When cold, the speed floats , with increased fuel supply to the cylinders for quick warm-up, when there is a leak of unaccounted air in the intake manifold, in case of problems with sensors (oxygen, throttle position, mass air flow, engine temperature sensor), low fuel pressure, faulty regulator idle speed and a number of others, depending on the type of engine. If the sensors are faulty, the ECU issues incorrect commands, due to which the engine speed may fluctuate when cold and become high or low.

Most of the problems, regardless of whether it is an injector, a carburetor or a diesel engine, are the same, but there are also some peculiarities that may be the reason why there are drops in speed when cold, and often when hot too. In short, all the reasons why the engine does not maintain speed when cold are displayed in the table, but if you need more specific recommendations for eliminating jumps in the speed of a cold engine, read the article and the comments to it, where car owners often share their experience.

| Cause of malfunction | Faulty node | Necessary actions |

| Injector | ||

| Atmospheric air suction |

| Check all the listed parts by pinching the hoses, using a compressor (compressed air), or a smoke generator |

| Engine sensor malfunction |

| Perform diagnostics of the listed sensors. If necessary, replace them with new ones. |

| Insufficient fuel to maintain engine speed |

| Perform diagnostics, cleaning or replacement of injectors. Fuel up with better quality gasoline. |

| Problems with the ignition system |

| Check the operation of the listed elements. The spark plugs can be cleaned or replaced. Wires and coils are replaced with new ones. |

| Compression reduction |

| Perform a compression check in the cylinders, repair measures depending on the diagnosis |

| Low fuel pressure |

| You need to check the fuel pump, fuel filters (fine filters and mesh), and pressure regulator (the mesh may become clogged). |

| Carburetor | ||

| Not enough fuel or air | Incorrectly adjusted carburetor or clogged jets | Adjust the carburetor, select the optimal idle speed, and clean the jets. |

| Excess air intake | Dirty throttle valve | Clean the damper, check its drive |

| Aperture malfunction | Check and, if necessary, replace the unit | |

| Carburetor gasket | Replacing the node with a new one | |

| Solenoid valve | Diagnostics and, if necessary, valve replacement | |

| Diesel engines | ||

| Insufficient fuel pressure |

|

|

| Incorrect commands from the electronic control unit |

|

|

| Excessive exhaust gases in the intake manifold | EGR system | Check the EGR valve and the operation of the entire system. Correct it or properly suppress it. |

| Air in the fuel line |

| Check the listed elements, if there is a diesel leak, restore the seal, replace the fuel filter. |

Possible reasons

If the speed fluctuates when cold, this is not due to a malfunction of one particular sensor or mechanism. If the internal combustion engine is unstable, you need to diagnose each system in turn:

- Intake tract. Air leaks in the intake system are the most common cause of floating speed when cold.

- Fuel system. We look at the filter, pump and injectors. The latter should be given special attention, especially if it is a diesel engine. Yes, the car starts and pulls up any incline, but when it’s cold, the engine won’t hold speed.

- Sensors Check the mass air flow sensor, air sensing sensor, lambda probe, and idle air control valve. They may be excessively dirty, or may not work due to a short circuit or poor contact.

- Cylinder-piston group. If the compression measurement showed disappointing results, the reason is precisely the CPG.

High engine speed at idle: injector

Engine speed and operation at idle actually means that air is supplied to the engine bypassing the throttle valve. In other words, at idle the specified damper is closed. Note that the normal idle speed for different units is about 650-950 rpm. In parallel with this, a common malfunction is that when the engine is warm, the idle speed remains at around 1500 rpm and above. This indicator is a sign of a malfunction that should be eliminated.

It should also be noted that the idle speed “floats”, that is, for example, it increases to 1800 rpm, after which it decreases to 750 and increases again. Very often, increased idle speed and floating speed are the result of the same breakdowns. Let's take a look at a gasoline-injected unit as an example. In such an internal combustion engine, engine speed depends on the amount of intake air. It turns out that the more the throttle valve opens, the more air enters the intake manifold. Then the ECU determines the amount of incoming air, simultaneously takes into account the throttle opening angle (throttle position) and a number of other parameters, after which it supplies the appropriate amount of gasoline.

Another case is when the engine keeps the idle speed at about 1500-1900 rpm, while running smoothly, the speed does not fluctuate. In this case, we can assume that the injector supplies enough fuel in idle mode that it is enough to operate at such high speeds. In other words, there is excessive fuel consumption. These features may be typical for some engines and absent for others, since there is a dependence on the design of a specific injection system (units with an air flow meter, engines with a pressure sensor in the intake manifold). It is obvious that air leaks are a common cause of increased engine speed or floating speed at idle.

