After the appearance of the first internal combustion engines, the main task of designers and engineers from the very beginning was to increase the performance of the power plant. In other words, the main goal is to increase engine power. As you know, the simplest way is to physically increase the engine displacement and the number of cylinders. The engine “sucks” more air from the atmosphere, as a result more fuel can be burned.

At the same time, such power units with an increased displacement are large in size and weight, they are expensive to produce, it is not always possible to place such a motor in the engine compartment of a compact passenger sports car, etc. Another way to increase engine power is to build a unit that will “produce” the required power and torque without increasing the volume of the combustion chamber.

The problem can be solved by forcing air into the cylinders under pressure. To pump air into many internal combustion engines, turbocharging is used; another solution is a compressor (mechanical supercharger). In this article we will look at how a car compressor works on an engine, as well as what pros and cons a compressor engine has.

How does a compressor work?

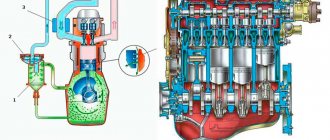

In order to understand how this mechanism works, consider the operation diagram of a conventional four-stroke internal combustion engine. With the downward movement of the piston, a vacuum of air is created, which, under the influence of atmospheric pressure, enters the combustion chamber. Once air enters the engine, it combines with the fuel mixture and creates a charge that can be converted into useful kinetic energy through combustion. Combustion is created by the spark plug. Once the fuel oxidation reaction occurs, a large amount of energy is released. The force of this explosion moves the piston, and the force of this movement is applied to the wheels, causing them to rotate.

A denser flow of fuel-air mixture into the charge will create larger explosions. But it is worth understanding that burning a specific amount of fuel requires a certain amount of oxygen. The correct ratio is: 14 parts air to 1 part atmospheric air. This proportion is very important for the efficient operation of the car’s power unit and expresses the rule: “in order to burn more fuel, more air must be supplied.”

This is the job of the compressor. It compresses the air entering the engine, allowing large quantities of it to be filled into the engine and creating a pressure build-up. At the same time, more fuel can enter the engine, causing an increase in power. On average, the compressor adds 46% power and 31% torque.

The mechanical supercharger is driven by a drive belt wrapped around a pulley that is connected to the drive gear. The drive gear drives the supercharger gear. The compressor rotor takes in air, compresses it, and throws it into the intake manifold. The rotation speed of the compressor is 50 - 60 thousand revolutions per minute. As a result, the supercharger increases the air supply to the car's engine by approximately 50%.

Because hot air is compressed, it loses its density and cannot expand much during an explosion. In this case, it cannot deliver as much energy as is produced when the spark plug ignites a cooler fuel-air mixture. It can be concluded that in order for the supercharger to work at maximum efficiency, the compressed air leaving the device must be cooled. The intercooler handles the air cooling process. Hot air is cooled in the intercooler tubes using cold air or cold liquid, depending on the type of mechanism. Reducing the air temperature, increasing its density, makes the charge that enters the combustion chamber stronger.

Electrical wire length

The length of the electric wire and air hose should be sufficient to inflate any wheel. When choosing the length of the wire and hose, you should be guided by the length of the car and where you will connect the compressor: to the cigarette lighter or to the battery. There are compressors with a short wire and a long air hose, and there are compressors with a long wire and a short hose. It is best if the sum of the lengths of the electrical wire and the air hose is at least 5 meters.

Types of compressors

There are three types of compressors: twin-screw, rotary and centrifugal. The main difference between them is the way air is supplied to the intake manifold of a car engine.

Twin screw compressor

A twin-screw supercharger consists of two rotors within which air circulates. This design creates a lot of noise in the form of compressed air whistling, which is muffled by special engine soundproofing methods.

Photo. Twin screw compressor

Rotary compressor

A rotary supercharger is typically located at the top of a car engine and consists of rotating cam shafts that move atmospheric air into the intake manifold. It is heavy and adds significant weight to the vehicle. In addition, the air flow in this type of compressor has an intermittent structure, which makes it the least efficient compared to other types of compressors.

