1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

The causes of fuel pump failure are not always the same, and the devices themselves can be electrical or mechanical. Diagnostics of the performance of these types has differences, so we will consider ways to check the operation of gasoline pumps separately. However, the operation of the fuel pump can be checked in a maximum of 7 stages.

The need to check the fuel pump appears when the following signs of malfunction occur:

- the engine stalled;

- the car moves unevenly, jerkily;

- the engine idles unstable and does not start;

- there are “floating” speeds;

- increasing noise, whistling when the car is moving.

Fuel pump gazelle 405 injector does not work

Gazelle fuel pump is a device for ensuring the transportation of gasoline or diesel fuel from the gas tank to the car engine. Let's look at two types of Gazelle gasoline pumps (fuel pumps): mechanical pumps and electric pumps. What these devices are, how they operate, what are their similarities and differences will be discussed in this article.

What is a fuel pump (Gas fuel pump) of a car?

The fuel pump is an element of the fuel system necessary for supplying fuel. To operate a car engine, you need to supply gasoline from the fuel tank, which is located at the other end of the car on the Gazelle frame, directly to the engine. Fuel is pumped from the gas tank to the engine, depending on the design of the Gazelle’s fuel system, using one of two types of pumps: mechanical or electric.

Carburetor engines use mechanical pumps. These motors do not require high pressure. Electric fuel pumps are used in modern vehicles with fuel injection equipment, where it is necessary to supply gasoline or diesel under high pressure.

Mechanical fuel pumps are not mounted in the Gazelle’s gas tank, but on the engine.

They are simple and reliable, they are driven mechanically, from the engine (hence the name “mechanical”). Modern cars do not use a carburetor, but an injection system or injector. This system already requires high pressure. To do this, an electric fuel pump is installed in the Gazelle’s fuel system, which provides such pressure. Sometimes two fuel pumps are used at once: one of them is low pressure and the other is high pressure.

The low pressure fuel pump is placed in the gas tank, and the high pressure pump is placed directly on the car engine.

For the normal functioning of the vehicle’s fuel system, it was necessary to increase the characteristics of the fuel pump and ensure its operation at a pressure of up to six atmospheres. At the same time, the pump increased slightly in size, became more powerful and noisier. To optimize its operation, the Gazelle pump was immersed in the fuel tank. At the same time, several problems were solved. Firstly, the noise of the electric pump is not audible during operation, since it is located inside the Gazelle’s gas tank.

Its operation can only be heard for a short time when the ignition is turned on. Secondly, with the pump immersed in the tank, gasoline began to perform two necessary functions: cooling the electric pump itself, as well as directly lubricating this pump with gasoline passing through it. Based on the design of the electric pump, non-returnable pumps are now gaining popularity, that is, pumps in which the bypass valve is installed directly on the pump.

The system where the fuel drain line came from the fuel rail is currently becoming obsolete.

Description of the operation of the electric fuel pump

The electric fuel pump is driven by its own electric motor. When you turn the key in the car's ignition switch, on-board voltage is supplied from the electronic unit through a relay to the fuel pump electric motor. The gas fuel pump comes into operation with a characteristic sound that is heard for two to three seconds immediately before the vehicle engine starts.

At the same time, the system creates the pressure necessary for gasoline to flow from the gas tank through the fuel supply line through the fuel filter installed to clean gasoline from debris contained in it, to the fuel rail, and then through the injectors to the engine pistons to start it. The car engine starts. A signal about the successful start and operation of the engine goes to the car computer. The vehicle's engine is running, and the fuel pump continues to function.

If the engine does not start for some reason, the car’s computer will also receive a signal about this, and the fuel pump will turn off.

For the smooth operation of an electric fuel pump, a number of rules must be followed. First, and most importantly, you need to keep the Gazelle fuel filter clean and do not forget to replace it during maintenance, especially if you are using fuel that is not of the best quality. In addition, on many modern cars the fine filter is built directly into the fuel pump.

Replacing such a filter is a rather labor-intensive operation (you have to remove the gas pump from the tank to replace the filter in it), but sometimes it is simply necessary to do this. And, secondly, you need to make sure that the gas tank is always more than one-third full. In this case, the pump is completely immersed in fuel. If you do not follow this simple rule, then there is a high probability that the electric pump may fail due to overheating.

Another type of fuel pump is a pump for pumping diesel fuel. Designed for pumping diesel from the tank of one car to the tank of another, or from a canister to a tank. There are restrictions on using the pump to transfer gasoline, as gasoline may ignite.