Now let's figure out where excess air can enter the intake. You should look for the problem in four main directions:

- throttle valve;

- channel XX;

- device for maintaining “warm-up” speed;

- servomotor for forced increase in speed XX;

As for the first case, the opening of the throttle valve is controlled by the gas pedal. At idle, the engine should run without pressing the accelerator. It is worth considering that on many cars the gas pedal is mechanical, that is, it is connected to the throttle opening mechanism with a regular cable. If this cable is soured, kinked or overtightened, and problems arise with the mechanism itself, then a banal effect of pressing the gas pedal may occur. In this case, the engine will maintain increased speed, since the ECU believes that the driver is pressing the accelerator and the throttle is slightly open.

Could it be due to the battery?

Let's dispel all the myths right away.

No matter how “dead” the battery is, it will not cause the speed to jump after a cold start. The starter may turn slowly, but the engine will run normally after starting.

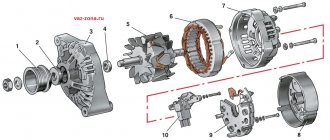

It's another matter if the battery warning light flashes at idle. At the same time, the instrument panel lights flicker, the lights strobe, and the car’s revs fluctuate. Why is this happening? A faulty generator cannot provide normal voltage for the operation of all engine systems. In this case, you can hear a characteristic noise or whistle from under the hood. Usually brushes, voltage regulator, bearings and diode bridge fail.

The conclusion is this: if the revs fluctuate when starting from cold, and the battery light is on, look towards the generator.

In the morning the idle speed of the Lada Kalina is floating

In the morning at -1, the revs on the tachometer are first 500, and after 1-2-3 seconds the warm-up speed is 1100. I changed the wires, changed the idle, changed the TPS, changed the spark plugs, changed the coil, called with a multimeter. I checked the DMRV readings 0.98. I installed a new air filter. I changed the idle sensor, removed the throttle, it was clean.

And still the relay makes one click and from 500 it is set to 1100, as it warms up everything is fine, then it is set to 900 and it starts without any hang-ups. I don’t know where to dig, what to look for?

The firmware has not changed, original Bosch. I don’t really know what the numbers are, just if you can write something. I’m already thinking, maybe there’s something wrong with the firmware during a cold start? So the main thing is that it warms up for 1 minute, I turn it off, start it again, this is no longer the case. It’s just some kind of trouble, and if the frost hits -30, it will completely shut down, well, in general, such things.

- At XX, the engine runs intermittently in the Lada Kalina - 7 answers

- The idle speed on the VAZ Kalina jumped up - 6 answers

- VAZ Kalina stalls 2-4 seconds after starting – 6 answers

- It revs itself in the morning at idle, Kalina – 6 answers

- VAZ Kalina stalls when cold or in the cold - 5 answers

If the engine is already running and produces 500 rpm. Then for some reason the relay clicks, right? There the IAC can only click, then yes, the speed will change if it is faulty. Do you have an IAC or a throttle assembly without it? As for changes in the weather and the dependence of engine operation - this could be due to a faulty mass air flow sensor or just because of the “wrong” air filter.

Which relay clicks? Which relay makes the click?

There in the engine only the IAC can click when starting. And these Russian regulators are of disgusting quality (I bought a new remote control, it was clogged and the heating did not work, and on the new IAC it jammed, replaced it, installed the old IAC and the motor worked fine).

You can read about the same story (about the wrong IAC) here.

You don’t have to bother with the firmware, you have a normal controller. And you can’t fix this question with firmware.

Source

Air leak in intake

These are cracks in the intake manifold, hoses, leaky connection of pipes or breakdowns in the vacuum hose of the brake booster. Often air gets trapped at the junction of the throttle valve and the manifold. Air that is not taken into account by the sensors enters the system, which changes the composition of the fuel mixture.

Broken pipe

The control unit cannot adjust the mixture, because “on paper” everything is clean - exactly as much oxygen as needed has passed through the sensors. On some cars, the ECU still tries to correct the injector corrections, but cold engine operation still remains unstable. By the way, as it warms up the problem may disappear. Why? As the temperature increases, engine parts expand, and if air is sucked in, it is only slightly, without causing problems when the car operates.

If the speed fluctuates on a cold engine, the problem may be hidden by a “sagging” intake manifold gasket, which is completely impossible to notice with your eyes. Visually there are no cracks, there is nowhere for air to get in, and even when hot, the speed levels out. Do not rush to open the manifold - air leaks can be checked with a smoke generator.

