves on the ZMZ-402 can be adjusted in two ways. In the first option, the adjustment is made as follows (let's take the GAZ 24 car as an example):

- stop the engine, turn off the ignition, put the car in neutral;

- open the hood, remove the air filter housing;

- remove the valve cover, it is held on by six bolts;

- crank the crankshaft, align the first cylinder with the marks. The mark is located on the front crankshaft pulley;

- It should be noted that the marks on the pulley may coincide at TDC (top dead center) of the 1st and 4th cylinders, and if the valves of the 1st cylinder are clamped while the valves of the fourth are free, then the marks coincide with the 4th cylinder , and not with the 1st. This can be easily checked - remove the distributor cover and look where the slider points;

- adjust both valves on the first cylinder (gap 0.3 mm), turn the engine half a turn clockwise (the marks should be at the bottom)

- adjust both valves on the second cylinder;

- turn it another half turn (the marks are again at the top and coincide), adjust the valves of cylinder 4;

- We make another half revolution of the crankshaft (the marks are again below) and make adjustments on the third cylinder.

Close the valve cover, start the engine and check how the engine works. Valve clearances on all GAZ vehicles are adjusted using special feeler gauges; they are usually collected in one set.

There is such a thing as valve overlap, and if the valves of the first cylinder (at TDC) are free, both valves of the 4th cylinder will be clamped, but on the second and third, one valve each will remain free. Therefore, the adjustment can be done in two crankshaft rotations:

- set the TDC of the first cylinder, adjust the valves 1-2-4-6, counting them from the front of the engine;

- make a revolution of the crankshaft and adjust all the other valves (3-5-7-8).

In the books, it is recommended to carry out the adjustment on the cold side, on the outer valves (1) and set the gap to 0.35 mm, on the rest - 0.3 mm. But the cold adjustment cannot be done - aluminum rods expand as the engine heats up, and the gaps in the valves on a hot internal combustion engine decrease. Practice has shown that the most optimal option is adjustment on a well-warmed-up engine with gaps of 0.3 mm on all valves. By the way, the valve clearances on the GAZ 21 Volga are adjusted in the same way.

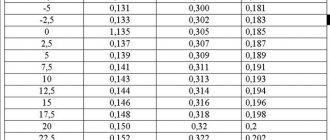

The size of the gaps in the valve drive:

| Cylinder number | Valve | size , mm |

| 1 | Inlet Outlet | 0,40 – 0,45 0,35 – 0,40 |

| 2 | Inlet Outlet | 0,40 – 0,45 0,40 – 0,45 |

| 3 | Inlet Outlet | 0,40 – 0,45 0,40 – 0,45 |

| 4 | Inlet Outlet | 0,40 – 0,45 0,35 – 0,40 |

Tightening torque of the cylinder head and other connections of the ZMZ 402 (ZMZ 4021) engine

How to regulate?

When all the preparatory work has been completed, you need to proceed to the actual setup. The piston in the first cylinder must be set to TDC during the compression stroke. The valves are closed at this moment. Try to insert a dipstick between the pusher and the valve. If it goes very easily or, on the contrary, does not fit at all, adjustment is needed. To do this, loosen the locknut and hold it with a wrench. By rotating the adjusting screw, the desired clearance is achieved. In this way, the valves of the UMZ-4216 Gazelle engine are adjusted for elements 2, 4 and 6. After the gaps are adjusted, do not forget to tighten the lock nut.

Next, the crankshaft is rotated 180 degrees, and access to valves 3, 5, 7 and 8 will open. After these elements have been adjusted, you should turn the engine over again and use a feeler gauge to check the gap. This will guarantee that the valve adjustment of the 4216 Gazelle engine is performed correctly.

Preparation process

Tools and consumables necessary for the procedure are included in the following list:

- universal probes for measurements;

- set of socket and socket wrenches;

- set of wrenches;

- valve cover gasket;

- spark plug key;

- powerful flat and Phillips screwdrivers;

- hammer;

- clean rag.

Before you begin work on adjusting the valve clearances of the ZMZ-402 valves, you need to familiarize yourself with some of the nuances of the operation. It is important to remember that valve adjustment can only be done when the engine is cold. The state of a cold engine implies equality of the internal temperature of the motor and the external temperature.

The preparation stage includes the following activities:

Checking the engine clearance with a feeler gauge

- unscrewing the license plate in order to install the starter (unit of the starting system of the mechanism);

- removing spark plugs;

- removing the distributor cover (ignition distributor);

- Isolating the negative charge of a car battery.