General scheme

Modern engines are largely focused on economical operation with reference to environmental requirements.

Therefore, they differ:

- A large number of various sensors;

- Increased length of wires;

- Electronic control units for subsystems and the entire power unit;

- On-board diagnostic module (computer).

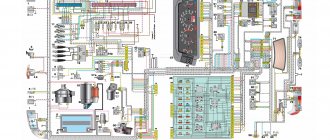

Poster from the service manual for a GAZelle with a ZMZ-40522 engine

Accordingly, the wiring diagram for the Gazelle 405 has its own characteristics, most of which relate to ensuring the correct operation of the injection system, often called the injector.

This is where, according to many diagnosticians and auto electricians, lies the weak link that affects the car engine. And one such feature will be discussed in this publication.

Electronics help

On cars with EURO 3 engines, the wiring diagram for the 405 Gazelle provides a diagnostic module.

Its frequently encountered names among motorists:

- on-board computer,

- trip computer;

- multitronics (by manufacturer's name), etc.

In addition to its basic information functions, the on-board computer is also able to inform the driver:

- Stepper motor position.

- Engine speed.

- Injection controller error codes.

- Mass air flow.

- Throttle position.

- Onboard voltage value.

Note. If a malfunction occurs in the operation of the power unit, the route PC will report errors. From their decoding, you can guess which electrical wiring diagram for the Gazelle 405 is subject to close monitoring. But he, of course, “will not say” about the true reason, but will only point out the probable reason that caused the unstable operation of a particular node.

Vehicle weight

Let's look at an example when a car stops obeying the gas pedal . The car refuses to move, when starting it keeps the speed at 2000 rpm and does not allow movement.

Read more: Crash test ZIL 130

The trip computer often reports in such situations that there are errors:

- With throttle;

- With crankshaft sensor;

- With air flow sensor.

The example shown in the video below shows unstable operation of the power unit.

The factory instructions prescribe diagnostics using special equipment, as a result of which the owner, using a brute force method, excludes one or another node from the “suspect list”.

In fact, the reason for the failure is tritely simple - a break in the throttle ground wire , which, being screwed to the exhaust manifold stud, is subject to vibration and simply falls off (this kind of trouble happens not only with GAZ products - see the article original wiring diagram for VAZ 2112).

Please note: For better contact with the vehicle ground, the throttle electronics are powered by a separate wire - in the photo below.

Fuel pump relay ZMZ 406 injector

Auto GAZ 31105, 406 engine, injector, 2001. Suddenly, after the trip, the next day the car wouldn’t start! You turn the ignition key, but the pump is silent. The car won't start!

It was checked:

1. Fuel pump - working 2. Fuel pump relay - OK 3. Fuel pump operation when the contacts of the fuel pump relay are closed - the fuel pump is working 4. Fuse - intact 5. Presence of gasoline in the tank - yes 6. No additional lights with errors light up 7. Checked 4- x contact relays in the passenger compartment in the driver’s feet are operational

that when the ignition is turned on, there is a plus on contact 85 of the fuel pump relay, but there is no minus on 86. Visually, all the wires from the fuel pump-driver-hood are intact. All that remains is to get to the block under the glove compartment. What is there? As I understand it, the wire (c/w) from the relay goes to some kind of large connector or directly to the brains under the dashboard. Is it so?

Help me please!

Has anyone encountered a similar problem?

This is my father-in-law's car and he lives far from the regional center. Due to the fact that this is the Kaliningrad region and there is a minimum of domestic cars, finding a specialist is a problem.

If I posted this in the wrong thread, I'm sorry. This is my first post! Please, dear admins, don’t kick too hard!

I read the topic on electrics, but so far I haven’t found anything similar!

Replacing fuses and relays on a Volga GAZ 31105 car

Tools:

- open-end wrench 10 mm

- Phillips screwdriver medium

Notes:

On a Volga GAZ 31505 car, remove the wire terminal from the “negative” terminal of the battery.

1. To replace the fuses installed in the engine compartment of the GAZ 31105 car, press the block cover latches on both sides and remove the cover.

2. Using a 10mm wrench, unscrew the two nuts securing the faulty fuse.

3. We remove the wire ends and the faulty fuse from the studs. Spare fuses are stored under the cover plate. The tripping current value is stamped on the fuses.

4. Install a new fuse (with the appropriate response current), put the wire lugs on the studs and tighten the fastening nuts. 5. To replace the fuses installed in the interior of the Volga GAZ 31105 car, move the emblem all the way.