Smoke generator

Such a device is available at many service stations. The technician runs a smoke generator into the intake system and controls where the leak is coming from. This is a quick and accurate way to determine leakage, and most importantly, it is absolutely safe for the engine.

Cleanliness of the damper assembly

The throttle valve assembly is diagnosed by visual inspection for contamination. Clean the part with cotton swabs and a toothbrush moistened with a cleaning solution. For ease of work, the device is dismantled. After cleaning, it is recommended to blow out all channels and pipes of the unit with compressed air using a tire inflator.

To clean the part, it must be dismantled.

Attention! It is recommended that the channel responsible for removing gases from the crankcase be completely filled with a cleaning solution before purging - the diameter of the element is very small and there is no other way to access it.

Low fuel pressure

We begin the check with the elementary - fuel filters. There are two of them - coarse and fine cleaning. The first is located together with the pump (usually in the tank), the second is under the bottom or in the engine compartment. The coarse filter should be changed every 100 thousand kilometers, and the fine filter once every 30 thousand. Replacement may be required earlier if bad fuel was accidentally filled in.

If after replacing the filters the car still does not hold speed, starts poorly when cold and may stall, check the fuel pressure regulator.

Fuel pressure control

On a car with high mileage, the valve membrane is damaged, causing the engine to not receive the required amount of fuel. Fortunately, the part is inexpensive and can be changed quickly.

If diagnostics show that the old regulator maintains fuel pressure, the pump may be the cause of all the troubles. The blades, bearing or the electric motor itself may be faulty.

Popular brands:

Audi RS 7, Mazda CX–7, Skoda Octavia

Description of actions to eliminate speed instability

When carrying out measures to restore air leaks, the tightness of the lines supplying air to the collector is checked. Each tube is removed and purged using a pump or compressor. Additionally, a WD 40 solution is used. Where the liquid evaporates quickly, the integrity of the line is compromised, in which case the hose must be replaced with a new sample.

To diagnose the idle air control valve, use a multimeter to measure its resistance. If the resistance value is 40–80 Ohms, the regulator needs to be replaced.

The crankcase is disassembled to remove the ventilation valve and then washed in kerosene to remove oil deposits. After thorough drying, the valve is returned to the ventilation system.

If the mass air flow sensor fails, it is replaced with a new one.

When cleaning the throttle valve, special aerosols, a brush, and rags are used. This procedure can be performed directly on the engine, which has had time to warm up, or by removing it from the power unit. The appearance of white smoke indicates that oil sludge has been removed. After flushing and installation are completed, the dampers are reprogrammed to set the nominal opening gap.

Adjusting the engine in idle mode is done using a set of screwdrivers to adjust the rotation screws.

A breakdown of the solenoid valve contributes to the occurrence of jumps in engine speed. This item cannot be restored and must be replaced.

The jet is cleaned using a special aerosol liquid used when washing carburetors. The product is poured into the nozzle, after five minutes the cleaning liquid is removed using compressed air.

To treat the fuel injection pump impeller, a special agent is used to remove traces of corrosion. It is sprayed directly into the neck before pouring fuel. Cleaning the inside of the tank is done using this product. To prevent corrosion, 200 grams of engine oil is poured into the fuel tank to protect the blades.

If the engine starts to jump at idle, the speed is disrupted when the engine warms up, you need to undergo diagnostics at a service station in order to check and restore the integrity of the components and parts of the power unit systems.

Idle speed control

The regulator tends to become dirty at a distance of more than 100 thousand kilometers. Because of this, the regulator rod begins to jam, and sometimes jams in one position. The speed fluctuates when cold, sometimes even when hot. At the same time, the motor rotates without problems under load.

Idle speed control

There are two options for solving the problem - disassemble and clean the old regulator, or replace the IAC with a new one. It is important to know that Chinese substitutes quickly fail, so try to buy original IACs or analogues from trusted manufacturers.

How can I check the regulator and flow meter?

If the speed begins to fluctuate with enviable regularity, it is better to start diagnostics by checking the air-fuel mixture flow sensor. The following symptoms indicate a malfunction of the air flow sensor:

- A cold motor “floats” and there are interruptions.

- The engine does not start the first or even the second time, sometimes it does not start at all.

- Fuel consumption exceeds all permissible limits.

How can you determine when it’s time for the sensor to retire? It’s very simple - use a regular tester. It should show 1 V if the MAF is ok. Otherwise, you will need to make a replacement.

We've sorted out the flow meter - now let's talk about the regulator. The speed in your engine may fluctuate due to the fact that the idle speed regulator has failed. It is responsible for quickly increasing or decreasing the fuel supply, using a rod with a needle for this purpose. Among the key malfunctions of the regulator are:

- Quite unstable, “ragged” operation of a cold engine when idling.