The type of fuel also affects the dimensions of thermal gaps. The cylinder head, which is designed for No. 92 gasoline, but is used with No. 80 fuel, needs to increase the clearances to 0.4 mm. The use of gas and gasoline No. 76 for the cylinder head is not recommended, since such a case can cause burnout of the valves.

GAZ 2002, 92 l. With. - with your own hands

Novoaltaysk

GAZ 3110 Volga, 2004

50 000 ₽

Khabarovsk

GAZ 31029 Volga, 1994

30 000 ₽

Ulan-Ude

GAZ 3102 Volga, 2000

90 000 ₽

Chelyabinsk

GAZ 31029 Volga, 1996

60 000 ₽

See more cars on Drome

Participate in the discussion can only registered users.

Login Register

Required Tools

To correctly adjust the valves of a Gazelle with a 402 engine, you need to prepare the following tools:

- set of screwdrivers;

- probes of different sizes or a universal probe;

- ratchet with extension and 10 mm socket;

- a set of keys, sizes from 8 to 14 mm;

- spark plug key;

- hammer;

- rags.

This is interesting: Adjusting headlights with your own hands - how to set them up

Why do you need to adjust valves?

If suddenly there is extraneous noise when the engine is running, then most likely you will have to check the engine or valves. Gazelle diagnostics:

- It is best to do the inspection using a stethoscope; the K-69M GARO model is suitable for this case.

- In this case, the gazelle engine must be warmed up, and it must be checked at different crankshaft speeds.

- You will have to listen carefully at the lowest speed, then at the middle one, starting with the distribution mechanism, and then checking the operation of the valves (750-1000 rpm).

Sounds from damaged valves are heard best in the place where the head is located, above their locations.

Disassembled engine 4216

But if the sounds are too loud and they come from the valves or pushrods, or if the crankshaft speed increases and these sounds merge into a general hum, then the engine is fine.

It is necessary to adjust the Gazelle 4216 valves if they periodically knock, appearing and then disappearing if you sharply change the crankshaft speed.

Adjusting the valves of Gazelle 4216

UAZ valve clearances

One of the main types of work is periodic adjustment of valves on UAZ 469, UAZ 417, UAZ 421, and also, if possible, cleaning them from carbon deposits.

The UAZ 469 valves on UMZ 421 and 402 are quite reliable in operation, since they are made of chromium steel, and when working on the exhaust valves, heat-resistant steel was used. To adjust the valves on the UAZ 469, like the UAZ 3303, including those with the 402 engine, it is necessary to check the gap between the valves and pushers at certain intervals. If the gaps are larger than normal, then it is more difficult to start the engine, and its operation is accompanied by knocking in the valves and a drop in power.

In the case of reduced valve clearances in the UAZ 469, problems occur in the carburetor, “coughing” and popping noises in the muffler, and the engine cannot develop maximum power. There is a problem with the carburetor (you can hear it). The gaps should be set in accordance with the standards on a cold engine during TO-2.

How often does it need to be tuned?

When operating a vehicle under high load - transporting heavy loads, driving in the mountains and at low speeds - the adjustment period is reduced to 8-10 thousand km. And if gasoline that does not match the cylinder head is poured into the tank, the valves need to be adjusted every 5-6 thousand kilometers. Otherwise they will burn out and the engine will lose compression.

To avoid stripping the threads while adjusting the valves, the nut must be rotated very smoothly with a wrench at the beginning of unscrewing and at the last turn of tightening. The tips of the valve mechanism rods of the ZMZ-402 engine are made of duralumin, and not steel, as on the ZIL-130, for example. Therefore, it is extremely difficult to adjust the valves by ear. Rattling and knocking noises can be made by:

- worn camshaft cams;

- unevenly operated rocker arms;

- worn out axis;

- loose springs.

Valves with a defective camshaft cannot be adjusted properly. Therefore, it would be more advisable to replace the camshaft. The same applies to worn-out spring retainers, since the rocker arms in this case will rest not against the valves, but against the spring cups.

Table: useful technical data for 402

| Cylinder operating order | 1-2-4-3 |

| Direction of rotation of the distributor rotor | counterclock-wise |

| Ignition timing, degrees | |

| centrifugal regulator | 15-18 |

| vacuum regulator | 8-10 |

| Spark plug | A14VR |

| Spark plug gap, mm | 0,8-0,95 |

| Slider resistance, kOhm | 5-8 |

| Spark plug tip resistance, kOhm | 4-7 |

| Resistance of the central contact of the cover, kOhm | 8-13 |

| Stator winding resistance, kOhm | 0,4-0,45 |

Preparatory work

How to adjust engine valves? To begin with: all work on the engine unit must be carried out after the machine has cooled. After the trip, leave the car in the garage for several hours, this will be quite enough.