The fuel pump does not pump: causes and diagnostics

Let's start with the fact that if the gas tank is full, the battery is charged, the spark plugs are dry and there is a spark, the starter turns the engine normally, but the engine does not seize, then you should pay attention to the gas pump. A common problem is that there is no power to the fuel pump after the ignition is turned on. In a similar way, the malfunction manifests itself in motion, when the power to the fuel pump is lost and the engine suddenly stalls.

An equally important point is how much the fuel pump pumps. In other words, the pump may hum and buzz (power is being supplied), but not create the required pressure in the fuel line. The pressure in the fuel system with a working fuel pump must be more than 3 bar (which depends on the specific car model). The indicated pressure is accumulated in the fuel rail and has an indicator of 300 kPa and above.

To check, you need to measure the pressure in the fuel rail with a pressure gauge, taking into account the indicators that are the norm for a specific car model. Using the example of injection VAZs, the pressure when the ignition is turned on is 3 atmospheres, at idle the figure is 2.5 atmospheres, when you press the gas 2.5-3 atmospheres. This method will help you accurately determine:

- malfunction of the fuel pressure regulator in the rail;

- breakdown of the fuel pump or a noticeable decrease in its performance due to wear;

- severe contamination of filters (fuel filter and/or fuel pump mesh);

Create an account

Register a new account in our community. It's very simple!

Zavolzhsky Motor Plant (ZMZ) is one of the first domestic manufacturers of automobile engines to begin producing engines with an injection power system. One such high-quality engine can be called the ZMZ 405 - an engine from a family of four-cylinder engines that have been produced for almost 15 years. For the first time, this particular engine hit the market back in 2000, installed on the GAZ-3111 car. The plant itself positions the engine as an engine for small trucks and minibuses. It is installed on them - various cars of the GAZelle and Sobol injector line have this engine.

Over the past time, the ZMZ 405 has established itself as an excellent, unpretentious engine, ready for even the greatest difficulties on the road. The 405 motor is capable of withstanding heavy loads and this will not affect its service life. Also, the design of the motor is based on the unprecedented simplicity of the device - this engine, installed on any car, can be repaired and maintained by anyone in an ordinary garage with minimal knowledge, everything is done according to the included book and does not raise any questions. The same applies to fuel system repairs. In particular, the engine fuel pump injector is very easy to repair yourself.

Checking with a pressure gauge

It is also possible to check the performance with a pressure gauge. This method is also quite accurate if you check the fuel pump correctly. We will need a special pressure gauge to measure the pressure in the fuel network of the GAZelle 405 injector. You can do all the operations yourself; you don’t need the help of specialists. The instructions for such a pressure gauge say that it must be connected to the injector rail and secured so that the pressure gauge readings can be seen from the passenger compartment. When the driver turns on the ignition, the pressure gauge starts working and takes readings of the pressure created by the fuel pump. The norm for pressure fluctuations in the fuel system of the GAZelle 405 injector is from 300 to 380 kPa (kilo Pascal). After this, you need to drive along such a section of the road that at least third gear is engaged and then measure again. If the pressure gauge readings have not changed, then there is no need to worry about anything yet, and something else needs to be repaired, not the fuel pump.

If there are significant changes in the readings, you will have to contact a GAZelle 405 injector repair specialist.

If the car starts to stall while driving, then the problem lies in the electrical component. You can check if this is why the fuel pump is not working correctly by performing a test of the fuel pump relay. To do this, we need a regular control lamp, and the test itself looks like this: when the lamp is connected to the yardarm and the ignition is turned on, the lamp should light up for a few seconds. If a leak was noticed at low pressure and it was determined that it was the culprit, then it needs to be eliminated. To do this, you need to establish where exactly the leak is, and then, depending on the situation, choose what will help - replacing some gaskets, valves, diaphragms and other things. In order to quickly understand what exactly is broken and how best to fix the breakdown, it is necessary to clearly understand the diagram of the fuel equipment of a particular machine, and what place the fuel pump occupies in it.

January 9, 2013, 15:48 #1 123

Good afternoon everyone. Evening is already approaching, and in the morning I can’t start the gas 3110 d406i yesterday, but today it’s silent when starting (the gas pump doesn’t work), the fuse is intact, the relay contacts were cleaned, they tried connecting directly to the relay socket. The gasoline pump connected to the battery works. What could be the problem?

- Posts: 95

- From: Moscow Region, Chekhov

January 10, 2013, 21:37 #2 123

is there an alarm?