- In neutral, the engine suddenly turns off.

- Unexpected changes in speed even when the engine is well warmed up.

- Lack of normal power growth when the engine is already running.

Power (more precisely, engine speed) drops when several consumers come into operation at once. Even ordinary headlights can make noise. If the above symptoms are observed, the regulator will need to be replaced.

Sensors

We inspect all sensors that may affect engine idle operation. These are the sensors:

- mass fuel consumption;

- throttle position;

- internal combustion engine temperatures;

- absolute air pressure;

- intake air temperature.

The engine ECU receives information from the sensors based on their voltage, which varies under different conditions. If the contact is bad or damaged, the data will be incorrect.

The ECU will incorrectly adjust the mixture or go into “emergency mode” - try to at least somehow maintain the speed, just so as not to stall the engine. It’s not necessarily a matter of wiring - despite the simplicity of the device, the sensor itself can also become unusable. There are frequent cases when owners installed sensors that were not suitable for a specific internal combustion engine or sensors from unknown manufacturers, which is why the speed problem did not go away.

Only after proper diagnostics will it become clear which sensor is faulty and requires replacement.

Checking the sensors

Unstable operation of a cold engine can also be affected by malfunctions of the speed and crankshaft operating position sensors. The speed sensor is located on the gearbox itself, which serves to transmit signals to the controller, thereby monitoring engine operation in idle mode.

Together with the XX regulator, the controller regulates the supply of air volume outside the throttle valve, and the frequency of the signal is directly proportional to the vehicle speed. In addition, thanks to this sensor, there is a significant saving in fuel consumption. If the sensor rod breaks, the speedometer needle will remain motionless until it is repaired.

The sensor responsible for the working position of the crankshaft is not only capable of influencing the floating operation of the engine, but also completely disabling it. It serves to synchronize the engine ignition systems and fuel supply system. If this sensor fails, the relationship between these systems is disrupted, i.e. it just won't start. You can determine its performance using a multimeter, and if the reason is still in it, then you need to hurry up with its replacement.

Oxygen sensor

It is also a “lambda probe”. A sensor that analyzes the percentage of carbon dioxide in the exhaust. Interacting with the lambda, the ECU adjusts the mixture entering the combustion chamber. Note that this sensor only works in warm mode (from 300 degrees) - at a time when the probe is not warmed up, a slight fluctuation in revolutions is possible. This should happen for no more than 20 seconds.

Oxygen sensor

But if the engine continues to mope even at operating temperature, it is worth examining the lambda in more detail. Often this sensor becomes dirty or the contacts bend, causing the output voltage to change (more than 0.45 Volts) and the unit receives incorrect data. If computer diagnostics show errors in the lambda (there may be several of them), it is worth replacing the sensor and checking the engine operation again.

In general, the lambda probe is a common problem, both on our cars and on foreign cars. With our fuel quality, the sensors do not last more than 100 thousand kilometers and, from time to time, cause headaches for owners.

You can solve the problem radically - install “decoys” or reflash the ECU for Euro-2, while removing the catalysts. Or leave everything as is and just change the sensors periodically.

Do-it-yourself troubleshooting

Many faults from the above list can be eliminated yourself in a few minutes. It will take much more time to identify.

Diagnostics of mass air flow sensor and IAC

The mass air flow sensor and idle air control act as regulators of air supply to the combustion chamber.

Failure of these sensors will lead to an increase in fuel consumption, and a broken rod will affect the speedometer needle; it will remain motionless until the problem is fixed.

Diagnosis of DPCV

Crankshaft rotation sensor location

Failure of the crankshaft position sensor will negatively affect the operation of the engine as a whole. A failure in synchronization between the engine and the injection system will result in the car not starting. You can accurately determine the condition of the sensor only by using a multimeter.

To do this you need to do the following:

- Set the position on the sensor with a maximum value of 200mV;

- Connect the multimeter and close the core with a screwdriver;

Checking DPKV with a multimeter

Video about checking the crankshaft rotation sensor

Lambda probe diagnostics

Location of the oxygen sensor (lambda probe)

The sensor reads the amount of oxygen in the exhaust gases and sends a signal to the computer to increase or decrease the air supply to the combustion chamber. Diagnostics is performed with a multimeter on a warm engine. The procedure is as follows:

- One core of the device clings to the ground, the second to the output from the sensor;

- When re-gassing the engine, the multimeter readings should be in the range from 0.2 to 0.9 V;

Wear of CPG parts

At first, this problem may only occur when the engine is started cold. The owner will notice terrible vibrations and a slight deviation in idle speed. As they warm up, the parts of the cylinder-piston group expand and the backlash goes away. The motor works as it should. But as soon as it cools down, the vibrations repeat again.

