03/04/2022 5,733 Electrical package

Author: Ivan Baranov

The windshield cleaning system includes many elements connected to each other and performing one important function - cleaning the windshield from dirt. If for some reason the system stops working, the driver's visibility of the road will be impaired and, accordingly, this may affect his safety. Find out what functions the windshield wiper arm performs and what elements the system consists of in this article.

[Hide]

Windshield wiper motor repair

There are several factors and reasons that can cause such an important device to fail. In most cases, this occurs when there is no contact between the commutators and the brushes. If after inspecting the motor and thoroughly cleaning the contacts the problem does not disappear, you will most likely have to disassemble it and replace it.

However, before taking such drastic action, there are a few more ways to take decisive action to consider. If the gearbox is stuck and the levers are jammed, most likely a certain fuse in the system, called a bimetallic fuse, has tripped. As a result, the system will not be able to cope with its responsibilities and will cause additional problems for the driver.

True, if you remove the part in time and carry out the appropriate repairs by replacing the fuse, most likely the malfunction will be eliminated in a short time. Provided that everything is done correctly, the windshield wiper will start working normally, as before.

The development of cases where the device is capable of operating only in a specific speed mode cannot be ruled out. This problem is of a completely different nature and lies in a problem with the switch or resistor. Here the brushes do not come to the lower position at all, which makes it necessary to adjust the stopping mechanism.

Situations where strange sounds and noises are heard when starting the windshield wiper are also not uncommon. If such phenomena are in no way related to dry glass, perhaps we are talking about some more serious problem.

As mentioned above, the design characteristics of the wiper motor are extremely simple and understandable. There are small brush levers on the fingers, which most often make an unpleasant sound. Sometimes it happens that the mechanism begins to sour in the bracket bushings due to a violation of the protection. As a result, dirt and water get inside.

If, after a final check of the device, no malfunctions are found, but the noise still makes it difficult to live in peace, the need to replace the motor cannot be ruled out. Now you should disconnect the device from the electrical supply, and then begin dismantling work.

Motor Troubleshooting

There are several different types of failure. The electric motor stopped working, the bimetal fuse is also faulty, while the integrity of the fuse link, which is an indispensable part of the power circuit, is still preserved.

In this case, you should conduct a full analysis of the wiring, the quality of the contact connections and localize possible problems. If there are no wiring problems, you most likely need to evaluate the condition of the wiper switch. Any faulty sharpenings or small parts should be removed and replaced. The risk of engine failure cannot be excluded, which is associated with burning contacts or sticking brushes.

Here you will need to repair the motor, which involves a complete replacement of failed parts and thorough cleaning of contaminants. You also need to look at the condition of the wires going to the motor and pads. At the next stage, you will have to carry out a full diagnosis of the bimetal fuse.

It is thoroughly cleaned of contaminants, and if this is not possible, a new one is replaced.

If the situation has not changed, pay attention to the integrity of the motor armature winding. If there is no chain, it is necessary to replace the anchor or the entire structure

Another situation looks completely different. In this case, the bimetal fuse may work, but the engine does not even start. Before starting any actions, you should make sure that the levers are intact. Very often they fail due to deformation or freezing of the blades to the surface of the windshield.

It is also useful to read: Features of hybrid wiper blades

Repairs are particularly difficult in cases where a short circuit occurs in the anchor circuit. Here you need to decide on one of two solutions: replace the armature or the gearbox.

There are times when the motor stops functioning in intermittent operation. Most often, the problem is explained by some problem with the relay or switch. Both options involve replacing the faulty unit.

If the intermittent windshield wipers still do not stop, it is most likely a faulty limit switch or relay. In the first option, the spring plate is simply not pressed by the cam of the gearbox gear. To solve the problem, you need to bend it slightly.

How do windshield wipers work on a car? Let's disassemble the system

Such a simple design as windshield wipers on a car, but who knew that even they could present structural surprises? Let's look at the operation diagram and design of a conventional windshield wiper.

There are many spare parts in a car that we incorrectly consider to be secondary. This is a given, which we consider as such, which means that we often do not notice how fascinating the design of this or that part of the machine can be. These things work well, and why know the structure of these “gray mice”? By the way, this is an extremely fascinating and diverse world. It also includes an element without which it is impossible to imagine safe and comfortable movement during various types of precipitation - car windshield wipers.

We lift the lever and the wipers start moving across the windshield due to the action of the electric motor. Indeed, this is how they work, but the description is extremely basic; in reality, everything is much more varied and fun.