Before getting to the valves themselves, the assembly must be partially disassembled and some parts removed. Here is the sequence of work:

- Disconnect the battery terminals.

- Next, you will need to remove the top cover of the air filter, unscrew the fasteners of the part, disconnect the crankcase pipe and the ignition distributor hose.

- We remove the filter itself.

- Carefully disconnect the throttle linkage from the carburetor, then do the same with the air damper.

- In front of us is the valve compartment cover; all that remains is to remove it by twisting a few fasteners.

Step-by-step instruction

Once you have reached the valves and the 402 engine has completely cooled down, you can begin the adjustment process itself. Here's what will come in handy when working:

- spanners;

- probes.

The work sequence is as follows:

- The first thing to do is get the crankshaft in the correct position for the job. We take a 36mm wrench, hook the ratchet and start rotating it clockwise. We're not in a hurry. As soon as the last mark on the pulley is opposite the mark on the cover, stop the rotation.

- We begin checking the valves of the first cylinder. First make sure they are all closed.

- Adjustment begins with the exhaust valves. We take out the probes and start checking. Normal readings are 0.4 mm, but 0.05 mm less is acceptable. Loosen the locknut before tightening the screw. If the value is greater, tighten the screw, insert the probe and double-check. Twist until a satisfactory result.

- After adjustment, tighten the locknut. After manipulation, the large probe should not pass into the gap between the parts.

- Next is the inlet element. We check the gap again, but this time the limit is 0.4 mm + 0.05 mm. If necessary, loosen the locknut, tighten the screw, tighten the locknut. Let's check.

- Next, the cylinders are adjusted in the following sequence: 2, 4, and the last 3.

- When moving from one cylinder to the next, you need to turn the crankshaft half a turn (180°).

- Adjusting the valves will take a few hours the first time, but the next time everything will go much faster.

- After adjustment, clean the cover and valves.

- We put the gasket on and screw on the compartment lid.

- We put the air filter back and install everything that was previously dismantled, only in the reverse order.

After cleaning and adjusting the valve on the Gazelle 402, the car’s engine should run much quieter. In addition, the vehicle’s normal speed performance will be restored. Fuel consumption will also be reduced. For the next 100 thousand km, you can forget about re-adjustment. After 3-4 adjustments, do not forget to inspect the integrity of the assembly parts; some of them may need to be replaced during operation.

UMZ-4216 with hydraulic compensators

There is an opinion that on engines with hydraulic compensators no adjustment of valve clearances is necessary. But this is not about this engine.

On this unit the valves never release and are constantly clamped. To determine which elements can be adjusted, you will need a level bar. It is installed between the third and fourth valve. Using the bar you can see the slope in one direction. By this slope you can understand whether the valve is clamped. If the bar is inclined towards the fourth valve, then it is weakened, and towards the third it is clamped. This will indicate that the valve adjustment of the 4216 Gazelle engine with hydraulic compensators will begin from the first cylinder. The first, second and fourth valve can be configured.

To adjust, first unscrew the nut. Then unscrew the bolt until the hydraulic compensator stops pressing on it. Make one turn of the screw on the intake valve, and two and a half turns on the exhaust valves.

After such valve adjustment, the 4216 Gazelle Business engine begins to operate much quieter. And the work itself becomes softer. For those whose Gazelle runs on gas, such adjustment is simply necessary. As for mileage and the need for tuning, everything is individual and depends on the style of use of the car. Often the interval is about 15-20 thousand kilometers. But if the engine begins to make a characteristic clattering sound, valve adjustment may be required earlier. Therefore, it is better to prevent this problem.

The easiest way to adjust valves on a gazelle engine

Correct valve adjustment is one of the most important processes responsible for the operation of the gas distribution mechanism. A clear sign that the valves need to be adjusted is a characteristic ringing sound and poor engine starting when hungry. Adjusting the valves on a Gazelle with a 402 engine is not difficult and can be done by any car owner, the main thing is to know the procedure for adjusting the valves on a Gazelle and the gap that needs to be set depending on what fuel the engine runs on (gas or gasoline).

After watching this video, you can clearly see the easiest way to adjust the valves on the 402 Gazelle Business engine.

And so, to start adjusting the Gazelle valves, you need to remove the valve cover. Then use the key to “36” to set the crankshaft according to the mark (rotate clockwise) to install it at TDC. Then, using the keys “11” and “14”, we check the gaps with a feeler gauge and set them to the required value. Before you start checking and setting valve clearances on the Gazelle engine, you need to know three main points:

- The engine operating order is 1-2-4-3 ;

- Adjustment is made only on a cold engine ;

- The clearances on the exhaust valves of cylinders 1 and 4 should be slightly smaller than on the others (about 0.05 mm).