Wear of the cylinder-piston group

If you notice this feature, check the compression in the cylinders:

- for gasoline engines the normal value is from 10 to 14 Bar;

- for diesel engines - from 20 to 28.

The pressure difference across the cylinders should be no more than 10 percent. If the results are disappointing, it is worth performing an endoscopy of the engine. It happens that the “hon” on the walls is intact, but the compression is still low. There are several reasons. One of the simplest ones is burnout of the cylinder head gasket. If the gasket is intact, look at the valves and rings.

Occurrence of rings

A common cause of low compression is coked rings. This occurs due to the use of bad oil or fuel, or untimely maintenance. Decarbonization will help solve the problem, but this requires disassembling the engine.

Engine temperature sensor

If the device breaks down, the dashboard provides incorrect data regarding the engine temperature. To check and change the temperature sensor, proceed according to the following algorithm :

- Prepare an autothermometer for working with high temperatures, a tester and a metal basin with water for heating on the stove.

- Disconnect the connectors and, substituting the basin, remove the sensor from the socket. A plug is placed in place of the sensor.

- The device is placed in cold water with the side screwed into the cylinder head. Measure the resistance and put the basin on the gas.

- Measurements are taken several times at different temperatures and compared with the standard data in the service book.

Significant discrepancies indicate the need to replace the temperature sensor with a new one.

Why do carburetor speeds fluctuate?

If the cold speed of a carburetor engine fluctuates, it could be:

- Incorrect carburetor setting. Often it is not possible to adjust the idle jet.

- Diaphragm wear. When cold, the material may become stiff, causing the speed to fluctuate.

- Carburetor gasket. It also gets dull and causes air leaks. Typically, as it warms up, the material softens and the speed levels out.

- Solenoid valve. If it does not make a click when connected directly, the part must be replaced.

Is the EGR system on the injector working?

"Floating" speed can be caused by jamming of the exhaust gas recirculation (EGR) valve, which is installed in the exhaust manifold. It is necessary to periodically remove dirt from the valve seat and its seat using a carburetor cleaning aerosol, avoiding liquid getting on the sensor diaphragm.

The valve seat must be kept clean.

Attention! If cleaning the unit does not give a positive result, the device must be replaced.

Why do diesel engine speeds fluctuate?

We immediately look at the fuel injection pump. Over time, rust can develop in the pump. Natural wear and tear should not be excluded. As a result, fuel is supplied to the injectors under low pressure, injection occurs too early, and detonation occurs. If you're lucky, you can limit yourself to adjusting the injection advance. In the worst case, a complete repair or replacement of the fuel injection pump.

High pressure fuel pump

A diesel engine may also suffer due to EGR. The recirculation valve sticks, causing the speed to fluctuate when cold. Cleaning or replacing the valve helps eliminate the problem.

Loss of speed when starting the engine when hot

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

So my problem was that during the launch the DPZ showed 3-6 percent. and precisely at an engine temperature of about 20 degrees.

Good day everyone! I still have a problem with starting the engine. It started with the fact that immediately after starting the engine at a certain temperature (10-25 degrees Celsius), the engine does not run smoothly for 2-5 seconds, but does not fluctuate, the speed fluctuates by ear, is underestimated, about 1000, but the tachometer does not reflect the swimming, the BC shows a slight floating of about 50 rpm, if immediately after starting you lightly press the gas pedal for a split second and release, then the rpm immediately reaches the warm-up speed, about 1200-1500, and in the future this problem does not recur, now this The problem began to appear when starting a hot engine, if it sits for about 5-10 minutes, after turning off the ignition, everything is the same, only the speed is lower, no errors appear. When starting the engine at a temperature below 5 degrees, everything works fine, it immediately warms up and that’s it. The mileage is 35k, the problem started at about 4k, it does not appear all the time, out of 3-4 starts one is with a drop in speed.

Same problem. When it warms up to 36 degrees, the revs start to fluctuate and the engine twitches. It seems that this happens at the moment the calculation of the mixture is switched to the oxygen sensor (after it warms up).

_________________

Same problem. When it warms up to 36 degrees, the revs start to fluctuate and the engine twitches. It seems that this happens at the moment the calculation of the mixture is switched to the oxygen sensor (after it warms up).

Source

What to do to fix the problem

As we have already seen, the problem of floating speed can be hidden in different places. Therefore, if you notice unstable engine operation, you need to seek diagnostics in time. Experienced DDCAR specialists will help determine the cause of the malfunction and eliminate it as soon as possible.