How the device works

Despite the simple functionality of the cleaning system, it is necessary to understand how windshield wipers work. Key details you need to know:

- The electromagnetic relay receives the control command and sets the operating mode of the brushes. Depending on the vehicle, the wipers may operate intermittently at short intervals of 3-5 seconds, continuously move at a set speed, or enter wash mode with the washer on.

- The windshield wiper motor receives power from the on-board electrical system. The exact connection diagram depends on the car model.

- The windshield wiper arms, and along with them the glass cleaning brushes, are driven by an electric motor with a worm gear and a lever drive (trapezoid). The trapezoid transmits and converts rotational motion from the electric motor to brushes, which, pressing tightly against the working surface, remove dirt and moisture from the glass.

How does a trapezoid work?

The windshield wiper trapezoid consists of a system of rods and levers that convert the rotational movement from the gearbox into the reciprocating movement of the leads with brushes. A standard device should perform the following functions:

- movement of the brushes when the windshield wiper motor is running;

- ensuring the required amplitude and speed of cleaning;

- Windshield wiper arms with two or more blades must move synchronously.

Trapezoid wipers

The trapezoid, like the electric motor, is an important component of the system. In case of any malfunctions (the appearance of backlashes) in its operation, the efficiency and quality of glass cleaning deteriorates.

For greater reliability, the trapezoid elements are made of sheet steel, which is resistant to aggressive environments and also has high bending rigidity.

Wiper motor

The windshield wiper motor has a basic design regardless of the car model. The main elements include the electric motor itself and the gearbox (usually a worm gear), which increases the force from the electric motor several times. Modern devices can be equipped with additional elements, including fuses for protection against heavy loads, heating elements for operation at low temperatures, and much more.

Windshield wiper motor for VAZ 2110

The windshield wiper gear motor is the most important element of the system, which ensures its performance. The brushes must fit tightly to the glass and move freely along it, otherwise there will be an increased load on the electric motor.

Types of brushes

Car manufacturers provide car owners with a choice of brush types. Depending on the design and operational characteristics, they can be of the following types:

Frame brushes

- Frame brushes are the best and affordable option. They adapt well to the working surface of the windshield, but deteriorate the quality of cleaning at sub-zero temperatures and high speeds.

- Frameless wipers are a more expensive option that provides high-quality glass cleaning. The device is more resistant to freezing and also lasts longer. Among the disadvantages, it is necessary to note the difficulty of selecting brushes to ensure proper fit to the glass.

- Hybrid windshield wipers - these are often called winter wipers due to their closed design and moisture resistance. Ideal for regions with low temperatures, where it is important to ensure the functionality of the cleaning system.

Frameless wipers

Windshield wiper design elements

Design features depend on the type of device and the type of fastening elements. The standard windshield wiper circuit consists of the following parts:

- lever drive (trapezoid);

- leashes;

- relay for controlling operating modes;

- electronic control unit (if equipped);

- electric motor with gearbox;

- hinged fastenings;

- brushes

Additionally, control devices are provided. For example, for manual control, a steering column switch for windshield wiper operation modes is used, and for automatic mode, a special electronic control unit and a sensor for analyzing glass contamination (rain sensor) are installed in the vehicle.

Purifier management

The windshield cleaning system can be controlled in two ways - electronic and electrical. The last option involves manually changing operating modes. Under the steering wheel there is a special control lever that allows you to turn on the device, adjust the pause in the wipers and change the cleaning modes. But this option requires constant driver participation.

Understeering's shifter

The electronic control system is completely autonomous and does not require human intervention. The car is equipped with a special electronic unit and a rain sensor, which analyzes the cleanliness of the glass and weather conditions. Electronic control provides a range of functions:

- automatic switching on and off;

- changing the operating parameters of the purifier;

- blocking the motor in the presence of obstacles on the windshield;

- additional cleaning with windshield washer;

- preventing brushes from freezing when the engine is off.

Electric windshield wiper front and rear

With the advent of the era of high technology, the air system was abandoned. It was replaced by compact electric motors, which spun the mechanism quite quickly and are the most reliable and efficient today.

This type of windshield wiper consists of an electric motor installed under the windshield of the car, a special trapezoid and a pair of windshield wipers. Such a windshield wiper is controlled using a steering column switch installed in the vehicle interior. When lowering it down, the motor is set in motion and spins a special trapezoid, which moves the wipers to one position and then returns to their original position. Once the cleaning is complete, the cycle repeats again. This ensures that the windshield wipers are fully automatic regardless of engine operation.

The electrical circuit of such wipers contains a special electronic wiper relay. This device allows you to take certain pauses between cleaning the glass, when it becomes dirty or covered with moisture not too intensely. This is done so that the windshield wipers do not obstruct the driver’s view and prevent visual fatigue.