- Posts: 95

- From: Moscow Region, Chekhov

The Importance of Schemas

You can understand the fundamental importance of the Gazelle 405 electrical circuit simply based on how often this car has to be repaired. After all, as a rule, it is bought not for personal needs, but as a commercial machine. This means that he travels every day. You also need to make allowances for the conditions in which Gazelles drive, and how they are usually used:

- Exposure to natural conditions (poor wire insulation, short circuits).

- Poor build quality (cheap and bad wires that do not last long).

- Bad fuel, which has a detrimental effect on the electrical components of ignition and injection.

And only by using the electrical diagram can you figure out where which device is located and which wires are suitable for it.

If you try to replace something in the system yourself, without looking at the diagram, you can simply mix up the wires and do something to the car that you will then have to change all the wiring in the car.

It’s just trite that two closed wires can easily make such a short circuit, so before you climb under the hood of a Gazelle, you always need to prepare a circuit in advance.

Power check

You can establish the presence of voltage at the TN connector using a simple test to check electrical circuits. To check the fuel pump, in the electrical diagrams for your car model, find the pinout of the electrical connector of the fuel module. For the pump motor to operate, “–” and “+” are required. If, after turning on the ignition and connecting the control contacts to the corresponding pins of the block, the light comes on, then everything is in order with the supply voltage. Using this method, you can check for the presence of +12V and ground in the fuel pump relay connector, and establish the presence of supply voltage from the ECM to the relay. If the fuel pump does not turn on, but there are no problems with the components of the electrical circuit, the reason is in the fuel pump itself.

The most convenient way to determine why there is no power to the fuel pump is to use a multimeter. Let's say that + 12V to the pump comes from the relay, but does not reach the fuel module connector. In this case, it is necessary to ring the wires from the relay to the fuel section. In ohmmeter mode, you will not only find an open, but you will also be able to see the parasitic resistance in the circuit. When considering possible reasons why the fuel pump does not pump, do not forget about the immobilizer failure. Often in such cases the engine starts, but stalls after a few seconds.

Technical differences

A power unit that has exhausted its service life is replaced, often giving preference to more modern versions.

Structurally, everything fits into the factory seats, and the differences, for example, are in the location of the equipment:

- Another form of connecting blocks;

- A different diagram for connecting devices;

- Different voltage.

Supply system

Leaving the carburetor in the past, replacing the power unit inevitably entails replacing the power system:

- A new gas tank is installed, since the injector must dump excess fuel back, and the old tank design is not suitable for this;

- The gas line is replaced (the return line is laid + the supply connection is modified);

- The operation of the injectors is regulated using connecting wiring.

Cooling system

The new injection engine ZMZ-406 is more demanding on the cooling system, therefore, during the installation of a new power unit:

- An electric fan is installed on the cooling radiator;

- The engine compartment wiring harness is being replaced.

Fuel injection control system

Do not forget that the power supply system of an injection engine is controlled by an electronic unit, which also needs to be connected to the vehicle’s standard electrical network. Accordingly, the electrical wiring on the Gazelle 406 is different than on older versions of the car with 402 series engines, and must be replaced.

Pump diagnostics and repair

The importance of maintaining the fuel pump in a constant working condition is that if it does not work correctly, constant breakdowns of other components of the GAZelle 405 car will begin, and the injector may not work correctly or even fail.

You need to start repairing the fuel pump by determining what exactly the problem is, that is, diagnosing it. The first alarm bell that the fuel pump is not working properly is that the GAZelle 405 injector moves unevenly, as if in jerks. If this particular symptom appears, then do not be discouraged - repairs are possible on your own. Also, if the GAZelle 405 engine takes a long time to start, and the injector usually always starts with half a turn, this is another bad sign that the fuel pump is starting to fail, although it is still far from complete failure.

Although, if you do not repair the fuel pump for a long time and do not pay attention to such a breakdown, then at one point the car may simply not start. The cause of this problem is a drop in pressure in the fuel system, which is caused by a faulty fuel pump.

You can check the fuel pump using a special indicator, which can be bought at any spare parts store for the GAZelle 405 injector. This device is installed on the gas pump and you can do it yourself, the main thing is to strictly follow the instructions and not make mistakes. The check takes place with the engine turned off; the device itself will do everything. If a significant decrease in pressure in the fuel network was noticed in less than 10 minutes, this means that the fuel pump is working properly, and either the pressure regulator or the injectors of the GAZelle 405 injector are to blame.