Engine diagnostics

Correct diagnosis is 90% of success in solving a problem. You should not spend money prematurely on purchasing sensors and other parts in the hope that after replacing them the problem will go away. There's a good chance it will be wasted effort. Listen to your car, have it serviced at trusted service stations and contact experienced diagnosticians!

Choosing an auto electrician - main features

Most problems with increased speed, increased fuel consumption, and unstable idling are solved by an electrician. This specialist finds problems in the electrical part of the car, diagnoses all components, and carries out repair work in the electrical part. You are unlikely to figure this out on your own; you will have to try hard to study the wiring diagram for all the parts of your car. And finding the location of all the sensors is often difficult, especially in a technologically complex modern car. So you need to entrust the work to an experienced craftsman.

When choosing an auto electrician, consider the following features:

official service - in most cases this will be the best solution, since here specialists work only with one specific brand of car and provide a guarantee of quality; the equipment of the service station plays an important role in identifying potential problems in your car; you just need to make sure that the station is well equipped and has normal equipment; experience of a specialist - pay attention to who exactly will service your car, the technician must be quite experienced, it is better to check reviews about him from different sources; a good option is to choose an electrician by recommendation; if you do not use the services of an official station, the recommendations of your friends will help you find the optimal service; It is worth starting cooperation with diagnostic services; diagnostics will show how competent the specialist is and whether there is any point in further cooperation with these specialists.

As you can see, there are several ways to check a person’s competence and make sure of his professionalism. If you decide to have your car serviced at an unverified station, be sure to be present during the repair and monitor every step of the technician. This is your right, it is quite possible to be present during repairs even in a garage station, where not a single master will like it. You can leave your car unattended either with the officials or with a trusted service that you have been working with for quite a long time. Keep this in mind the next time you need to go get your car repaired.

We also suggest watching a video about car diagnostics:

Methods for eliminating floating engine speeds

When starting to find and eliminate the reasons that cause unstable operation of the engine in idle mode, you first need to check:

- Condition of the air filter and spark plugs. If they become critically dirty, they need to be replaced.

- Integrity of insulation of high-voltage wires. If damage is found, they must be replaced.

It is recommended to make sure that there is no suction at the junction of the intake manifold with the engine cylinders. To do this, with the engine running, you need to sequentially spray all joints at the joints with carburetor cleaner or other flammable liquid. If atmospheric air enters there, the car engine jerks sharply, which is why, if a damaged gasket or plug is detected, the element is replaced.

Checking the tightness of the intake manifold (video guide)

Let's consider the remaining elements of the car, the malfunction of which can affect the smooth operation of the VAZ 2114 engine in idle mode.

Solenoid valve diagnostics

Cars with engines equipped with a carburetor are equipped with idle speed solenoid valves. Devices are checked as follows:

- Disconnect the power cord.

- Start the engine to warm up.

- Connect the wire. If a clear click is not heard, the part must be replaced.

Attention! To fully ensure that the valve is working properly, be sure to clean the nozzle and repeat the test.

Is the EGR system on the injector working?

"Floating" speed can be caused by jamming of the exhaust gas recirculation (EGR) valve, which is installed in the exhaust manifold. It is necessary to periodically remove dirt from the valve seat and its seat using a carburetor cleaning aerosol, avoiding liquid getting on the sensor diaphragm.

Keep the valve seat clean

Attention! If cleaning the unit does not give a positive result, the device must be replaced.

Adjusting the idle speed on a carburetor engine (with video)

Note that the main reason for the appearance of floating idle speed in engines of this type is the incorrect operation of the carburetor. The device is adjusted by rotating the fuel quality and quantity screws.

Is the idle air control valve working correctly?

The IAC is checked by measuring the electrical resistance at the contacts - to diagnose the device you will need a tester (multimeter) set to the “ohmmeter” operating mode. To check the details:

- Let's turn off the ignition.

- Disconnect the connection block.

- Let's measure the resistance on contacts A - B and C - D of the device. The optimal readings of the device vary from 40 to 80 ohms.

- Let's repeat the measurements with contacts B - C and A - D. In this case, the multimeter should show “infinity” or an open circuit.

Any violation of the normal resistance values means a malfunction of the regulator. IAC failure is a common cause of floating engine speed at idle, and if a malfunction is detected, the device must be replaced. Before you begin dismantling the part, you must disconnect the negative wire from the battery. After installation, the new IAC is calibrated - the removed terminal is returned to its place, the ignition is turned on and after 5-10 seconds (there is no need to start the engine).

IAC failure is a common cause of floating engine speeds.