When the engine is running on gas, the valve clearances are set 0.05 mm larger (exhaust - 0.4 mm, and intake - 0.3 mm) than when running on gasoline, because then the valves will be pinched.

The feeler gauge under the seat should go in with little effort.

The easiest way is to set the clearances (intake and exhaust) first on the first cylinder, and then set the clearances through one valve. Then, turning the shaft 360 degrees, continuing to set the gaps from the 4th cylinder.

If anyone needs to see the whole process clearly, then watch a video on adjusting valves on a Gazelle.

Attention:

The tip of the screwdriver should fit tightly into the screw slot, so you need to select the appropriate screwdriver. Otherwise, you will simply damage the spline, and it will be inconvenient to adjust the valves in the future.

. We insert the probe appropriate for your engine model into the gap between the rocker arm and the valve stem and, by tightening or releasing the adjusting screw, ensure that the probe passes through the gap with little effort. After this, tighten the locknut while holding the adjusting screw. The GAZ 21 engine, in addition to a slot for a screwdriver, has 11 wrench edges on the adjusting screw; when adjusting, I advise you to use the wrench. It's much more convenient. We check the gap again. After adjusting the second valve of the first cylinder, set the TDC of the second cylinder and repeat the procedure with it. We repeat the operation until the cylinders run out. The gas ignition order, as we remember, is: 1-2-4-3 After all the valves are adjusted, we put the valve cover in place with a new gasket. If you have straightened it and the bead now lies entirely in one plane, no sealant will be required. When tightened evenly with the required force, oil will no longer leak out. We return the air filter, ventilation hose and vacuum corrector tube to their place. That's all the work. If you prepared everything in advance and used a good tool, you are unlikely to spend more than 40 minutes on everything. Start the engine and enjoy its smooth operation.

Engine Features

The Gazelle 402 is equipped with a 4-cylinder Cummins engine. The total engine volume is 2.7 liters, and its approximate service life is 500 thousand km.

If you use high-quality oil, this period increases slightly, but adjustments must be carried out even when using high-quality technical fluid. The engine has 16 valves - 4 per cylinder, 2 of which are intake, and 2 are exhaust.

Recommendations for action

The adjustment of the engine valve 402 is similar to other similar ones, since this device is not unique.

According to the technical documentation, namely the service manual, the clearances for the intake and exhaust valves should be 0.4 mm. If the GAZelle valves are adjusted, the 402 engine will be quite happy with this setting. Since the car is designed to transport heavy loads, this problem occurs quite often.

When adjusting the valves of a UAZ 402, the engine must be tuned to reduce fuel consumption, which means that the gaps should be at the level of 0.25-0.3 mm, which will also increase its throttle response.

If you are a fan of fast driving, driving in the mountains or off asphalt surfaces, gaps of 0.3-0.35 mm will be just right.

When using gasoline that is not suitable for the cylinder head (for example, using AI-80 on a cylinder head for AI-92), the gaps should be at the level of 0.4 mm.

Why make adjustments?

Why adjust engine valves at all? This procedure is necessary to maintain the unit in working order. More specifically, there are negative effects that worsen the operating condition of the engine, namely:

- An increase in the gap leads to deterioration in valve performance, as a result of which the air-fuel mixture is of poor quality, which deteriorates engine performance.

- As the gap increases, the chance of parts breaking during the operating cycle increases.

- Wear of parts also increases by about 2-3 times.

In general, you may notice a slight deterioration in performance, which will subsequently lead to complete failure of the unit. If you don’t want extra costs, spend an extra hour on adjustments.

Why regulate?

They are usually tuned to make the engine run more stable across all speed ranges. Valves are a very important part of the gas distribution mechanism. If the clearance settings are lost, then the wear of various parts in the timing belt increases significantly. The noise level of the power unit increases and fuel consumption increases, which is very significant for commercial vehicles.

You will be interested: How dangerous is the new coronavirus?

If you hear a ringing sound while the engine is running, if it has become more difficult to start a cold engine, and during a cold start the spark plugs are filled with fuel, then it’s time to adjust the valves of the 4216 Gazelle engine.

How to determine when it's time to make adjustments

There are several signs that the mechanism needs servicing:

- a metallic knock is heard from the engine;

- drop in engine power;

- Unstable motor operation.

Even if nothing like this happens, after a run of 100 thousand km it is strongly recommended to inspect and service the unit. When adjusting the valve on the gazelle 402 model, do not forget to check the integrity of other structural elements.

The process of adjusting valves on the ZMZ 402 engine

- set of probes;

- a new gasket for installation under the cover;

- nuts and bolts (in case the fastenings break);

- bearings for replacement.