We fix it ourselves

As a rule, the price of diagnostics and work by a service station technician or electrician is quite expensive. Therefore, it makes sense to check the GAZelle wiring yourself . Very often, the cause of such sudden failures is loss of contact with the vehicle's ground. Moreover, such a problem occurs in many domestic cars - the same wiring Moskvich 2141, for example.

This wire should always be kept under control. Source

When detected, such a malfunction can be repaired quite easily:

- Cut the fallen wire 5-7 centimeters below the oxidized contact;

- Clean up;

- Screw on the new contact;

- Isolate;

- Screw it to the stud, having previously cleaned the contact area with a small file.

Advice: if you have to replace the wiring yourself, then do not be too lazy when removing the old harnesses to mark on the new wiring the nodes and contacts to which it will be connected. To do this, you will need tape and paper with a pen - sign and stick handmade clues to the wiring (this advice will also help when using parts from other cars - see the article GAZelle 406 wiring diagram).

If you disconnected the old wire on the car, mark it on the new one. This approach will significantly simplify the work and help avoid mistakes.

Pump diagnostics and repair

The importance of maintaining the fuel pump in a constant working condition is that if it does not work correctly, constant breakdowns of other components of the GAZelle 405 car will begin, and the injector may not work correctly or even fail.

You need to start repairing the fuel pump by determining what exactly the problem is, that is, diagnosing it. The first alarm bell that the fuel pump is not working properly is that the GAZelle 405 injector moves unevenly, as if in jerks. If this particular symptom appears, then do not be discouraged - repairs are possible on your own. Also, if the GAZelle 405 engine takes a long time to start, and the injector usually always starts with half a turn, this is another bad sign that the fuel pump is starting to fail, although it is still far from complete failure.

Although, if you do not repair the fuel pump for a long time and do not pay attention to such a breakdown, then at one point the car may simply not start. The cause of this problem is a drop in pressure in the fuel system, which is caused by a faulty fuel pump.

You can check the fuel pump using a special indicator, which can be bought at any spare parts store for the GAZelle 405 injector. This device is installed on the gas pump and you can do it yourself, the main thing is to strictly follow the instructions and not make mistakes. The check takes place with the engine turned off; the device itself will do everything. If a significant decrease in pressure in the fuel network was noticed in less than 10 minutes, this means that the fuel pump is working properly, and either the pressure regulator or the injectors of the GAZelle 405 injector are to blame.

Fundamental Concepts

Opening the hood of a Gazelle 405 you can see a huge mass of wires, especially if an injector is installed there. As you know, the operating principle of an injection engine is very different from a carburetor engine and includes a lot of electrical elements, which only an electrical circuit can help you find. It looks like a large map on which all the wires and cables that are laid in the car are marked, where and where they go, what is connected to what. The need to draw up these diagrams is due to the fact that the car uses alternating current, and there is no easy way to figure it out. Graphically, on the Gazelle 405 diagram you can see absolutely all the elements, both the main ones (battery, distributor breaker, ignition coil, starter, generator, spark plugs) and all the secondary ones (headlights, wipers, radio, power windows, etc.).

Repair

Mechanical fuel pump repair

Repairing a mechanical fuel pump consists of installing a new repair kit (diaphragm and valves) and, if necessary, a worn pusher with a spring. A deeper repair of this device is impractical, since the costs of purchasing and repairing worn parts are close to the cost of a new product. If the pump housing is deformed or damaged, it must be completely replaced.

Electric fuel pump repair

The electric fuel pump is equipped with a non-separable housing, and if it breaks down, the product is replaced with a new one. Without special skills, equipment and spare parts, opening and repairing it is impossible. But some workshops undertake similar work, the price of which is lower than buying a new pump. The main failures of the device are as follows:

- Damage to brushes and motor commutator. Repair involves replacing them with new ones.

- Breakage of the plastic coupling connecting the rotor and the motor armature shaft. The clutch is replaced with a new one.

- Anchor failure. The repair involves rewinding this part.

The described actions allow us to eliminate the gas pump malfunction on all models of the VAZ: 2101, 2102, 2103, 2104, 2105, 2106, 2107, 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, Niva, Priora, Kalina, Grant, Vesta and most foreign cars.

Trouble-shooting

To repair a mechanical fuel pump, you will need to purchase a repair kit, which includes a diaphragm and valves - you can change these parts yourself. It will also not be difficult to replace the pusher with a spring. If the breakdown is more serious, then there is no point in resuscitation; it will be cheaper and easier to install a new fuel pump.

