How can you tell if your car's air conditioning clutch is faulty?

To understand that the car air conditioner clutch is faulty, you should pay attention to the fact that the air becomes burnt and any extraneous noise occurs when the clutch rotates. By the way, the last sign indicates bearing damage. It is worth mentioning that when the car’s air conditioning clutch begins to operate, it emits a characteristic click, indicating its engagement and the start of movement. In this regard, if the clutch does not make a characteristic clutch click, the problem most likely does not lie with it.

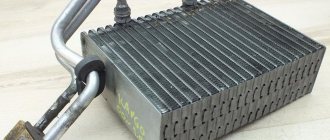

Most often, it is the bearing that is faulty, since it is the most vulnerable part of the air conditioner.

This is due to the fact that it is constantly in operation from the moment the car engine is turned on. Because of this, the bearings wear out. As a result of wear, the bearing often makes noise that the driver can hear in the engine compartment. However, it is worth saying that the noise can be different, sometimes it can even resemble a howl. It is better to notice the malfunction and eliminate it immediately, since the more neglected it is, the more the surrounding mechanisms will be affected, for example, the evaporator of a car air conditioner. So, it is best to replace faulty and worn parts immediately after they are discovered. You can do this in our workshop

What bearings are on the Priora generator (VAZ 2170): size, price, article number

We have already figured out how to replace failed parts. Now it remains to understand which bearing is better to buy. There are different generators on Priors - 115A or 90A. The second is for a less powerful car without air conditioning and power steering. Ball bearings have a number (marking). The front element is 6303, the rear element is 6202.

There are a lot of both original and non-original spare parts on the market:

- Front ball bearing 6303: FAG 6303 2ZR (Germany), SKF 6303-2Z (Sweden), KOYO 6303 ZZ, CM (Japan), NTN 6303 ZZ (Japan).

- Rear ball bearing 6202: FAG 6202-С-2HRS, SKF 6202-2-RSH, KOYO 2RS, NTN; 6202LLU.

In addition to the bearings listed above, below is a table that will help you navigate the offers on the market and select the best quality part:

Selecting a generator bearing - price and manufacturers

| No. | Brand | Catalog number | Price 2022, rub. | ||

| Front | Rear | Front | Rear | ||

| 1 | ASAM Romania | 30904 | 30903 | 200 | 270 |

| 2 | Bosch Germany | 1120905533 | F00M990410 | 420 | 450 |

| 3 | NTN France | 6202-LLU | 6303-LLU | 280 | 330 |

| 4 | KOYO Japan | 140084 | 140093 | 400 | 500 |

Priora generator bearing dimensions

| Characteristic | Unit | Values according to GOST (TU) | |

| 6-180202 | 6-180303 | ||

| Inner diameter | mm | 15 | 17 |

| External diameter | mm | 35 | 47 |

| Height | mm | 11 | 14 |

| Static load capacity | N | 3550 | 6650 |

| Dynamic load capacity | N | 7800 | 13500 |

| Speed | rpm | 24000 | 19000 |

| Radial clearance | mm | 0,008-0,022 | |

| Steel type | — | SHH-15 | |

| Hardness of rings and balls | H.R.C. | 61-65 | |

| Lubricant type | — | C17, Litol | |

| Ring roughness | Ra | 0,32 | |

| Torque | H*M | — | |

| Number of rolling elements | PC. | 8 | 6 |

| Ball diameter | mm. | 5,953 | 9,525 |

| Weight | G. | 0,045 | 0,115 |

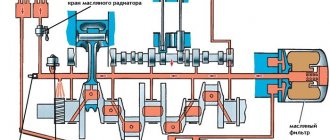

Electromagnetic clutch device

The compressor clutch on a car air conditioner is a fairly simple device, consisting of only three main parts:

- electromagnet coil;

- belt pulley;

- pressure plate (driven disk).

You can also add fasteners (bolts, snap rings) and shims to this list.

Typical faults and their symptoms

Most often you have to deal with two main failures: wear of the pulley bearing and a malfunction of the electromagnet. The destruction of the bearing is indicated by a characteristic hum that is heard constantly, regardless of whether the air conditioner is on or not.

If the bearing is not replaced in time, pulley play may occur. In this case, it will touch the pressure plate, producing an unpleasant grinding noise and the smell of a burnt clutch.

If the electromagnet fails, the plate does not press against the pulley and, accordingly, the compressor shaft does not rotate. Sometimes this is accompanied by smoke and the smell of burning insulation, and the fuse blows.

Recommendations for replacing and operating the clutch bearing

Tips for performing operations on the compressor rolling unit:

- Before changing a part, it is necessary to thoroughly clean the surface of dirt. The soured part exhibits noticeable resistance when pressed out. There is no need to hit the pulley with a hammer or heat it until red - this will lead to its deformation and cracking.