With the advent of a large number of station wagon and hatchback cars, there is an urgent need to clean the rear window. For this purpose, a windshield wiper was also installed on the trunk lid. It is powered by exactly the same motor; one trapezoidal mechanism is now designed for one windshield wiper, not two. This innovation allowed the driver to maintain visibility not only in the forward direction, but also in the rear, which improved the comfort of driving the car in various weather conditions.

To save electrical energy from the generator and battery, the rear wiper drive is activated from a separate button. That is, the activation of an additional wiper should only be done if there is an urgent need for it.

Methods for attaching brushes

Before 1999, most car manufacturers used a type of mounting for OEM windshield wiper blades called a "hook" or "hook". This is a universal device in the shape of the letter “U”, which allows you to snap the brush into place and not worry about the reliability of its installation. The following types of mounts are currently gaining popularity:

- Side pin - appeared in 2005 on BWM, Volvo and other cars. Allows brushes to be fixed using a special 22 or 17 mm side pin.

- Button or “Push Button” is an adapter for standard 16 mm wide wiper blades. It is enough to snap the device into place for fastening, and to remove it you need to press a special button.

- Pin lock - fixation of brushes using a special built-in lock. Used in Audi cars.

How the windshield wiper works

On VAZ 2108, 2109, 2113, 2114 (hatchback body) cars a windshield wiper and rear window washer are installed. On VAZ 2199, 2115 (sedan) models there is no rear window wiper.

Windshield wipers have several operating modes: intermittent (work with a pause), low (first) speed, high (second) speed, one-time triple cleaning of the glass, operating mode with a windshield washer. The rear wiper operates only in one position and in conjunction with the rear window washer.

Typical windshield wiper malfunctions and methods for eliminating them:

Windshield wiper malfunctions include:

1) Complete inoperability of the system (not a single mode works, the electric motor cannot be heard):

- check the presence of voltage of 12 volts at terminal 6, in the windshield wiper connector, ground 4, and also check all supply circuits (fuses 4 and 5, switch, mounting block, ignition switch, etc.);

- check the operation of the mode switch (presence of 12 V control voltage at terminals 1 and 2 of the windshield wiper connector when switching modes);

- check the functionality of the electric motor itself (dismantling and disassembly is required);

2) Intermittent mode does not work (all others work);

the main reason is a non-working “short circuit” relay, in the diagram, and a mode switch (the easiest way to check is by substitution, for a known good one)

3) The windshield wiper blades do not stop in the down position, but stop anywhere (the blades can extend beyond the windshield):

- the limit switch in the electric motor is broken (or burnt out) (it is not possible to replace it, only the entire motor, but you can try to fix and repair the switch);

- incorrect adjustment of the position of the wipers (align the wipers in place);

- the drive shaft of the brush mechanism began to be dismantled (disassembly and replacement of failed parts);

4) The noise of the electric motor is heard, but the brushes do not move (the brushes may twitch in one place):

- the drive shaft of the windshield wiper mechanism has been damaged (“licked off” the splines) (replace or fix the splined part of the electric motor);

- the nut securing the mechanism rod to the electric motor shaft has become loose (tighten the nut);

5) The wipers do not operate after turning on the windshield washer:

- Most likely, the steering column mode switch has failed (replace with a known good one);

- there may be a malfunction in the operation and serviceability of the mounting block (measure the voltage at terminals 9 and 18);

6) Poor quality of glass cleaning.

- The windshield wiper blades have lost their elasticity (replace the blades with new ones);

- contact with oily materials on the glass (oil from the exhaust pipe of a car in front, waxing at a car wash, contamination after polishing, etc.)

Troubleshooting and repair of the rear windshield wiper follows similar principles (the diagram is attached below), with the exception of the absence of operating modes in the rear windshield wiper, and accordingly the absence of some parts (relay, limit switch in the electric motor, and so on).

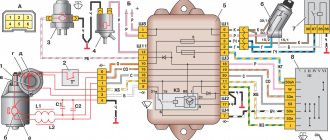

Electrical part of the windshield wiper:

The windshield wiper circuit has several types of design. With any design, windshield wipers must ensure cleaning of the windshield regardless of the amount of precipitation. Automotive windshield wiper drives usually have two speeds. It should ensure that the brushes are placed in the extreme position when turning off, which does not interfere with the driver’s view.