Photo. Rotary compressor

Centrifugal compressor

A centrifugal supercharger is the most effective for forcibly increasing the pressure inside a machine engine. It is an impeller that rotates with enormous force and forces air into a small compressor housing. Centrifugal force pushes air to the edge of the impeller, forcing it to leave its cavity at great speed. Small blades located around the impeller convert high-speed, low-pressure air flow into low-speed, high-pressure air.

Photo. Centrifugal compressor

What to look for when choosing

Based on the above, the basic features of various types of devices are visible, and it becomes clear how to make the right choice of an automobile compressor of one design or another. By paying attention to small details, you can get a device with very attractive characteristics of reliability and stability.

When choosing a piston compressor for inflating tires, you should first of all focus on the materials used. The walls of the cylinder must be thick enough; it itself is made of stainless steel. It is also worth paying attention to the crankshaft and piston. Plastic means quick and inevitable failure, and tool or wear-resistant stainless steel will guarantee durable operation.

Advice! O-rings should also be made of wear-resistant materials. The best choice is brass and its alloys, fluoroplastic. A modern, but not very common option is technopolymer, characterized by high abrasion resistance.

For a diaphragm pump, the availability of spare parts is a top priority. When a membrane fails, you need to be able to quickly and inexpensively buy the part needed for repair. It is also important to pay attention to the availability of the manufacturer's service network, and if you make sure that the cam mechanism is made of high-grade steel, you can purchase a truly durable device.

For a rotary model, which has record levels of wear of structural elements during operation, both manufacturing materials and the availability of spare parts and service points play an important role. When choosing this type of compressor, you need to pay attention to everything.

Advantages of the compressor

The main advantage of a compressor is, naturally, an increase in vehicle engine power. Experts consider mechanical superchargers to be slightly better than turbocharged engines because engines equipped with them do not have a delayed response to the driver pressing the gas pedal because mechanical compressors are driven directly from the engine's crankshaft. Turbochargers, in turn, are subject to lag, since the exhaust gases gain the speed necessary to spin the turbines only after some time has elapsed.

Continuous operation time

The optimal choice is compressors with a continuous operation time of at least 20-30 minutes. Budget car compressors often have a short time of continuous operation; after 10-15 minutes they need a break to cool down. If the maximum continuous operation time is exceeded and the compressor does not have overheating protection, it may simply burn out.

Disadvantages of engines

Since the compressor is started using the engine crankshaft, this slightly reduces the power of the power unit. The compressor increases the load on the engine, so the engine must be strong enough to withstand strong explosions in the combustion chamber. Modern automakers take this condition into account and create stronger units for engines designed to work in tandem with a compressor, which increases the cost of the car, as well as the cost of its maintenance.

Overall, superchargers are the most effective way to add horsepower, or power in other words, to a vehicle's engine. The compressor can add from 50 to 100% of power, which is why racers and fans of high-speed driving often install it on their cars.

Features to choose from

The main part of the design of a particular compressor, which directly works with air, is far from the main one in terms of ease of use and functional suitability of the device model. Control and support systems also play an important role. Therefore, in a store, when choosing a unit to pump tires or inflate your favorite boat, you should pay attention to all the design elements.

Pressure gauge

The pressure gauge is the main device for monitoring the operation of the compressor. It is important to evaluate how small the cost of dividing it is. This will allow:

- properly inflate the tires, strictly following the manufacturer’s recommendations regarding optimal pressure values;

- accurately monitor the process during operation.

The last point is worth dwelling on in more detail. During operation of a compressor, especially a productive and powerful one, the pressure gauge needle fluctuates within a wide range. Therefore, the lower the division price, the more accurately the pressure indicator can be observed.