Attention! If the battery is not disconnected before dismantling the device, the electronic control unit will not calibrate the IAC.

Cleanliness of the damper assembly

The throttle valve assembly is diagnosed by visual inspection for contamination. Clean the part with cotton swabs and a toothbrush moistened with a cleaning solution. For ease of work, the device is dismantled. After cleaning, it is recommended to blow out all channels and pipes of the unit with compressed air using a tire inflator.

To clean the part, it must be dismantled

Attention! It is recommended that the channel responsible for removing gases from the crankcase be completely filled with a cleaning solution before purging - the diameter of the element is very small and there is no other way to access it.

Video: How to clean the throttle body

Is it possible to diagnose DPKV and DSA?

A breakdown of the DPKV and DSA (Hall sensor) is indicated by the Check Engine indicator that lights up on the car’s dashboard. Testing these devices is only possible using special instruments (oscilloscopes). You can first check the integrity of the wiring; if it is broken, the damage should be repaired.

- The DPKV sensor is installed on a bracket located in close proximity to the generator drive pulley.

- The DSA is located on the speedometer drive mechanism of the gearbox.

For a more detailed introduction to methods for detecting faults associated with engine malfunction in idle mode, it is recommended to watch the following video.

Video: Computer diagnostics of VAZ 2114 idle problems

So, the main steps to rid the car of floating engine speed at idle are considered. Remember: if performing these operations yourself does not lead to a positive result, you will have to contact a service station with the necessary diagnostic equipment and qualified repairmen.

The main culprits of problems with the level of revolutions

We must admit that each car will have its own nuances in this regard. RPM can increase both due to problems and errors in the software. Sometimes it happens that the driver simply operates the car incorrectly, which can cause the most unpredictable problems and malfunctions. It is worth using a thematic forum and finding specific answers to questions. Very often, owners of the same cars can tell you the reasons for problems with speed.

Frequent culprits of problems are the following:

- electronic engine control unit - the firmware that gives commands to set certain speeds may fail, and mechanical damage to the unit is also possible;

- the IAC sensor or regulator is a childhood disease of almost all Lada cars, the IAC quickly fails, since it is quite complex, only replacing it will help save the situation;

- other sensors - TPS, DBP (or mass flow sensor), coolant temperature sensor and other electronic elements in the control system of your car may be responsible for the speed level;

- throttle valve - usually increased speeds are associated with the fact that the ECU switches the throttle operation to emergency mode, opening it slightly, which is why the engine begins to roar;

- wiring - it is the lack of contacts or intermittent contact in the wiring that leads to the fact that the car begins to have real problems with speed and the activation of certain sensors.

Such problems are inevitable if your car is old enough. In this case, the machine will receive a number of risks in terms of wiring operation. Factory terminals and wire crimps become loose, oxidize, and this leads to wiring problems. Of course, you should be very careful with the diagnosis in this case, since the electrical part of the car is quite thin and delicate. Wrong decisions here can cause a short circuit and even a car fire. So it is better to entrust work with electricity to an electrician.

Drawdown in speed when hot after startup

#1 yujin

Locals 100 messages

- D/b: 09/13/1984

- Gender: Man

- Car: S-Max

- Engine: 2.3i (160PS)

- Name: Yuri

- Transmission: Automatic

- Year of manufacture: 2008

- Lives: Lyubertsy

Engine 2.3 petrol. When cold it starts well and the speed gradually drops as the engine warms up. When you start it hot, the speed first jumps as expected at the start, but then drops below idle, and then returns back to normal. Sometimes with such a drawdown the car stalls and you have to start it again.

What could be the problem?

#2 ZIRON

Club residents 3,020 posts

- Gender: Man

- Car: Other

- Engine: Other

- Name: Ilnur

- Transmission: Automatic

- Year of release: 2018

- Resides: N-URENGOY

Post edited by ZIRON: 07 November 2016 - 8:01

#3 yujin

Locals 100 messages

- D/b: 09/13/1984

- Gender: Man

- Car: S-Max

- Engine: 2.3i (160PS)

- Name: Yuri

- Transmission: Automatic

- Year of manufacture: 2008

- Lives: Lyubertsy

#4 ZIRON

Club residents 3,020 posts

- Gender: Man

- Car: Other

- Engine: Other

- Name: Ilnur

- Transmission: Automatic

- Year of release: 2018

- Resides: N-URENGOY

#5 yujin

Locals 100 messages

- D/b: 09/13/1984

- Gender: Man

- Car: S-Max

- Engine: 2.3i (160PS)

- Name: Yuri

- Transmission: Automatic

- Year of manufacture: 2008

- Lives: Lyubertsy

The filter mesh was changed along with the motor. The paper one in the non-separable part of the fuel pump remained. For other points, you need to contact the service department. I just don’t understand why there are dips when it’s hot if the pump doesn’t pump well?