- When manipulating the pulley, it is important not to lose the spacer. It has a special size. A new washer may lead to incomplete activation of the magnetic clutch, which means that it will be difficult to turn on the compressor.

- To tighten threaded connections more accurately, use a torque wrench.

- It is better to save a failed unit. This will help you find a replacement faster.

- Clean all surfaces during the renovation process. This is the key to the operation of the node.

- The main advice is to always listen to the operation of the units under the hood. Excessive noise is a signal of a problem.

Is dismantling necessary?

As a rule, to repair a compressor, it has to be dismantled. In this case, naturally, the freon from the air conditioner is drained. After the repair, the air conditioner needs to be recharged again, which means extra money. Is it possible to remove the compressor clutch without removing the compressor itself and without compromising the tightness of the system?

Repair of the air conditioning compressor clutch on a car without dismantling, but not on all car models. Some manufacturers position the compressor so that it is quite easy to remove the belt, pulley and solenoid coil. In other cases, you will have to remove the wheels, bumper or other parts, but the compressor itself can be left in place. Well, and finally, in the third case, you cannot do without complete dismantling. You can check with a car service employee about the situation on your car. At the same time, he will tell you how long the procedure will take and how much it will cost.

Common causes of air conditioner breakdowns

The main part of the load during operation of the cooling system goes to the compressor. Therefore, most often it is he who fails. Its timely repair and preventive actions will save you from the need to save money for a new part. If the air conditioning compressor does not turn on, there may be two reasons for this breakdown. The air conditioner may operate intermittently either due to a compressor failure or due to a faulty clutch. In this case, it is possible to repair the air conditioning compressor yourself.

How does the air conditioning compressor clutch work?

The main purpose of the air conditioning compressor clutch is to provide a force connection between the compressor and the engine.

The main elements of the coupling are:

- belt pulley;

- spring-loaded disc with hub;

- electromagnetic coil.

In their work they interact with each other like this:

- You press a button to turn on the air conditioning;

- power is supplied to the electromagnetic coil;

- the magnetic field created by the coil attracts the pressure plate to the pulley;

- torque is transmitted from the engine to the compressor shaft;

- the compressor, starting to work, pumps freon;

- the car interior becomes fresh and cool.

That is, everything is simple: inclusion-attraction-work. Things get much more complicated when you need to determine where in this chain the failure occurred.

Troubleshooting

- First you need to make sure that the breakdown is in the air conditioning compressor. A fuse check is required. If you still need to replace them, then do it and then do not forget to tighten the fastening bolts. In some cases, only this is enough to resume normal operation of the compressor. After checking the fuses, did you realize that they are normal? We continue to look for the cause of the breakdown.

- Let's proceed to the next step, which consists of diagnosing the wires going directly to the compressor. Also, don't forget to check your contacts. The breakdown may also involve damage to the compressor drive belt. Replace this part if necessary.

- For this purpose, we look at the presence of lubricant on the pressure plate and rotor. After this, special care must be taken to inspect such a part as the air conditioner compressor clutch bearing; there may be a lubricant leak or extraneous noise. Using an ohmmeter, you should set the coil resistance. In cases where it differs from acceptable, replacement is necessary.

- When a compressor makes too much noise while running, it is most likely a sign of a bad drive pulley bearing. If necessary, it should be replaced. Remember that you need to use a special lubricant, without this there is no way. Just as you should check the air conditioner clutch bearing, you need to diagnose and, if necessary, replace faulty parts.

- We check the compressor for the presence of refrigerant. In addition, potential leakage sites of this substance need to be diagnosed. To perform this action, fluorescent paint is required. You can buy it at almost every car store.

It is recommended to check the air conditioner and its compressor using a flashlight with ultraviolet light to identify possible leaks. If a leak is detected, you can fix the problem. It is worth noting that damage can be different and of a very diverse nature. So, this can include the mechanical origin of the breakdown - damage to the refrigerant lines or the compressor itself. It may also be “temporary” in nature, due to the effects of corrosive processes.

If faults and damage are detected in a timely manner, their nature, scale and possibility of correction should be assessed. Sometimes a puncture or crack can be patched, but for this purpose it is necessary to have special welding equipment. After repairs are completed, the compressor is charged with a special substance intended for these purposes.

If repairing the air conditioner clutch does not help, or the problem is somewhat different, then it is better to contact a specialized technician. He will help in solving the problem. This will restore normal operation of the air conditioner.

Step by step replacement

Let's consider the replacement sequence. The first step is to remove the compressor from the car. There may be slight differences on different models and brands of cars, but the general sequence is approximately the same everywhere. For this purpose, we place the car in the “pit”, and if this is not possible, we jack up the front of the car from the compressor side and remove the wheel.