It is worth paying attention to one more characteristic of the pressure gauge. Those car owners who buy a compressor model with a high maximum pressure rating may be limited in their ability to control pressure. The fact is that the course of the needle on the instrument scale is finite; the higher the limiting measurement indicator, the lower the division price.

Advice! Therefore, for those users who are interested in high inflation pressures, it is useful to purchase a compressor whose minimum pressure gauge control indicator is not zero. For example, it starts with 4 and ends with 10 atmospheres.

A useful functionality that a pump-compressor pressure gauge can have is the ability to measure pressure only in tires, when the device is isolated from the main air exchange network of the supercharger. Models with digital pressure gauges that show the pressure value during operation with vibration smoothing have excellent convenience characteristics.

Cable and power system

Most compressors are designed for a single power source. This can be a single-phase 220 volt network or 12 volts from a battery. When purchasing a model of this type, you should pay attention to the length of the power cable. It should be comfortable for average conditions of use.

The most convenient are compressors with a voltage conversion system. Such a device can be powered either from a car battery or from a 220V network. In this case, the compressor may have two power cables.

Performance

When choosing a compressor of one type or another, you should not skimp on performance. This is especially true for piston models.

Advice! For a passenger car, the optimal indicator for this parameter is in the range from 40 to 60 liters. For a truck or SUV, it's worth buying a more powerful model.

The time it takes to inflate a car's tires depends on how much air the compressor supplies. This immediately affects ease of use. The closer the performance is to the optimal value, the less the battery drain will be on the battery compressor, and the less the piston model will heat up. For diaphragm blowers everything is simpler. The lower their productivity, the longer the wait for pumping to complete.

Hose

The proposed complete inflation hose should be selected according to the usual ways of using the compressor. For example, if you plan to install the pump in a garage or don’t want to take it out of the trunk, it is recommended to purchase a model with a long outlet. And if we are talking about a compact membrane compressor, which does not seem heavy even to a woman, it is worth minimizing the hose for compact placement.

Safety and automatic control devices

It is recommended not to purchase a compressor whose power supply system does not offer overload and short circuit protection. Such a device can cause a fire, which is especially scary in a car. Each automobile compressor must have a protection system, fuses and load control circuits.

For piston models, it is desirable to have an automatic shutdown system when overheating. A compressor designed for a limited operating time and used in hot weather without such protection can easily fail.

The most useful automated control system for the motorist is automatic shutdown when the set pressure is reached . This functionality is extremely convenient. The compressor needs to be adjusted once to the optimal pressure for the tires, and then minimally monitor the inflation parameters. The device will turn off automatically when the configured value is reached.

Additional attachments and accessories

How annoying most people are by the numerous advertising phrases from consultants about the presence of numerous attachments, adapters, even a flashlight in the compressor package. However, these little things marketers push out can be extremely useful.

- Push-in connections and deflator valves installed on a hose for a car compressor provide easy fixation and prevent temperature increases (deformations and clamps) in the connection area. These same elements will protect your hands from burns and other troubles.

- Adapters for different valve systems (nipple, spool) will make the compressor quite versatile. It can be used for car wheels, children's bicycles, strollers, boats, and even swing soccer balls.

- Power adapters or voltage conversion units will allow you to power the compressor from almost any energy source, from a cigarette lighter to non-standard sockets.

- The backlight system will allow you to distinguish the pressure gauge readings and find the desired switch at any time of the day. A similar convenience is provided by scale inscriptions made with glow-in-the-dark paints.

- A flashlight on the remote cable will allow you to easily find the point of connection of the air supply hose to the tire, assess the condition of the wheel, and, if necessary, carry out prompt repair of the valve.

Advice! Do not neglect other features of convenience. For example, a special bag frame and non-slip pads on its bottom will allow you to carefully place the compressor in the trunk. Detachable cables and a spring-collapsed hose allow you to compactly place the device and conveniently take care of its cleanliness.