On modern cars, the windshield wiper drive has an intermittent operation mode. It is provided by a thermal or electronic relay included in the power supply circuit of the wiper drive. This mode can be either with a constant period of time or adjustable. During intermittent operation, one or two cycles of brushes pass across the windshield with breaks of 3 - 5 seconds. In addition, on some cars, for example VAZ classic, the intermittent mode serves as a low-speed wiper drive.

On some imported cars, intermittent operation uses a smooth speed control, which is ensured by changing the voltage to the electric motor by an electronic unit.

Where does which wire go, or just a diagram

Connecting wipers and washer

“Plus” power is supplied from the ignition switch through fuse No. 2 at 10 Amp of the mounting block. The permanent “plus” goes along the black and yellow wires to contacts “4” of the connectors of the gear motor and the steering column switch. It should not disappear even when the switch is in the “off” position. The blue wire supplies “+” 12 V power to the motor when the switch is in the “continuous mode” position. On the blue-white wire, in the “off” position there should be a “minus”, and in the “continuous mode on” position the “minus” is turned off. This is done to slow down the motor when the power to the closer is turned off.

The red wire supplies the relay with “+” 12 V from the switch when the intermittent mode is turned on. At the moment of operation, contacts “2” and “4” close, and “1” and “3” open, the motor starts working and the brushes make one or two movements. Then “+” 12 V is turned off, and contacts “1” and “3” are closed to each other and to “minus”. The motor stops for a few seconds and then the cycle repeats.

The washer pump motor is connected to “+” 12 V constantly with a black and yellow wire through the same fuse No. 2. “Minus” is applied when you press the windshield wiper lever from bottom to top.

Video about how a windshield wiper works

About heated wiper blades

The option of heating the windshield, which is extremely useful in Russia, is not always available and is not offered on all models. But there is an alternative and budget solution - windshield wiper blades with an electric heating function. They are heated from the inside due to a flexible heating element installed in the body, powered by the vehicle's on-board network. Heating occurs from the inside evenly throughout the entire body, the heating temperature is about 70 ° C. The frameless wiper blade is designed in such a way that when the rubber wiper blade wears out, it can be easily replaced without removing the frame with a flexible heating element. There are several options for connecting to the on-board network. The simplest is to install a button, but as an option you can use a “radio key fob” to remotely control the heating, or you can install an automatic thermal relay that will independently turn on the heating when the engine is running and the temperature is below zero degrees.

Video “Features of replacement”

How to replace cleaners without a puller and what you need to take into account - learn from the video (author - AssistanceTV channel).

Drivers of the “Seven” are aware of the problem with the operation of the windshield wiper, which does not consist in frequent breakdowns, but in the fact that the cyclical movement of the wipers makes them nervous. But, more on that a little later. In general, the relay plays a very important role, and such a role appears only in rainy weather. After all, the operation of wipers is impossible not only without power, but also without a regulator. It is the relay that performs this function, which provides great convenience during bad weather. But this is not the only function of this device, however, this is described below.

Why are car wipers needed and how do they work?

Car wipers are designed to clean the windshield from water, dirt, snow, etc. falling on it while driving. The principle of operation of the windshield cleaning system, which includes wipers, is quite simple - the electric drive motor, through a system of rods and levers, acts on the drive rollers, with leads attached to them, and the windshield wiper blades themselves are attached to them. The system of rods and levers does not ensure circular movement of the drive rollers; they only rotate around their axis by 90-110 degrees and then return back. Almost all cars have two wipers on the windshield. The same system of rods and levers is made so that both drive rollers rotate synchronously; as a result, the brush leads themselves move synchronously, which prevents them from touching. Providing better downforce - the leashes are spring-loaded.

Video: Testing wiper blades

Often another wiper is installed on a car - on the rear window. Its function is the same as that of windshield wipers. But the design itself is somewhat simpler. The rear wiper is also driven by an electric motor. It is usually located next to the drive roller of the leash, but drives it not through levers, but through a small gear reducer.

In principle, the drive mechanism is reliable and breaks down infrequently. Much more important in this system is the condition of the wipers themselves. After all, they provide visibility to the driver in driving conditions during rain and snow. When driving on a busy highway, especially in the autumn-spring period, water with mud impurities often rises into the air from under the wheels of overtaking cars, which settles on the windshield. Much the same thing happens when driving on a snowy road. If the windshield is not cleaned, it will be impossible to move on very quickly due to poor visibility through the glass.

But in addition to the performance of this system, you also need to monitor the wipers themselves. Severely worn cleaning elements will not ensure proper cleaning of the glass. As a result, visibility will be insufficient, and the driver will have to strain his eyesight more, which will lead to rapid fatigue.