The electric fuel pump has a non-separable body, and it is not worth trying to repair it without certain skills; it is better to entrust such work to specialists. The only thing you can do yourself is to replace the mesh of the internal coarse filter. But even here you need to know that there are different types of meshes, so you will have to remove the filter from the tank to get a sample.

The fuel pump relay does not turn on.

If the fuel pump does not work, then first of all you need to check the attraction of the main relay and the fuel pump relay. If the main relay does not click, then it is necessary to check its switching circuit and its serviceability. How to do this is described in the article the main relay does not turn on,

In the case when the main relay turns on, but the fuel pump relay does not, it is necessary to check the power at pins 85 and 86. When using a test lamp, its current consumption should not exceed 0.25A, otherwise damage to the controller may occur. If the control lamp does not light up on any terminal, then the relay is not receiving power. This may be caused by a blown fuse or a broken power cord.

In the case when the lamp burns brightly on one terminal, and at half-glow on the second, and the relay may be activated, you should remove the relay from the socket and connect terminals 85 and 86 with a test lamp. When the ignition is turned on, the control lamp should light up and go out after approximately 20 - 30 seconds. If the lamp lights up and there is poor contact in the connection between the block and the fuel pump relay. If the lamp does not light up, there may be a break in the wire connecting the relay to the controller or the controller itself may be faulty.

Tips for motorists

In the operation of the submersible electric fuel pump on a Gazelle car, the following take part: the main relay, the fuel pump relay, the electronic control unit, and fuses protect this electrical circuit. In addition, if the car has an anti-theft system installed, then another relay will be added to the circuit, which will cut off the voltage supply to the fuel pump terminals.

And those Gazelle cars that run on gas will still start on gasoline and in their electrical circuit of the fuel pump, an additional relay will also be installed that will turn off the operation of the fuel pump at the moment the engine switches to gas.

Therefore, when troubleshooting problems associated with a non-working gas pump on a Gazelle, you need to start by checking the integrity of the fuses . You also need to check the condition of the contacts for oxidation. Next, we check the operation of all relays that are used on this vehicle in the electrical circuit for supplying voltage to the fuel pump terminals. If this does not help, then you will have to check the wiring and connections from the electronic control unit to the main relay and the fuel pump relay.

Another common cause of fuel pump failure is oxidation or burning of the negative contact located on the fuel pump inside the tank. There is a white block there, but please do not confuse it with the block that is located on the surface of the gas tank. Typically, this malfunction initially manifests itself by periodically turning the fuel pump on and off. If this problem occurs, then these contacts will have to be periodically cleaned by removing the module or connected directly once and for all, bypassing the terminal.

Unfortunately, the driver is not always able to independently find faults associated with the failure of the submersible fuel pump on a Gazelle car and has to look for a competent auto electrician to solve this problem.

If the starter of your car turns normally, but the car does not start, the first thing you need to do is check that the fuel pump is turned on. On domestic cars, its operation can be heard from the passenger compartment; when the ignition is turned on, a characteristic buzzing sound comes from under the rear seat or trunk. If the fuel pump does not work, you need to check the integrity of the fuses and the activation of the main relay of the engine management system and the fuel pump relay. On the VAZ-2107, VAZ-2108, VAZ-2109 and their modifications, relays and fuses are located on the shelf under the glove compartment or under it. On VAZ-2110 and similar ones, you should look in the heater console on the passenger side by unscrewing the fastening screws and removing the side cover. On GAZ cars they are located under the hood on the front wall of the cabin, closer to the passenger side.

Fuel pressure measuring device

As mentioned above, the operation of the fuel pump is checked with a special device - a pressure gauge. The most common MP is 100 produced by NTS LLC. We have been using it in our service since 2008, the accuracy of the readings has remained at the factory level. The kit includes adapters and a pressure relief valve.

Pressure gauge MP - 100

Allows you to measure fuel pressure both in the rail if there is a fitting, and anywhere in the fuel line. The set with the pressure gauge includes adapters:

UP-2 adapter extension allows you to take measurements on rear-wheel drive classics.

TPB-2 adapter for quick-release connectors.

Allows you to easily measure pressure on most modern cars.

There are many similar testers for checking fuel pressure. The differences are in price, size, dial. Structurally, all meters are similar. You can make a pressure gauge with your own hands, but the price is not worth it. It is much easier and more effective to contact diagnosticians or any service. They will draw a conclusion and fix the problem.