#6 ZIRON

Club residents 3,020 posts

- Gender: Man

- Car: Other

- Engine: Other

- Name: Ilnur

- Transmission: Automatic

- Year of release: 2018

- Resides: N-URENGOY

#7 yujin

Locals 100 messages

- D/b: 09/13/1984

- Gender: Man

- Car: S-Max

- Engine: 2.3i (160PS)

- Name: Yuri

- Transmission: Automatic

- Year of manufacture: 2008

- Lives: Lyubertsy

Perhaps I did not describe the problem quite correctly, but the idle speed remains excellent. But it is precisely when starting on a hot engine that they sag for just a couple of seconds, and then return to normal. Maybe the injectors should be washed, but this is unlikely to solve the problem. As for the throttle, I don’t want to get into it. I read a lot on the forum about people having problems after performing this procedure, but it doesn’t really help

#8 ZIRON

Club residents 3,020 posts

- Gender: Man

- Car: Other

- Engine: Other

- Name: Ilnur

- Transmission: Automatic

- Year of release: 2018

- Resides: N-URENGOY

Perhaps I did not describe the problem quite correctly, but the idle speed remains excellent. But it is precisely when starting on a hot engine that they sag for just a couple of seconds, and then return to normal. Maybe the injectors should be washed, but this is unlikely to solve the problem. As for the throttle, I don’t want to get into it. I read a lot on the forum about people having problems after performing this procedure, but it doesn’t really help

Nonsense about the throttle, everything can be removed and washed without any problems, you can do it without removing it, just fold back the rubber pipe, do not turn on the main ignition, and for greater safety, remove the terminal from the battery, perhaps a coating has formed behind the throttle valve and the gap has decreased between the valve and the body when the damper returns to the idle position, the engine stalls due to lack of air, and sometimes the engine’s brains manage to correct the lack of air.

#9 yujin

Locals 100 messages

- D/b: 09/13/1984

- Gender: Man

- Car: S-Max

- Engine: 2.3i (160PS)

- Name: Yuri

- Transmission: Automatic

- Year of manufacture: 2008

- Lives: Lyubertsy

I decided to change the air filter. When I removed the filter casing, I discovered that the pipe going to the throttle was not tightened, and almost came off on its own. I removed all the plastic and at the same time wiped the damper along with the walls. Replaced the filter. I screwed everything back and the problem disappeared. Perhaps the failures appeared due to a poor fit of the pipe to the damper.

#10 yujin

Locals 100 messages

- D/b: 09/13/1984

- Gender: Man

- Car: S-Max

- Engine: 2.3i (160PS)

- Name: Yuri

- Transmission: Automatic

- Year of manufacture: 2008

- Lives: Lyubertsy

in general, after more than six months the problem returned

Source

How do you know when high revs are a problem?

You need to understand why the engine started running at high speeds, and what a high speed level actually means specifically for your motor. For example, Lada Granta can increase engine rotation to 2000 RPM if it is cold outside. This is done by most injection machines that have an engine warm-up program. In the summer, startup usually occurs at a level of 1100-1200 RPM, but in winter the picture may be different. But this is not at all connected with malfunctions and problems. Rather, it indicates the correct operation of the sensor system and electronic components in your car.

The following behavior of the car can be considered a problem:

- there are difficulties with starting, and after starting the engine begins to spin up to a level of more than 2500 rpm, in this situation there is clearly a problem, it needs to be solved as quickly as possible;

- after a successful start, the speed level begins to wander, jump, the tachometer needle trembles or moves across the entire field of numbers, the process is accompanied by a constant roar of the engine;

- the car reaches normal speed to warm up (up to 2000 rpm for most cars), and then the tachometer needle no longer drops to the proper place of idle speed;

- after successful warming up and immediately upon starting to move, the tachometer needle hangs for a long time at high speeds, this is abnormal behavior of the car and a very frequent breakdown;

- sharp transitions from one speed level to another - the engine can warm up normally, and then suddenly drop the speed until the engine stalls or shakes under the load.

All these nuances indicate that it’s time to work on the car.

Pay attention to the car's behavior. It is quite possible that changes in the behavior of the car when starting are due to the fact that the car is simply warming up the engine before driving

If everything happens smoothly and within the permissible speed limits, there is no point in worrying. But any extremes will cause trouble. If you notice specific problems, it's time to act and return the car to normal. True, this may not be easy to do.