Don’t forget, to avoid the car falling off the jack, place something suitable under the body in the suspension area. I do not recommend placing stops under the thresholds; they wrinkle very easily. Then unscrew the bolts securing the compressor. Usually there are four of them, but on some car models there may be three. It is possible that the generator will interfere with this procedure. Then it is better to remove it first for ease of work.

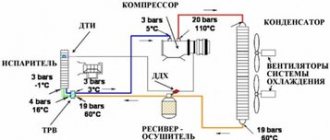

Filling the air conditioner with freon

After completing the system assembly process, you will need to put back its compressor. Next, you need to check for leaks. Thus, you will face your first difficult task. In refrigerators, air can be pumped inside quite simply, since some freon residues should remain inside. But in the case of a car air conditioner, the refrigerant has managed to decompose. Of course, it will not harm the ozone layer, but the need to check the tightness of the system is only once again proven. You should also know how to remove the air conditioning compressor clutch.

You need to find a service valve, after which you can connect the manifold. Then you should pump air inside if there is low pressure. After all this, you can start using the leak detector. It should be remembered that not all brands of freon can be suitable for a particular device. To ensure a successful search, the pressure must be about fifteen atmospheres. This is true if there are copper tubes. Remember to check the manual.

Next, we proceed to diagnosing and repairing the compressor. After this, you can put it in place and assemble the system. In this case, it is also necessary to check it for leaks. All rules must be followed.

- The system is subjected to a nitrogen purging or vacuum process to eliminate any remaining freon, as well as moisture and/or air. It is imperative that the receiver-dryer is operational. This is explained by the fact that it is he who will have to absorb moisture during vacuuming. As for the nitrogen component, it has found its application not only to prevent the possibility of fire. It does not absorb moisture, but transports it. As it passes through the receiver-dryer, all the water will be absorbed.

- The evacuation process, in turn, occurs through a collector. As for control, it must be carried out using a pressure gauge. For more effective and, at the same time, reliable removal of moisture, it is highly recommended to wait a certain period of time with the pump running.

- Also, the electromagnetic clutch of the air conditioning compressor may be the reason that led to the compressor breaking down. In this regard, it would not be superfluous to carry out diagnostics of this component.

- Upon completion of the above processes, you can begin to shut off the collector taps. Regarding what kind of filling mass is taken, you need to check what is indicated on the instructions pages. Control is carried out by weight. As for the refrigerant, it goes inside under its own pressure. After completing the filling process, do not forget to turn off the tap.

This can finally complete the repair process. At the same time, we should not forget about possible leaks. Alternatively, you can pump air inside before vacuuming and then perform soaping. True, this method is not the most reliable, although it often helps out at the junctions. Thus, he will be able to help in troubleshooting problems associated with compressor damage with his own hands.

Panasonic Priora air conditioner bearing

Just find the Lada air conditioner bearing and any other spare parts for this car. The catalog contains complete information on the applicability of spare parts in addition to a huge number of varieties of car equipment. Almost always, it is enough to turn to our professionals for assistance in the selection and advice on the applicability of the part and the choice of the desired price sector and property. The online store presents spare parts from both branded manufacturers that supply their products to assembly lines, as well as lesser-known manufacturers, but at a really low price.

Among the spare parts presented in our web store, there are parts for all the main components of the car, which can be used for:

- scheduled maintenance

- body restoration repairs,

- major engine repairs

- replacing chassis parts,

- salon care.

Let's look at an ordinary example of how to save on purchasing parts using our web store. As is clear, all the unique spare parts packaged in boxes from Toyota, Mercedes and other brands are not made by them without the help of others, but are packaged from the production lines of branded manufacturers such as Mann, Bosch and others. In other words, if you don’t want to overpay 3 or 4 times the price for beautiful boxes, then this is a good reason to contact us. We studied the purchase of parts for maintenance using the example of a Toyota Camry and in fact it turned out that Unique spare parts cost 16,000 rubles, and the same analogues that are included in Toyota packaging, if taken with the manufacturer’s factory packaging, cost 4,500 rubles. Agree, the difference is enormous, so why donate funds?

Our goal is to provide the highest level of advice and good payment service (payment for goods purchased or services received)

, delivery and dispatch of TC. Our specialists use the most advanced technologies for selecting spare parts and guarantee the applicability of parts to cars, with the mandatory implementation of the vehicle’s VIN code, select parts in unique catalogs and provide the best brands, reasonable prices and prompt delivery.

Almost everyone is accustomed to finding products all over the Internet and looking for the lowest cost for the same Lada air conditioner bearing , but why do this and trust unverified companies or simply private owners because of an insignificant difference in price. There are more than 500 suppliers represented on our website, and any of them sees the prices of competitors and naturally they have a desire to sell more and accordingly reduce their cost.