Function and principle of operation of wipers

The key task of the windshield wiper mechanism is to clean the windshield from water during rain, as well as dirt that falls on its surface during movement. These wipers operate using special mechanisms.

Using the scheme of rods and hinges, the non-circular movement of special cones is ensured; they only provide translational-rotational action, after which they return. Almost every car has two wipers. The design of the rods and hinges is designed in such a way that the drive cones work synchronously, which facilitates the simultaneous movement of the wiper arms. This helps prevent them from touching.

Often a wiper is also installed on the rear window of the car. Its function is similar, but the circuit is a little simpler. An electric motor helps drive the rear window wiper, since these mechanisms work almost the same on all cars. Most often it is located close to the drive cone of the lever, but begins its movement with the help of a small gear reducer.

There are three types of wind wipers:

- Holder device without frame

- Holder device with frame

- A holder for a hybrid brush, the structure of which is similar to the others.

Pressure plates help connect the base to the body. In the diagram, they are made in the form of strips made of a springy alloy, with cuts along the edges that ensure fixation of the holder to the base. The base holders are inserted into special side grooves.

Then the elastic band with inserted springs is secured to the holder itself. In the case of frame fasteners, a design is used that consists of bent rocker arms - the body. Such a scheme has a main rocker arm, where there is a fastener for fixing it to the lever. At the edges of the movable rocker arms there are clamps that help hold the base with springs.

The tape of frameless fasteners is installed and secured in the clamps of an even elastic spring in the shape of an arc. This spring presses the rubber band to the surface of the glass, and an adapter is used to install it on the lever in the elastic spring. As for hybrid wipers, they have a frame hidden in a plastic housing.

Quality control and tests: a mandatory component of the production of Masuma wipers at our factory

The plant has its own testing laboratory, where products are tested for compliance with a wide range of indicators.

The quality of parts and their compliance with the declared characteristics are checked in our own laboratory. Tests are carried out here to:

- determine the resistance of Masuma wiper blades to abrasion, temperature changes and other factors;

- make sure that there is a good fit to the surface and that there is no possibility of damage to the glass during operation;

- evaluate the quality of paintwork frames and their resistance to external factors;

- check how effectively the glass surface is cleaned with brushes.

Based on the results of tests in the laboratory, if necessary, decisions are made to make changes to the production technology of specific brush models. These processes take place continuously at the enterprise, ensuring product quality.

Go to the Masuma wiper catalog

Advice from car enthusiasts and professionals

1. How to change the rear wiper motor

The mounting of the rear window of a car is usually different from the front. Therefore, the windshield wiper drive system is also designed differently there. Accordingly, the answer to the question of how to change the rear wiper motor also has a number of nuances:

- First of all, the windshield wiper is fixed in a vertical position to provide access to the fastening screws.

- The next stage is to disconnect all external communications from the mechanism and disassemble the structure itself. First of all, dismantle the lever, then the protective cap of the rotary shaft and unscrew the bracket fasteners.

- It is impossible to remove the rear wiper motor without freeing the trunk from the upholstery. It is held on by pistons that need to be removed in those places where the wiring connection block to the gearmotor is located.

Be sure to disconnect two pads. One is used for connecting cables, the second for cables.

- After disconnecting the electrical part, unscrew the screws holding the motor.

- Then you can remove the engine by turning it left and right.

We recommend

“The wipers squeak: causes and solutions to the problem” More details2. How to check the performance of the wiper motor

During repairs or inspections for preventive purposes, there are several ways to see malfunctions in the operation of the glass cleaning system:

Brushes must be secured in their holders in a normal position, swing at a speed appropriate to the task, and not encounter any obstacles along the way. To diagnose the electric motor, use a tester. Its capabilities are sufficient to detect broken contacts and identify poor-quality connections. Disassembly of the mechanism is necessary for visual inspection of the condition of the gearbox gears

Pay special attention to the condition of the gears and threads on the rollers. Other mechanical components can be assessed during inspection even without disassembly.

Right choice

It is better to select according to the time of year in which you most often drive; the car will not be worse off. Nowadays, counterfeiting various car parts is just a mega profitable business, this has not escaped our topic, even wiper blades are counterfeited. Here, the selection before purchasing must be done very carefully. Ideally, you need to familiarize yourself with the most common companies on the Internet and see how to distinguish each one from a fake, by what markers. If we judge, in general, then any normal and high-quality auto chemicals must have high-quality printing, with a label carefully and in the right place, all details and the date of issue must be clearly printed on the wrapper. Start choosing for yourself by checking these points.

If you are too lazy to think through all this for you, then you can simply come to a good expensive store, where they will recommend you the best that can be available today.