Additional functionality

All additional features that a compressor can offer should be assessed in terms of their usefulness. For example, the average motorist does not need a pressure gauge with switchable scales, ATM and PSI. Also, most buyers are not interested in a pressure relief valve with an adjustable limit; they can do this operation with manual control. But, for example, for fishing enthusiasts, the reverse mode will be useful, with the help of which you can very quickly deflate a rubber boat with a compressor.

Important! Since all the additional features, features and modes often greatly increase the cost of the compressor, they should all be assessed by their level of usefulness and selected with special attention.

Adviсe

- Buy high-quality pumps from well-known brands in specialized stores. Ask the seller for a warranty card. Manufacturers usually provide a 1 year warranty.

- Carefully inspect the product: a high-quality pump has legible stamps and numbers, parts are free of defects (including burrs and notches). Make sure the cable has no cracks or other flaws.

- It is desirable that the compressor be compact and not too heavy.

- Do not buy piston compressors with a plastic piston - they quickly fail.

- When using a compressor, the engine motor must be turned on so as not to discharge the car battery.

- To care for the pump, it is enough to clean the hose fitting and the air grilles on the device body from time to time.

Additionally

Hose length – the longer the hose, the more convenient it is to work with the pump. In practice, a 1.5-meter hose is sufficient for domestic use. More productive models that are used in car repair shops have a hose length of 7 meters or more.

Important: the hose must withstand maximum pressure and maintain its elasticity in the cold.

It is desirable that the hose has a threaded fitting for secure attachment to the tire valve. The quick-release adapter that is sometimes used to connect the hose to the wheel should be corrosion-resistant (brass is a good option).

The length of the power cable – for comfortable operation of the device – is at least 2 m, and better – 2.5-3 m.

Important: the length of the hose and cable must be sufficient to inflate any wheel in the car.

Housing is the shell of the pump that protects its elements from external influences. Budget devices have a plastic case, while more expensive devices have a more durable metal case. Characteristics of a high-quality case: shock and low temperature resistance, fire resistance.

Availability of a receiver

A receiver is a device that allows you to accumulate air. Popular manufacturers of pumping equipment have in stock such models with a receiver of 3 liters or more.

These models are used:

- For tire fitting;

- For airbrushing;

- To create a car pneumatic system.

All these features will appeal to professionals. An example of such a device is the Aggressor AGR-8LT compressor. From the name it is clear that the receiver is designed to pump 8 liters.

TURBO - NOT TURBO

In short, there are now many design varieties of compressors. Some work using the energy of exhaust gases (TURBO), others - using a drive (NOT TURBO). It is the latter that we will talk about today. By the way , which is better, a turbine or a compressor, you can read at the link.

If you examine the design of such units, you can identify a certain similarity in structure. Namely, such compressors operate from a drive that does not require intervention in the standard engine systems, namely the lubrication and exhaust gas system, which is very important! This design is really very simple - a direct connection is established with the “crankshaft”, which allows the engine and supercharger to interact perfectly during acceleration. That is, the higher the speed, the faster the “crankshaft” rotates, and accordingly the supercharger spins! Thanks to this interaction, there is practically no such thing as “turbo lag”. Also, an additional advantage is the lack of operation at high temperatures, like with TURBO options, which means that the service life is greatly increased - after all, there is no need for the “turbine” to cool down, that is, “turbo timers” or “boost controllers” are not necessary, we just turn off the car and work stops. The site autoflit.ru recommends doing exactly the same. If you're interested, come in.

Top 5 best auto compressors

Dozens of compressor manufacturing companies compete in the Russian automotive goods market today. For the convenience of drivers, a rating of the best devices according to users was compiled.

Aggressor AGR50L

The Aggressor AGR50L model has excellent quality and an inexpensive price. The compressor is quite efficient. In a minute it pumps up to 50 liters. air. The device automatically turns off after 30 minutes of continuous operation.

The case is equipped with a carrying handle, and you can also see an analog pressure gauge here. At the end there is a flashlight, with which you can inflate tires at night. The package includes a 5 meter long hose, as well as several nozzles. With their help, the user will be able to inflate boats and mattresses.

Daewoo DW40L

The Daewoo DW40L model is a high-quality device with a bright design. The appearance of the compressor resembles a box with working tools, so the kit does not include a carrying bag. Instead, the manufacturer installed an LED flashlight. Under the lid of the box there are adapter needles and a coiled end of the hose. Before you start pumping, you need to set the required pressure, upon reaching which the device will turn off on its own.

Autoprofi AK-65

The Autoprofi AK-65 model is far from a budget device. It has a dual-piston design and an all-metal body. Each piston is equipped with a Teflon sealing ring.

The device has increased productivity - 65 l/min. This means that it is suitable for inflating tires on both passenger cars and SUVs.

BERKUT R20

The Berkut 20 model is a premium device. There are practically no parts made of fragile material in the design of the device. The minimum pressure is 14 atmospheres.

The device can work without interruption for an hour. It is for this feature that it is appreciated by avid car enthusiasts, as well as mechanics and owners of sports cars.

Hyundai HY 1540

The Hyundai HY 1540 model is an excellent piston compressor among budget models. The productivity of the device is 40 liters per minute.

The device has an interesting design and is additionally equipped with a flashlight. It functions perfectly not only in the dark, but also at temperatures from -30 to +80°C. The package includes 3 nozzles that allow you to pump up other rubber objects.

Nutrition

12V (cigarette lighter) – for pumps with a capacity of up to 45-50 l/min. This is the standard connection option for these devices.

24V are more powerful devices that are connected to the battery terminals using alligator clips. Such pumps cannot be connected to the car’s on-board network (12V) to prevent damage to the wiring and fire. This does not apply to trucks whose mains voltage is 24V.

220V – pumps are powered directly from the household electrical network. Such compressors are used to inflate tires in the garage or at home. But for obvious reasons, these devices are ineffective on the road.

12/220V – universal options.

Performance

This parameter means the air pumping speed and is measured in liters per minute (l/min). A pump with a higher capacity will inflate the tire faster than a low-powered analogue.

The performance depends on the type of pump:

- membrane - usually within 30-40 l/min;

- piston - from 30-35 l/min to 160 l/min;

- rotary – 200-300 l/min.

It is worth knowing that electric pumps require breaks in operation to cool down. The heavier the car, the more powerful the pump will be needed to inflate the tires:

- passenger cars (station wagons, sedans, compact cars) – 30-50 l/min;

- SUVs, crossovers – 50-70 l/min;

- cargo - 70-160 l/min.

A pump with an indicator of 20-40 l/min will inflate a tire in 2-5 minutes; more efficient devices will cope with the same task in less than 2 minutes.

The pump performance is also selected according to the tire diameter:

- up to 14 inches - 30-40 l/min;

- 15-17 inches – 45-55 l/min;

- 18-20 inches – 65-75 l/min;

- from 20 inches and more – from 75 l/min and more.

Important: a more productive device is also characterized by greater reliability. Such pumps have a higher safety margin, and the design often includes a cooling system.

Screw type

This is a more advanced and reliable supercharger design. The principle of operation here is also simple - compression occurs by changing the volume of the cavities between the body and the rotation screws (a kind of rotors). The air here moves diagonally. The big advantages of this option are high efficiency up to 85%, as well as high air pressure (from 1 bar to higher), this is achieved by high speeds, sometimes up to 12,000 rpm. It is because of this that the body can be made more miniature. It must be said that this option is often used on racing cars due to its reliability and small body.

The only downsides are the complex structure and repairs, which increases the price of the final product. If such a drive compressor fails, it needs to be repaired at specialized stations, preferably from the manufacturer.

As you can see in the design there are two rotors, with serrated spiral teeth. Their profiles fully correspond to each other when in contact, which makes the design very reliable.